Professional Documents

Culture Documents

Sec Tion 1 - Produc T and C Ompany Identific Ation: Personal Protective Equipment Whmis Pictograms DOT Pictograms

Uploaded by

mohd fairuz talibOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sec Tion 1 - Produc T and C Ompany Identific Ation: Personal Protective Equipment Whmis Pictograms DOT Pictograms

Uploaded by

mohd fairuz talibCopyright:

Available Formats

Personal Protective WHMIS

DOT Pictograms

Equipment Pictograms

Safety Protective D2A Toxic

Glasses Gloves

SEC TION 1 - PRODUC T AND C OMPANY IDENTIFIC ATION

NFPA

Product Name: Lead Solder Alloy

Product Code: Lead Solder A lloy

MSDS Manufacturer Number: Lead Solder A lloy 0

Product Use/Restriction: Solder 2 0

Manufacturer Name: Kester

A ddress: 800 W. Thorndale A venue

Itasca, IL 60143

General Phone Number: (630)-616-4000

Customer Service Phone (800)-2KESTER (253-7837) HMIS

Number: Health Hazard 2*

CHEMTREC: CHEMTREC 24-Hour Emergency Telephone Number:

(800)424-9300 Fire Hazard 0

CHEMTREC 24-Hour Emergency Telephone Number:

((O utside of the U.S. and Canada):): (703)527-3887 Reactivity 0

Website: msds@kester.com Personal X

MSDS Creation Date: A ugust 15, 2008 Protection

MSDS Revision Date: March 11, 2010 * Chronic Health Effects

SEC TION 2 - C OMPOSITION/INFORMATION ON INGREDIENTS

Chemical Name CAS# Ingredient Percent EC Num.

A ntimony 7440-36-0 0 - 10 by weight

Bismuth 7440-69-9 0 - 10 by weight

Zinc 7440-66-6 0 - 10 by weight

Copper 7440-50-8 0 - 10 by weight

Lead 7439-92-1 0 - 100 by weight

Tin 7440-31-5 0 - 100 by weight

Silver 7440-22-4 0 - 10 by weight

SEC TION 3 - HAZARDS IDENTIFIC ATION

Emergency O verview: CA UTIO N! Irritant. Exposures to soldering fumes and vapors may be irritating to

eyes, respiratory system, and skin.

Route of Exposure: Eyes. Skin. Inhalation. Ingestion.

Eye: Smoke during soldering can cause eye irritation.

Skin: May cause irritation.

Inhalation: Prolonged or excessive inhalation may cause respiratory tract irritation.

Ingestion: May be harmful if swallowed. May cause vomiting.

Chronic Health Effects: Suspected of damaging fertility or the unborn child

Repeated and prolonged exposure to lead and lead compounds may cause

abdominal pain, diarrhea, loss of appetite, metallic taste, nausea, vomiting,

lassitude, insomnia, muscle weakness, joint and muscle pain, irritability, headache

and dizziness.

Red blood cells may be damaged resulting in anemia. Gastritis and injury to the

kidneys, liver, male gonads, and central nervous system may also occur.

Lead :

Carcinogenicity: IA RC: Group 2B: Possibly carcinogenic to humans.

Lead Solder Alloy Kester

Revison:03/11/2010, Version:0.0000 Page:1 of 4

SEC TION 4 - FIRST AID MEASURES

Eye Contact: Immediately flush eyes with plenty of water for 15 to 20 minutes. Get medical

attention, if irritation or symptoms of overexposure persists.

Skin Contact: Immediately wash skin with soap and plenty of water.

Get medical attention if irritation develops or persists.

Inhalation: If inhaled, remove to fresh air. If not breathing, give artificial respiration or give

oxygen by trained personnel. Seek immediate medical attention.

Ingestion: If swallowed, do NO T induce vomiting. Call a physician or poison control center

immediately. Never give anything by mouth to an unconscious person.

SEC TION 5 - FIRE FIGHTING MEASURES

Flash Point: > 93 °C (> 199 °F)

Lower Flammable/Explosive Limit: Not applicable.

Upper Flammable/Explosive Limit: Not applicable.

Extinguishing Media: Use alcohol resistant foam, carbon dioxide, dry chemical, or water fog or spray

when fighting fires involving this material.

Unsuitable Media: Do not use a solid water stream as it may scatter and spread fire.

Protective Equipment: A s in any fire, wear Self-Contained Breathing A pparatus (SCBA ), MSHA /NIO SH

(approved or equivalent) and full protective gear.

Hazardous Combustion O xides of carbon, oxides of nitrogen, aliphatic aldehydes, and other organic

Byproducts: substances may be formed during combustion.. Melted solder above 1000 deg F

will liberate toxic lead and/or antimony fumes

NFPA Ratings:

NFPA Health: 2

NFPA Flammability: 0

NFPA Reactivity: 0

NFPA O ther:

SEC TION 6 - AC C IDENTAL RELEASE MEASURES

Personnel Precautions: Evacuate area and keep unnecessary and unprotected personnel from entering the

spill area. A void inhaling vapors, mists, or fumes. A void contact with skin, eyes

and clothing.

Environmental Precautions: A void runoff into storm sewers, ditches, and waterways.

Methods for containment: Melted solder will solidify on cooling and can be scraped up.

Methods for cleanup: Solidfied solder can be scraped up upon cooling. Use caution to avoid breathing

fumes if a gas torch is used to cut up large pieces.

SEC TION 7 - HANDLING and STORAGE

Handling: Use with adequate ventilation. A void breathing vapor and fumes. Use only in

accordance with directions.

Storage: No special storage conditions required.

Hygiene Practices: Wash thoroughly after handling. A void inhaling vapors, mists, or fumes.

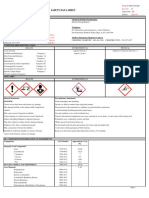

SEC TION 8 - EXPOSURE C ONTROLS, PERSONAL PROTEC TION - EXPOSURE GUIDELINES

Engineering Controls: Use appropriate engineering control such as process enclosures, local exhaust

ventilation, or other engineering controls to control airborne levels below

recommended exposure limits. Where such systems are not effective wear suitable

personal protective equipment, which performs satisfactorily and meets O SHA or

other recognized standards. Consult with local procedures for selection, training,

inspection and maintenance of the personal protective equipment.

Eye/Face Protection: Safety glasses with side-shields.

Hand Protection Description: Wear appropriate protective gloves. Consult glove manufacturer's data for

permeability data.

Respiratory Protection: When ventilation is not sufficient to remove fumes from the breathing zone, a

safety approved respirator or self- contained breathing apparatus should be worn.

EXPO SURE GUIDELINES

Antimony :

Guideline A CGIH: TLV -TWA : 0.5 mg/m3

Guideline O SHA : PEL-TWA : 0.5 mg/m3

Copper :

Guideline A CGIH: TLV -TWA : 1 mg/m3

Guideline O SHA : PEL-TWA : 1 mg/m3

Lead :

Guideline A CGIH: TLV -TWA : 0.05 mg/m3

Guideline O SHA : PEL-TWA : 0.05 mg/m3

Tin :

Lead Solder Alloy Kester

Revison:03/11/2010, Version:0.0000 Page:2 of 4

Guideline A CGIH: TLV -TWA : 2 mg/m3

Guideline O SHA : PEL-TWA : 2 mg/m3

Silver :

Guideline A CGIH: TLV -TWA : 0.1 mg/m3

Guideline O SHA : PEL-TWA : 0.01 mg/m3

SEC TION 9 - PHYSIC AL and C HEMIC AL PROPERTIES

Physical State A ppearance: Solid

Color: Silver grey

O dor: O dorless

Boiling Point: Not determined.

Melting Point: > 100 °C (> 212 deg F)

Density: >7 g/cm³ (@ 20 °C (68 °F))

Flash Point: > 93 °C (> 199 °F)

SEC TION 10 - STABILITY and REAC TIVITY

Chemical Stability: Stable under normal temperatures and pressures.

Hazardous Polymerization: Not reported.

Conditions to A void: No thermal decomposition if used according to specifications.

Incompatible Materials: O xidizing agents. Strong acids and alkalis.

Special Decomposition Products: When heated to soldering temperatures, the solvents are evaporated and rosin

may be thermally degraded to liberate aliphatic aldehydes and acids.

SEC TION 11 - TOXIC OLOGIC AL INFORMATION

Antimony :

Ingestion: O ral - Rat LD50: 100 mg/kg [Details of toxic effects not reported other than lethal

dose value.] (RTECS)

Bismuth :

Ingestion: O ral - Mouse LD50: 10 gm/kg [Details of toxic effects not reported other than

lethal dose value.]

O ral - Rat LD50: 5 gm/kg [Details of toxic effects not reported other than lethal

dose value.] (RTECS)

Zinc :

Skin: Skin - Human Standard Draize Test. : 300 ug/3D-I - [mild](RTECS)

Inhalation: Inhalation. - Human TCLo - Lowest published toxic concentration: 124

mg/m3/50M - [Lungs, Thorax, or Respiration - cough Lungs, Thorax, or

Respiration - dyspnea Skin and A ppendages - sweating ] (RTECS)

Ingestion: O ral - Bird duck LDLo: 388 mg/kg - [A utonomic Nervous System - other (direct)

parasympathomimetic oral - ataxia Blood - changes in leukocyte (WBC) count ]

(RTECS)

Copper :

Ingestion: O ral - Mouse LD50: 413 mg/kg [Details of toxic effects not reported other than

lethal dose value.]

O ral - Mouse LD50: >5000 mg/kg [Behavioral - food intake (animal)

Gastrointestinal - hypermotility, diarrhea Gastrointestinal - nausea or vomiting]

(RTECS)

Silver :

Ingestion: O ral - Mouse LD50: 100 mg/kg [Details of toxic effects not reported other than

lethal dose value.] (RTECS)

SEC TION 12 - EC OLOGIC AL INFORMATION

Ecotoxicity: No ecotoxicity data was found for the product.

Environmental Fate: No environmental information found for this product.

SEC TION 13 - DISPOSAL C ONSIDERATIONS

Waste Disposal: Consult with the US EPA Guidelines listed in 40 CFR Part 261.3 for the

classifications of hazardous waste prior to disposal. Furthermore, consult with your

state and local waste requirements or guidelines, if applicable, to ensure

compliance. A rrange disposal in accordance to the EPA and/or state and local

guidelines.

SEC TION 14 - TRANSPORT INFORMATION

DO T Shipping Name: Not Regulated.

DO T UN Number: Not Regulated.

IATA Shipping Name: Not Regulated.

IATA UN Number: Not Regulated.

IMDG UN NUmber : Not Regulated.

IMDG Shipping Name : Not Regulated.

RID UN Number : Not Regulated.

Lead Solder Alloy Kester

Revison:03/11/2010, Version:0.0000 Page:3 of 4

RID Shipping Name : Not Regulated.

SEC TION 15 - REGULATORY INFORMATION

Canada Reg. Status: This product has been classified in accordance with the hazard criteria of the

Controlled Products Regulations and the MSDS contains all of the information

required by the Controlled Products Regulations.

Canada WHMIS: Controlled - Class: D2A Very Toxic

Antimony :

TSCA Inventory Status: Listed

Canada DSL: Listed

Bismuth :

TSCA Inventory Status: Listed

Canada DSL: Listed

Zinc :

TSCA Inventory Status: Listed

Canada DSL: Listed

Copper :

TSCA Inventory Status: Listed

Canada DSL: Listed

Lead :

TSCA Inventory Status: Listed

Canada DSL: Listed

Tin :

TSCA Inventory Status: Listed

Canada DSL: Listed

Silver :

TSCA Inventory Status: Listed

Canada DSL: Listed

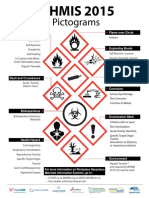

WHMIS Pictograms

SEC TION 16 - ADDITIONAL INFORMATION

General Use: Solder

HMIS Health Hazard: 2*

HMIS Fire Hazard: 0

HMIS Reactivity: 0

HMIS Personal Protection: X

MSDS Creation Date: A ugust 15, 2008

MSDS Revision Date: March 11, 2010

Disclaimer: The information contained herein is based on data considered accurate and is

offered solely for information, consideration and investigation. Kester extends no

warranties, makes no representations and assumes no responsibilty as to the

accuracy, completeness or suitability of this data for any purchaser's use. The

data on this Material Safety Data Sheet relates only to this product and does not

relate to use with any other material or in any process. A ll chemical products

should be used only by, or under the direction of, technically qualified personnel

who are aware of the hazards involved and the necessity for reasonable care in

handling. Hazard communication regulations require that employees must be

trained on how to use a Material Safety Data Sheet as a source for hazard

information.

Copyright© 1996-2010 A ctio Software Corporation .

A ll Rights Reserved.

Lead Solder Alloy Kester

Revison:03/11/2010, Version:0.0000 Page:4 of 4

You might also like

- The Health & Safety Guide for Film, TV & Theater, Second EditionFrom EverandThe Health & Safety Guide for Film, TV & Theater, Second EditionRating: 4 out of 5 stars4/5 (1)

- 951 (1) FluxDocument5 pages951 (1) FluxluisNo ratings yet

- Primers CenterfireDocument9 pagesPrimers CenterfireMoysés Isper NetoNo ratings yet

- Safety Data Sheet: Telephone (704) 987-4555 8935 Northpointe Executive Huntersville, NC 28078 DRDocument6 pagesSafety Data Sheet: Telephone (704) 987-4555 8935 Northpointe Executive Huntersville, NC 28078 DRRinaldi SatriaNo ratings yet

- Teroson MS 5510 GY-EnpdfDocument6 pagesTeroson MS 5510 GY-EnpdfAbel ZamudioNo ratings yet

- Asn96a3c05-0.63 enDocument5 pagesAsn96a3c05-0.63 enZoran ConstantinescuNo ratings yet

- Silvo - Ficha Tecnica 1447813238Document11 pagesSilvo - Ficha Tecnica 1447813238Papaleguas gamesNo ratings yet

- Safety Data Sheet: 1. Product InformationDocument6 pagesSafety Data Sheet: 1. Product InformationJessie O.BechaydaNo ratings yet

- Product and Company Identification: Safety Data SheetDocument8 pagesProduct and Company Identification: Safety Data SheetAhmed KhameisNo ratings yet

- Material Safety Data Sheet: Page 1 of 6Document6 pagesMaterial Safety Data Sheet: Page 1 of 6EndraNo ratings yet

- Product and Company Identification: Safety Data SheetDocument8 pagesProduct and Company Identification: Safety Data SheetAhmed KhameisNo ratings yet

- MSDS Loctite Nordbak Wearing Compound ResinDocument6 pagesMSDS Loctite Nordbak Wearing Compound ResinSadamNo ratings yet

- Safety Data Sheet: 1. Product InformationDocument6 pagesSafety Data Sheet: 1. Product InformationJessie O.BechaydaNo ratings yet

- MSDS Loctite 5438Document7 pagesMSDS Loctite 5438ajoilhamNo ratings yet

- 43-Loctite LB8008 C5a MSDSDocument7 pages43-Loctite LB8008 C5a MSDSTRC GroupNo ratings yet

- Safety Data Sheet: Non-Spillable, Lead-Acid BatteryDocument7 pagesSafety Data Sheet: Non-Spillable, Lead-Acid BatteryOperations Admin100% (1)

- Safety Data Sheet: 1. IdentificationDocument6 pagesSafety Data Sheet: 1. IdentificationJessie O.BechaydaNo ratings yet

- Brigth Zinc-ItDocument11 pagesBrigth Zinc-Ityuliana robledoNo ratings yet

- Product and Company Identification: Safety Data SheetDocument6 pagesProduct and Company Identification: Safety Data Sheetmohamed hamedNo ratings yet

- Loctite 988Document5 pagesLoctite 988WALTER CORIAHUAMANI ROLDANNo ratings yet

- Raid Home Insect Killer EDocument8 pagesRaid Home Insect Killer EFillo IbrahimNo ratings yet

- En - Cigweld Satincrome 316LDocument12 pagesEn - Cigweld Satincrome 316LFikriey AbdullahNo ratings yet

- MsdsDocument10 pagesMsdsmcgteccadNo ratings yet

- Cemento Conductivo TerraweldDocument5 pagesCemento Conductivo Terraweldmarina_yucra15100% (1)

- TOXIC TITLEDocument16 pagesTOXIC TITLEganesh kumarNo ratings yet

- Product and Company Identification: Safety Data SheetDocument6 pagesProduct and Company Identification: Safety Data SheetSJHEIK AbdullahNo ratings yet

- MSDSDocument10 pagesMSDSmiguelNo ratings yet

- Andacollo Copper Concentrate SDSDocument6 pagesAndacollo Copper Concentrate SDSPaulie Salgado DelaParra100% (1)

- SDS 1109 Pilot II AV Aluminium HR Eng CADocument8 pagesSDS 1109 Pilot II AV Aluminium HR Eng CAArya Suganda100% (1)

- Sodium Carbonate SDS Safety SummaryDocument9 pagesSodium Carbonate SDS Safety SummaryDeo FactuarNo ratings yet

- Tin Coated Copper Wire SDS - V2Document6 pagesTin Coated Copper Wire SDS - V2quycoctuNo ratings yet

- MSDS 114937Document4 pagesMSDS 114937ajay mishraNo ratings yet

- Safety Data Sheet for Aluminum Extrusion MetalDocument10 pagesSafety Data Sheet for Aluminum Extrusion MetalCocoNo ratings yet

- SDS 791351002 TiAl6V4 Gd23 Type 2 EnglishDocument9 pagesSDS 791351002 TiAl6V4 Gd23 Type 2 EnglishAkshay DolasNo ratings yet

- Titanium Dioxide MSDS SummaryDocument7 pagesTitanium Dioxide MSDS SummaryCokroNo ratings yet

- SDS - 80214 - Sto Flexible Crack Filler - ENDocument6 pagesSDS - 80214 - Sto Flexible Crack Filler - ENMichael A FarinNo ratings yet

- ANACHEMIA (MSDS) NITRIC ACID 60-70% Expires 15-10-15Document4 pagesANACHEMIA (MSDS) NITRIC ACID 60-70% Expires 15-10-15PubcrawlNo ratings yet

- Henkel Alumiprep 33 GallonDocument7 pagesHenkel Alumiprep 33 Gallon오창원No ratings yet

- Safety Data Sheet for Aluminium PowderDocument9 pagesSafety Data Sheet for Aluminium PowderRibeiro Elias ConcursosNo ratings yet

- Safety Data Sheet for Sika Monotop 615 CementDocument11 pagesSafety Data Sheet for Sika Monotop 615 CementAshadi AmirNo ratings yet

- Toluene Diisocyanate (Tdi) Msds enDocument11 pagesToluene Diisocyanate (Tdi) Msds enKameliza Saranghe Choi-siwon SujuelfNo ratings yet

- Cy9-4045 Eco Solder Rma98 Super p3 m705 PDFDocument8 pagesCy9-4045 Eco Solder Rma98 Super p3 m705 PDFHector GonzalezNo ratings yet

- Product and Company Identification: Safety Data SheetDocument6 pagesProduct and Company Identification: Safety Data SheetFurqan ShabbirNo ratings yet

- Safety Data Sheet: Revised: AEDocument7 pagesSafety Data Sheet: Revised: AERoberto VargasNo ratings yet

- Hoja de Seguridad de SoldaduraDocument8 pagesHoja de Seguridad de SoldaduraYazmin Araceli Saldaña PeraltaNo ratings yet

- Dow Corning 688 Glazing Cladding Sealant Black-AUS SDSDocument24 pagesDow Corning 688 Glazing Cladding Sealant Black-AUS SDSKeeth DilendyNo ratings yet

- Material Safety Data Sheet MSDS Ni MH PDFDocument11 pagesMaterial Safety Data Sheet MSDS Ni MH PDFkrishnadas kotaNo ratings yet

- Lincolnweld L-S3 (LNS133U, L50M)Document17 pagesLincolnweld L-S3 (LNS133U, L50M)Jhonathan TiradoNo ratings yet

- Sds For Gray CastDocument7 pagesSds For Gray CastPravin PatilNo ratings yet

- MSDS, Uncharged VRB ElectrolyteDocument7 pagesMSDS, Uncharged VRB ElectrolytedeaNo ratings yet

- Safety Data Sheet: Sodium Chromate SolutionDocument7 pagesSafety Data Sheet: Sodium Chromate SolutionhamMhamNo ratings yet

- Antiaferrante Grado Marino 34026Document6 pagesAntiaferrante Grado Marino 34026ambiente_01No ratings yet

- Safety Data Sheet: 1. Material IdentificationDocument5 pagesSafety Data Sheet: 1. Material IdentificationMichele BovomiNo ratings yet

- Khairat Al-Emar Co. For Oil Services: Material Safety Data SheetDocument6 pagesKhairat Al-Emar Co. For Oil Services: Material Safety Data SheetqwaszxcdeNo ratings yet

- SDS1Document1 pageSDS1johnNo ratings yet

- Safety Data Sheet: November 1, 2014Document8 pagesSafety Data Sheet: November 1, 2014DANY SUJINo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument20 pagesSafety Data Sheet: 1. Product and Company IdentificationPubcrawlNo ratings yet

- CBLF-HT 2000 Grasa MsdsDocument27 pagesCBLF-HT 2000 Grasa MsdsCarlos PeñaNo ratings yet

- MSDS Waterplug SdsDocument6 pagesMSDS Waterplug Sdsmovie clipNo ratings yet

- Boston Spray Paint SdsDocument8 pagesBoston Spray Paint SdsShopMeNo ratings yet

- Butylated hydroxytoluene MSDSDocument6 pagesButylated hydroxytoluene MSDSTon BlokNo ratings yet

- MTBE-Data and Safety SheetDocument5 pagesMTBE-Data and Safety SheetDr.AhmedNo ratings yet

- Msds DaviessunrainDocument11 pagesMsds Daviessunrainpyrl divinagracia50% (2)

- Hempalin Enamel 5214000030 En-UsDocument9 pagesHempalin Enamel 5214000030 En-UszayzanNo ratings yet

- Picric acid safety data sheetDocument6 pagesPicric acid safety data sheetTaufiq Nur RachmanNo ratings yet

- Safety Data Sheet: Amasil® 85Document16 pagesSafety Data Sheet: Amasil® 85Armaghan ShiekhNo ratings yet

- Safety Data Sheet: 1 Identification of The Substance/mixture and of The Company/undertakingDocument6 pagesSafety Data Sheet: 1 Identification of The Substance/mixture and of The Company/undertakingBHASKAR HALDARNo ratings yet

- MSDS Neelcoat 1591Document4 pagesMSDS Neelcoat 1591Azim Hussain ZaidiNo ratings yet

- FMVSS 208 - 1Document585 pagesFMVSS 208 - 1Surya MokkapatiNo ratings yet

- 09-91 v2 PhytoflORAL TPII 0907 Classic Material Safety Data SheetDocument4 pages09-91 v2 PhytoflORAL TPII 0907 Classic Material Safety Data SheetAlfie Alven Dela CruzNo ratings yet

- SDS - ACTIPHYTE OATMEAL GL - Lipotec (Ago 2017) ENGDocument10 pagesSDS - ACTIPHYTE OATMEAL GL - Lipotec (Ago 2017) ENGJulian David Leal AcostaNo ratings yet

- HP3100 (Bi)Document8 pagesHP3100 (Bi)shamirah98No ratings yet

- Cataclean MSDSDocument9 pagesCataclean MSDSdannoxyzNo ratings yet

- WHMIS Pictograms FinalDocument1 pageWHMIS Pictograms FinalJessie TNo ratings yet

- Msds EpoxythinnerDocument12 pagesMsds EpoxythinnerBansal Engineers Grain Milling Pvt LtdNo ratings yet

- AADE-17-NTCE-086 Uintaite Application in Deepwater OperationsDocument7 pagesAADE-17-NTCE-086 Uintaite Application in Deepwater Operationsrobin0151No ratings yet

- Nitric Acid Safety Data SheetDocument9 pagesNitric Acid Safety Data SheetdanielNo ratings yet

- Topic V: Environmental Risk AssessmentDocument14 pagesTopic V: Environmental Risk AssessmentBASKAR ENo ratings yet

- Fiamm Technologies Big HornDocument8 pagesFiamm Technologies Big HornPubcrawlNo ratings yet

- SDS for Fixapret F-ECO textile auxiliaryDocument8 pagesSDS for Fixapret F-ECO textile auxiliarySajida HafeezNo ratings yet

- TM 5-3825-270-10 Engineer Mission Module Water DistributionDocument484 pagesTM 5-3825-270-10 Engineer Mission Module Water DistributionAdvocate100% (2)

- MSDS-Acumer 1000Document8 pagesMSDS-Acumer 1000daniNo ratings yet

- CSR PC-122806 13-Jan-09 ADocument31 pagesCSR PC-122806 13-Jan-09 ATomás Afonso CavacoNo ratings yet

- Safety Data Sheet: Product Name: MOBIL SHC 630Document10 pagesSafety Data Sheet: Product Name: MOBIL SHC 630Athiphap SrisupareerathNo ratings yet

- Msds Hydroxypropyl Starch Ether HpsDocument8 pagesMsds Hydroxypropyl Starch Ether HpsWANGYUSHENG Kima Chemical Co LtdNo ratings yet

- 57136Document123 pages57136ahmadpolyNo ratings yet

- AVGAS 100LL Safety Data SheetDocument11 pagesAVGAS 100LL Safety Data SheetVesna NikolicNo ratings yet

- 103-Q228 - Oil Tolerant Primer - Hardener - SDS11076 - UkDocument14 pages103-Q228 - Oil Tolerant Primer - Hardener - SDS11076 - Uk陈辉No ratings yet

- GPS Safety Summary GPS Safety Summary GPS Safety Summary GPS Safety SummaryDocument5 pagesGPS Safety Summary GPS Safety Summary GPS Safety Summary GPS Safety SummaryAndhi Septa WijayaNo ratings yet

- Msds h202Document7 pagesMsds h202permatayaNo ratings yet

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsFrom EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNo ratings yet

- Laws of UX: Using Psychology to Design Better Products & ServicesFrom EverandLaws of UX: Using Psychology to Design Better Products & ServicesRating: 5 out of 5 stars5/5 (9)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Lean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsFrom EverandLean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsRating: 4 out of 5 stars4/5 (2)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- Design Is The Problem: The Future of Design Must Be SustainableFrom EverandDesign Is The Problem: The Future of Design Must Be SustainableRating: 1.5 out of 5 stars1.5/5 (2)

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsFrom EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsRating: 5 out of 5 stars5/5 (1)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceFrom EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceRating: 4 out of 5 stars4/5 (19)

- Dynamic Aquaria: Building Living EcosystemsFrom EverandDynamic Aquaria: Building Living EcosystemsRating: 4 out of 5 stars4/5 (4)