Professional Documents

Culture Documents

Strikemaster Article

Uploaded by

andres silvestre0 ratings0% found this document useful (0 votes)

14 views4 pagesStrike master.. Revista

Original Title

Strikemaster_Article

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentStrike master.. Revista

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views4 pagesStrikemaster Article

Uploaded by

andres silvestreStrike master.. Revista

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

ULL VaU ESL a

BY JIM NEWMAN

plane designs were evolved only be-

cause some R/C equipment required

testing and probably the most well

Known model to be born this way was

the Ugly Stik, Strikemaster came

about in more or less the same way

because, after years of using highly

unreliable home built equipment, 1

finally received a big break and found

that I was able to afford my first real

R/C gear —a brand new Series 70

Kraft six channel, so it was natural

that I should want to get it into thevair

in the shortest possible time. I could

have built an Usly Stik, I suppose, but

as 4 good Chicago Scalemaster, 1 felt

that my creation should have at least

some likeness to full size aireraft and

my original lunch time sketches bore

resemblances to the Anglo-French

Jaguar, BAC TSR 2 and ihe BAC

ning, all of which I had_been

intimately connected with back in the

ld country. In fact, the model pre-

sented here in its Mark Three version,

bears psuedo $6 Squardron, Royal Air

Force markings stolen from a Light-

ning of that ilustsious and historic

squadron.

‘The early fights with Mark Two

were quite an adventure. | was very

uncertain of the modified and larger

Jeading edge radius so the C.G, was

Kept forward of the design position,

Just how far forward 1 discovered

Inter — almost too late as it turned

out,

‘One calm, smokey, Spring evening,

1 could no’ longer offer any valid

excuses s0 the McCoy .40 was pulled

over into life. With my ever patient

wife, Kathy, mentally fingering The

Modeler’s Rosary and Joe Bush of the

Midwest Sundowners acting as “chase

pilot’ at my. elbow, Strikemaster

cleared the ramp and lined up on the

‘duty runway. 100% power was applied

‘and we began the roll, but, at about

two thirds distance I had the feeling

that the available runway was insufti-

cient and a slight change of heading

was requested — in fact it was about

45 degrees right.

With the model about to. vanish

into the adjacent county | felt it was

about time to call, “Rotate!” Well,

rotate I did, all the way back to the

stops and the aitplane climbed out at

about 40 degrees. The trip around the

field was just a little worrying but only

to the point where I was wishing I had

‘worn my dasker colored slacks. Seems

Thad run out of up trim, almost run

ot of back stick and just about out of

ideas. Fortunately, Uncle Joe is a good

‘guy to have around in such situations

and four dummy approaches later,

followed by his own special brand of

V.G.CP.A. (Verbal Ground Controlled

in trim MonoKote,

Precision Approach) he had me sliding

nicely down the Glide Slope and onto

the numbers. That C.G. really had

beon forward! One other thing we

leamed that evening was that Strike-

master Mark Two had one devil of a

fat glide, a fact which Elmer Ahlberg

was to discover much later and to his,

considerable embarrassment when he

floated right out of the field and into

‘our parking lot ~ which is how Mark

‘Three came about.

‘The main differences between Mark

‘Two and Three are in the distribution

of the plywood doublers, the reseating

of F3 to accomodate the 45. degree

ramp and a change to 832 nylon

screws. I found the 1/4” screws were

too tough and not shearing under

impect as they were supposed to. In

addition, the grain of certain fuselage

top and bottom sheeting was re

orientated cross ways and the fuselage

will now absorb much more impact

without the tendency to split open

longitudinally,

Tm afraid my fying will never do

any modol justice, being just an ordin-

ary ham fisted Sunday flier with all

the finesse of a batile tank and good

landings being the exception rather

than the male. So, 1 can. honestly

recount that the Strikemaster bas been

‘more than forgiving, the low wing

loading and that generous leading edge

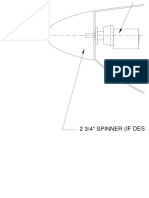

jombs are made from Estes rocket nose cones,

radius taking care of me on many

‘occasions. The model's characteristic

axe that it should have enough perfor-

mance to satisfy the “almost expert”

and yet it will ly slow and docile

enough to make it a good transition

model for any RCer trying multi for

the frst time. Mehlin Stith (respons-

ble for the first ever Goldberg Shoe-

string your may recall) can really show

off is low speed angling by flying it

low and slow, dragging it in nose high

just above the weeds to finaly rab my

nose init by dumping it om its elevator

right at my feet! Another party piece

is tohover into the wind with the stick

vay back, throttle closed, using rudder

‘only to maintain heading and finally

sinking right ino the field

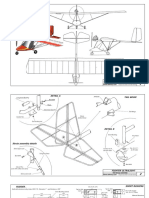

Little need be said about the

consinietion since itis very basie with

its all sheet fuselage, but a couple of

notes on the order of things will be an

assistance I’m sure.

CONSTRUCTION

Assemble the wing first —a

sightforward 1/16” balsa. sheeting

job over a foam core. I used

Southern’s Sorghum to attach the

skins and have found it satisfactory.

Five Minute epoxy holds the tips,

leading and trailing edges in place.

Next, assemble the fuselage sides

remembering, of course, to make a

RIGHT anda LEFT. 1 did find it a

distinct advantage to use 3M77 spray

contact adhesive when laminating the

sides to the balsa and plywood doub-

lers but | also took care to mask off

other areas. where conventional glues

would be used. (Iudging by the lusti-

ness of young Scoit there is nothing

wrong with my chromosomes, either!)

‘The sides are erected over the plan

with F1, 2, and 3 epoxied in piace and

‘once they have set and are squared up,

you can add the remaining formers

and the rear wing hold-down blocks.

This is now a good time to test that

the wing and stabilizer seats are paral

lel with each other by laying a couple

of straightedges across them and sight

ing from front to rear.

Set the wing in place, squaring it up

from all directions and by measuring

up from the building board to the

Jeading and trailing edge, verifying that

the wing and the stabilizer will be at

zero incidence. A reliable volunteer

should now be pressed into service to

hold the wing fonly on its seat while

you use the 5/16” hole in F2 as the

guide to drill the 5/16” hole in the

wing teading edge t0 accomodate the

hold-down dowel. Five Minute epoxy

can be introduced into the hole with

stick before inserting the dowel. While

your volunteer is stil in an acceptable

frame of mind, carefully mark and

Grill No. 29 holes down through the

wing. tiling edge and into the hold:

diown blocks in the fuselage. By now

the front dowel will have set up so

remove the wing and open out the two

holes in it with a No. 19 dill, The

holes in the fuselage blocks should be

tapped with an 8-32 tap.

‘The top and bottom fuselage plank-

ing can be glued in place but be sure

that you have the nosogear bearing and

the motor mounting blind nuts in

place before epoxying the cowl blocks

to the front of FI. only mention this

because of my own bitter experience

“The canopy block is only tack ce-

mented on at this stage and with the

planking completed you are ready to

raror plane and sand the fuselage to

shape. By way of interest, while build-

ing my fuselage, I seached this rough

shaped stage at 10:30 p.m. on a

Saturday, having only commenced cut

ting parts on my Dremel saw at 1:30

im., so it is reasonebly fast model

to build because Lam most definitely

Not the world’s speediest_ builder.

Before final sanding the canopy block

is removed with a smart “bunny chop’

and speedily hollowed out with a

sanding drum and wire brush ina

Dremel flexible drive. I would advise

against omitting the hollowing out

slage because this ship has a fairly long

nose and you really cannot afford too

much weight forward. The only com

‘mercial motor mount that 1 can re-

commend for this reason is the excel-

lent Kraft-Hayes mount, Using Hobby-

poxy No. 2, thoroughly fuel proof the

inside of the tank bay and the under-

side of the canopy block. Most

important —do not omit the tittle

bulishead around the nosegear bearing.

Without it a strong flow of exhaust

residue is induced because of the open

jet exhaust at the rear of the fuselage.

While the canopy block was off 1

found it convenient to fit the tank and

plumbing between sponge rubber

locks; likewise [ fitted the nose leg

and centered it all up before clipping

‘on the steering pushrod.

Gne of the pleasing aspects of this

model is that its lines will accept the

color scheme of numerous air forces

and still come out looking right.

RAF. and USN. schemes are pretty

common so how about trying Royal

Navy, West German, Swedish, Nor-

wegian, or even a Russian scheme.

Start with your favorite finishing

system then dig up some good maga-

ine photos or erib from the excellent

rofile Publications for authenticity.

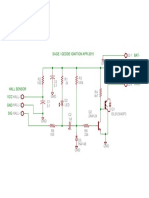

I have experienced some strong

reaction to the unusual placing of the

receiver. This became necessary be-

cause, for styling reasons alone. the

model has 2 fairly long nose for ¢

swept wing ship. Not being a compet-

tion machine I felt we could tolerate @

little excess Polar Moment of Inertia.

Since I refuse to mount batteries or

servo trays behind my receiver for

obvious reasons, the battery sits ahead

of everything, wrapped in foam, and

balance considerations dictates that it

sits fairly well aft, leaving the receiver

nowhere to go but behind F3, where a

light rubber band Keeps it’ snugged

down below the pushrods. In reality, |

found no difficulty in stowing the

bundle by first looping the band over

the tab with a stout wire hook and

keeping it in that position while the

receiver is inserted. Then you just pull

the band up and over to loop around

screws or tabs on the servo mounts.

‘The system has never given any

trouble and, after all, how often do

you remove your radio gear?

T know you will get a lot of fun out

of your Sirikemaster. The addition of

missiles or weapons pylons has little

effect on the flight characteristics, but

what you gain in raised eyebrows and

camera clicks is reward enough for the

effort.

If you are interested in experiment-

ing a little further 1 know of a varia-

tion with outboard ailerons and large

inboard split flaps. Yet another vers

has @ retract system using @ nosegear

and a single tandem main wheel under

the fuselage. Lateral stability is at-

tended to by wing tip whiskers. As 1

‘understand it, the nosegear is a stan-

dard Carl Goldberg retract. The single

main wheel just swings free ina

horizontally mounted nosegear bearing

and is linked by a rod— via a Carl

Goldberg retract servo to the nosegear

which provides all the up and down

Jock forces, which speaks very highly

for the quality and design of it. The

nose unit retracts backward, 3s

normal, and the main wheel swings

forward to compensate the C.G.

ingenious,

From

RCModeler

Mar.1974

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Two Stroke Tuning GuideDocument171 pagesTwo Stroke Tuning Guideavista123100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 3D Engine ModelingDocument16 pages3D Engine Modelingandres silvestreNo ratings yet

- Bob Angel Spark Ignition Trouble ShootingDocument3 pagesBob Angel Spark Ignition Trouble Shootingandres silvestreNo ratings yet

- Eaglet KK 24inDocument7 pagesEaglet KK 24inAnonymous J1sELDp7No ratings yet

- Cabinete 2Document4 pagesCabinete 2andres silvestreNo ratings yet

- Postal Contest Rules PDFDocument5 pagesPostal Contest Rules PDFandres silvestreNo ratings yet

- 445 035149 1939 WakefieldDocument2 pages445 035149 1939 Wakefieldandres silvestreNo ratings yet

- Tandy Walker Laser Cut GasketsDocument4 pagesTandy Walker Laser Cut Gasketsandres silvestreNo ratings yet

- Acro Four Star 60 ManualDocument26 pagesAcro Four Star 60 Manualandres silvestreNo ratings yet

- Ultimate Tiled 9mm EppDocument20 pagesUltimate Tiled 9mm EppDario DominguezNo ratings yet

- f45972552 Edge 540t DXF DXFDocument63 pagesf45972552 Edge 540t DXF DXFandres silvestreNo ratings yet

- f43696824 Sage Gedde Ignition SCHDocument1 pagef43696824 Sage Gedde Ignition SCHandres silvestreNo ratings yet

- Marvv Stern Mark IIIDocument1 pageMarvv Stern Mark IIIandres silvestreNo ratings yet

- f44572536 Sheet1Document25 pagesf44572536 Sheet1andres silvestreNo ratings yet

- JayBurkart Speed 400 Motor Replacement 26jul2022-1Document2 pagesJayBurkart Speed 400 Motor Replacement 26jul2022-1andres silvestreNo ratings yet

- Rainbow 30 Article-1Document2 pagesRainbow 30 Article-1andres silvestreNo ratings yet

- Is Now Part ofDocument11 pagesIs Now Part ofandres silvestreNo ratings yet

- Fighter Ultralight: Osvaldo DuranaDocument24 pagesFighter Ultralight: Osvaldo Duranaandres silvestreNo ratings yet

- Wee - Bee Air World 02 48 - Oz5788 - VectorDocument1 pageWee - Bee Air World 02 48 - Oz5788 - Vectorandres silvestreNo ratings yet

- Avion Katana Full Plano PDFDocument1 pageAvion Katana Full Plano PDFKEVIN FAJARDO100% (1)

- Caja de Vuelo GoldbergDocument15 pagesCaja de Vuelo Goldbergandres silvestreNo ratings yet

- Puma IIIDocument3 pagesPuma IIIandres silvestreNo ratings yet

- PT 19 Builders Guide PDFDocument20 pagesPT 19 Builders Guide PDFandres silvestreNo ratings yet

- Fieseler FL156 StorchDocument1 pageFieseler FL156 Storchandres silvestreNo ratings yet

- PT 40 PlanDocument1 pagePT 40 Planandres silvestreNo ratings yet

- Sky Chief RC Oz8676Document1 pageSky Chief RC Oz8676andres silvestreNo ratings yet

- Pilot QB 40S.Document3 pagesPilot QB 40S.andres silvestreNo ratings yet

- Castaibert IV 1Document1 pageCastaibert IV 1andres silvestreNo ratings yet

- Cap 232 TiledDocument25 pagesCap 232 Tiledandres silvestreNo ratings yet