Professional Documents

Culture Documents

(HT-15) Bond E (Black) Recipe Rev.1

(HT-15) Bond E (Black) Recipe Rev.1

Uploaded by

Dung Do ThanhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(HT-15) Bond E (Black) Recipe Rev.1

(HT-15) Bond E (Black) Recipe Rev.1

Uploaded by

Dung Do ThanhCopyright:

Available Formats

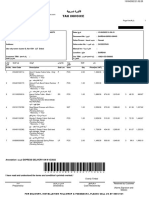

1-6 Katsuma 2 Chome, Hofu, Yamaguchi, 747-0822 JAPAN

Website: www.ohji-rubber.co.jp TEL: +81-835-22-0056

FAX: +81-835-24-0958

REV. 1

Date: 17 October 2016

Messrs:

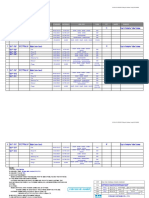

MIXING PROCEDURE OF OHJI BOND-E (BLACK)

1. Compound BOND-E (Black) Recipe:

No. Ingredients Weight (g) Weight (g)

1 Bond E (Black) Compound 1,000 4,000

2 Toluene 2,349 9,396

3 SP-134 65 260

4 130-G 18 72

TOTAL 3,432 13,728

Pot Life: 90 days

Storage: below 23℃

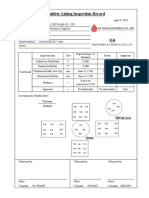

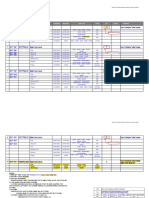

2. BOND-E (Black) Mixing Procedure

(1) Compound BOND-E (Black) shall be cut at approx. 20 ~ 30mm and solve with Toluene at above

mixing rate. Mixing time is approx. 8 hours.

(2) After mixing with Toluene, put SP-134 and 130-G into the pre-mixed bond and mix for more than

24 hours. (Mixing for 40 hours is recommended.)

(3) Viscosity: 300-450 cps without solid unsolved rubber

*Note: Putting SP-134 & 130-G after pre-mixed bond is to solve those ingredients properly.

If mixing all at one time may cause SP-134 & 130-G undissolved and remained as solid.

Page: 1/1

You might also like

- TSH7702GDocument8 pagesTSH7702GEmir AkçayNo ratings yet

- Martillo Manual EC 155 TDocument32 pagesMartillo Manual EC 155 TBrook MercadoNo ratings yet

- Jotun Jota Ep Mastic 66Document4 pagesJotun Jota Ep Mastic 66Abi PutraNo ratings yet

- IndeentrenDocument12 pagesIndeentrenAzizNo ratings yet

- Packing List Tokuden Coil (Rev)Document1 pagePacking List Tokuden Coil (Rev)suto widjoyoNo ratings yet

- COA - Nitocote EN901 Grey - 19-02-20Document1 pageCOA - Nitocote EN901 Grey - 19-02-20Jossef.ahsan Jossef.ahsanNo ratings yet

- 150 Thick ResinDocument2 pages150 Thick ResinFahmi Januar AnugrahNo ratings yet

- Bang Mau KCC 2021Document5 pagesBang Mau KCC 2021Trường NguyenNo ratings yet

- A. Schulman POLYBATCH™ White LL8350 AP Concentrate Based in LLDPEDocument1 pageA. Schulman POLYBATCH™ White LL8350 AP Concentrate Based in LLDPEmohammedNo ratings yet

- Easypoxy: Modern Polyurethane EnamelDocument2 pagesEasypoxy: Modern Polyurethane EnamelTristian BloodNo ratings yet

- Laporan Hasil Uji Birch 0,28 Coating Dan Non CoatingDocument2 pagesLaporan Hasil Uji Birch 0,28 Coating Dan Non CoatingBella RamadhaniNo ratings yet

- Ashmi EnterprisesDocument1 pageAshmi EnterprisesUmesh chandra ThakurNo ratings yet

- Jotamastic 87 MIO50Document5 pagesJotamastic 87 MIO50Biju_PottayilNo ratings yet

- Metallon E 2602: Technical Data SheetDocument4 pagesMetallon E 2602: Technical Data SheetAnabelNo ratings yet

- Elan-Tech® EC 157.1/W 152 XXLR: Product Information ENDocument4 pagesElan-Tech® EC 157.1/W 152 XXLR: Product Information ENMarjan ArhNo ratings yet

- Jotaprime 500: Technical Data SheetDocument5 pagesJotaprime 500: Technical Data SheetRudhi AfghaniNo ratings yet

- Calalog Data Glasspowders Glasspastes en PDFDocument12 pagesCalalog Data Glasspowders Glasspastes en PDFEduardo FerreiraNo ratings yet

- Jotamastic 87 Technical Data SheetDocument5 pagesJotamastic 87 Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Ece B52Document2 pagesEce B52willy HNo ratings yet

- DPLV 2.1 Epoxy Primer: DP48LV (White) DP50LV (Gray) DP90LV (Black)Document4 pagesDPLV 2.1 Epoxy Primer: DP48LV (White) DP50LV (Gray) DP90LV (Black)michaelguzziNo ratings yet

- Sanho Chemical Co., LTD.: Kingmide 370Document1 pageSanho Chemical Co., LTD.: Kingmide 370uocmogiandi_aNo ratings yet

- Technical Data Sheet - Jotun Jotatemp 540 ZincDocument5 pagesTechnical Data Sheet - Jotun Jotatemp 540 ZincPolem IskandarNo ratings yet

- Lampiran Pengecatan Struktur BajaDocument6 pagesLampiran Pengecatan Struktur BajaBalimbukNo ratings yet

- Jota EP15 MIO 快干环氧云铁中间漆 (6VN) (United Kingdom - English)Document5 pagesJota EP15 MIO 快干环氧云铁中间漆 (6VN) (United Kingdom - English)long chanNo ratings yet

- Erkoloc Pro PDB en - KopyaDocument2 pagesErkoloc Pro PDB en - KopyaALEGOZ ALEGOZNo ratings yet

- Erkoloc Pro PDB en - KopyaDocument2 pagesErkoloc Pro PDB en - KopyaALEGOZ ALEGOZNo ratings yet

- Temacoat GPL-S Primer SV PDS TikkurilaDocument4 pagesTemacoat GPL-S Primer SV PDS TikkurilaRoshan aravinthNo ratings yet

- Rust-Oleum GHS 16 Section SDSDocument7 pagesRust-Oleum GHS 16 Section SDSGerardo RodriguezNo ratings yet

- 【英文】SDCコート#402TエコGDocument2 pages【英文】SDCコート#402TエコGDocholosoNo ratings yet

- JotamasticDocument5 pagesJotamasticBuat DownloadNo ratings yet

- Jotafix PU Topcoat: Technical Data SheetDocument5 pagesJotafix PU Topcoat: Technical Data SheetBagaskara AdityaNo ratings yet

- Painting ReportDocument15 pagesPainting ReportWildan AlfarizyNo ratings yet

- Manufacture of Rubber ProductsDocument20 pagesManufacture of Rubber Productsortizan8No ratings yet

- Suction Cup FCF50P Polyurethane 55/60, G3/8" Male, With Mesh FilterDocument3 pagesSuction Cup FCF50P Polyurethane 55/60, G3/8" Male, With Mesh FilterflowNo ratings yet

- Especificação de GraxasDocument1 pageEspecificação de GraxasDouglas TondelloNo ratings yet

- Tds 6Document2 pagesTds 6mj03127477706No ratings yet

- Compra de PruebaDocument8 pagesCompra de Pruebanagelispadilla0No ratings yet

- Phenoline 187 VOC: Selection & Specification DataDocument4 pagesPhenoline 187 VOC: Selection & Specification Datarajiv_quantumNo ratings yet

- Jotamastic 80.TDS - EngDocument5 pagesJotamastic 80.TDS - EngchepurthiNo ratings yet

- Master Schedulle 2017Document33 pagesMaster Schedulle 2017Fahrul MuhamadNo ratings yet

- Melamine KawagoeDocument1 pageMelamine Kawagoehpjacktplee6362No ratings yet

- Jotamastic 87 TDSDocument5 pagesJotamastic 87 TDSSathishkumar SrinivasanNo ratings yet

- 6 - Basic of Polyester - K&Vglobal PDFDocument7 pages6 - Basic of Polyester - K&Vglobal PDFpritam1509No ratings yet

- Baking Schedule Ex 3Document2 pagesBaking Schedule Ex 3icepascuNo ratings yet

- Alfodet xl46Document1 pageAlfodet xl46SALMAN M. TABANINo ratings yet

- 0re inDocument7 pages0re inMustika Benur KupaNo ratings yet

- N7 12 2 394dustygreenDocument2 pagesN7 12 2 394dustygreenAneel ChandwaniNo ratings yet

- DCPD Resin - TDS - ProspectDocument1 pageDCPD Resin - TDS - ProspectSattam DattaNo ratings yet

- Motor Gasoline Specifications and Trend in IndiaDocument2 pagesMotor Gasoline Specifications and Trend in IndiavivekagNo ratings yet

- Bpxe B6ctalDocument2 pagesBpxe B6ctalVusal HasanovNo ratings yet

- Ab 139Document1 pageAb 139entesharat.tarasht3No ratings yet

- Stock Raw MaterialDocument6 pagesStock Raw MaterialZurani UmayraNo ratings yet

- Hy-Poxy Steel FastDocument2 pagesHy-Poxy Steel FastAqueel KhanNo ratings yet

- PT. EMG Internasional Group Green Village - Rukan Ginza Blok C 09 Cipondoh - Tangerang Telp. 021-55715190 Fax. 021-55717446Document10 pagesPT. EMG Internasional Group Green Village - Rukan Ginza Blok C 09 Cipondoh - Tangerang Telp. 021-55715190 Fax. 021-55717446Arif RiantoNo ratings yet

- Receipt 000000 BR03000175066Document2 pagesReceipt 000000 BR03000175066duttaanirban68No ratings yet

- HU Mineral OilDocument1 pageHU Mineral OilBraulio Mujica AguileraNo ratings yet

- QF-200-20-07 Ampco Supplier Profile QuestionnaireDocument5 pagesQF-200-20-07 Ampco Supplier Profile QuestionnaireDung Do ThanhNo ratings yet

- R-16 RL Specification For VHE Pipe SpoolsDocument11 pagesR-16 RL Specification For VHE Pipe SpoolsDung Do Thanh100% (1)

- (HT-8) HT Inspection Report - Final Inspertion FormDocument1 page(HT-8) HT Inspection Report - Final Inspertion FormDung Do ThanhNo ratings yet

- Sony - Scope of WorksDocument2 pagesSony - Scope of WorksDung Do ThanhNo ratings yet

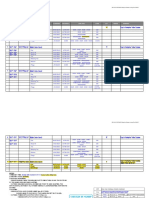

- Master Schedule Sony 19 RL 200331Document2 pagesMaster Schedule Sony 19 RL 200331Dung Do ThanhNo ratings yet

- (HT-8) HT Inspection Report - Curing Chart Record Report FormDocument1 page(HT-8) HT Inspection Report - Curing Chart Record Report FormDung Do ThanhNo ratings yet

- (HT-13) Hardness Conversion Table by Temperature (E-7, E-15)Document1 page(HT-13) Hardness Conversion Table by Temperature (E-7, E-15)Dung Do ThanhNo ratings yet

- Sp-20-015-Rfq023-Fitting-For-Rubber-Lining-R1-200617 CheckedDocument18 pagesSp-20-015-Rfq023-Fitting-For-Rubber-Lining-R1-200617 CheckedDung Do ThanhNo ratings yet

- SP-20-015 RFQ022 Rubber Lining R1a 20200622Document22 pagesSP-20-015 RFQ022 Rubber Lining R1a 20200622Dung Do ThanhNo ratings yet

- NO Drawing No. Drawing Title Specification Standard Materials Nom. Size Conn. QTY Maker RemarksDocument21 pagesNO Drawing No. Drawing Title Specification Standard Materials Nom. Size Conn. QTY Maker RemarksDung Do ThanhNo ratings yet

- NO Drawing No. Drawing Title Specification Standard Materials Nom. Size Conn. QTY Maker RemarksDocument17 pagesNO Drawing No. Drawing Title Specification Standard Materials Nom. Size Conn. QTY Maker RemarksDung Do ThanhNo ratings yet

- User Title: App. Chk. Drawing No. Rev. Unit Purchaser Scale Works NoDocument15 pagesUser Title: App. Chk. Drawing No. Rev. Unit Purchaser Scale Works NoDung Do ThanhNo ratings yet

- SP-20-015 RFQ023 Fitting For Rubber Lining R1b 20200622Document18 pagesSP-20-015 RFQ023 Fitting For Rubber Lining R1b 20200622Dung Do ThanhNo ratings yet

- Itiiiiiiiiiii: Aa Oo OoDocument4 pagesItiiiiiiiiiii: Aa Oo OoDung Do ThanhNo ratings yet