Professional Documents

Culture Documents

Duplex Tank and Stack Mounted Systems 10 PDF

Duplex Tank and Stack Mounted Systems 10 PDF

Uploaded by

Eng.Gihad EladlOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Duplex Tank and Stack Mounted Systems 10 PDF

Duplex Tank and Stack Mounted Systems 10 PDF

Uploaded by

Eng.Gihad EladlCopyright:

Available Formats

DUPLEX TANK MOUNTED

"Q" SERIES MEDICAL AIR SYSTEMS

7.5 THROUGH 20 HP

The Amico Alert-2 continuous duty Medical Air system

is a completely packaged NFPA 99 and NEC compliant

assembly featuring 100% oil-less air compressors, a U.L.

listed electrical control cabinet, an ASME receiver and the

necessary accessories required to meet and exceed the

current code requirements. All components are pre-piped

and pre-wired to single-point service connections. The

only field connections are air intake, air discharge and

power connection at the control panel. All interconnect-

ing copper/brass piping as well as wiring is completed and

operationally tested prior to shipment. Liquid tight con-

duit, fittings and junction boxes are provided for all

control and power wiring.

The medical air compressors are of the oil-less reciprocat-

ing air-cooled design. The air compressors feature a cast

iron crankcase, teflon-composite compression and rider

rings, lubricated and totally sealed bearings, stainless steel for compressor thermal malfunction and "Backup in use".

reed valves, non-asbestos gaskets. No oil is used in The alarms include indicating lights as well as the horn. In

operation of the compressors, so the discharge air is addition, the thermal malfunction shut-down is provided

100% oil-free. Cooling is provided by a fan type com- with a manual reset. The audible alarm can be acknowl-

pressor pulley with air shroud. edged with the "Silence" button. The visual alarm will

Compressors are V-belt driven by 3 phase, 60 cycle, 1750 remain energized until the problem has been corrected.

RPM, NEMA design B motors. Each alarm function includes a set of dry contacts for

connection to the master alarm. All control and alarm

The system includes a receiver tank of ASME construc- functions will remain energized while any compressor in

tion rated for 200 PSI MWP service. The tank is sus- the system remains electrically on-line.

pended between the heavy duty base supports, so it is Field adjustable control switches are pre-set to operate the

isolated from the weight of the compressors. The tank is lead compressor between 80 PSIG and 100 PSIG. The lag

equipped with a pressure gauge, safety relief valve, 3 way compressor will automatically start at 75 PSIG if the lead

by-pass, gauge glass and automatic electronic tank drain compressor fails to operate.

with manual override.

Also included as standard equipment are compressor The Medical Air system is guaranteed by the manufac-

discharge check valves of bronze construction, safety turer for a period of 12 months from the date of start-up or

relief valves, bronze intake and discharge flexible con- 18 months from the date of shipment (whichever comes

nectors, solenoid unloaders for reliable no-load starting, first) against defects in design, materials, or construction.

isolation valves, high discharge temperature shut-down

switches, pressure control switches as well as copper

tubing with shut-off cock for gauge and switches.

The system includes a UL labeled control panel in a

NEMA 12 enclosure. The panel includes the following Optional System Accessories

standard accessories for each pump: externally operable (only checked options will be supplied)

circuit breaker with a door interlock, control circuit trans- "Dura-coat" rust protection receiver lining

former with fused primary and secondary coils, H-O-A

Galvanized receiver

switch, run light, hour meters and magnetic starter with 3

Air-cooled aftercoolers

leg overload protection and reset switch. The panel is

Dual medical air treatment system

equipped with a multiple position selector switch for selec-

with refrigerated air dryers

tion of normal operation (automatic alternation) or manual

Dual medical air treatment system

selection of lead and lag pumps if one of the pumps is taken

with desiccant air dryers

out of service due to scheduled maintenance.

Interface to AIMS (AMICO Information

Local audible and visual alarms are provided per NFPA 99

Management System)

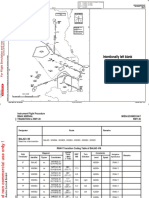

DUPLEX TANK MOUNTED

"Q" SERIES MEDICAL AIR SYSTEMS

7.5 THROUGH 20 HP

LAYOUT AND PERFORMANCE TABLE

INTAKE DISCHARGE

COMPRESSOR

ELECTRIC

MOTOR

CONTROL PANEL

RECEIVER

L W

System Horsepower Capacity SCFM (Each Pump) Disch. Tank Dimensions, In. Weight

Model Number Each Total 50 PSIG 100 PSIG Conn. (Gal.) L W H Lbs.

3DOQ7.5T120 7.5 15 32.5 28.5 3/4" 120 77 60 64 1880

3DOQ10T240 10 20 40.8 36.3 1" 240 92 60 74 2570

3DOQ15T240 15 30 58.3 51.0 1" 240 92 60 74 2820

3DOQ20T240 20 40 75.0 65.1 1-1/4" 240 92 60 74 3010

Note: Maximum ambient temperature:100°F. For higher ambient temperatures consult factory.

Power Requirements:

(Two) _____ HP Motors, 3 Phase 60 Hertz 208 v 230 v 460 v

Phone 1-800-962-5385, Fax 1-973-227-9223, Web Site: http://www.amico.com January-2005

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 11KV Kiosk Panel DrawingDocument12 pages11KV Kiosk Panel Drawingerkamlakar223483% (6)

- Simplex Tank Mounted "Space Saver" Lubricated Rotary Vane Vacuum Systems 1.5 Through 5 HPDocument2 pagesSimplex Tank Mounted "Space Saver" Lubricated Rotary Vane Vacuum Systems 1.5 Through 5 HPEng.Gihad EladlNo ratings yet

- Duplex "Space Saver" Dry Rotary Vane Medical Vacuum Systems 3 Through 7.5 HPDocument2 pagesDuplex "Space Saver" Dry Rotary Vane Medical Vacuum Systems 3 Through 7.5 HPEng.Gihad EladlNo ratings yet

- Duplex Systems 7Document2 pagesDuplex Systems 7Eng.Gihad EladlNo ratings yet

- Quadruplex Systems 3 PDFDocument2 pagesQuadruplex Systems 3 PDFEng.Gihad EladlNo ratings yet

- Triplex Systems 2 PDFDocument2 pagesTriplex Systems 2 PDFEng.Gihad EladlNo ratings yet

- Quadruplex Stack Mounted Lubricated Rotary Vane Medical Vacuum Systems 7.5 AND 10 HPDocument2 pagesQuadruplex Stack Mounted Lubricated Rotary Vane Medical Vacuum Systems 7.5 AND 10 HPEng.Gihad EladlNo ratings yet

- Triplex Systems 3Document2 pagesTriplex Systems 3Eng.Gihad EladlNo ratings yet

- Duplex "Space Saver" Dry Rotary Vane Medical Vacuum Systems 1 Through 2 HPDocument2 pagesDuplex "Space Saver" Dry Rotary Vane Medical Vacuum Systems 1 Through 2 HPEng.Gihad EladlNo ratings yet

- Duplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 7.5 Through 10 HPDocument2 pagesDuplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 7.5 Through 10 HPEng.Gihad EladlNo ratings yet

- System Selection 6Document2 pagesSystem Selection 6Eng.Gihad EladlNo ratings yet

- Duplex Systems 19Document2 pagesDuplex Systems 19Eng.Gihad EladlNo ratings yet

- Duplex Tank Mounted Lubricated Rotary Vane Medical Vacuum Systems 7.5 AND 10 HPDocument2 pagesDuplex Tank Mounted Lubricated Rotary Vane Medical Vacuum Systems 7.5 AND 10 HPEng.Gihad EladlNo ratings yet

- Duplex Systems 16Document2 pagesDuplex Systems 16Eng.Gihad EladlNo ratings yet

- Duplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPDocument2 pagesDuplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPEng.Gihad EladlNo ratings yet

- Duplex Tank Mounted Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPDocument2 pagesDuplex Tank Mounted Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPEng.Gihad EladlNo ratings yet

- Medical Air Treatment System With Refrigerated Air Dryers 3DRZ10-50Document2 pagesMedical Air Treatment System With Refrigerated Air Dryers 3DRZ10-50Eng.Gihad EladlNo ratings yet

- Duplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPDocument2 pagesDuplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPEng.Gihad EladlNo ratings yet

- Duplex Systems 9Document2 pagesDuplex Systems 9Eng.Gihad EladlNo ratings yet

- Triplex Stack Mounted Systems 1Document2 pagesTriplex Stack Mounted Systems 1Eng.Gihad EladlNo ratings yet

- Duplex Tank and Stack Mounted Systems 11Document2 pagesDuplex Tank and Stack Mounted Systems 11Eng.Gihad EladlNo ratings yet

- Duplex Tank and Stack Mounted Systems 1Document2 pagesDuplex Tank and Stack Mounted Systems 1Eng.Gihad EladlNo ratings yet

- Triplex Systems 3Document2 pagesTriplex Systems 3Eng.Gihad EladlNo ratings yet

- Project Report On String InvertersDocument9 pagesProject Report On String InvertersEIRI Board of Consultants and PublishersNo ratings yet

- AMX Prodigy Install ManualDocument13 pagesAMX Prodigy Install Manualsundevil2010usa4605No ratings yet

- Catalogue 24 KV Switchgear - Simoprime A4 PDFDocument11 pagesCatalogue 24 KV Switchgear - Simoprime A4 PDFhermawanNo ratings yet

- FixturesDocument3 pagesFixturesEricka Mae FedereNo ratings yet

- Instruction Manual Instruction Manual: ODW717W 14 Place Settings ODW717XDocument21 pagesInstruction Manual Instruction Manual: ODW717W 14 Place Settings ODW717Xyardeen1No ratings yet

- Office Safety Inspection Checklist: Inspection Items Y N Corrective ActionDocument3 pagesOffice Safety Inspection Checklist: Inspection Items Y N Corrective Actionanmec20No ratings yet

- Terex Finlay MP-300Document4 pagesTerex Finlay MP-300eaglego00No ratings yet

- Datex-Ohmeda, Inc, - Aespire 7900 Maintenance Procedures 1037Document26 pagesDatex-Ohmeda, Inc, - Aespire 7900 Maintenance Procedures 1037Alexandra Janic100% (2)

- AXS Series - Double Suspension Set For ADSSDocument2 pagesAXS Series - Double Suspension Set For ADSShcindustryNo ratings yet

- Medium Voltage SwicthgearDocument11 pagesMedium Voltage SwicthgearRuben MaychelNo ratings yet

- Mis 01.2019 PDFDocument8 pagesMis 01.2019 PDFKiran DandileNo ratings yet

- WO 2053 Handling Sec 5-1 Electric Diagram PreliminaryDocument245 pagesWO 2053 Handling Sec 5-1 Electric Diagram PreliminaryMinh TrầnNo ratings yet

- CJZC Engine Ignition SystemDocument4 pagesCJZC Engine Ignition SystemDanielNo ratings yet

- 36 AccessoriesDocument11 pages36 AccessoriesNasr Eldin AlyNo ratings yet

- Updated Lab Manual Power ElectronicsDocument43 pagesUpdated Lab Manual Power ElectronicsMuhammad Ali ImranNo ratings yet

- Sensore Vibrazioni Manual VIB2000 CrowDocument2 pagesSensore Vibrazioni Manual VIB2000 CrowAngelo DottoreNo ratings yet

- Short Description FFT01-P ENDocument2 pagesShort Description FFT01-P ENDiego CalvoNo ratings yet

- Solar Panel Cleaning RobotDocument4 pagesSolar Panel Cleaning RobotKaustubh.Dwivedi Btech2020No ratings yet

- Experiment No. 3 Transfer Function of Two Phase A. C. Servo MotorDocument3 pagesExperiment No. 3 Transfer Function of Two Phase A. C. Servo MotorSHIVAM KUMAR SINGHWALNo ratings yet

- Canon Printer Mp258 Error Code 5200Document3 pagesCanon Printer Mp258 Error Code 5200TindusNiobeto0% (2)

- Authorised Examiners Lifting EquipmentDocument13 pagesAuthorised Examiners Lifting EquipmentdunglxNo ratings yet

- Smartphone Servo - Make - 4Document6 pagesSmartphone Servo - Make - 4Wanek TamásNo ratings yet

- LOWW - Arrival - Transition 29 - 26012023Document5 pagesLOWW - Arrival - Transition 29 - 26012023Rogelio TapieroNo ratings yet

- FireEdge FE400 Spec Sheet - 1Document4 pagesFireEdge FE400 Spec Sheet - 1Tuyên VũNo ratings yet

- Agilent G3470A Auxiliary Electronic Pressure Control (Aux EPC) ModuleDocument12 pagesAgilent G3470A Auxiliary Electronic Pressure Control (Aux EPC) ModuleDaniel LeclercNo ratings yet

- Issac Pressure DecayDocument2 pagesIssac Pressure DecaydcobbNo ratings yet

- Is.8535.1987 - 0 ANCHOR BOLTS NOMENCLATUREDocument38 pagesIs.8535.1987 - 0 ANCHOR BOLTS NOMENCLATUREamitjustamitNo ratings yet

- Used Heino Ilsemann BMP 300 Blister Machine M1903421563 26Document4 pagesUsed Heino Ilsemann BMP 300 Blister Machine M1903421563 26Vu Thieu TuanNo ratings yet

- Care and Maintenance of Shaping MachinesDocument1 pageCare and Maintenance of Shaping MachinesabaynehNo ratings yet