Professional Documents

Culture Documents

Lec16 PDF

Lec16 PDF

Uploaded by

Shiva KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lec16 PDF

Lec16 PDF

Uploaded by

Shiva KumarCopyright:

Available Formats

NPTEL – Chemical – Mass Transfer Operation 1

MODULE 3: MASS TRANSFER COEFFICIENTS

LECTURE NO. 8

3.6.2 Overall mass transfer coefficients

Experimentally the mass transfer film coefficients ky and kx are difficult to

measure except for cases where the concentration difference across one phase

is small and can be neglected. Under these circumstances, the overall mass

transfer coefficients Ky and Kx are measured on the basis of the gas phase or the

liquid phase. The entire two-phase mass transfer effect can then be measured in

terms of gas phase molar fraction driving force as:

N A K y ( y AG y*A ) (3.76)

where, Ky is based on the overall driving force for the gas phase, in mole/m2.s

and y *A is the value of concentration in the gas phase that would be in the

equilibrium with xAL. Similarly, the entire two-phase mass transfer effect can then

be measured in terms of liquid phase molar fraction driving force as:

N A K x ( x*A xAL ) (3.77)

where Kx is based on the overall driving force for the liquid phase, in mole/m 2.s

and x*A is the value of concentration in the liquid phase that would be in the

equilibrium with yAG. A relation between the overall coefficients and the individual

mass transfer film coefficients can be obtained when the equilibrium relation is

linear as y Ai mxAi . The linear equilibrium condition can be obtained at the low

concentrations, where Henry’s law is applicable. Here the proportionality

constant m is defined as m= H/P. Utilizing the relationship, y Ai mxAi , gas and

liquid phase concentrations can be related by

Joint initiative of IITs and IISc – Funded by MHRD Page 1 of 6

NPTEL – Chemical – Mass Transfer Operation 1

y*A mxAL (3.78)

and

y AG mx*A (3.79)

Rearranging Equation (3.76), one can get

1 y y *A

AG (3.80)

Ky NA

From geometry, y AG y*A can be written as

y AG y*A ( y AG y Ai ) ( y Ai y*A ) (3.81)

Substituting Equation (3.81) in Equation (3.80)

1 y y*A ( y AG y Ai ) ( y Ai y*A ) ( y AG y Ai ) m( x Ai x AL )

AG (3.82)

Ky NA NA NA NA NA

The substitution of Equation (3.76) into the Equation (3.82) relates overall gas

phase mass transfer coefficient (Ky) to the individual film coefficients by

1 1 m

(3.83)

K y k y kx

Similarly the relation of overall liquid phase mass transfer coefficient (Kx) to the

individual film coefficients can be derived as follows:

1 x*A x AL y AG y Ai x Ai x AL

(3.84)

Kx NA mN A NA

Or

1 1 1

(3.85)

K x mk y k x

The following relationships between the mass transfer resistances can be made

from the Equations (3.83) and (3.85):

Resistance in gas phase 1/ k y

(3.86)

Total resistance in both phases 1 / K y

Resistance in liquid phase 1/ kx

(3.87)

Total resistance in both phases 1 / K x

Joint initiative of IITs and IISc – Funded by MHRD Page 2 of 6

NPTEL – Chemical – Mass Transfer Operation 1

If solute A is very soluble in the liquid, m is very small. Then the term m/kx in

Equation (3.83) becomes minor and consequently the major resistance is

represented by 1/ky. In this case, it is said that the rate of mass transfer is gas

phase controlled. In the extreme it becomes:

1 1

(3.88)

K y ky

The total resistance equals the gas film resistance. The absorption of a very

soluble gas, such as ammonia in water is an example of this kind. Conversely

when solute A is relatively insoluble in the liquid, m is very large. Consequently

the first term of Equation (3.85) becomes minor and the major resistance to the

mass transfer resides within the liquid. The system becomes liquid film

controlling. Finally this becomes:

1 1

(3.89)

K x kx

The total resistance equals the liquid film resistance. The absorption of a gas of

low solubility, such as carbon dioxide or oxygen in water is of this type of system.

Example problem 3.3: In an experimental study of the absorption of ammonia

by water in a wetted-wall column, the value of overall mass transfer coefficient,

KG was found to be 2.75 10-6 kmol/m2-s-kPa. At one point in the column, the

composition of the gas and liquid phases were 8.0 and 0.115 mole% NH 3,

respectively. The temperature was 300K and the total pressure was 1 atm.

Eighty five % of the total resistance to mass transfer was found to be in the gas

phase. At 300 K, Ammonia –water solutions follows Henry’s law upto 5 mole%

ammonia in the liquid, with m = 1.64 when the total pressure is 1 atm. Calculate

the individual film coefficients and the interfacial concentrations. Interfacial

concentrations lie on the equilibrium line.

Joint initiative of IITs and IISc – Funded by MHRD Page 3 of 6

NPTEL – Chemical – Mass Transfer Operation 1

Solution 3.3:

The first step in the solution is to convert the given overall coefficient from KG to

Ky .

K y K G P = 2.75 10-6 101.3 = 2.786 10-4 kmol/m2-s

For a gas-phase resistance that accounts for 85% of the total resistance,

Ky

ky 3.28 10 4 kmol/m 2 - s

0.85

1 1 m

From Equation, , by substituting the values of Ky , ky and m

K y ky kx

kx = 3.05 10-3 kmol/m2-s

To estimate the ammonia flux and the interfacial concentrations at this particular

point in the column use the equation, y A mx A, L to calculate

y A mx A, L 1.64 1.15 10 3 1.886 10 3

The flux is from equation

N A K y ( y AG y *A ) 2.768 10 4 (0.080 1.866 10 3 ) 2.18 10 5 kmol / m 2 s

Calculate the gas-phase interfacial concentration from equation,

N A k y ( y AG y A,i ) as

NA 2.18 10 5

y A,i y AG 0.080 0.01362

ky 3.28 10 4

Since the interfacial concentrations lie on the equilibrium line,

y A, i 0.01362

x A, i 8.305 10 3

m 1.64

Joint initiative of IITs and IISc – Funded by MHRD Page 4 of 6

NPTEL – Chemical – Mass Transfer Operation 1

Nomenclature

a Cross-sectional area [m2] s Fraction of surface renewed/unit

time [-]

C Molar concentration [mol/m3] Sav Average cross-sectional area for

diffusion [m2]

d Diameter [m] T Temperature [K]

dp Diameter of a particle [m] t Time [s]

DAB Diffusivity of A in B [m2/s] u Velocity [m/s]

DE Eddy diffusivity [m2/s] U average velocity [m/s]

DK Knudsen diffusion coefficient U Free stream velocity [m/s]

[m2/s]

DS Surface diffusion coefficient V Volume [m3]

[m2/s]

ED Activation energy [J/mol] w Mass fraction [-]

Gm Molar mass velocity [mol/m2.s] W Mass transfer rate [mol/s]

Gy Mass velocity of gas [kg/m2.s] x Mole fraction for liquid [-]

H VA Latent heat of vaporization of y Mole fraction for gas [-]

component A [J/mol]

J Flux based on arbitrary X, Coordinates

reference [mol/m2.s] Y, Z

K Proportionality constant x*,y* Equilibrium mole fraction of

defined in Equation (1.79) [-] solute in liquid and gas phase,

respectively [-]

K Overall mass transfer φ Association factor [-]

coefficient [m/s]

k/, k Individual mass transfer Porosity [-]

coefficient [m/s]

Joint initiative of IITs and IISc – Funded by MHRD Page 5 of 6

NPTEL – Chemical – Mass Transfer Operation 1

l Length [m] Molar volume [mol/m3]

m Mass [kg] Packing fraction [-]

M Molecular weight Characteristic length parameter

of binary mixture of A and B [m]

N Flux [mol/m2.s] Tortuosity [-]

p Partial pressure [N/m2] collision integral [-]

P Total pressure [N/m2] Density [kg/m3]

PAV Vapor pressure of A [N/m2] Film thickness [m]

r Radius [m] Viscosity [kg/m.s]

R Universal gas constant

[J/mol.K]

References

1. Treybal, R. E., “ Mass-Transfer Operations”, 3rd Eddition, McGraw-Hill,

1981

2. Geankoplis, C.J., “Transport Processes and Separation Process

Principles”. 4th Edition, Prentice-Hall of India, New Delhi, 2005.

3. Dutta, B.K., “Principles of Mass transfer and Separation Processes”.

Prentice-Hall of India, New Delhi, 2007.

Joint initiative of IITs and IISc – Funded by MHRD Page 6 of 6

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Government of India, Ministry of External Affairs Passport Application FormDocument6 pagesGovernment of India, Ministry of External Affairs Passport Application FormrituneshmNo ratings yet

- Plumbingqa/Qc Manual Sample: Selected Pages (Not A Complete Plan)Document26 pagesPlumbingqa/Qc Manual Sample: Selected Pages (Not A Complete Plan)Andri Konyoa KonyoaNo ratings yet

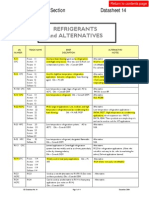

- Refrigerants and Alternatives: Service Engineers' Section Datasheet 14Document4 pagesRefrigerants and Alternatives: Service Engineers' Section Datasheet 14rituneshmNo ratings yet

- Oil Inlet TemperatureDocument2 pagesOil Inlet TemperaturerituneshmNo ratings yet

- Agilent 34970A/34972A Data Acquisition / Switch Unit: Service GuideDocument194 pagesAgilent 34970A/34972A Data Acquisition / Switch Unit: Service GuiderituneshmNo ratings yet

- BookDocument1 pageBookrituneshmNo ratings yet

- Devi Ahilya Vishwavidyalaya, Indore: Employment NoticeDocument21 pagesDevi Ahilya Vishwavidyalaya, Indore: Employment NoticerituneshmNo ratings yet

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document1 pageIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)rituneshmNo ratings yet

- Ratnesh 0900319Document2 pagesRatnesh 0900319rituneshmNo ratings yet

- CCL1Document2 pagesCCL1rituneshmNo ratings yet

- Indian Institute of Technology IndoreDocument5 pagesIndian Institute of Technology IndorerituneshmNo ratings yet

- Catalog Bearing IkoDocument306 pagesCatalog Bearing IkoSoni XNo ratings yet

- Manufacture of BalloonsDocument8 pagesManufacture of BalloonsFebry HandikaNo ratings yet

- Cannon Anchorage To ConcreteDocument47 pagesCannon Anchorage To ConcretePaul EvansNo ratings yet

- CA IdentityMinder Implement GuideDocument111 pagesCA IdentityMinder Implement GuideMixNo ratings yet

- 6 Storey Condominium Mines View Option 1Document5 pages6 Storey Condominium Mines View Option 1Rein Michael MendozaNo ratings yet

- X02 User ManualDocument25 pagesX02 User ManualZelectronNo ratings yet

- IGCSE Mock Test Paper - Static ElectricityDocument5 pagesIGCSE Mock Test Paper - Static ElectricityRizzzme100% (1)

- 12-How To Write A Methodology SectionDocument20 pages12-How To Write A Methodology SectionShelaniejean LimNo ratings yet

- Most Important Cables KVG MechatronicsDocument27 pagesMost Important Cables KVG MechatronicsgluykNo ratings yet

- 6F05G Formation Ibm Sterling Selling and Fulfillment Inventory and Order MNGMNT Business Rules PDFDocument1 page6F05G Formation Ibm Sterling Selling and Fulfillment Inventory and Order MNGMNT Business Rules PDFCertyouFormation100% (1)

- Classical ElectromanDocument1 pageClassical Electromanayush kumarNo ratings yet

- Operation Guide GT MS5001 PDFDocument5 pagesOperation Guide GT MS5001 PDFHassanSaidi50% (2)

- AocvDocument5 pagesAocvgowripNo ratings yet

- SR841/SR842 (B706) : This Parts Catalog Includes MB No. 1 To 10Document63 pagesSR841/SR842 (B706) : This Parts Catalog Includes MB No. 1 To 10OFBA srlNo ratings yet

- Project ZigguratDocument17 pagesProject ZigguratRalph BurroughsNo ratings yet

- 3.6.1 Self-Drilling Screw Fastener Selection and Design 3.6.1.1 Drill Point SelectionDocument12 pages3.6.1 Self-Drilling Screw Fastener Selection and Design 3.6.1.1 Drill Point SelectionEduardo Antonio Duran SepulvedaNo ratings yet

- Bedu Pumpen RFQ Centrifugal Pump (Horizontal Arrangement) As Per Attached Technical DataDocument1 pageBedu Pumpen RFQ Centrifugal Pump (Horizontal Arrangement) As Per Attached Technical DataSamir AjiNo ratings yet

- Design and Architecture of Intel's Core I7 ProcessorDocument6 pagesDesign and Architecture of Intel's Core I7 Processorpratik mahajanNo ratings yet

- MODAxx 1 20WDocument5 pagesMODAxx 1 20Wtosh_smthNo ratings yet

- BEE-Unit - IDocument44 pagesBEE-Unit - Ipavankumar tvvNo ratings yet

- Electromagnetic Flowmeter ProcessMaster FEP300 ABBDocument54 pagesElectromagnetic Flowmeter ProcessMaster FEP300 ABBAnonymous V6n9ZCNo ratings yet

- Preparation of Sample For AnalysisDocument27 pagesPreparation of Sample For Analysisapi-26215965100% (3)

- Pipe Flow - Upadhyay 2017Document35 pagesPipe Flow - Upadhyay 2017John Ceasar PascoNo ratings yet

- Board of Technical Education (Student Marksheet)Document2 pagesBoard of Technical Education (Student Marksheet)Manoj SainiNo ratings yet

- QDB 15 MeteorologyDocument233 pagesQDB 15 MeteorologyKueh Chew Chai96% (25)

- Lab Report 6 Organic ChemistryDocument7 pagesLab Report 6 Organic ChemistryclassicguitarheroNo ratings yet

- 2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsDocument34 pages2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsMagdy BakryNo ratings yet

- Intro To Industrial Security ConceptsDocument13 pagesIntro To Industrial Security ConceptsSinagTala100% (1)