Professional Documents

Culture Documents

A9R4837 TMP PDF

A9R4837 TMP PDF

Uploaded by

Cag0 ratings0% found this document useful (0 votes)

14 views4 pagesOriginal Title

A9R4837.tmp.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views4 pagesA9R4837 TMP PDF

A9R4837 TMP PDF

Uploaded by

CagCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

SEVERE

DUTY HIGH

same aNteny

MPELLER

KETO PUMPS SEVERE DUTY HIGH

EFFICIENCY IMPELLERS (KHEE)

Keto KHEE Impellers are optimised so they do not sacrifice wear life and maintain a

higher efficiency over their life without additional throat bush wear.

Keto KHEE Impellers do not increase seal chamber pressure, do not increase thrust

bearing loads and due to their severe duty design, they are used in both fine and course

slurry services and low NPSHR applications.

Current Standard

Standard HE Impeller

High efficiency impels without

‘the aump out vanes can tear up

‘the throat bush and increase seal

chamber pressure.

27% Chrome ron 6x4 throat bush

wear pattern using conventional

high efficiency impel. Produces

severe localised erosion (>25mm

gouges) towards eye of impel.

Lite wear towards perioher.

Throat bush wear - 16 weeks

KETO Alternative

KHEE Severe Duty

HE Impeller

‘The speciased KHEE impelers maintain

their efciency overtime and unlike others

do not increase throat bush wear.

Vane design remains thick section e

for severe duty service but improved

hydraulics resutin higher efficiency,

lower NPSHR and increase wear life p

We've beefed up the impellers al around

to make sure KETO KHEE impeller wil last

Just as lng as the others,

he eas

27% chrome ron 6x

thot bush wee pate ™

sig HETO KHEE High

efceney noe be

Prodces a relay een {

wear spread over entre

‘throat bush surface,

“Throat bush wear - 26 weeks

www.ketopumps.com

KETO PUMPS vostro

SEVERE DUTY HIGH

EFFICIENCY

IMPELLERS (KHEE)

Conventional high efficiency impellers can increase throat bush

wear, thereby opening the setting clearance which results in a rapid

loss of efficiency on severe duty slurry applications.

They also increase seal chamber pressure and thrust bearing load.

To reduce hydraulic losses, most high efficiency impellers have very

thin section vanes in comparison to severe duty impellers. The result

is most high efficiency impellers can only be used on fine particle

slurries and not in servere duty applications.

That's been changed!

The result is a KETO impeller that reduces your site inventory (you

no longer need heavy duty for course and high efficiency for fine

slurries), reduces operating costs, and reduces carbon emissions.

Impeller Comparison

“I

Standard High Effcleny Slury Impeller Standard Heavy Duty Slurry Impeller _KHEE Severe Duty High Etfiiency Impeler

KETO

pic) BTU acer)

LL Sec) OL Seen UnAG)

Pac) en Ocom oy

DMC) or CO)

Pieri enact

Tel: +61 8 6310 4100, PERLE

aR B Uy aE

DT CFCC PS ity

LOT eg La eae

eC 168 North Cove Drive

aC Renan ern Mast RPV

aa eae vy

Meu) epee aa)

iar Seer

eer BEET)

General Enquiries

SCIELO esto

Fax: +61 8 9249 1617

aCe toa

ee eet

Dee et nase ed uy

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- A9R3DFB TMP PDFDocument8 pagesA9R3DFB TMP PDFCagNo ratings yet

- 163-120 - Falk Drive One Type DH2, Sizes M1130-M1210 Shaft Drives - Parts ManualDocument4 pages163-120 - Falk Drive One Type DH2, Sizes M1130-M1210 Shaft Drives - Parts ManualCagNo ratings yet

- Curva S - Plantilla y EjemploDocument2 pagesCurva S - Plantilla y EjemploCagNo ratings yet

- PresentacióN SGM Ltda IIDocument14 pagesPresentacióN SGM Ltda IICagNo ratings yet

- 163-130 - Falk Drive One Type DH3, Sizes M1130-M1210 Shaft Drives - Parts ManualDocument4 pages163-130 - Falk Drive One Type DH3, Sizes M1130-M1210 Shaft Drives - Parts ManualCagNo ratings yet

- 163-110 - Falk Drive One Type DHC1, Sizes M1130-M1190 Shaft Drives - Parts ManualDocument4 pages163-110 - Falk Drive One Type DHC1, Sizes M1130-M1190 Shaft Drives - Parts ManualCagNo ratings yet

- KSB MTC 150-5 11.2Document1 pageKSB MTC 150-5 11.2CagNo ratings yet

- Instrucciones de UtilizacionDocument15 pagesInstrucciones de UtilizacionCagNo ratings yet

- bomba-ksb-MEGANORM 150-250Document1 pagebomba-ksb-MEGANORM 150-250CagNo ratings yet

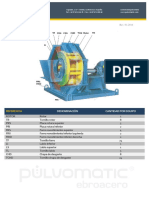

- Despiece Trituradora Impacto PulvomaticDocument1 pageDespiece Trituradora Impacto PulvomaticCagNo ratings yet