Professional Documents

Culture Documents

Sop Con Cloruro PDF

Sop Con Cloruro PDF

Uploaded by

Felipe Hoyos0 ratings0% found this document useful (0 votes)

10 views10 pagesOriginal Title

sop con cloruro.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views10 pagesSop Con Cloruro PDF

Sop Con Cloruro PDF

Uploaded by

Felipe HoyosCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

INNER

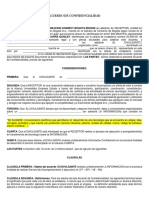

‘US 2016037652681

cu») United States

2) Patent Application Publication co) Pub. No.: US 2016/0376526 Al

Smith (43) Pub. Date: Dec. 29, 2016

(54) POTASSIUM SOAPS THAT CAN BE A619 19/10 (200501)

THICKENED WITH CHLORIDE SALTS cub 10 (2006.01),

C1OM 16904 (200501),

(71) Applicant: Vanguaed Soap LLC, Memphis, IN (42) US. €

«

) ce CHE 1925 2013.01; CHD 970

(2013.01): CHD 17/049 (2013.01), COM

10524 (2013.01); C1OM 169/04 2013.01)

7 s AGIK 8/36 (2013.01); ABIK 8/20 (2013.01),

(73) Assignee: Vanguard Soap LLC, Memphis, TN arg son Guisoly arg fae calsole

(ws) CHC 1000 (2013.01, C1OM 2207/1203

(2013.01); C1OM 2201/08) (2013.01); 461K

‘280088 (2013.01)

(72) Inventor: Scott A. Smith, Memphis, TN (US

21) Appl. Now 15/197,486

(22) Filed: Jun. 29, 2016 “ny ABSTRACT

Related U.S. Application Data ‘Natural quid potassium soap compositions and methods of

smantfacturing and using the same are provided with thick-

ening by the addition of chloride salts, such as sodinm

chloride and potassium chloride. The natural liquid potas-

sium soap compositions may contain one or more fatty acids

‘with carbon length ranging Irom four (C4) to twenty-two

(60) Provisional application No, 62/186,099, filed on Jun.

29, 2015

Publication Classification

(1) Inc. (€22) oF natural fatty acd mixtures with eoconut oi, olive

cuic im (2006.01) oil, tallow, sunflower ol, sallower oil andor tll oil fay

cup 1704 (2005.01) acids which are saponified with lye. The saponification lye

cioM 105724 (2005.01) is preferably potassium hydroxide. Prefered embodiments

cic 1m (2006.01), contain potassium salts of fatty acids comprising at least

AGIK 836 (2006.01) oleic acid (C18:1 cis-), olive ols, coconut oils or mixtures

461K 8720 (2006.01) thereol. The chloride satis added in ether solid oliguid

A610 502 (2006.01) form following saponification and neutralization

US 2016/0376526 Al

POTASSIUM SOAPS THAT CAN BE

‘THICKENED WITH CHLORIDE SALTS

CROSS-REFERENCE TO RELATED

'APPLICATIONS|

10001] This application claims priority to U.S. Provisional

Application No. 62/186,099 to Scott A. Smith fled on Jun.

20, 2015, the contents of which are incorporated here by

reference in its entety

FIELD OF THE INVENTION

10002] The present invention is generally dirvcted towards

natural Higuid soap compositions that can be thickened with

chloride salts and methods for manufacturing thickened

natural soap compositions made from various earbon ehain

Jength fatty acids

BACKGROUND OF THE INVENTION

0003} | Soap can be defined asa salt of one or more of the

higher fany acids with an alkali oe metal. Most soaps are

made by the action of potassium or sodium hydroxide on

‘animal Tals and vegetable ols (or faty acids), Tae prepa

ration of soap directly from the raw fatty acids by the use of

‘lye ether potassium of sodium hydroxide) is refered 10

fs saponification, which is well known in the art of soap

manufacture

10004) Commercial potassium soaps generally have low

Viseosites, a hash afterfeel, and are not able to achieve

viscosity build characteristics with the addition of chloride

falls, Poduets curently sold inthe market place are pi

cally thickened with cellulosic (such as hydroxyethyl cel

Iulose or HEC) or polymeric thickeners if not just left in

their natural law viscosity Cwatery”) state. Such thickened

‘commercial potassium soaps are found in numerous prod

ucts used as general cleaning soaps. shampoos, body

washes, et

10005)" There is a need for soap made with all natural

products that ean maintain a luxurious Feel through peopee

Tilly acid and natura oil seletion as well a thee ability 10

be thickened with chloride salts without separating, losing

their raised viscosity, and clarity

SUMMARY OF THE INVENTION

10006] _ Accordingly, tis an object of the present invention

to provide novel natal liquid soap compositions and meth-

‘ods that overcome these and other problems of the prio at

by providing natural liquid soap compositions thickened

wth chloride salts that ean maintain a luxurious fee through

proper fay acid and natural ol selection as well as tei

bility to not lose their raised viseosity and elaity In one

aspect, the preseat invention provides @ method of manu

facturing of & natural liquid soap composition comprising

the step of saponifying one or more fatty acids ranging in

‘carbon length from four (C8) to twenty-two (C22). In some

nboiments, the Faty acids comprise a mixture of Tatty

ids ranging in carbon length from four (C4) to twenty-two.

(C22), In some embodiments, natural fatty acid mixtures

‘with coconut oil, ove ol, tallow, sunflosser ol, sallower

oil, and/or tall oil fatty ackls are used. In some preferred

‘embodiments, the fatty acids comprise at least oleic acid

(CI8:1 cis-9). In other preferred embodiments, the fatty

ids comprise at leat olive oils. In ther preferred embod

ments, the fatty acids comprise at least coconut oils. Instill

Dee. 29, 2016

other preferred embodiments, the faty acids comprise at

least oleic acid (C18:1 cis-9}, olive oils, coconut oils or

mixtures thereof, The step of saponification may be per

formed by adding Iye in some embodiments. In preferred

embodiments, the Iye is potassium hydroxide. For thieken-

ing, chloride salts are added following saponification and

neutralization and may be added to the reaction vessel in

solid or solution form. Preferably. the chloride salts are

Selected from either sodium chloride or potassium chloride

fr combinations thereof

[0007] In another aspect, the present invention provides @

‘atural_tiquid soap composition comprising one or more

ssponified fatty acids ranging in carbon length from four

(C4) to twenty-two (C22). In some embodiments, the fry

acids comprise a mixture of fatty acids ranging in earbon

Teng from four (4) to twenty-two (C22). In some embed

cals, natural ety acid mixtures with coconut ol, ove oi

tallow, sunflower ol, slower el, andor tal ol fatty acids

fare used, In some preferred embodiments, the faty acids

comprise at least oleic aid (C18: cis). In other preferred

embodiments, the fatty acids comprise at last olive ols. In

other preferred embodiments, the faty acids comprise at

Teast coconut oils. In stil other preferred embodiments, the

fatty acids comprise atleast oleic acid (C18:1 cis), olive

oils, coconut oils or mixtures thereof, In preferred embod

‘ments, the saponified fatty acids are prepared with potas-

sium hydroxide. The natural liquid soap composition is

thickened with a chloride salt, which may be added to the

reaction vessel in solid or solution form. Preferably, the

chloride salt is selected from either sodium chloride or

potassium chloride or combinations thereof.

[0008] In another aspect, the present invention provides 2

‘aural figuid soap composition in vatiows administration

forms, such as soaps (iguid or foaming cleansers), wipes

shampoos, lotions, body’bath soap gels, exfoliate cleansers

‘nd industrial soaps and lubricants comprising one or more

Ssponified fatty acids ranging in carbon length from four

(C4) to twenty-two (C22). In some embodiments, the fatty

acids comprise @ mixture of fatty acids ranging in earbon

Jenuth from four (C4) to twenty-two (C22). In some embod

‘ments, natural fatty eid mixtures with coconut ol, olive o}

‘allo, sunflower oi, sflower oil, andor tal ol fatty acids

fre used. In some preferred embodiments, the fatty

‘comprise at least oleic acid (C18: cis). In other preferred

embodiments, the fatty acids comprise at least olive ols. in

other preferred embodiments, the fit acids comprise at

Teast eocontt ols In still other preferred embodiments, the

fatty acids comprise atleast oleic acid (C18:1 eis), olive

oils, coconut oils or mixtures thereof, In preferred embodi-

‘meats, the saponified faty acids axe prepared with potas-

sium hydroxide. The natural liquid soap composition is

‘hickened with a chloride salt, which may bo added to the

reaction vessel in solid or solution form. Preferably, the

chloride salt is selected from either sodium chloride oF

potassium chloride oF combinations thercof,

DETAILED DESCRIPTION

[0009] The following detailed description is presented to

tenable any person skilled in the art to make and use the

invention. For purposes of explanation, specific details are

set forth to provide thorough understanding of the present

invention, However, it will be apparent to one skilled in the

these specific details are ot required to practice the

nti, Descriptions of specitie applications are provided

US 2016/0376526 Al

conly as representative examples. Various modifications t0

the prefered embodiments will he readily apparent to one

shilled in che ar, and the general principles defined herein

may be applied to other embodiments and applications

‘without departing from the scope of the invention. The

present invention i no intended wo be limited wo the embodi-

‘ments shown, bu isto be accorded the widest possible seape

‘consistent with the principles and features disclosed herein,

[0010] ‘The present invention provides a series of novel

natural Higuid potassium soap compositions thickened with

‘chloride salts and methods making the same that overeome

the problems of the prior art discussed above, as well as

other problems. While the embodiments are discussed

herein as being directed toward natural liguid potassium

soap compositions and related methods, a pe

the art would appreciate thatthe present inv

liquid potassium soep compositions and elated methods can

be used or as a base of a soap composition (© treat and

prevent a variety of microbial infections (or, for example

prevention of microbial contamination) by cleansing oF

treating the skin andr har of a subject in need thereof, Por

‘example, a subject in need thereof ean be an animal with

‘exposure fo oF susceptibility to a microbial infection oF

transfer on or from its skin and/or hair (fur). In preferred

‘embodiments, a subject in nced thereof is @ person with a

‘exposure to or suscepibilty to mierobial infection on the

skin or a general need to cleanse the subject's skin of

microbial flora, Furthermore, @ person of skill in the art

‘Would appreciate that the present inveation’s natal liquid

potassium soap compositions and related methaxls ean be

used alone or asa base ofa soap composition eomprising an

industria/commereial cleaning agent, an anti-microbial su

Jace cleanser, a bath or hand soap(gel, ashampoo, and skin

‘are tions andl creams.

[0011] Thus, in one aspect, the present invention provides

8 method of manufacturing a natural liquid potassim soap

‘composition comprising the step of siponifying one or more

{itty acids ranging in carbo length fom four (C4) to

twenty-two (C22), In some embodiments, the fatty acids

‘comprise a mixture of fatty acids ranging in carbon length

Jom four (C4) to twenty-two (C22). In some embodiments,

natural ity acid mixtures with coconut ol, live ol, allow.

sunflower oil, saflower oil, andor tall ol fay acids are

used. In some preferred embodiments the fatty acids com-

prise at Teast oleic acid (C18:1 cis-9). In other preferred

‘embosdiments, the fatty acids eoraprise at Teast olive oils, In

‘other preferred embodiments, the fatty acids comprise at

least coconut ils. In still other preferred embodiments, dhe

fatty acids comprise atleast oleic acd (C181 eis), olive

cis, coconut oils or mixtures thereol. The step of supor

‘eation may be performed by adding Iye. Any saponifying

‘counterion ean be used in some embodiments. In preferred

‘embodiments, the lye is potassium hyronide. thickening

sep is then performed by adding an appropriate amount of

chloride salt, which may be aed tothe reaction vessel in

Solid or solution form. Preferably, the ehloride salt is

selected from either sodium chloride or potassium chloride

‘or combinations thereof. An appropriate amount is sueh an

mount that results in thickening of the natural liquid

potassium soap composition without affecting clarity, color,

‘or cause the soap composition to separate or become less

viscous afler step completion. The saponified fatty acids

(Goap) ate generally foaming water soluble natural liquid

potassium soap compositions that are mild tothe skin and

Dee. 29, 2016

Ihave excellent color, clarity, and odor. The natural liquid

potassium soap compositions exemplified herein are par-

ticularly suited for personal care applications like hand

‘washes, body washes, shampoos, and bubble baths. They are

also excellent additives for pet care products, hard surface

cleaners, and industrial lubrication applications. They may

then be processed with other soaps, pigments, detergents,

andlor adjuvants/ragrances that are well known in the field

or otler processing for preparing commercial soaps, sham-

poos, wipes, lotions, hody/hath soap gels, exfoliate eleans-

ers, or ereams for use by a subject in need thereof ro ereste

1 further natural Tiguid potassium soap composition of the

invention

another aspect, the present invention provides a

iquid potassium soap composition comprising ome

‘or more saponified fatty acids ranging in carbon length rom

four (C4) to twenty-two (C22). In some embodiments, the

Tiny acids comprise @ mixture of Fatty acids ranging in

carbon length frm for (C4) to twenty-two (C22), In some

embodiments, natural fatty acd mixtires with coon 0}

olive ol, tallow, sunflower ol, sallower oi, andr tal il

fatty acids are used. In some preferred embodiment, the

fatty acids comprise atleast oleic acid (C181 cis-D). Inther

preferred embodiments, the fatty acids comprise at least

olive oils. In other preferred embodiments, the Tay acids

comprise at least coconot oils, In still other preferred

embodiments, the fatty acids comprise at least oleic acid

(C18:1 cis), olive oils, coconut oils, oF mixtures thereof.

‘The fatty acs ranging in carbon length from four (C4) 10

swenty-two (C22) or natural fatty acid mixtures with eoeo-

ut oil, olive ol, tallow, sunflower cil, salllower oil, andior

tal ol fatty acids are saponified by addition of a lye or other

‘appropriate potassium counterion to create the saponified

fatty acids, in some preferred embodiment, the saponifisd

{amy acids are prepared with potassium hydroxide as the ye

In some preferred embodiments the fatty acide comprise at

Teast olete acid (C181 cis-9) In other preferred embodi-

ments, the fatty acids comprise at least olive oils. In other

preferred embodiments, the fatty acids comprise at least

‘coconut oils. In still other prefered embodiments the fatty

acids comprise atleast oleic acid (C1831 cis 9), olive oil,

coconut ols, or mixtures thereof. In my practice, the type

And source of olive oil has eased no signifieant difference

(other than color) in a process batch

[0013] 1 have surprisingly found dat substituting at least

4 portion of coconut oil in process batches with natural

‘unsaturated fatty acids, sueh a, but not limited to, oleic acid

ricinoleie fatty acid, eurucc fatty ace, olive ols, sunflower

oils, andr sallower oils allows fora lower requirement for

percent solids in a potassium fatty acid soap while main-

‘aining efetive cleaning ability, However, Thave also found

high saturated fatty acid components, such as eocomt

oil, is needed to efficiently complete saponification eaetions

that also contain oleic acid (inning unsaturated fatty acids

and oils, suc as, but not limited to, olive ol). Heving oo

‘much olee acd (unsaturated fatty acidsois) in the reaction

‘ean force the retin to break and resort in high residual oils

‘due to incomplete saponification. A person of skill in the at

‘ean follow the diselosuze herein to determine the best ratio

of coconut oils (saturated) to oleic acid (unsaturated) that

‘maintains efficient completion of saponification and main-

tains the texture and viscosity required for the intended

application

US 2016/0376526 Al

10014] |The natural iquid potassium soap compositions are

thickened with an appropriate amount of ehlorde,suel as @

chloride salt, which may be added to the reaction vessel in

solid or solution form. Preferably, the chloride salt is

selected from sodium chloride and potassium chloride, or

‘combinations thersaf. An appropriste amount is such an

amount that results in thickening of the soap composition

without affecting clarity, color, oF eause the soap composi

tion to separate or become less viscous after step comple-

tion. The reaction ean be monitored by a person of skill in

the art to achieve this, T have surprisingly found that the

thickening of the seap compositions with chloride allows for

lower percent solids while maintaining cleaning effective-

ness and desirable viscosity in abroad range of liquid soap

applications, Ihave also supprisingly found that combining

the chloride additive with a substitution of cocontt oil

(predominantly saturated fatty acids) with oleic acid (pre-

‘dominantly unsaturated fatty acid) has a synergistic effect on

the requirements for percent solid ina liquid soap compo-

sition while maintaining cleaning effectiveness and desir

able viscosity in a broad range of liquid soap applications.

For example, as litle as 4.7% (weight) of added sodium

chloride to reaction batch will achieve high viscosity in

‘many natural fatty aid or combination natural fatty acids

soap compositions

10015] A person of skill in the aet will be able to monitor

‘batch resction during the addition of ehloride to achieve

the desired viseosity forthe intended application of that soup

‘composition batch It is also understood that depending om

the intended final application forthe natural potassium soup

‘composition, the desired viscosity will vary. Por example,

some liquid saponified fatty acids (soap) described herein

fare generally foaming water soluble natural soap composi

tions that are mild to the skin and have excellent color,

clarity, and odor. A viscosity value of about 2,000 cPs at

room temperature is generally acceptable for @ hand soap.

However, a body wash may be desired to be around 12,000

‘Ps at room temperature Tor customer acceptance. Also,

body wash gels and shampoos may similarly need to be

within 12,000 and 40,000 Ps at room temperature. An

abrasive or exfoliate liquid soap product will be more

“desirable tthe consuming public if thas the consistency of

a gel, which is about 40,000 ePs_at room temperature

Decreased percent solids in the final consumer product

allows for processing batches as liquid soap concentrates

that can be further diluted by water to achieve the desired

final viscosity for different applications. This discovery has

Jed to decreased processing time and wear on reaction

vessels, as well at decreased costs per unit of final soup

product, among other benefits over the prior ar.

{0016} ‘The natural liquid potassium soap compositions

‘exemplified herein are particularly suited for personal eare

pplication like hand washes, body washes, shampoos, and

bubble baths. They are also excelent additives for pet care

products, hard surfice cleaners, and industcial lubrication

applications. They may then be processed with other soaps,

detergents, pigments, and/or adjuvants/fragrances that are

‘well know in the fick! or other processing for preparing

‘commercial scaps, shampoos, wipes, lotions, bodybath

soap gels, exfoliate cleansers, or ereams for use by a subject

jin need thereof to crete a further natural lsu potassinm

soap composition ofthe invention.

Dee. 29, 2016

Example 1

Method of Manufacture

[0017] Manufacturing natural liquid potassium soap com-

positions that are thickened With ebloride salts has proven

{ifcult to achieve in a consistent clear particulate free form.

Most commercial produets are therefore thickened with

HEC (hydroxyethyl cellulose) or polymeric compounds

The following example provides the general procedure sed

{o achieve consistent clear particulate freeform for natural

Tiquid potssium soap compositions that are thickened with

chloride salts. To a reaction flask equipped with agitation,

Doeat, thermometer, and nitrogen sparge is added the spe

fied amount of fatty acid and or natural ills). Next the

specified mas (eg, number of grams) of potessium hy rox-

‘de reactant is added under good agitation with and without

‘nitrogen sparge. Sodium hydroxide ean be used in lew of

‘or in mixtures with potassium hydroxide, which wil quire

ferent specified mass bused on the mass difference

between sodium and potassium, However, potassinm

hydroxide is preferred for Tiguid soap concentrates and

‘applications, Next i added enough water lo make the final

product havea solids content af 30-60% by weight, depend

Jing on the application or concentrate being prepared. This

can be determined by monitoring the reaction as water is

added. Nitrogen sparge, whea utilized, is simply nitrogen

‘3 bubbled through the liguid contents ofthe flask ata rate

Tow enough aot to produce too muck Foam and arate high

enough t0 Keep the color light by minimizing oxidation.

While nitrogen spurge is not required in the method, iis

advantageous to use in reactions containing base oils or fatty

acids of carbon chain length having a susceptibility 10

‘oxidation in order to prevent color bodies from buildin, The

reaction mass i heated to 90-105" C, and i held for 255

hours.

[0018] Testing for the itis alkali fllows the reaction

progress, Once the theoretical value is reached, the reaction

‘s teminated, When the reaction is terminated, the free

alkalinity is then neutralized to an acceptable pH andior

alkalinity range with an aceeptable neutralizing agent. For

the purpose of dese examples hydrochloric acid andor

citric acid were uilized for neutralization: however, those

stalled in the art may use other neutralizing agents without

Sparing from the spirit and seope of the invention. A

person of ordinary skill in the art will understand that an

acceptable pH and/or alkalinity range may depend on the

intended use ofthe final product (et, hand soap, antiseptic

cleaning soap, shampoo, bath gel, et) with most having an

alkaline pH. All simple and blended sample compositions

Were tested over a range of pH from 8.8 to 13.5, with the

‘optimum range being. from 5 t0 10.2 for liquid soap

applications. Upon neutralization to an aceepiable pH andior

alkalinity, an appropriate amount of a chloride sal is added

{o thicken the compenition. The chloride salt may be added

to the reaction vessel in solid or solution form. Preferably,

the chloride salt is selected from either sodium chloride or

potassium chloride or combinations thereo Preferably, the

product is used without adlitional purification or processing.

With each Sample (see TABLE. 1), multiple simple and

blended compositions of the fatty acidsoils Below were

assembled to achieve optimization for different applications.

‘The perwent solids were tested ata range of 18.0% (weight)

to 75% (weight), with the optimum being inthe range of

‘38.59% (weight) fo 41.5% (weight) or liquid soap applica-

US 2016/0376526 Al

tions, As described further below, the batches (especially

those with # range around 40% solids, but ot limited 40

these) may be produced as a liquid soap concentrate that

may be flsther diluted with water to achieve a final con-

sumer quid soap product having 20% or less percent solids

Altematively, the concentrated formulations may be pack-

‘age and sold to consumers as eoncenteated potassium soap

‘compositions, which also” generates costs savings in

‘decreased packaging and shipping costs, as well as

‘decreased shelving/somage needed by rl

TABLE 1

Sample Fay Asia or OL Nave Cabon Chin

1 Buyroca cace

2 Capote a

3 cape cho

4 Cipgtociee Sten

6 Myre cm

7 Laie eines

Fase cle

3 See cit

0 Ome cit

Te Ranateis crE0%

2 BewsBunse ence

1 acon Of Wiste OM Dstt

1 lneo Wisi OM Detbton

1S TAO Fay Acid Whe OM Datta

Example 2

Butyrie and Caproie Acid:

10019] A sample composition including both butyric faty

acid (C4) and caproie fatty acid (C6) according to the

teachings above was prepared. The composition comprised

about 12.6% (‘seight) butyric fatty acid and about 17.9%

(vcight) caproie faty acid. Potassium hydroxide was

‘nchided a about 10.4% (weight). The remaining material in

the batch was mostly water, Sulicent citric acid (citrate)

was add 10 neuirlize the pH to an acceptable Jevel as

discussed above. Also, less than 4% (weight) of sodium

chloride was arided to increase the viscosity to a desired

evel. Compositions following this general formulation

(sth and without modifications) can be used in applications

‘of deodorizing and disinfecting hard surfaces, skin, and b

(fur) with low foam, Also, heavy duty cleaning applications

Tor metal srfces and other industrial surfaces,

Example 3

‘Caprylic andlor Capric Acid Sample Formulation 1

10020] A sample composition including either or both

‘caprlie fatty acid (C8) and capri fatty acid (C10) accord

ing to the teachings above was prepared. The composition

‘comprised about 30.5% (weight) total of eaprylie fatty acid

‘and/or capric Falty acid, Potasim hydroxide was included

atabout 10.4% (weight) The remaining material in the batch

‘was mostly water. Silicent cite aed eiteate) was added 10

neutralize the pH to an acceptable level as discussed above.

Also, less than 49% (weight) of sodium chloride was added

to increase the viscosity to a desired fevel. Compositions

‘ollowing this general formulation (with and without modi

fications) can be used in applications of deodorizing and

disinfecting hard surfaces, skin, and baie (ur) with low

Dee. 29, 2016

foam. Also, heavy duty cleaning applications for n

surlaces and other industrial surfaces

Example

CCaprylie and Caprie Acid Sample Formutation 2

[0021] _A sample composition inch

acid (C8) and capric fatty aeid (C10) accor

teachings above was prepared. The composition comprised

about 12% to about 15% (weight) of eapryie fatty aed and

about 12% 10 about 15% (weight) of capeic fatty acid.

Pevassium hydroxide was included at about 10.4% (weight).

‘The remaining material in the hatch was mostly water

Suliient citi acd (citrate) was added to neutralize the pH

toan acceptable level as discussed above. Iso less than 4%

(veight) of sodium ebloride was added to increase the

viscosity to a desired level. Compositions following this

tener Fomulation (with and without modifications) can be

‘sed in applications of deodorizing and disinfecting ard

surfaces, skin, and baie (Fur) with low foam, Also, eavy

duty cleaning applications for metal surfaces and other

industrial surfaces.

Pxample 5

Laurie Acid Sample Formation

0022] A sample composition including laurie fatty acid

(C12) according to the leachings above was prepared. The

‘composition comprised about 28.8% (sight of laurie fatty

acid. Potassium hydroxide was included at about 11 2%

(Gveight). The remaining material in the batch was mostly

ater, Sullicient cite acid (citrate) was added to neutralize

the pil to an acceptable level ax discussed above, Also, less

‘than 4% (weight) of sodium chloride was added o increase

the viscosity o a desired level, Compositions following this

general formulation (with and without modifications) can be

‘used in applications of general cleansing and washing where

high foam is desirable.

Example 6

Laurie Acid und Myristc Acid Sample Formulation

[0023] A sample composition ineluding both laurie fatty

acid (C12) and myristic fay acid (C14) according to the

teachings above was prepared. The composition comprised

about 20% (weight) of laurie fatty acid and about 8 8%

(Gseight) of myristic fatty acid. Potassium hydroxide was

‘included at about 11.4% (weight), The remaining material in

the hatch was mostly water. Sufficient citric acd (citrate)

vas added 10 neutralize the pH to an acceptable level as

discussed above, Also, less than 4% (weight) of sodinm

chloride was added to increae the viscosity to a desired

level. Compositions following this general formulation

(vith and without modifications) ean be used in applications

fof general cleansing and washing where high foam is

esirable

Example 7

Myrisic Acid Sample Formulation

[0024] A sample composition including mystic fy acid

(C14) according to the teachings above was prepared. The

‘composition comprised about 30% (weight) of mystic fatty

US 2016/0376526 Al

id, Potassium hydroxide was included at about 11.4%

(Gveight). The remaining material in the batch was mostiy

ater, Sullicient ite acid (citrate) was added to neutralize

the pll to an acceptable level at discussed above, Also, less

than 4% (weight) of sodium chloride was added 10 inerease

the viseosty to a desired level. Compositions following this

general formulation (with and without modifications) can be

‘sed in applications of general cleansing and washing where

high foam is desirable.

Example §

Palmitie Acid Sample Formulation

10025] A sample composition including palmitie fay acid

(C16) aeconting to the teachings above was prepared. The

‘composition comprised about 30.2% (weight) of palmitic

fatty acid. Potassium hydroxide was included at about

10.4% (weight). The remaining material in the bateh was

mostly water. Sullcient citric acid (citrate) was added

neutralize the pH o an acceptable level as discussed above.

Also, loss than 4% (weight) of sodium chloride was added

to increase the viscosity o a desired level. Compositions

following this general formulation (with and without modi

fcations) can be used in applications of general cleansing

and washing where high foam is desirable

Example 9

Palimitic Acid and Stearic Acid Sample Formulation

10026] sample composition including both palmitic fatty

cid (C16) and stearic fatty acid (C18) according to the

teachings above was prepared, The composition comprised

about 20.5% (weight) of palmitic fatty acid and about 10%

(oseight) of stearic funy" acid. Potassium hydroxide was

‘included at about 108% (weight) The remaining material in

the batch was mostly water. Suficient citric aid (citrate)

was adkled to neutralize the pH] to an acceptable level as

discussed above. Also, less than 4% (Weight) of sodium

‘chloride was aded to increase the viseosly to a desired

Tevel. Compositions following this general formation

(sth and without modifications) canbe use in applications

‘of general cleansing. and washing. where high foam is

desirable,

Example 10

oO

[0027] _A sample composition including both oleie fatty

‘acid (C181; omega-9) and stearic fatty acid (C18) according

to the teachings above was prepared. The composition

‘comprised about 20% (weight of oleic fatty acid and about

11% (weight) of stearic fatty acid, Potassium hydroxide was

included at about 11% (weight). The remaining material i

the batch was mostly water. Suficent citric acid (citrate)

was added 10 neutralize the pH to an acceptable level as

discussed above. Also, less than 4% (weight) of sodium

chloride was axided to increase the viscosity to a desired

level Compositions following this general formulation

(sth and without modifications) canbe use in applications

‘of general cleansing and washing where high foam is

desirable,

c Acid snd Stearic Acid Sample Fortnlatos

Dee. 29, 2016

Oleic Acid and Olive Oil Sample Formulation

[0028] _\ sample composition including both oleic fay

acid (C18:1; omega-9) and olive oil (ole ol distribution

‘of constituent ils, which will naturally vary by lot and

source) according to the teachings above was prepared, The

composition comprised about 24% (weight) of oleic fatty

acid and about 4% (weight) of olive oil. Potassium hydrox-

jde was included at about 9:8% (weight). The remaining

‘material inthe batch was mostly water. Sullcient citric acid

(citrate) was added to neutralize the pH 10 an acceptable

level as discussed above, Also, less than 49% (weight) of

sodium chloride was added to increase the visoosity to a

desired level. Compositions following this general foenm-

lation (ith and without modifications) ean be used in

applications of general cleansing and washing where hiph

{eam is desimble.

Example 12

Coconut Oi, Oleic Acid, sod Olive Oil Sa

Fomulation

le

[0029] A. sample composition including cocomt oil

(shole oil distribution of constituent oils, which will natw-

rally vaty by lot and source), oleie fatty acid (C181;

‘omegi-9), and olive vil (shoe ol distribution of constituent

oils, which will naturally vary by Jot and source) according

{o the teachings above was prepared, The composition

comprised about 14% (weight) of eoeonst oil, about 10%

(eight) of ole fatty acid, and about 2% (weight of olive

oil Potassium hydroxide’ was included at about 98%

(weight), The remaining material in the batch was mostly

‘water. Sulicient citric acid (citrate) was added to neutralize

the pH to an acceptable level as discussed above, Also, less

than 4% (weight) of sodium chloride was added to increase

the viscosity to a desired level, Compositions following this

gener formulation (with and without modifications) ean be

‘used in applications of general cleansing and washing where

high foam is desimble. For some applications, batches

following this general formula of Example 12 (or modified

versions that comprise less coconut ol and more oli fa

acid) can be processed as a concentrated liquid soap com-

position while mainisining desired viscosity (controled by

percent weight of chloride addition) forthe final product

‘pplication. The concentrates can be diluted with Water to

about 20% (weight) solids with no appreciable loss in

cleaning effectiveness or packaged as “green” concentrate

products

Example 13

Myristic Acid and Coconut Oil Sample Fomulation

[0030] A sample composition including both myristi fatty

acid (C14) and coconut oil (whole oil distibution of eon-

stituent ols, which will naturally vary by lot and source)

‘cording 1 the teachings above was prepazed. The com-

Position comprised about 20% (weight) of myristic fatty

acid and about 12% (weight) of coconut i Potassium

hydroxide was included at about 11.8% (weight). The

remaining material a the batch was mosly water, Sulicent

citric acid (citrate) was added to neutralize the pH to an

acceptable level as discussed above, Also, less than 4%

US 2016/0376526 Al

chloride was added to increase the

level. Compositions following this

tener formulation (with and without modifications) can be

‘sed in applications of general cleansing and washing where

high foam is desirable. For some applications, batches

following this general formula of Example 13 (or modified

versions that substitute at Teast some coconut il far oleic

fatty acd) can be processed as a concentrated liquid soap

‘composition while msintaining desired viscosity (controlled

by percent weight of chloride addition) forthe final product

application. The conceniates can be diluted with water 10

about 20% (weight) solids with no appreciable loss in

‘leaning effectiveness or packaged as “green” concentrate

products

Example 14

Coconut Oil and Ricinoleie Acid Sample

Formulation

10031] A sample composition including both coconut oil

(shole ol distnbation of constitient oils, which will nati-

rally vary by lot and souree) and rcinoleie fatty acid (C18:1,

‘Ol omega-9) according to the teachings above was pre

pared The composition comprised about 19% (weigh) of

‘coconut ol and about 14% (weight) of ricinolee fatty avi,

Potassium hydroxide was included at about 9.8% (weigh.

“The remaining material ia the batch was mosly water

Sullieient cir acd (citrate) was ade to neutralize the pET

to an acceptable level as discussed above. Also less than 4%

(Gveight) of sodium chloride was added to increase the

Viseosty to a desired level. Compositions following this

‘ener formulation (with and without modifications) can be

‘sed in applications of yeneral cleansing and washing where

high foam is desirable. For some applications, batches

following this general formula of Example 14 (or modified

versions that comprise less encom oil and! more ricinoleie

Zany acid or substituted with atleast some oleic Fatty acid)

‘cane processed asa concentrated liquid soap composition

While maintaining desired viscosity (contalled hy percent

‘eight of chloride adlitinn) fr the final product application,

The concentrates ean be diluted with water to about 20%

(seight) solids with no appreciable loss in cleaning ellee-

liveness or packaged as “green” concentrate products

Example 15

Coconut Oil, Ricinoleie Acid, and Beheni/Purucie

Fatty Acids Sample Formulation

{0032} A. sample composition including coconut oil

(shole oil distribution of constituent oils, which will natu-

rally vary by lot and soure),riinoleie fay acid (C181,

‘OF, omega-9), and behenic (C22) andlor eurucicterucie

(C22:1; omegs-9) faty acids according to the tea

above was prepared. The choice of individual or ratio of

behonic fatty acid to eurvce fatty acid will depend on the

Jnended final product application or desired viscosity. The

‘composition comprised about 10% (weight) of coconut oi,

about 10% (weight) of rcinolee fay aed, and about 8%

(Gvcight) total of behene andlor eurucie/ercic fatty acids

Potassium hydroxide was ineluded at about 109% (eight.

‘The remaining material in the batch was mostly wate

Sullicient citi acd (irate) was added to neutralize the pF

to an acceptable level as discussed above. Also less than 4%

(eight) of sodium chloride was added (0 inerease the

Dee. 29, 2016

viscosity to a desired level. Compositions following this

general formulation (with and without modifications) can be

‘used in applications of general cleansing and washing where

low to moderate foam is desirable, as wel a skin care and

concitioning. applications. For some applications, batches

following this general formula of Example 15 (or modified

versions that comprise ess coconut oil and! more riinoleie

fatty acid and/or enrucie fatty acid) can be processed as a

concentrated liquid soap composition while maintaining

esired viscosity (controlled by percent weight of chloride

sadition) forthe final product application. The concentrates

fan be diluted with Water to about 20% (weight) solids with

‘ho appreciable oss in cleaning effectiveness or packaged as

“green” concentrate products

Example 16

Coconut Oil and Olive Oil Sample Formulation

[0033] sample composition including both coconut oil

(shoe oil distibution of constituent oils, which will nam

rally vary by lot and source) and olive oil (whole oil

istrbution of constiruent ois, which will natwally vary by

Jot and source) according to the teachings above was pre-

pared. The composition comprised about 24% (wejaht) of

coconut oil and about 5% (weight) of olive ol. Potassium

hhydroxide was included at out 11% (weight). The remain-

ing material inthe bateh was mostly water, Suicient cite

‘acid (citrate) was added to neutralize the pH to an acceptable

level as discussed above, Also, less than 4% (weight) of

sodium chloride was added to increase the viscosity to a

Sesired level. Compositions following this general fornn-

Jation (vith and without modifications) ean be sed in

applications of general cleansing and washing where high

eam is desirable. For some applications, batches following

this general formula of Example 16 (or modified versions

that substitute atleast some eocontt oil for oleiefaty acid

andor more olive oil, which typically contains oleic and

Tinoleie fatty acids as a majority fraction) can be processed

‘asa concentrated liquid soap composition while maintaining

‘sired viscosity (controlled hy percent weight of chloride

addition) for the final product application. The concentrates

‘an be diluted with water to about 20% (weight) solids with

no appreciable loss in cleaning elfectiveness or packaged as

“green” concentrate products

Example 17

‘Coconut Oil and Tall Oil Fatty Acids Sample

Fonmulation

[034] sample composition including both coconut oil

(stole ol distribution of constituent oils, which will natu-

rally vary by lot and source) and tall ol fatty acids (whole

oil distribution of eonstitaet oils, which will naturally vary

by lot and source) according to the teachings above was

prepared. The composition comprised about 24% (weight)

fof coconut oil and about 5% (weight) of tal el fatty aids

Potassium hydroxide was included at about 11% (weigh).

‘The remaining material in the batch was mostly water

Suliient citric ace (itate) was added to neutralize the pH

toan acceptable level as discussed above. Iso, less than 4%

hn) of sodium chloride was added to’ increase the

viseosty to a desired level. Compositions following this

general formulation (with and without modifications) can be

‘used in applications of general cleansing and washing where

US 2016/0376526 Al

high foam is desirable, For some applications, batches

following this general formula of Example 17 (or modified

versions that substitute at Teast some coconut il far oleic

Titty ack) can be processed as « concentrated liquid soup

‘composition while maintaining desired viscosity (controlled

by percent weight of ebloride addition) forthe final product

application, The concentrates can be diluted with water to

about 20% (eight) solids with no appreciable loss in

‘leaning effectiveness or packaged as “green” concentrate

products,

Example 18

Coconut Oil and Tallow: Sample Formulation 1

10035] A sample composition including both coconut oil

(shole oil distribution of constituent oils, which will natu-

rally vary by lot and source) and tallow (whole oil distri-

bution of constituent oils, which will narraly vary by lot

‘and Source) aecoring othe teachings above Was prepared,

‘The composition comprised about 24% (weight) of coconut

oil and about $% (weight) of tallow: Potassium hydroxide

‘as included at about 11% (eight), The remaining material

inthe batch was mostly water Suficient etic acid (citrate)

‘was added to neutralize the pil to an acceptable level as

discussed ahove. Also, less than 4% (weight) of sodium

chloride was auided to increase the viseosty to a desired

level. Compositions following this general formulation

(vith and without modifications) can be use in applications

‘of general cleansing and washing where high foam is

desirable, For some applications, batches following this

eneral formula of Example 18 (or modified versions that

Substitute atleast some coconut oil for oleic fatty) ean be

processed as a concentrated lguid soap composition while

‘maintaining desired viseosity (controled by percent weight

‘of chloride addition) for the final product application. The

‘concentrates can be diluted with water to about 20%

(Gscight) solids with no appreciable los in cleaning ellee-

tiveness or packaged as “green” concentrate products

Example 19

Coconut Oil and Tallow Sample Formulation 2

10036] _A sample composition including both coconut oil

(sbole oil distribution of constimint oils, whiel will nate

rally vary by lot and souree) and tallow (whole oil distr-

bution of constituent oils, which will nanrally vary by lot

and source) according to the teachings above was prepare.

‘The composition comprised about 20% (weight of coconut

cil and about 9% (weight) of tallow: Potassium hydroxide

Was included at about 11% (Weight). The remaining material

inthe batch was mostly water. Sufiient citric acid (citrate)

was added to neutralize the pH to an acceptable level as

discussed above. Also, less than 4% (weight) of sodium

‘chloride was axlded to increase the viseosty to a desired

Jevel. Compositions following this general formation

(sth and without modifications) canbe use in applications

‘of general cleansing and washing where high foam. is

desirable. For some applications, batches following this

‘general formula of Example 19 (or modified versions that

Substitue at last some eaconurt ol for olee fatty acid) can

be processed as a concentrated liguid soap composition

while maintaining desired viscosity (contalled hy percent

‘eight of chloride adlitinn) fr the final product application,

The concentrates ean be diluted with water 10 about 20%

Dee. 29, 2016

(vcight) solids wit

tiveness or package

tno appreciable loss in cleaning effee-

‘a “green” concentrate products,

Example 20

Coconut Oil Sample Formulation

0037] A sample composition including coconut il only

(shole ol distribution of eonstituent oils, which will nat

rally vary by lot and souree) according to the teachings

above was prepared. The composition comprised about 29%

(vcight) of coconut ol, Potassium hydroxide was included

at about 19% (weight). The remaining material in the bateh

‘was mostly water. Sufficient citi ac citrate) was aed to

neutralize the pH to an acceptable level as discussed above

Abo, less than 4% (weight) of sodium chloride was added

to increase the viscosity to a desired level. Composito

following this general omulation (with and without modi-

fications) can be used in applications of yeneral cleansing

‘and washing where high foam is desirable. For some eppl

cations, bates following this general formula of Fxample

20 (or preferably, modified versions that substitute at least

some coconut ol for oleic fety acid) can be processed as 3

concentrated liquid soap composition while. maintaining

desired viscosity (controled by percent weight of chloride

addition) for the final product application. The concentrates

fan be diluted with water to about 20% (weight) solids with

‘ho appreciable loss in cleaning elfestiveness or packaged as

“on” concentrate proiets

Example 21

‘Sunflower Oil and Coconnt Oil Sample

Fomulation

[0038] A sample composition including both sunflower oil

(sole ol distribution of constituent oils, which will natu-

rally vary by lot and source) and coconut oil (whole oil

distribution of constituent ois, which will naturally vary by

Jot and source) according to the teachings above was pre-

pated. The composition comprised about 24% (weight) oF

sunflower oil and about 5% (weight) of eoconut oil. Potss-

sum hydroxide was inckuded at about 12% (ocight). The

remaining material i the batch was mosily water, Sulice

citric acid (citrate) was added to neutralize the pH to an

acceptable level as discussed above, Aso, less than 42%

(eight) of sodium chloride was added to increase the

viscosity to a desired level. Compositions following this

general formulation (with and without modifications) can be

‘used in applications of general cleansing and washing where

high foam is desimble. For some applications, batches

following this general formula of Example 21 (or modified

versions that substitute at least some coconut cil far oleic

faty acid or more sunflower oil) can be processed as

concentrated liquid soap composition while maintaining

Gesired viscosity (controlled by percent weight of chloride

dition) forthe final product application. The concentrates

‘ean be diluted with water to abont 20% (weight) soids with

‘0 appreciable loss in cleaning effectiveness or packaged as

“geen” concentrate products

Example 22

Satllower Oil sad Coconut Oil Sample Formulation

0039] sample composition including both saflower oil

(shole oil distribution of eonstituent oils, which will nate

US 2016/0376526 Al

rally vary by lot and souree) and coconut oil (whole oil

lisiribution of constituent oils, which will naturally vary by

Jot and source) according tote teachings above was pre-

pared, The composition comprised about 249% (weight) of

salllower oil and about 5% (weight) of eoeontt oil, Potas-

um hydroxide was included at about 12% (eight). The

remaining material in the bateh was mostly water. Suficient

citric acid (citrate) was added to neutralize the pH to an

acceptable level as discussed above. Also, less than 4%

(Gveight) of sodium chloride was added to increase the

viscosity to a desired level. Compositions following this

ener formulation (with and without modifications) ean be

‘sed in applications of general cleansing and washing where

high foam is desirable. For some applications, batches

following this general formula of Example 22 (or modified

Versions that substitute at Teast some eXeonnt il for oleic

fatty acid or mote safflower oil) can be processed 3s

‘concentrated liquid soap composition while maintaining

desired viscosity (controlled by pereent weight of chloride

‘dkition) forthe final produet application. The concentrates,

‘canbe diluted with wster to about 20% (weight) solids with

no upprecable lost in cleaning ellectiveness or packaged as

“green” concentrate products

Example 23

Sunflower Oil, Coconut Oil, and Olive Oil Sample

Formulation

[0040] A sample composition including sunflower oil

(oshole oil distribution of constiment oils, whieh will nati-

rally vary by lot and source), caconnt oil (whole oil distri-

bution of constituent oils, which will naaraly vary by lot

and source), and olive oil (whole oil distribution of

stituent oils, which will naturally vary by lot and source)

‘acconling to the leacings above was prepared. The com-

Position comprised about 20% (weight) af sunflower oi,

about 5% (weight) of coconut oi and about 4% (weight) of

‘olive oil. Potassium hydroxide was inclided a about 12%

(eight) The remuining material in the batch was mostly

‘water. Suficent etic acid (citrate) was added to neutralize

the pli to an acceptable level ak discussed above, Also, less

than 4% (weight) of sodium chloride was added to inerease

the viscosity to desired level. Compositions following this

‘general formulation (with and withou modifications) can be

‘sed in applications of general cleansing and washing where

high foam is desirable. For some applications, batches

following this general formula of Example 23 (or modified

versions that substitute st least some coconut oil for oleic

fatty acid or more olive andor sunflower oi) can be pro-

ccetsed as a concentrated liguid soap composition while

‘maintaining desired viscosity (controled by percent weight

‘of chloride addition) for the final product application. The

‘concentrates can be diftted with water to about 20%

(Gvcight) solids with no appreciable loss in cleaning effee-

tiveness or packaged as “green” eoneentate products,

ample 24

‘Salllower Oil, Coconut Oil, snd Olive Oil Saaple

Formulation

{0041} A sample composition including safflower oil

(sbole oil distribution of constimint oils whi will nata-

rally vary by lot and source), caconut oil (whole oil distri-

bution of constituent oils, which will naturally vary by lot

Dee. 29, 2016

and source), and olive oil (whole oil distribution of eon-

Stituent oils which will naturally vary by lot and source)

according 10 the teachings above was prepared. The €0

position comprised about 20% (weight) of salllower ol,

about 5% (weight) of coconut ol, and about 4% (weight) of

olive oil. Potassium hydroxide was included at about 12

(eight), The remaining material in the batch was mostly

‘ater. Sulicient citric acid (citrate) was added to new

the pH to an acceptable level as ciscussod above. Also, less

than 4% (eight) of sodium chloride was added o increase

the viscosity o a desired level. Compositions following this

gener formulation (with and without modifications) ean be

‘sed in applications of general cleansing and washing where

high foam is desimble. For some applications, batches

following this general formula of Example 24 (or modifiod

versions that substitute atleast some esconut cil for ol

fatty acid or more olive andr saflower eil) can be py

cessed as a concentrated liquid soap composition whi

‘maintaining desired visosity (controled by percent weight

of chloride addition) for the final produet application. The

foncentrates can be diluted with water f0 about 20%

(veight) solids with no appreciable loss in cleaning elec

tiveness or packaged as “reen” concentrate products.

[0042] The terms “comprising.” “including,” and “tav-

ng,” as used inthe claims and specification herein, shall be

considered as indicating an open group tat may inelude

other clements not specified. The terms ana the

Singular forms of words shall be taken to include the plural

{orm ofthe state word, sich that the terms mean that one

fo more of something is provided. The term “one” or

“single” may be used to indicate that one and only one of

sontething is intended. Similarly, other specie

things is intended. The terms “prefered

“prefer,” “optionally.” “may.” and similar terms are used to

indicate that an item, condition or stp being refered t0 is

‘an optional (not required) feature of the invention

[0043] ‘The invention has been described with reference to

various specific and prefered embodiments and techniques

However it should be understood that many variations and

‘modifications may be made while remaining within the spitit

and scope of the invention. It will be apparent to one of

ordinary skil in dhe at that methods, devices, device ele-

‘ments, materials, procedures and techniques other than those

specially described herein ean be applied wo the practice of

the invention as broadly disclosed herein withoot resort t0

‘undue experimentation. All ar-known functional equiva.

lents of methods, devices, device elements, materials, pro-

cedures and techniques deseribed herein are intended 0 be

fencompassed by this invention, Whenever @ range is dis-

closed, al subranges and individual valves are intended 10

be encompassed, This ivention is not to be limited by the

embodiments disclosed, inluding any shown in the draw-

‘ngs or exemplified inthe specification, which are given by

way of example and not of limitation,

[0044] While the invention has been deseribed with

respect to limited number of embodiments, those skilled in

the art, having benefit of this disclosure, will appreciate that

other embodiments can be devised which do not depart rom

the scope ofthe invention as disclosed herein, Accordingly,

the scope of the invention should be limited only by the

attached claims.

[0045] AIL references throughout this application. for

‘example patent documents including issued or granted pate

US 2016/0376526 Al

is or equivalents, patent application publications, and

w-pateat literature documents or other source material re

hereby incorporated by reference herein in their entireties, as

though individually incorporated by reference, to the extent

‘each reference is atleast partially not inconsistent with the

‘disclosure in the present application (Tor example, a refer-

‘ence that is partially inconsistent is incorporated by refer

fence except fr the partially inconsistent portion of the

reference).

Tela:

1A soap composition comprising saponifiod fatty acids

with a carbon chain length of C4 to C22 or mixtures thereat

and added chloride

2, The soap composition of claim 1, wherein the sapon-

fied fatty acids comprise natural oils selected from the group

‘consisting of coconut ol, eve oil tallow, tall fatty acids,

sunflower oil sallower oil, and combinations thereof.

3. The soap composition of claim 1, wherein the saponi-

fled fatty acids comprise omepa-9 unsaturated fatty acids

scleted from the group of oleic acid, ricinaleie acid, and

‘eurcie seid, snd combinations thereot.

4, The soap composition of claim 1, wherein the saponi-

fled faty acids were saponified with a lye comprising

potassiuin hydroxide and the added chloride was added 10

the saponified fatty aids afer a neutralizing process

8, The soap composition of claim 1, wherein the soap

‘composition with added chloride is more viscous than &

similar soap composition only lacking inthe added chloride

‘component

6, The soap composition of claim 1, wherein the soap

‘composition is a hund soup, 1 liguid hand soap, a foaming

Tiguid hand soap, bath gt, an exfoliate cleanser, cleaning

wipe, a shampoo, a lotion, 2 cream, an industrial soap, or a

lubricant,

7. The soap composition of claim 1, wherein the soap

‘composition asa percent solid fom about 18.0% (weight)

to about 75% (weigh)

8, The soap composition of claim 7, wherein the soap

‘composition fas a percent solids from about 30% (weight)

to about 60% (weight

9, Tho soap composition of claim 8, wherein the soap

‘composition has a percent solid from about 38.5% (weight)

to 41.5% (weight,

10. The soup composition of ela 1, wherein the soup

‘composition his a percent solids of 208% (weight) or less.

11, The sogp composition of elaim 1, wherein the added

chloride does not affect clarity or color, or eause the soap

‘composition to separate oF become less viscous,

Dee. 29, 2016

12. The soap composition of ea

fone or more additives from the ar

seteruent a soap, a pigment, an adjnvant

‘combinations thereof.

13, The scap composition of claim 1, wherein the added

chloride comprises om 4% (Weight) to 7% (weight).

14, The soap composition of claim 1, wherein tae added

chloride comprises less than 4% (weight),

15, The soup composition of claim 1, wherein the soap

‘composition iss & viscosity of about 3,000 ePs to about

50,000 oPs.

16, A method of manufacturing a soap composition com

prising saponifying fatty acids with «carbon chain length of

C410 C22 or mixtures thereof, neutralizing the saponifica-

tion reaction to an acceptable level of pH, and adding

chloride

17. The method of claim 16, wherein the fatty acids

comprise natural oils selected fiom the group consisting of

cont ol, olive ol, tally, tall il fatty acid, sunflower

oil, salllower ol, and combinations there

18, The method of cluim 16, wherein the fatty acids

comprise omega-9 unsaturated fatty acids selected from the

aroup of oleic acid, ricinoleic ack, and eurueie acid, and

combinations thereof,

19. The method of claim 16, wherein the fatty acids

comprise coconut ol and oleic acid

20, The method of claim 16, wherein the fany

comprise coconut oil and olive ©

21, The method of claim 16, wherein the stop of saponi-

fication comprises reacting the fatty acids with Ie.

722. The method of claim 21, wherein the ie i potassium

hydroxide

23, The method of claim 16, wherein the soceptable level

of pil is between about 8.8 and about 13.5

24, The metho of claim 23, wherein the aoceptabe level

‘of pi is between about 9.5 and about 10.2.

25, The method of claim 16, wherein the chloride is a

chloride salt selected from the group consisting of dry

sodium chloride, aqueous sodium chloride solution, dry

potasium chloride, aquoous potassium chloride solution,

‘and combinations thereot.

26, The method of clsim 16 further comprising diluting

the soap composition with water.

27. The method of claim 16 further comprising adding

fone or more additives fom the group consisting of 3

etorgent, a soap, a pigment, an adjuvant, a fragrance, and

combinations thereof,

28. The method of claim 16, wherein the step of neutral-

ination comprises adding a neutralizing agent comprising

hydrochloric acid, citric ace, or combinations thereat

1 father comprising

‘consisting of

ia fagrance, and

fds

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Intructivo Inducción 2022Document7 pagesIntructivo Inducción 2022Felipe HoyosNo ratings yet

- Práctica No 9 Reacciones Redox Aplicación y ElectroquímicaDocument20 pagesPráctica No 9 Reacciones Redox Aplicación y ElectroquímicaFelipe HoyosNo ratings yet

- Modelo Acuerdo de Confidencialidad PDFDocument5 pagesModelo Acuerdo de Confidencialidad PDFFelipe HoyosNo ratings yet

- A Curso Virtual Hazmat Aph Nfpa 473Document1 pageA Curso Virtual Hazmat Aph Nfpa 473Felipe HoyosNo ratings yet

- PickUpStatement2 PDFDocument3 pagesPickUpStatement2 PDFFelipe HoyosNo ratings yet

- COVID-19 Surface Persistence: A Recent Data Summary and Its Importance For Medical and Dental SettingsDocument10 pagesCOVID-19 Surface Persistence: A Recent Data Summary and Its Importance For Medical and Dental SettingsFelipe HoyosNo ratings yet

- List N Products With Emerging Viral Pathogens AND Human Coronavirus Claims For Use Against SARS-CoV-2Date Accessed 06112020Document1 pageList N Products With Emerging Viral Pathogens AND Human Coronavirus Claims For Use Against SARS-CoV-2Date Accessed 06112020Felipe HoyosNo ratings yet

- TMPG 1 de 1Document233 pagesTMPG 1 de 1Felipe HoyosNo ratings yet

- ES2468215T3Document101 pagesES2468215T3Felipe HoyosNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2007/0155598A1Document10 pagesPatent Application Publication (10) Pub. No.: US 2007/0155598A1Felipe HoyosNo ratings yet