Professional Documents

Culture Documents

Triplex Systems 4 PDF

Triplex Systems 4 PDF

Uploaded by

Eng.Gihad EladlOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Triplex Systems 4 PDF

Triplex Systems 4 PDF

Uploaded by

Eng.Gihad EladlCopyright:

Available Formats

TRIPLEX STACK MOUNTED "Q" SERIES MEDICAL

AIR PLANTS WITH DESICCANT AIR DRYERS

15 THROUGH 20 HP

The Amico Alert-2 continuous duty Medical Air Plant is

a stack mounted modular NFPA 99 and NEC compliant

system featuring 100% oil-less air compressors, a U.L.

listed electrical control cabinet, an ASME receiver and

redundant twin tower desiccant air dryers with integral

purge saver control, pre-filters, after-filters, line pressure

regulating valves, safety relief valves, dew point monitor,

CO monitor and a test port.

All components are pre-piped and pre-wired to single-

point service connections. The only field connections are

air intake, air discharge and power connection at the control

panel. All interconnecting stainless steel/brass piping as

well as wiring is completed and operationally tested prior

to shipment. Liquid tight conduit, fittings and junction

boxes are provided for all control and power wiring. maintenance is included per current NFPA 99 for each

The medical air compressors are of the oil-less reciprocat- instrument.

ing air-cooled design. The air compressors feature a cast The system includes a UL labeled control panel in a NEMA

iron crankcase, teflon-composite compression and rider 12 enclosure. The panel includes the following standard

rings, lubricated and totally sealed bearings, stainless steel accessories for each pump: externally operable circuit

reed valves, non-asbestos gaskets. No oil is used in breaker with a door interlock, control circuit transformer

operation of the compressors, so the discharge air is with fused primary and secondary coils, H-O-A switch, run

100% oil-free. Cooling is provided by a fan type compres- light, hour meter and magnetic starter with 3 leg overload

sor pulley with air shroud. protection and reset switch. The panel is equipped with a

Compressors are V-belt driven by 3 phase, 60 cycle, 1750 multiple position selector switch for selection of normal

RPM, NEMA design B motors. Slide bases for convenient operation (automatic alternation) or manual selection of

belt tension adjustment and totally enclosed OSHA ap- lead and lag pumps if one of the pumps is taken out of

proved belt guards are provided. service due to scheduled maintenance.

The system includes a corrosion resistant receiver tank of Local audible and visual alarms are provided per NFPA 99

ASME construction rated for 200 PSI MWP service. The for compressor thermal malfunction, "Backup in use", high

tank is equipped with a pressure gauge, safety relief valve, dew point and high carbon monoxide. The alarms include

3 way by-pass, gauge glass and automatic electronic tank indicating lights as well as the horn. In addition, the thermal

drain with manual override. malfunction shut-down is provided with a manual reset.

Also included as standard equipment for each compressor The audible alarm can be acknowledged with the "Silence"

are spring vibration isolators, air cooled aftercoolers, com- button. The visual alarm will remain energized until the

pressor discharge check valves, safety relief valves, intake problem has been corrected. Each alarm function includes

and discharge flexible connectors, solenoid unloaders for a set of dry contacts for connection to the master alarm. All

reliable no-load starting, high discharge temperature shut- control and alarm functions will remain energized while any

down switches for each cylinder and isolation valves. compressor in the system remains electrically on-line.

The dryer assembly consists of two identical banks of air Field adjustable control switches are pre-set to operate the

treatment equipment, piped in parallel and provided with lead compressor between 80 PSIG and 100 PSIG, the lag

valves to by-pass either bank without sacrificing air qual- compressor between 75 PSIG and 100 PSIG. The stand-by

ity. Each desiccant air dryer is sized for 100% of the system compressor will automatically start at 70 PSIG if one of the

NFPA peak calculated demand. The dryer is designed to other compressors fails to operate.

provide a maximum dew point below the frost point of 0o C The Medical Air Plant is guaranteed by the manufacturer

(+32oF) per NFPA 99, 2002 Edition. Built-in purge saver for a period of 12 months from the date of start-up or 18

control will automatically minimize and adjust the amount months from the date of shipment (whichever comes first)

of purge air to match the variable air flow. Each dryer is against defects in design, materials, or construction. In

equipped with a 0.01 micron pre-filter with electronic drain addition, the compressors are guaranteed for 36 months

and element change indicator, 0.5 micron after-filter with from the date of shipment.

element change indicator and a pressure regulator.

Digital dew point and CO monitors with alarm set points at Optional System Accessories

390F and 10 PPM are provided. A "demand check" for Interface to AIMS

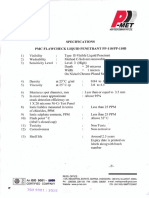

TRIPLEX MODULAR STACK MOUNTED "Q" SERIES

MEDICAL AIR PLANTS WITH DESICCANT AIR DRYERS

15 THROUGH 20 HP

LAYOUT AND PERFORMANCE TABLE

CONTROL RECEIVER

PANEL

INTAKE

AIR DRYER (TYP.)

AIR COMPRESSOR

H

DISCHARGE

E

L W

System Horsepower Capacity SCFM (Each Pump) Disch. Tank Dimensions, In. Weight

Model Number Each Total 50 PSIG 100 PSIG Conn. (Gal.) L W H Lbs.

3TOQ15MS240D 15 45 58.3 51.0 1" 240 118 70 94 5170

3TOQ20MS240D 20 60 75.0 65.1 1" 240 118 70 94 5420

Note: Maximum ambient temperature: 100°F. For higher ambient temperatures consult factory.

Power Requirements:

(Three) _____ HP Motors, 3 Phase 60 Hertz 208 v 230 v 460 v

Phone 1-800-962-5385, Fax 1-973-227-9223, Web Site: http://www.amico.com January-2005

You might also like

- POGIL - Heat TransferDocument4 pagesPOGIL - Heat TransferDon SekarNo ratings yet

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- The Holographic Paradigm and Other Paradoxes Exploring The LeadDocument316 pagesThe Holographic Paradigm and Other Paradoxes Exploring The LeadTinaMaleena100% (6)

- Bomba de Vacio Emse 1drr5ht120 Ing Ficha TécnicaDocument2 pagesBomba de Vacio Emse 1drr5ht120 Ing Ficha TécnicaCaro VelezNo ratings yet

- .: 139 One GE, Frame 5, MS 5001 N, Zero Hour Overhauled - Gas Turbine Package 24,25 MWDocument10 pages.: 139 One GE, Frame 5, MS 5001 N, Zero Hour Overhauled - Gas Turbine Package 24,25 MWAkram GeadNo ratings yet

- Triplex Systems 3Document2 pagesTriplex Systems 3Eng.Gihad EladlNo ratings yet

- Duplex Systems 6Document2 pagesDuplex Systems 6Eng.Gihad EladlNo ratings yet

- Duplex Tank Mounted Scroll Medical Air Plants With Desiccant Air Dryers 2 Through 5 HPDocument2 pagesDuplex Tank Mounted Scroll Medical Air Plants With Desiccant Air Dryers 2 Through 5 HPEng.Gihad EladlNo ratings yet

- Duplex Systems 4Document2 pagesDuplex Systems 4Eng.Gihad EladlNo ratings yet

- Triplex Stack Mounted Systems 1Document2 pagesTriplex Stack Mounted Systems 1Eng.Gihad EladlNo ratings yet

- Triplex Stack Mounted Scroll Medical Air Plants With Desiccant Air Dryers 5 HPDocument2 pagesTriplex Stack Mounted Scroll Medical Air Plants With Desiccant Air Dryers 5 HPEng.Gihad EladlNo ratings yet

- Quadruplex Stack Mounted Scroll Medical Air Plants With Desiccant Air Dryers 5 HPDocument2 pagesQuadruplex Stack Mounted Scroll Medical Air Plants With Desiccant Air Dryers 5 HPEng.Gihad EladlNo ratings yet

- Duplex Systems 9Document2 pagesDuplex Systems 9Eng.Gihad EladlNo ratings yet

- Duplex Tank and Stack Mounted Systems 11Document2 pagesDuplex Tank and Stack Mounted Systems 11Eng.Gihad EladlNo ratings yet

- Duplex Systems 1Document2 pagesDuplex Systems 1Eng.Gihad EladlNo ratings yet

- Triplex Systems 2 PDFDocument2 pagesTriplex Systems 2 PDFEng.Gihad EladlNo ratings yet

- Duplex Tank Mounted Lubricated Rotary Vane Medical Vacuum Systems 7.5 AND 10 HPDocument2 pagesDuplex Tank Mounted Lubricated Rotary Vane Medical Vacuum Systems 7.5 AND 10 HPEng.Gihad EladlNo ratings yet

- Quadruplex Stack Mounted Lubricated Rotary Vane Medical Vacuum Systems 7.5 AND 10 HPDocument2 pagesQuadruplex Stack Mounted Lubricated Rotary Vane Medical Vacuum Systems 7.5 AND 10 HPEng.Gihad EladlNo ratings yet

- Duplex Tank and Stack Mounted Systems 1Document2 pagesDuplex Tank and Stack Mounted Systems 1Eng.Gihad EladlNo ratings yet

- Duplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 7.5 Through 10 HPDocument2 pagesDuplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 7.5 Through 10 HPEng.Gihad EladlNo ratings yet

- Triplex Systems 3Document2 pagesTriplex Systems 3Eng.Gihad EladlNo ratings yet

- Quadruplex Systems 3 PDFDocument2 pagesQuadruplex Systems 3 PDFEng.Gihad EladlNo ratings yet

- Duplex Systems 19Document2 pagesDuplex Systems 19Eng.Gihad EladlNo ratings yet

- Duplex Systems 7Document2 pagesDuplex Systems 7Eng.Gihad EladlNo ratings yet

- Duplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPDocument2 pagesDuplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPEng.Gihad EladlNo ratings yet

- Duplex "Space Saver" Dry Rotary Vane Medical Vacuum Systems 3 Through 7.5 HPDocument2 pagesDuplex "Space Saver" Dry Rotary Vane Medical Vacuum Systems 3 Through 7.5 HPEng.Gihad EladlNo ratings yet

- Duplex Tank Mounted Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPDocument2 pagesDuplex Tank Mounted Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPEng.Gihad EladlNo ratings yet

- Duplex Systems 16Document2 pagesDuplex Systems 16Eng.Gihad EladlNo ratings yet

- Duplex "Space Saver" Dry Rotary Vane Medical Vacuum Systems 1 Through 2 HPDocument2 pagesDuplex "Space Saver" Dry Rotary Vane Medical Vacuum Systems 1 Through 2 HPEng.Gihad EladlNo ratings yet

- COMPRESOR Powerex Scroll Sed-Set-Seq (1) Sistema ExistenteDocument2 pagesCOMPRESOR Powerex Scroll Sed-Set-Seq (1) Sistema ExistenteCAROLINA MONGUINo ratings yet

- MedicalOilLessScrollSpec Rev5Document5 pagesMedicalOilLessScrollSpec Rev5Roger BustosNo ratings yet

- Simplex Tank Mounted "Space Saver" Lubricated Rotary Vane Vacuum Systems 1.5 Through 5 HPDocument2 pagesSimplex Tank Mounted "Space Saver" Lubricated Rotary Vane Vacuum Systems 1.5 Through 5 HPEng.Gihad EladlNo ratings yet

- Air-Cooled Liquid Chillers With Integrated Hydronic Module: AquasnapDocument12 pagesAir-Cooled Liquid Chillers With Integrated Hydronic Module: AquasnappuertoparaisoNo ratings yet

- GS 38ap 15PDDocument6 pagesGS 38ap 15PDMichael JamesNo ratings yet

- Steffes 5100 Tech Data SheetDocument4 pagesSteffes 5100 Tech Data SheetcringsredNo ratings yet

- 30RYH017 080 FRDocument16 pages30RYH017 080 FRCARLOSNo ratings yet

- Medical Air Treatment System With Refrigerated Air Dryers 3DRZ10-50Document2 pagesMedical Air Treatment System With Refrigerated Air Dryers 3DRZ10-50Eng.Gihad EladlNo ratings yet

- Cat 30RB 2013Document10 pagesCat 30RB 2013Denise Koh Chin HuiNo ratings yet

- 30RB039-160 PSDDocument16 pages30RB039-160 PSDrudagochav3096No ratings yet

- Air To Water Heat Pumps 30RH040 240Document16 pagesAir To Water Heat Pumps 30RH040 240konstantinosNo ratings yet

- Oil-Less Scroll Air Compressor System With Desiccant Air TreatmentDocument2 pagesOil-Less Scroll Air Compressor System With Desiccant Air TreatmentroyvindasNo ratings yet

- Technical Data 30RH040-240Document16 pagesTechnical Data 30RH040-240Jhair Diaz AranaNo ratings yet

- Air DryerDocument4 pagesAir Dryerrashm006ranjanNo ratings yet

- 30HXC - 50 H: Water-Cooled Screw Compressor Liquid ChillersDocument8 pages30HXC - 50 H: Water-Cooled Screw Compressor Liquid ChillersvickersNo ratings yet

- Elgi Screw CompressorDocument12 pagesElgi Screw CompressorRAVINDER DHINGRA100% (1)

- Air Dryyer PDFDocument15 pagesAir Dryyer PDFrajishrrrNo ratings yet

- 30RB 039-160/30RQ 039-160: Air-Cooled Liquid Chillers Reversible Air-to-Water Heat PumpsDocument28 pages30RB 039-160/30RQ 039-160: Air-Cooled Liquid Chillers Reversible Air-to-Water Heat Pumpsdimkost2No ratings yet

- Product Guide - HCD600Document2 pagesProduct Guide - HCD600Anonymous R9Lpd68FTA0% (1)

- PF - SCD - Scroll With Dessicant DryerDocument2 pagesPF - SCD - Scroll With Dessicant DryerEmanuel Naskosi Santiz AguilarNo ratings yet

- Compu Mate Brochure v2Document11 pagesCompu Mate Brochure v2pabloabelgilsotoNo ratings yet

- Especificaciones Tecnicas Apc Aa InrowDocument6 pagesEspecificaciones Tecnicas Apc Aa InrowWilder Phill Arzapalo GinesNo ratings yet

- SATECH - Eagle Control-Matic - WHC System EH36 Series - Product Brochure (Ed011211 1214Hr) PDFDocument20 pagesSATECH - Eagle Control-Matic - WHC System EH36 Series - Product Brochure (Ed011211 1214Hr) PDFuserscribd2011No ratings yet

- 633LS ProdspecDocument14 pages633LS ProdspecAdrian AbellaNo ratings yet

- Powerex - Bombas de Vacio - Vane - Montado en Tanque - EspecificacionesDocument3 pagesPowerex - Bombas de Vacio - Vane - Montado en Tanque - EspecificacionesHugovillarruelNo ratings yet

- Oxygen Plant Features and SpecsDocument4 pagesOxygen Plant Features and SpecsKyaw Win ZanNo ratings yet

- DeaeratorDocument8 pagesDeaeratorfjoesandiNo ratings yet

- FOCSWATER.C Water Cooled Chiller - R134aDocument8 pagesFOCSWATER.C Water Cooled Chiller - R134antt_121987No ratings yet

- AG HA Eng PDFDocument20 pagesAG HA Eng PDFΓεώργιος ΠαπαδόπουλοςNo ratings yet

- Lupamat Oil Free 40 Bar CompressorDocument8 pagesLupamat Oil Free 40 Bar CompressorСергей Колесников100% (1)

- SEC 226100 Compressed Air SystemDocument3 pagesSEC 226100 Compressed Air SystemAkilaJosephNo ratings yet

- Simplex Tank Mounted "Space Saver" Lubricated Rotary Vane Vacuum Systems 1.5 Through 5 HPDocument2 pagesSimplex Tank Mounted "Space Saver" Lubricated Rotary Vane Vacuum Systems 1.5 Through 5 HPEng.Gihad EladlNo ratings yet

- Duplex "Space Saver" Dry Rotary Vane Medical Vacuum Systems 3 Through 7.5 HPDocument2 pagesDuplex "Space Saver" Dry Rotary Vane Medical Vacuum Systems 3 Through 7.5 HPEng.Gihad EladlNo ratings yet

- Duplex Systems 7Document2 pagesDuplex Systems 7Eng.Gihad EladlNo ratings yet

- Quadruplex Systems 3 PDFDocument2 pagesQuadruplex Systems 3 PDFEng.Gihad EladlNo ratings yet

- Triplex Systems 2 PDFDocument2 pagesTriplex Systems 2 PDFEng.Gihad EladlNo ratings yet

- Quadruplex Stack Mounted Lubricated Rotary Vane Medical Vacuum Systems 7.5 AND 10 HPDocument2 pagesQuadruplex Stack Mounted Lubricated Rotary Vane Medical Vacuum Systems 7.5 AND 10 HPEng.Gihad EladlNo ratings yet

- Triplex Systems 3Document2 pagesTriplex Systems 3Eng.Gihad EladlNo ratings yet

- Duplex "Space Saver" Dry Rotary Vane Medical Vacuum Systems 1 Through 2 HPDocument2 pagesDuplex "Space Saver" Dry Rotary Vane Medical Vacuum Systems 1 Through 2 HPEng.Gihad EladlNo ratings yet

- Duplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 7.5 Through 10 HPDocument2 pagesDuplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 7.5 Through 10 HPEng.Gihad EladlNo ratings yet

- System Selection 6Document2 pagesSystem Selection 6Eng.Gihad EladlNo ratings yet

- Duplex Systems 19Document2 pagesDuplex Systems 19Eng.Gihad EladlNo ratings yet

- Duplex Tank Mounted Lubricated Rotary Vane Medical Vacuum Systems 7.5 AND 10 HPDocument2 pagesDuplex Tank Mounted Lubricated Rotary Vane Medical Vacuum Systems 7.5 AND 10 HPEng.Gihad EladlNo ratings yet

- Duplex Systems 16Document2 pagesDuplex Systems 16Eng.Gihad EladlNo ratings yet

- Duplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPDocument2 pagesDuplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPEng.Gihad EladlNo ratings yet

- Duplex Tank Mounted Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPDocument2 pagesDuplex Tank Mounted Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPEng.Gihad EladlNo ratings yet

- Medical Air Treatment System With Refrigerated Air Dryers 3DRZ10-50Document2 pagesMedical Air Treatment System With Refrigerated Air Dryers 3DRZ10-50Eng.Gihad EladlNo ratings yet

- Duplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPDocument2 pagesDuplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPEng.Gihad EladlNo ratings yet

- Duplex Systems 9Document2 pagesDuplex Systems 9Eng.Gihad EladlNo ratings yet

- Triplex Stack Mounted Systems 1Document2 pagesTriplex Stack Mounted Systems 1Eng.Gihad EladlNo ratings yet

- Duplex Tank and Stack Mounted Systems 11Document2 pagesDuplex Tank and Stack Mounted Systems 11Eng.Gihad EladlNo ratings yet

- Duplex Tank and Stack Mounted Systems 1Document2 pagesDuplex Tank and Stack Mounted Systems 1Eng.Gihad EladlNo ratings yet

- Triplex Systems 3Document2 pagesTriplex Systems 3Eng.Gihad EladlNo ratings yet

- Manaligod, Yohan I. - Experiment 3 Steam InjectorDocument16 pagesManaligod, Yohan I. - Experiment 3 Steam InjectorYohan ManaligodNo ratings yet

- 02 Pfe ReportDocument129 pages02 Pfe ReportMaNo ratings yet

- Pairsof Angles LinesDocument16 pagesPairsof Angles LinesSero ArtsNo ratings yet

- Jun 12Document20 pagesJun 12phin easNo ratings yet

- Unit 10 Packet 2018 - 2019Document41 pagesUnit 10 Packet 2018 - 2019Sameera ShaikhNo ratings yet

- Excellence in Professional Engineering Review and Training SolutionsDocument3 pagesExcellence in Professional Engineering Review and Training SolutionsGlaiza Marie100% (1)

- Math 6 Unit 8 Volume of Solids and LiquidsDocument1 pageMath 6 Unit 8 Volume of Solids and LiquidsRobi AkmalNo ratings yet

- The History of The Atom Online ActivityDocument3 pagesThe History of The Atom Online ActivityRaven WilliamsNo ratings yet

- Daramola - 2022 - Numerical Assessment of Potential Sea Level Rise Impacts On Coastal Retreat Along The Nigerian Mahin Mud CoastDocument18 pagesDaramola - 2022 - Numerical Assessment of Potential Sea Level Rise Impacts On Coastal Retreat Along The Nigerian Mahin Mud CoastdmgsantosNo ratings yet

- 23a214407e69487fa286ee41776eb936Document287 pages23a214407e69487fa286ee41776eb936Jack WilliamsNo ratings yet

- Modul Cuti Sekolah F4 2016Document2 pagesModul Cuti Sekolah F4 2016Anonymous KQ5igANo ratings yet

- 3 Digit SeriesDocument5 pages3 Digit Seriesharshileng3992No ratings yet

- Preparation and Characterization of Tin Oxide Based Transparent Conducting Coating For Solar Cell ApplicationDocument5 pagesPreparation and Characterization of Tin Oxide Based Transparent Conducting Coating For Solar Cell Applicationcrypto fanbabyNo ratings yet

- HydraulicPowerUnits 108 118 168 175 SeriesDocument28 pagesHydraulicPowerUnits 108 118 168 175 SeriesTihomir MarkovicNo ratings yet

- Yield Line Analysis Analysis of Slab (Handout)Document5 pagesYield Line Analysis Analysis of Slab (Handout)Gabriel JamesNo ratings yet

- Solving The Problem of BuildDocument5 pagesSolving The Problem of BuildDebajit BurhagohainNo ratings yet

- Numerical Modeling of A Microwave Plasma CVD Reactor: A.M. Gorbachev, V.A. Koldanov, A.L. VikharevDocument5 pagesNumerical Modeling of A Microwave Plasma CVD Reactor: A.M. Gorbachev, V.A. Koldanov, A.L. VikharevYoucef FermiNo ratings yet

- Answer Key For Grade 12 Natural Science Revision Exercise 2Document8 pagesAnswer Key For Grade 12 Natural Science Revision Exercise 2Hussein Saleh0% (1)

- VRF Atom Series 50Hz - Heat PumpDocument10 pagesVRF Atom Series 50Hz - Heat Pumpperfectair25No ratings yet

- BF Dry GCP S-13 PDFDocument2 pagesBF Dry GCP S-13 PDFgautamcool100% (1)

- 02 ElmerWebinar MultiphysicsDocument51 pages02 ElmerWebinar MultiphysicsPhilippe SingletonNo ratings yet

- Filtertrak 660 SC Laser Nephelometer: Epa-Approved Method, Ultra Low-Range Turbidity MeasurementDocument4 pagesFiltertrak 660 SC Laser Nephelometer: Epa-Approved Method, Ultra Low-Range Turbidity MeasurementJose V GonzalezNo ratings yet

- Uenr8332uenr8332-00 SisDocument7 pagesUenr8332uenr8332-00 SisHalit YalçınkayaNo ratings yet

- Optical Metrology: October 2004Document34 pagesOptical Metrology: October 2004Jorge GuerreroNo ratings yet

- 6 - L-23 (DP) (Pe) ( (Ee) Nptel)Document1 page6 - L-23 (DP) (Pe) ( (Ee) Nptel)CharkNo ratings yet

- Report 7-Shell StructuresDocument8 pagesReport 7-Shell StructuresSoham SatamNo ratings yet

- Contaminant Release From Aged Microplastic: Nicole Bandow, Verena Will, Volker Wachtendorf and Franz-Georg SimonDocument12 pagesContaminant Release From Aged Microplastic: Nicole Bandow, Verena Will, Volker Wachtendorf and Franz-Georg SimonJavier AlcodoriNo ratings yet

- Polarized Light MicrosDocument6 pagesPolarized Light MicrosAdiSulaksonoNo ratings yet