Professional Documents

Culture Documents

IGNIS3D Early Fire Detection System with Contactless Infrared Temperature Measurement

Uploaded by

Sureesh VROriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IGNIS3D Early Fire Detection System with Contactless Infrared Temperature Measurement

Uploaded by

Sureesh VRCopyright:

Available Formats

IGNIS3D

Early Fire Detection System with

Contactless Infrared Temperature Measurement

Distance measurement for more safety

For the first time, the IGNIS3D combines an infrared

camera for temperature surveillance with a laser for

distance measurement. This means that the exact

distances to the hotspots can be determined in addi-

tion to their spatial direction.

▪ Improved alerting due to distance measurement

▪ Precise directing of the turret in consideration of

water stream ballistics

▪ Optimal cooling through distance-independent size

of quenched area

▪ Exact temperature measurement by taking into ac-

count the distance to the hotspot

▪ Independent positioning of the camera system and

turrets

▪ Prevention of false alarms through intelligent object

recognition (e.g., incoming vehicles)

Advantages of distance measurement The hotspot can be precisely located with the

help of three-dimensional coordinate measu-

rement.

The first early fire detection system with distance measurement

To monitor large areas, it must be ensured that the alarm works reliably regardless of the position of the

hotspot. Depending on the distance, a hotspot will be displayed differently in the camera. In close proximity this

would sooner exceed the triggering threshold of the sensor and trigger an alarm, while it would appear smaller

and smaller with increasing distance and would lead to a delayed alarm.

Thanks to the built-in distance measurement, IGNIS3D detects this difference and provides a constant

detection sensitivity for the entire surveillance area. In addition, a uniformsize of the quenched area can be

ensured regardless of the distance.

IGNIS3D

Early Fire Detection System with

Contactless Infrared Temperature Measurement

Independent positioning of camera system and turret

The direct mounting of a turret next to an infrared camera does not always have to be the most efficient

arrangement. In order to achieve an optimum view of the surveyed area it often makes sense, to install them in

separate locations. Costs can also be saved this way.

By measuring the hotspot coordinates, the IGNIS3D is able to control one or more turrets regardless of their

positioning in the space. The number of IGNIS3D infrared systems and turrets does not have to be the same.

▪ Cost savings by using a minimum number of camera systems

▪ Full flexibility for the set up

▪ Spatially separate mounting of turret and infrared camera

Industry standard for safety

Due to its very robust design, the IGNIS3D can also be used in harsh environments. In addition, operators can

carry out minor cleaning work and regular checks themselves and thus reduce the external maintenance effort.

Technical data

Detector resolution 320 x 240 pixels

Detector type Uncooled microbolometer as a Focal Plane Array (FPA)

Spectral range 7.5 µm - 13 µm

Measuring temperature ranges --20 °C to 120 °C [-4 °F to 248 °F]

for black spotlights 0 °C to 350 °C [32 °F to 662 °F] (standard for the IGNIS3D)

Temperature accuracy ± 2 K or ± 2% of the reading value

Sensitivity/NETD < 50 mK at 30 °C [86 °F]

Field of vision (FOV) 25° x 18.8°

Rotation range 0° to 350°

-10°C to 55°C [14 °F to 131 °F ] environmental class A

Environmental classes

-25 °C to 70 °C [-13°F to 158 °F] environmental class B (optional)

Tilt range -90° to + 25°

Input voltage 24 VDC ± 25%

Power input max. 120 W

Contact

Rosenbauer Brandschutz GmbH

Paschinger Straße 90

4060 Leonding, Austria

Tel.: +43 732 6794-0

Fax: +43 732 6794-91

E-Mail: stationary@rosenbauer.com

www.rosenbauer.com

Text and illustrations are non-binding. The images and descriptions may show special designs, which are deliverable against additional cost. Rights reserved for amendments

owing to technical advancements.

You might also like

- Position Sensing: Angle and Distance Measurement for EngineersFrom EverandPosition Sensing: Angle and Distance Measurement for EngineersNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Infrared Non-Contact Thermometer: 12:1 Distance-to-Target Ratio, Laser SightingDocument1 pageInfrared Non-Contact Thermometer: 12:1 Distance-to-Target Ratio, Laser SightingRodrigo PazNo ratings yet

- Instrumentation: Beam-A-Temp Wide Range Mini-Infrared ThermometerDocument12 pagesInstrumentation: Beam-A-Temp Wide Range Mini-Infrared ThermometerShahid AhmedNo ratings yet

- Evidir Infrared Cameras DatasheetDocument3 pagesEvidir Infrared Cameras DatasheetNavnetNo ratings yet

- Infrared Sensors Hand HeldDocument5 pagesInfrared Sensors Hand HeldEliasNo ratings yet

- E8Turboex (W) : HD1080P IR Turret CameraDocument2 pagesE8Turboex (W) : HD1080P IR Turret CameraYamiletNo ratings yet

- DH TPC PT8621A T Datasheet 20200901Document4 pagesDH TPC PT8621A T Datasheet 20200901Leonardo MaciasNo ratings yet

- Equipos TDR Universidad Agraria de Colombia - Ingeniera Del Riego (Septiembre de 2020)Document6 pagesEquipos TDR Universidad Agraria de Colombia - Ingeniera Del Riego (Septiembre de 2020)cesar andresNo ratings yet

- Non-Contact Infrared Thermometers Operating Manual: Downloaded From Manuals Search EngineDocument16 pagesNon-Contact Infrared Thermometers Operating Manual: Downloaded From Manuals Search EngineOmar RodriguezNo ratings yet

- Raycmltk3m DatasheetDocument4 pagesRaycmltk3m DatasheetPuji AntoroNo ratings yet

- Noncontact Temperature Measurement For Industrial Applications & OemsDocument4 pagesNoncontact Temperature Measurement For Industrial Applications & OemsHpnoteNo ratings yet

- 63-9378 - Rev D - ULTRA Puck - VLP-32C - Datasheet - WebDocument2 pages63-9378 - Rev D - ULTRA Puck - VLP-32C - Datasheet - WebCristi ValentinNo ratings yet

- CO2 Duct Transmitter Detects Temperature, RH & CO2Document4 pagesCO2 Duct Transmitter Detects Temperature, RH & CO2Edward Quispe CervantesNo ratings yet

- اجهزة معمل صيانة وتشخيص الاعطالDocument3 pagesاجهزة معمل صيانة وتشخيص الاعطالAhmed Abdalrazek100% (2)

- Raytek TXDocument4 pagesRaytek TXRafael Pertile CarneiroNo ratings yet

- Ircam640: Ir Thermo CameraDocument2 pagesIrcam640: Ir Thermo Camerajehan11No ratings yet

- Inclinimetro Boom RDSR3 BA 09 - BrochDocument3 pagesInclinimetro Boom RDSR3 BA 09 - BrochedgarlimasNo ratings yet

- Flir B335Document2 pagesFlir B335togoreanunuNo ratings yet

- COX-CG640 CatalogDocument3 pagesCOX-CG640 CatalogVIKRANT VISHALNo ratings yet

- Pyrosigma Operators GuideDocument12 pagesPyrosigma Operators GuidejackNo ratings yet

- CDS2000 CO2 Gas Detector Spec SheetDocument4 pagesCDS2000 CO2 Gas Detector Spec Sheetjyothishkumar007No ratings yet

- Double Beams Infrared Ir Motion Sensor With Detector Distance 100 MetersDocument1 pageDouble Beams Infrared Ir Motion Sensor With Detector Distance 100 Metersanonymous singhNo ratings yet

- Nightowl ZM-ER Datasheet enDocument2 pagesNightowl ZM-ER Datasheet ennabilNo ratings yet

- EIS16C ManualDocument2 pagesEIS16C Manualdongyean0208No ratings yet

- Raymt4u DatasheetDocument2 pagesRaymt4u DatasheetPrayoga AjaNo ratings yet

- Noncontact Temperature Measurement For Industrial ApplicationsDocument4 pagesNoncontact Temperature Measurement For Industrial ApplicationsDISJUNTORNo ratings yet

- Infrared Thermometer: No Hassle WarrantyDocument2 pagesInfrared Thermometer: No Hassle WarrantyPardeepNo ratings yet

- Inclinometer Lca326t PDFDocument10 pagesInclinometer Lca326t PDFManasi NaikNo ratings yet

- Intrusion Detector: Selection GuideDocument28 pagesIntrusion Detector: Selection GuidemoidutNo ratings yet

- Camara PDFDocument3 pagesCamara PDFCrimaros MartinezNo ratings yet

- Takex MS-12FE Data SheetDocument2 pagesTakex MS-12FE Data SheetJMAC SupplyNo ratings yet

- Irx 63Document20 pagesIrx 63JoeNo ratings yet

- Raytek TX DatasheetDocument4 pagesRaytek TX DatasheetM. Reza FahlefiNo ratings yet

- DeltaOHM HD52.3D Manual ENGDocument44 pagesDeltaOHM HD52.3D Manual ENGGuillermo BetancourtNo ratings yet

- 63-9665 Rev-A Puck 32MR Datasheet WebDocument2 pages63-9665 Rev-A Puck 32MR Datasheet WebAndrew PasqualeNo ratings yet

- DSeries FlyerDocument3 pagesDSeries FlyerRichard GumanitNo ratings yet

- Easidew I.S.-UK - DatasheetDocument2 pagesEasidew I.S.-UK - DatasheetJavier Enrrique Iglesias PelcastreNo ratings yet

- ThermalTronix TT 1960AMS NVBM DatasheetDocument3 pagesThermalTronix TT 1960AMS NVBM DatasheetIntellisystem TechnologiesNo ratings yet

- Noncontact Thermometer GuideDocument23 pagesNoncontact Thermometer Guidejavierfm666No ratings yet

- Wa0022.Document6 pagesWa0022.Hendry Putra RahadiNo ratings yet

- Thermo IrDocument20 pagesThermo IrThư NguyễnNo ratings yet

- Cat ThermoMETER InfraredDocument56 pagesCat ThermoMETER InfraredspyrosNo ratings yet

- Install & Calibrate Solar Irradiation Sensor GuideDocument10 pagesInstall & Calibrate Solar Irradiation Sensor GuideGaurav DwivediNo ratings yet

- DS-2CE16C0T-IT3 HD720P EXIR Bullet Camera: Key FeaturesDocument3 pagesDS-2CE16C0T-IT3 HD720P EXIR Bullet Camera: Key FeaturesAbraham Ima BejarNo ratings yet

- IR928Document4 pagesIR928William Orozco LópezNo ratings yet

- Faro Focus 3d Laser Scanner BrochureDocument4 pagesFaro Focus 3d Laser Scanner BrochureHrishikesh GarudNo ratings yet

- Irtd KayeDocument2 pagesIrtd Kayehosi3328No ratings yet

- Thermal Cameras for Substation Temperature Detection and Perimeter ProtectionDocument13 pagesThermal Cameras for Substation Temperature Detection and Perimeter ProtectionJorge LuqueNo ratings yet

- OSID Data SheetDocument2 pagesOSID Data SheetRahul DevaNo ratings yet

- Measure Temperature Without Touching with Infrared ThermometerDocument1 pageMeasure Temperature Without Touching with Infrared ThermometerChee Wen ZhiNo ratings yet

- Guide PC230 Specs Sheet For PC Thermal CameraDocument2 pagesGuide PC230 Specs Sheet For PC Thermal CameraRichard GumanitNo ratings yet

- Dewpoint transmitter for trace humidity measurement down to -45 °CtdDocument4 pagesDewpoint transmitter for trace humidity measurement down to -45 °Ctdautomacao2No ratings yet

- SRR 20X /-2 /-2C /-21 Short Range Radar: Safe - Reliable - Good Performance - Small DesignDocument2 pagesSRR 20X /-2 /-2C /-21 Short Range Radar: Safe - Reliable - Good Performance - Small DesignChristophe GreffeNo ratings yet

- DS-2TD2866-xx: Thermal and Optical Bi-Spectrum Network Bullet CameraDocument3 pagesDS-2TD2866-xx: Thermal and Optical Bi-Spectrum Network Bullet CameraRamalingam Rathinasabapathy EllappanNo ratings yet

- Ansul Conventional Heat DetectorDocument4 pagesAnsul Conventional Heat DetectorDnyaneshwarNo ratings yet

- PIRT25: Operation Operation Operation Operation Manual Manual Manual ManualDocument5 pagesPIRT25: Operation Operation Operation Operation Manual Manual Manual ManualIndustrial ZtresNo ratings yet

- 022516-364C - Trimble X7 - DS - USL - 1020 - LRsec PDFDocument4 pages022516-364C - Trimble X7 - DS - USL - 1020 - LRsec PDFWilfredoUreñoNo ratings yet

- FT Kiray200 2Document2 pagesFT Kiray200 2peaceltNo ratings yet

- Eaton Intelligent Addressable Sensors DatasheetDocument2 pagesEaton Intelligent Addressable Sensors DatasheetKayce MaravillaNo ratings yet

- ABB Transformers PDFDocument51 pagesABB Transformers PDFMostafa AliNo ratings yet

- PART 2 - WORK REQUIREMENTS Rev 4a - May Date and Revised Schedule Dates PDFDocument20 pagesPART 2 - WORK REQUIREMENTS Rev 4a - May Date and Revised Schedule Dates PDFSureesh VRNo ratings yet

- 2016 Dubai Free Seminar CalendarDocument1 page2016 Dubai Free Seminar CalendarSureesh VRNo ratings yet

- Intelliquad Multi-Criteria Fire Sensor Frequently Asked QuestionsDocument2 pagesIntelliquad Multi-Criteria Fire Sensor Frequently Asked QuestionsSureesh VRNo ratings yet

- Dry-Type Transformers: Installation and Instruction ManualDocument24 pagesDry-Type Transformers: Installation and Instruction Manualosvald97No ratings yet

- Edwards Signaling Smoke and Heat Detectors Application Bulletin PDFDocument44 pagesEdwards Signaling Smoke and Heat Detectors Application Bulletin PDFAhmed OmarNo ratings yet

- ABB Transformers PDFDocument51 pagesABB Transformers PDFMostafa AliNo ratings yet

- Transformers & Transformer Services: Overview of Products and Services For University of Illinois ECE 431Document71 pagesTransformers & Transformer Services: Overview of Products and Services For University of Illinois ECE 431Sureesh VRNo ratings yet

- Transformer Tec DetailsDocument23 pagesTransformer Tec DetailsSureesh VRNo ratings yet

- Guidelines For Preparation of Theses/ Dissertations/ Reports FOR B.Tech and M.Tech StudentsDocument19 pagesGuidelines For Preparation of Theses/ Dissertations/ Reports FOR B.Tech and M.Tech StudentsSureesh VRNo ratings yet

- Schedule of VRF Condensing/Outdoor UnitsDocument1 pageSchedule of VRF Condensing/Outdoor UnitsSureesh VRNo ratings yet

- Dubai Municipality Regulations For Green BuildingsDocument77 pagesDubai Municipality Regulations For Green Buildingsfaith-7100% (4)

- ACON IndoorDocument1 pageACON IndoorSureesh VRNo ratings yet

- IEC 62305-2010 Tieu Chuan Chong SetDocument489 pagesIEC 62305-2010 Tieu Chuan Chong SetThuậnHồ80% (5)

- Street Lighting CalculationDocument19 pagesStreet Lighting CalculationSureesh VRNo ratings yet

- Dewa Cover PageDocument1 pageDewa Cover PageSureesh VRNo ratings yet

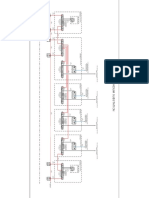

- Delmatic Lighting Management SchematicDocument1 pageDelmatic Lighting Management SchematicSureesh VRNo ratings yet

- Sequence of OperationDocument1 pageSequence of OperationSureesh VRNo ratings yet

- Delmatic lighting management system schematicDocument1 pageDelmatic lighting management system schematicSureesh VR0% (1)

- Block Diagram PDFDocument1 pageBlock Diagram PDFSureesh VRNo ratings yet

- Design DrawingDocument1 pageDesign DrawingSureesh VRNo ratings yet

- CC1608 - Fire Systems Design GuideDocument20 pagesCC1608 - Fire Systems Design GuidePhạm Thanh SơnNo ratings yet

- 3406c300kvastandbylowbsfc TZ Emcp4Document6 pages3406c300kvastandbylowbsfc TZ Emcp4shuvo134No ratings yet

- Review IR PDFDocument34 pagesReview IR PDFZvonko DamnjanovicNo ratings yet

- STREET NOTES Mobile Edition by Haptic Press August 2017 PDFDocument45 pagesSTREET NOTES Mobile Edition by Haptic Press August 2017 PDFPaco100% (1)

- 3a. Digital Camera ProfileDocument2 pages3a. Digital Camera ProfileDonia GhaithNo ratings yet

- Lab Report Beer Lambert'S Law Experiment: Determing The Concentration of Unknown Asa SolutionsDocument5 pagesLab Report Beer Lambert'S Law Experiment: Determing The Concentration of Unknown Asa Solutionsumair saleemNo ratings yet

- Sphere Technical GuideDocument22 pagesSphere Technical GuidePrabhu Raj HarakangiNo ratings yet

- National Electrical Installation Standard NECA-FOA 301-2xxx - Installing & Testing Fiber Optic CablesDocument37 pagesNational Electrical Installation Standard NECA-FOA 301-2xxx - Installing & Testing Fiber Optic CablesClifford Juan CorreaNo ratings yet

- Ece R07Document94 pagesEce R07Vinay KothapallyNo ratings yet

- HVDDocument18 pagesHVDVenu KongaraNo ratings yet

- XVC-S Datasheet - May 2015Document2 pagesXVC-S Datasheet - May 2015Anonymous W3iXN3f1No ratings yet

- The Essential Guide To Lighting Interiors - Techniques For Lighting With Small FlashDocument108 pagesThe Essential Guide To Lighting Interiors - Techniques For Lighting With Small FlashSergio OrtizNo ratings yet

- 34 BayanganDocument6 pages34 BayanganViptra SinagaNo ratings yet

- SpectDocument31 pagesSpectapi-1993758480% (5)

- GitUp Git2 Action Camera Manual from Document and SupportDocument21 pagesGitUp Git2 Action Camera Manual from Document and Supportromanos_10No ratings yet

- 5054 Handouts Topic-14 LightDocument22 pages5054 Handouts Topic-14 LightHira IqbalNo ratings yet

- RI CW BDocument5 pagesRI CW Bmangalraj900No ratings yet

- LightDocument4 pagesLightlilysuhanyNo ratings yet

- OFC - An IntroductionDocument26 pagesOFC - An IntroductionRaman KhullarNo ratings yet

- JNTUK B.tech R20 Mech Engg IV Years SyllabusDocument263 pagesJNTUK B.tech R20 Mech Engg IV Years SyllabusMoz KamalNo ratings yet

- The Frames DirectDocument10 pagesThe Frames DirectMohd Nasir OmarNo ratings yet

- Using the Histogram to Improve Solar PhotosDocument5 pagesUsing the Histogram to Improve Solar PhotosfireheartNo ratings yet

- Center 531Document1 pageCenter 531leagallo00No ratings yet

- Photoshop BubblesDocument3 pagesPhotoshop BubblesrayokNo ratings yet

- Leica DMi1 Flyer EnglishDocument2 pagesLeica DMi1 Flyer EnglishAnugerah Prima Era GlobalindoNo ratings yet

- Quick Guide to Shooting Video with the Panasonic GH4Document71 pagesQuick Guide to Shooting Video with the Panasonic GH4Amr MassoudNo ratings yet

- Lecture3 OptimisationDocument23 pagesLecture3 OptimisationlowteckweeNo ratings yet

- Ol 44 3 622Document4 pagesOl 44 3 622Jose Rolando Canteo PirirNo ratings yet

- Spectral, Photon Counting Computed Tomography-Technology and Applications-CRC Press (2020)Document446 pagesSpectral, Photon Counting Computed Tomography-Technology and Applications-CRC Press (2020)Marcelo NoronhaNo ratings yet

- Lab 10 Optics Intro - Bending LightDocument6 pagesLab 10 Optics Intro - Bending Lightjacjac100% (1)

- HK Hku 1Document73 pagesHK Hku 1Xtian JesúsNo ratings yet