Professional Documents

Culture Documents

M Tork New Catalogue

Uploaded by

Dinesh Chougule0 ratings0% found this document useful (0 votes)

93 views16 pagesactuator

Original Title

m tork new catalogue (1)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentactuator

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

93 views16 pagesM Tork New Catalogue

Uploaded by

Dinesh Chouguleactuator

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 16

M-Tork Inc.

Yum 35) eate TE Tam oe me) ele

for Manual Operation

,

Excellence

Features :

> 24 models upto 1,00,000 Nm output torque

> Alloy steel input shafts

> Rugged Design

> High performance axial bearings

> Epoxy Primer coating

> Powder Coated Handwheels for smooth

and easy operation

> Stroke - 0° to 90° (+ /-5°)

About the MT Series :

The MT series gear operators are quarter turn devices used

to operate butterfly, ball, plug values and dampers.

The MT series range of quarter turn worm gear operators

are robust industrial grade products manufactured with

cast iron housing components.

All models in this series are compact designed, epoxy

primer coated and feature high performance axial

bearings.

These gear operators are well suited for chemical, power,

oil and gas, waterworks, sewage, HVAC and other general

industrial applications.

Mechanical Actuators

M-TORKS_ Ja el Wa ease Wo akg oc

Mechanical Actuators (MANUAL OPERATION - MT SERIES)

Options :

> Locking arrangement

> Housing material options (Ductile Iron/ Carbon steel /

Stainless steel)

> Worm wheel material (Al. Bronze)

> Shaft, Hardware and Handwheel (Stailess Steel)

Specifications :

> Std Enclosure - IP- 65 & IP-67

> Lubrication - High Performance Grease Filled(NIGI-2)

REFER FIG (1) FOR MODELS UPTO MT 90

REFER FIG (1) FOR MODELS ABOVE MT 90

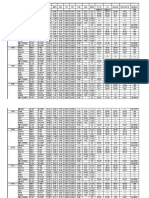

rwerore | oumur | aovar | nano | “ro” | aouwmne | onve| “Gwe: | “soronnes | 2 | ete] olele| «jo

‘onaut | “te close tone | woo |

ioe | 2308 cc

We] Ba ans a a a =]

TE] 308] aaa a or a ae ee]

TA 8] 30 aa a | 0 a a]

rae | er ae arses ae as ep]

we] [ar | |e ae ee |]

wre] roe | 36 | wor] as RFRA] so] | Rae] a] a | |e] we |]

Tae] a a ae ae as ae ay

is Te 3.

Trea) wees] were eo] 00 ae a a eae] Po

ff Tiss sm

ER aa] wane a] ea a 2 20a

ee

RT| EE ao 8 a a

Gi A Mc Mc ele

Ta T5000] 5] 300 |S Fa] TSI | RY BE | TIE

soaps

ec

0/82

MAO EROS PERS LBRO IS Pa a DY

sons

BOB HOE RTS FT|} BSR ITT a HY aE

3507

TAGES | RO] ATTY SEE OTAGO] TOBE] BOY a | | TE

TEL 3566S BOS TREE | —aaF | aE |RSS] SBOE LE CE | HPT

rsanyse =

Tolls [RRO | BT |e aaa ae a ae a

EA SERIES : Quarter Turn Worn Gear Operators .!

Cle adie Cael Mechanical Actuators

Excellence

Features :

> 19 models upto 85,000 Nm output torque

> Heat Treated worm shafts

>» Surface Hardened worm wheels

> High performance axial bearings

> Epoxy Primer coating

> Stroke - 0° to 90° (+ /-5°)

> Compatible with all electrical actuators

About the EA Series :

The EA series gear operators are quarter turn devices

suitable for electrical actuation to operate butterfly, ball,

plug valves and dampers.

The EA series gear operators are similar to the MT series

gear operators but with higher grade material or surface

treatment of internals.

M:TORK\_ Pol Ne ease eo ee aT kody ol}

Mechanical Actuators (ELECTRICAL ACTUATION - EA SERIES)

T Options :

> Housing material options (Ductile Iron / Carbon steel/

Stailess steel)

> Worm wheel material (Al. Bronze)

> Shaft and Hardware (Stailess Steel)

Specifications :

> Std Enclosure - IP-65 and IP -67

> Lubrication - High Performance Grease Filled (NLGI-2)

4,

REFER FIG (1) FOR MODELS UPTO MT 90 E

REFER FIG (1) FOR MODELS ABOVE MT 80 &

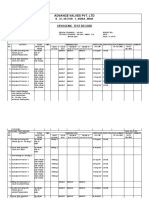

nareo | mece suans | wosaax | max | avenox | actuator

merorx | outpur| aovan- | nano | "to" | mounting | oave | “unr | “are |} a | 8 |clole|r|c | »

Torave | “Tace cose ore | werent | rlance

Om) | 2108 0)

TSE] FO] aa] i es sa Se ee

[arse es Sa | SS ee eee] ee eS]

TATE] sa] es | i a

7 ze a] aa]

RE | see er ses FE] 3s | Ba | Ba | | 38 | S|

aT | 00] 0 as || FD anes as aa | a eee |e

so/ysie || a Has) [|

mT | a] Tre 7 TS | EE |e]

rapysie 7 =

MT | 50] Oe 8] E98 FD] 5 | | 10 3

sofysie

s00/Sie "

Mat] 1a] 00 as S| FFE] 08 | 9 FA] | 20 | Bar| IO 77 |

sors

MAT) S000] RS SES Ds] P| |

2s0/s26

Mat] SOO] SE TS ES | seas] a ae || ae]

ss0/s3e

aT | SSO] SBT HSE | SES FRE DSO] 38] aa] OP | TOE | aE

soo) Sse

a) 65000] — 200 STB | 87] Fa Fa 308 as] BY TLE TOE | TOS

arse

Ba) S500] — 600 ET |S] FFE 300 | 860] SY TPE TOE | SOE

000/388

MOR SERIES : Quarter Turn Manual Overrides

ile rie Caleta)

x

,

a

Mechanical Actuators

Features :

> 10 models upto 5,000 Nm output torque

> Alloy steel input shafts .

> Rugged Design .

> High Performance axial bearings .

> Epoxy Primer coating.

> Powder Coated Handwheels for smooth

and easy operation

> Stroke - 0° to 90° (+/- 5°).

> Smooth and easy CLUTCH - DECLUTCH

mechanism

About the MOR Series :

The MOR series manual overrides are quarter turn devices

used to operate pneumaticaly actuated valves.

The MOR series of quarter turn manual overtides are

robust industrial grade products manufactured with cast

iron housing components.

All models in this series are compact designed, epoxy

primer coated and feature high performance axial bear-

ings.

The MOR series have optimum ratios for reduced effort

during operation.

M-TORK._ PERFORMANCE SPECIFICATIONS OF QUARTER TURN MANUAL OPERATORS

Mechanical Actuators tS)

Options :

> Locking arrangement

> Housing material options (Ductile Iron / Carbon steel/

Stainless steel)

> Worm wheel material (Al. Bronze)

> Shaft, Hardware and Handwheel (Stainless Steel)

Specifications :

> Std Enclosure - IP -54 ( IP-65 - Optional)

> Lubrication - High Performance Grease Filled (NLGI-2)

ao

REFER FIG (1) FOR MODELS UPTO MOR 5

REFER FIG (2) FOR MODELS ABOVE MOR 5

wm | cumur| aovan-| nano | “To” | waunne | onve | “owe | “tes | moo | s |elelolelrlel«ls| o

‘om | 8 tes)" | osm | mi

ee

TCR UR Ce) Croley

AME Re eMac CACC Mechanical Actuators

Features :

> 15 models upto 3,800 Nm and 1,100 KN thrust

> Grease filled for life

> Fully sealed gearbox and completely enclosed gear-

ing

> Multiple gear ratios for various applications

> Removable Stem Adaptor

> Spur and Bevel combinations available

> Epoxy Primer Coating

> Powder coated Hand wheels for smooth and easy

‘operation

About the BG Series :

The BG series of bevel gear operators are multi-turn devices

used to operate gate, globe, sluice and penstock valves. Easy

model in this series is suitable for manual as wel as motor-

ized operation.

Standard input (actuator side) and output (valve side)

mounting flanges are available as per ISO 5211 on all

models.

‘The BG series of multi-turn bevel gear operators features a

removable stem adaptor to facilitate spindle machining

Excellence thereby enabling customer stocking

PERFORMANCE SPECIFICATIONS OF MULTI - TURN GEAR OPERATORS

Mechanical Actuators (BG SERIES)

Options :

> Locking arrangement

> Housing material options (Ductile Iron / Carbon steel/

Stainless steel)

> Stem adaptor (Al. Bronze)

> Shaft, Hardware and Handwheel (Stainless Steel)

Specifications :

> Std Enclosure - IP -65 and IP-67

> Lubrication - High Performance Grease Filled (NLGI-2)

BG SERIES

= ps inom. | op

7 [reer | aan | soars | mane | mom | ae ae |e] a [a [|| 2

Sc Rd

Tes | sa | mee ase are eee | rae | ee pe aes ps Ts] ] ee

2 i

Tess | aa | ae a | are ee a es eee eee

esas ame is] ae ren] a ass a rr ar

28

Accessories

Mechanical Actuators

‘SERIES HANDWHEEL

SERIES HANDWHEEL

Handwheel with Keyway Handwheel with Hole / Pin

oa oa 4 L

7s Ts @ @

50 50 30 B

350 | 0 3»

00 | 130 3

300 a0 0

00 | a0 3%

730] 460 3

‘300 | 180 3

| tooo | ~t60 | —30

RIM Effort inv

2

EXAMPLE ON HOW TO USE THIS CHART

| 1. Get the input torque required

Input Torque = Output Required / MA

2. Define Maximum allowable RIM effort

(Standard is 360N)

3, Select Handwheel diameter

Haandwhee! Diameter in mm

Input Torque in Nm :

mcronis.. TOT

Al-TORK\_

Mechanical Actuators

i = 1 sess pws =r

New Genny | umes star

TEESE | SeFoee Neat

7 mea os 1 tee ies [wart —Y es 08

i oma MukilesTies —|Gomany | Leng 00mm

‘Sita rasan

7a pe Nmap Teed“

Pavan 2007" Mester gene, [ir] —cershppe Glog —[7aNaier [iw 0-200 mm

° MEMS Ss SectLang 0m

ake rarnee —errner a ae eens

7 Steuer ten Meuntcai 5

Rez nome] Ga Mennsa Gomm [v]earstepe tes in obo

Poe = eae

Seater em,

Sa Saadeh

—— fee se Niseunstesi 03

Specie Peete peecnomee

7B ar ene eon 1 - nen

= Sacie tectese Hees

TO] Ba aie Nod Nagra nee

: Miscamucsi a2

Toate Eo | eaoag Wego

el Seuny | uoveeaiem

= serena mans ea sion Seddon

7 rsarama roar ie Miseun Mele“

ir | oekaig aaa ten

7 ers — ae tee =oms

oe — fein Nite eede=saa

als Tesi [Pa 350-¢eae

7 | CSE reas | PTF

| atne Ecar

fea

Ears" | ieeeven

f} Gxep RDA 1100

or] Rab barra [West

| bashes

fl f Pee Set TS om

i] a Length —1 5 mews

[MEASURING INSTRUMENT

> Coordinate measuing machine 600.800 500

> Fett prcctor Heizntal 200200360"

> Frofleprejectovertes) 200200360"

> Height master

> Weigh gauge (0-600)

> Neith gauge (0— 300%)

> Surface roughess tester

> internal tube micrometer {0-600}

> Exernal mirameter—-Min(0~ 25mm; Max (500~ 60m)

> angemicameter —:Min (0-25; Max(

(150 — 1750)

> Blade mirometer ——:Min(O~25m);Max(25~SOmm)

> Verner ealpar Min (0 20am); Ma (0~1000ren)

> Digtalseriereiper_-Min(O 150mm) Max © ~ 300mm)

> Depthvernier caliper (03000)

> Fangemicameter —:Min (0-25nm);Max(

150-175)

> Bore geuge Min (25 1m); Mak (260-250)

> Serw tread micrometer 50-7)

> Screw ted micrometer :(25~SOmm)

> Pinmicroneter (025mm)

> Bevel prtecor (0.3607)

> Tooth erie caliper

> Grinatesurfaceplate —:(10001100nm)

> clbarchcenve (s00.d6on)

> Plngertype dal gauge: (0.01~10nm)

> Manger ype leauge: (0001-Imm)

ae

BALAMBIKAI INDUSTRIES - Sister Concern -1

Gear Hobbing Machines

SINe Description ‘ia SaeType OF

01 _| Gear Hobbing PfaiteGemaiy | DS00X6Mod

2 | Gear Hobbing Stchely DASONIMod [1

(03 Spline Hobbing Wanderer Germany | DIS0X 800mm |

‘04 | Spline Fobbing ADAMS-USA[D200XiMe__[ 1

05 [Spline Hobbing ‘Wanderer Germany | D300 mes [1

'06_[ CNC Gea Hobbing Machine | Premie-PHA 250 1

(07 [CNC Gew Hobbing Machine | Premier EGB i

‘Miing Machines

SINe Description Make ShoType [Oy

‘o1_[ Na aT ‘NOH 1

O_[ Thread Comag Me ‘Gemany DwOXIO |

Grinding Machines

SINo Description Nia SkeTpe [OW

‘1 _[ Cylindrical CGEM Dasoxi2s0 | 1

2 _[ Cylindrical 'St200-Gemany | D200x800 | 1

(03 | Surface Jots-Gemany | D200x500__[ 1

(04 [1D Grinding MeSHAUDT_| German; ‘Ds00x600 [1

(05 [1D Grinding Me Geman} 1300x500 [1

Lathes

SINe Description ‘Male SeeTpe

ol [Age ar Tr

[Rs Gemay TM

(CNC TURNING CENTRE

SiNo Description Make SeeTmpe [On]

1 _[Tobber XL. RE 200x350 |

Bandsaw’: Laxson D 150-2 nos

Bandsaw high speed cutting machine-01 no

‘ool & Cutter Grinding Machine ~German Make

‘Hydrualic Pressing/Straightning Machine - 50 tons Capacity.

‘Manjunatha Group of Industries. sister concern =2

‘Sree Bactamencar Lypustere:

‘An ISO 9001 ~2008 Certiied Company

s

[SNe ‘Name OF Machine ReferenceTD Make ‘Capacity, Accessories,

No ‘tan

a [ee ae SBrCNco_ [ace ——[soann

2 | CNC Laie SBLCNCO2_ [IML [Drs0xs35u0

‘3 | Werieal Ning Comme SBIVMCOT [AMS [TooxS00x500

‘ot [ Wereal Miling Cee SBL-VNC-I7 [AMS ——[0r435250037

5 | Weed Milling Cenve SBEVMC-I5 [AMS [60013508500

We ene SBLVME-O [AMS [0010351500

R fachine | SBLDSEOT [MT ——[1 ich

Madine | SBEDM03 [PARMAR [5s eh

indica Grinding Machine | SBLCGM-OT [NSO [1 ir

Lae SBICL-OL —[HMTAR [2 Mir

athe SBL-CL-02 [Toss [2.00

es SBIHROT Nr

Bench Grinder SBLACOL TE

Ar Compress SBI-Ac-01 [EIST

S| aie Compressor SBEACO2—[INDOCON[75EF

Mechanical Actuators

SUPPORT SYSTEMS

ome Egtpens— web pe enn ad pepsin

‘ee poteacepapan aay cb osc mtg Dhaar ane

song cme

compre? SHP3 Sap Eanes,

HCA 1k /C2-Comanre

aarp pe yo firmament

Mechanical Actuators

Subassonty for tarstomers

veces

mses sats eB marbo te

Baseman

es} MEIPL

9 Plot No. 6C, SIPCOT Industrial Complex,

Next to Titan Watch Factory,

Hosur - 635126, TamilNadu, India

© Phone : +91 4344-274195 / 274196 / 274197/

+91-9945181333

2 Email : manjunathaenggindus@gmail.co

© Website : www.meipl.co

9 #B-48/A, Industrial estate

Rajaji Nagar,

Bangalore-560044

0 9986991333/9945181333

@ mtork.mgc@gmail.com

@ www. mtork.co

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- FA-2 English PaperDocument2 pagesFA-2 English PaperDinesh ChouguleNo ratings yet

- Astm A106 PDFDocument13 pagesAstm A106 PDFDanny Milton Silva VasquezNo ratings yet

- WBCAL13675270000077683Document1 pageWBCAL13675270000077683Dinesh ChouguleNo ratings yet

- FA-2 English PaperDocument2 pagesFA-2 English PaperDinesh ChouguleNo ratings yet

- DSMTS-0108.1 WC10Ni5Cr AggSintDocument3 pagesDSMTS-0108.1 WC10Ni5Cr AggSintpawoe3064No ratings yet

- Aptitude Test Instructions and InformationDocument1 pageAptitude Test Instructions and InformationDinesh ChouguleNo ratings yet

- Glossary of Financial TermsDocument12 pagesGlossary of Financial TermsDinesh ChouguleNo ratings yet

- Fire Box DN 100Document1 pageFire Box DN 100Dinesh ChouguleNo ratings yet

- Sample Test QuestionsDocument14 pagesSample Test QuestionsDinesh ChouguleNo ratings yet

- 5Document1 page5Dinesh ChouguleNo ratings yet

- 1Document1 page1Dinesh ChouguleNo ratings yet

- Letter of Ack. (Alfa Laval)Document1 pageLetter of Ack. (Alfa Laval)Dinesh ChouguleNo ratings yet

- 2Document1 page2Dinesh ChouguleNo ratings yet

- Eletric ActuDocument1 pageEletric ActuDinesh ChouguleNo ratings yet

- EIL - Specification Sheet123Document1 pageEIL - Specification Sheet123Dinesh ChouguleNo ratings yet

- DVG CatalogDocument7 pagesDVG CatalogDinesh ChouguleNo ratings yet

- 15 FB / # 800 (3PC) Ball ValvesDocument10 pages15 FB / # 800 (3PC) Ball ValvesDinesh ChouguleNo ratings yet

- Filler Material Selection GuideDocument32 pagesFiller Material Selection GuidemaknileNo ratings yet

- EIL - Specification SheetDocument1 pageEIL - Specification SheetDinesh ChouguleNo ratings yet

- G 3/8, G 1/2 - 5/2, 3/2 Pilot Operated High Flow ValvesDocument2 pagesG 3/8, G 1/2 - 5/2, 3/2 Pilot Operated High Flow ValvesDinesh ChouguleNo ratings yet

- Advance Valves Pvt. LTD: Cryogenic Test RecordDocument3 pagesAdvance Valves Pvt. LTD: Cryogenic Test RecordDinesh ChouguleNo ratings yet

- General Purpose Butterfly ValvesDocument2 pagesGeneral Purpose Butterfly Valvesphe zenNo ratings yet

- Sample EO PolicyDocument31 pagesSample EO PolicyDinesh ChouguleNo ratings yet

- Gandhi Special Tubes LTD.: Product ProfileDocument6 pagesGandhi Special Tubes LTD.: Product ProfileDinesh ChouguleNo ratings yet

- Jamesbury 4000Document12 pagesJamesbury 4000Dinesh ChouguleNo ratings yet

- 5 HPHT API 6x - FowlerDocument13 pages5 HPHT API 6x - Fowlerchau nguyenNo ratings yet

- Lug Design R4Document4 pagesLug Design R4Esapermana RiyanNo ratings yet

- Support Lug CalculationsDocument26 pagesSupport Lug CalculationsDinesh ChouguleNo ratings yet

- Lifting Lug CapacityDocument1 pageLifting Lug CapacityDinesh ChouguleNo ratings yet