Professional Documents

Culture Documents

LaserR PDF

LaserR PDF

Uploaded by

Grover Concha Zavaleta0 ratings0% found this document useful (0 votes)

9 views1 pageOriginal Title

LaserR.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 pageLaserR PDF

LaserR PDF

Uploaded by

Grover Concha ZavaletaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Recommended Enraving and

Cutting Settings for 100W Laser

This is just a starting point - many different settings can be used

for different effects. Scan gap is very important when engraving

for depth and detail of engraving. To increase productivity,

increase speed, power and adjust scan gap proportionately.

Watt Power Speed Scan Gap NOTES

mm/sec DPI

Acrylic 100 30 400 0.05 lower speed or multiple engrave

passes to increase depth

Anodized Aluminum 100 35 400 0.07 engrave

Brick 100 65 35 0.10 engrave or cut with lens engrave

slightly out of focus to

produce glass effect

Cardboard Matt 100 30 400 0.10 engrave

Board

Ceramic 100 40 200 0.05 engrave

Glass 100 40 200 0.05 engrave

Laserable Plastic 100 25 400 0.05 on plastics with a white engrave

core, you can run the

engraving again at a low

speed to clean the dust.

Leather 100 30 300 0.10 engrave

Marble, Granite 100 40 200 0.05 engrave

MDF - 1/8” 100 30 400 0.10 use transfer tape to engrave

prevent scorch

Mirror Back Glass 100 30 300 0.10 engrave

Painted Metal 100 30 300 0.10 engrave

Paper 100 NR engrave

Rubber Stamp 100 30 300 0.10 use grade engrave to engrave

achieve 3D stamp effect -

set the angle

Sign Foam 100 30 400 0.10 engrave

Wood 100 40 200 0.10 use transfer tape to engrave

prevent scorch

Acrylic - 3mm 1/8” 100 100 40 cut

Acrylic - 6mm 1/4” 100 100 15 cut

Acrylic - 12mm 1/2” 100 100 5 cut

Acrylic - 25mm 1” 100 100 1 cut

Cardboard Matt 100 50 160 cut

Board

Laserable Plastic 100 20 20 cut

Leather 100 30 10 cut

MDF - 1/8” 100 30 20 cut

Paper 100 20 400 increase speed first / cut

decrease power if

scorching

Rubber Stamp 100 30 10 cut

Wood - 3mm 1/8” 100 100 50 use transfer tape to cut

prevent scorch

Wood - 6mm 1/4” 100 100 20 use transfer tape to cut

prevent scorch

Wood - 9mm 3/8” 100 90 10 use transfer tape to cut

prevent scorch

Wood - 12mm 1/2” 100 100 5 use transfer tape to cut

prevent scorch

You might also like

- Creality 10W Laser Settings ManualDocument1 pageCreality 10W Laser Settings ManualDan HendersonNo ratings yet

- James H. Stubblebine - Giotto The Arena Chapel Frescoes-W. W. Norton & Company (1995) PDFDocument248 pagesJames H. Stubblebine - Giotto The Arena Chapel Frescoes-W. W. Norton & Company (1995) PDFPedro100% (1)

- Hannes Meyer Die Neue Welt PDFDocument25 pagesHannes Meyer Die Neue Welt PDFMatija KraljićNo ratings yet

- 21st Century Architecture Beach Houses - Stephen CraftiDocument241 pages21st Century Architecture Beach Houses - Stephen Craftigaonaleiva100% (3)

- Lightolier Lightstyles Brochure 1989Document148 pagesLightolier Lightstyles Brochure 1989Alan Masters100% (1)

- Antiqui Et Moderni at Reims (Willibald Sauerländer)Document20 pagesAntiqui Et Moderni at Reims (Willibald Sauerländer)Marta García Val100% (1)

- 5W Laser Module Engraving ParametersDocument1 page5W Laser Module Engraving ParametersAlvis RamosNo ratings yet

- 7-Reference Table of LightBurn For OLM3 For LU2-10ADocument9 pages7-Reference Table of LightBurn For OLM3 For LU2-10AyhghjNo ratings yet

- Opt 02 - SK-12 - Parti DetailDocument1 pageOpt 02 - SK-12 - Parti DetailTristan Johnston-WoodNo ratings yet

- C5 Power Settings (100W & 80W)Document1 pageC5 Power Settings (100W & 80W)jugarucNo ratings yet

- Manual de Grabado y Corte A5 Pro 40W GRBLDocument3 pagesManual de Grabado y Corte A5 Pro 40W GRBLgalindobrendabNo ratings yet

- Recommended Parameters For 22WDocument1 pageRecommended Parameters For 22WSteven BaynesNo ratings yet

- LaserGRBL A20 PRO Engraving Cutting Parameter TableDocument7 pagesLaserGRBL A20 PRO Engraving Cutting Parameter TableRosa Maria Hdez OcañaNo ratings yet

- C-Helix BudgetDocument6 pagesC-Helix BudgetAradhya KapoorNo ratings yet

- Parameters For Different Materials-50watt SPDocument3 pagesParameters For Different Materials-50watt SPshavva achmadNo ratings yet

- Lightburn M50 Engraving Machine Parameter FormDocument1 pageLightburn M50 Engraving Machine Parameter FormGabriel Ivan Espinoza MartinezNo ratings yet

- Coated Abrasives & Accessories: Variety of Products To Quickly Cut and PolishDocument2 pagesCoated Abrasives & Accessories: Variety of Products To Quickly Cut and PolishTran KhanhNo ratings yet

- New Price ListDocument1 pageNew Price Listjagdish lonareNo ratings yet

- LaserGRBL A5 M50 PRO EngravingCutting Parameter TableDocument3 pagesLaserGRBL A5 M50 PRO EngravingCutting Parameter TableJuan Diego OspinaNo ratings yet

- LâminasDocument1 pageLâminasThales Vilas Boas MagalhãesNo ratings yet

- Parameter For 30watt RF Laser TubeDocument1 pageParameter For 30watt RF Laser TubeTosif MullaNo ratings yet

- Parametri Za Laser 100WDocument3 pagesParametri Za Laser 100WIvan MarjanovićNo ratings yet

- B.1. Seamtech - RO - V2022Document2 pagesB.1. Seamtech - RO - V2022Craciun CodrutNo ratings yet

- 6-Reference Table of LaserGRBL For OLM3 For LU2-10ADocument39 pages6-Reference Table of LaserGRBL For OLM3 For LU2-10AyhghjNo ratings yet

- A5 Pro Engraving Parameter TableDocument4 pagesA5 Pro Engraving Parameter TablecallampNo ratings yet

- Print PDFDocument6 pagesPrint PDFSamitha Soysa0% (1)

- Acoustic Louvers 2019Document9 pagesAcoustic Louvers 2019Ahmed MontashNo ratings yet

- GRBL A5 M40 Engraving Machine Parameter FormDocument4 pagesGRBL A5 M40 Engraving Machine Parameter Formfrancisco hernandexNo ratings yet

- LaserGRBL S30 Pro Laser Engraver Parameter TableDocument5 pagesLaserGRBL S30 Pro Laser Engraver Parameter TableJorge BraboNo ratings yet

- Pricelist TokoDocument2 pagesPricelist Tokoadit_sandhiNo ratings yet

- Discotom100 10 Tech EnglishDocument2 pagesDiscotom100 10 Tech EnglishKathia Bernal RamirezNo ratings yet

- List KacaDocument6 pagesList KacaRaka GunawanNo ratings yet

- PET Thermal Laminaitng FilmDocument1 pagePET Thermal Laminaitng FilmEnrique Garcia FuentesNo ratings yet

- Wall Accent Tile Layout DesignDocument1 pageWall Accent Tile Layout DesigneuniceNo ratings yet

- LightBurn P7 M30Engraving&Cutting Parameter TableDocument6 pagesLightBurn P7 M30Engraving&Cutting Parameter TablegalindobrendabNo ratings yet

- Unicon 2021 MDocument24 pagesUnicon 2021 Mbhavik gambhavaNo ratings yet

- Ceramic Diamond Stones PDFDocument1 pageCeramic Diamond Stones PDFleonardo silveiraNo ratings yet

- LaserGRBL P7 M30 Engraving - Cutting ParameterDocument5 pagesLaserGRBL P7 M30 Engraving - Cutting ParametergalindobrendabNo ratings yet

- Stoody 104Document1 pageStoody 104JUAN DAVID ESPITIANo ratings yet

- Hi-Speed Vibrating Sample Mill Hi-Speed Vibrating Sample Mill Hi-Speed Vibrating Sample Mill Hi-Speed Vibrating Sample MillDocument3 pagesHi-Speed Vibrating Sample Mill Hi-Speed Vibrating Sample Mill Hi-Speed Vibrating Sample Mill Hi-Speed Vibrating Sample MillUnknownNo ratings yet

- Glass Machinery Burners and Tools Sales List 2019Document2 pagesGlass Machinery Burners and Tools Sales List 2019Dan George IonescuNo ratings yet

- Floor Plan 01 Section 1-1 03: Detail 01Document1 pageFloor Plan 01 Section 1-1 03: Detail 01Hung NguyentheNo ratings yet

- 71 Byis AUJJLDocument2 pages71 Byis AUJJLMagabata GoguNo ratings yet

- Capstone LAbor and MAterials PricelistDocument4 pagesCapstone LAbor and MAterials PricelistAnne Klein LumbaNo ratings yet

- Canal EstructuraDocument2 pagesCanal EstructuraBenjamin Santamaria LongNo ratings yet

- Door Frame detailsABCDocument1 pageDoor Frame detailsABCC G Chaithanya 1JA20AT010No ratings yet

- Section S 02Document1 pageSection S 02Awadhi SuleimanNo ratings yet

- Bill of Materials and Labor CostDocument1 pageBill of Materials and Labor CostBenny Jose TomasNo ratings yet

- Cat-21 22 En-223Document1 pageCat-21 22 En-223Kartik MalhotraNo ratings yet

- CAST CLEAR 1000 X 600 Sheet Size: Perspex AcrylicDocument8 pagesCAST CLEAR 1000 X 600 Sheet Size: Perspex AcrylicRobNo ratings yet

- LaserGRBL X7pro Laser Engraver Parameter TableDocument3 pagesLaserGRBL X7pro Laser Engraver Parameter TableJoel AlbuquerqueNo ratings yet

- Location Wind Load Description Size/Cl To CL Zebian ProposalDocument1 pageLocation Wind Load Description Size/Cl To CL Zebian Proposalwaweng22No ratings yet

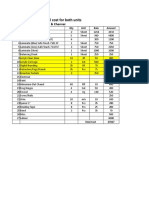

- Material & Internal Cost For Both Units: Sennheiser Wall Unit - GZB & ChennaiDocument2 pagesMaterial & Internal Cost For Both Units: Sennheiser Wall Unit - GZB & ChennaiEasyrecipes RajshreeNo ratings yet

- Material CostDocument8 pagesMaterial CostRebiyu KemalNo ratings yet

- MS Lab ConsumablesDocument2 pagesMS Lab ConsumablesupenderNo ratings yet

- EMI Graphene Absorber: For Thermal Management and EMI ShieldingDocument3 pagesEMI Graphene Absorber: For Thermal Management and EMI ShieldinggultekinNo ratings yet

- Clark Manor Improvements August 2016Document26 pagesClark Manor Improvements August 2016Gabriel Achacoso MonNo ratings yet

- Perfect Abrasive Products Faridabad, Haryana: Welcome TODocument14 pagesPerfect Abrasive Products Faridabad, Haryana: Welcome TOSanjay BhasinNo ratings yet

- alluminium Drilled HoneycombDocument1 pagealluminium Drilled Honeycombanastarcontracting9No ratings yet

- Stair Detail BDocument1 pageStair Detail BGRETCHEN SIYNo ratings yet

- CWLI Pricelist Updated Aug 18, 2021Document5 pagesCWLI Pricelist Updated Aug 18, 2021Ryan Anthony LimNo ratings yet

- Paver Tile - DecorativeDocument1 pagePaver Tile - DecorativeFirst ChoiceNo ratings yet

- Spesifikasi Final Mebel Polres MagelangDocument11 pagesSpesifikasi Final Mebel Polres MagelangPT Koka IndonesiaNo ratings yet

- Viljoen FVB Ornamentation PHD Thesis Univ Pretoria 1985Document384 pagesViljoen FVB Ornamentation PHD Thesis Univ Pretoria 1985Robert Hill100% (1)

- Oilpaint Weebly EdDocument22 pagesOilpaint Weebly Edapi-293964578No ratings yet

- Hi Everyone: School DiaryDocument2 pagesHi Everyone: School Diaryrcpsadmin13No ratings yet

- Japanese PatinasDocument2 pagesJapanese PatinasTomáš NěmečekNo ratings yet

- Photography As An ArtDocument10 pagesPhotography As An ArtJoanne Ario BillonesNo ratings yet

- Arts in The City 043008Document1 pageArts in The City 043008HeatherNo ratings yet

- Didi-Huberman G. Dialektik Des Monstrums Aby Warburg and The Symptom ParadigmDocument25 pagesDidi-Huberman G. Dialektik Des Monstrums Aby Warburg and The Symptom ParadigmJoaco Orgas100% (1)

- Photo at MoMA CampanyDocument2 pagesPhoto at MoMA CampanyCarlos Henrique SiqueiraNo ratings yet

- Hugon Kowalski - Water Tower SkyscraperDocument11 pagesHugon Kowalski - Water Tower SkyscraperFaiz ShamsudinNo ratings yet

- Roni HornDocument3 pagesRoni Hornapi-270303279No ratings yet

- The Architectural Legacy of The Greeks - A Timeless InfluenceDocument2 pagesThe Architectural Legacy of The Greeks - A Timeless Influencejz2sh8mg8cNo ratings yet

- Construction RatesDocument14 pagesConstruction RatesNikhil KumbharNo ratings yet

- Riverfront Park in Landscape ArchitectureDocument152 pagesRiverfront Park in Landscape ArchitectureNio Mentari100% (2)

- Speakout Contents Advanced PDFDocument4 pagesSpeakout Contents Advanced PDFTH_2014No ratings yet

- Adobo Design Awards 2015 WinnersDocument6 pagesAdobo Design Awards 2015 Winnersadobo magazineNo ratings yet

- Irfan Safeer On Ghani KhanDocument6 pagesIrfan Safeer On Ghani KhanIbad UllahNo ratings yet

- CUBISMDocument8 pagesCUBISMsakshiNo ratings yet

- Love BugsDocument2 pagesLove BugsSonia Campestre AbejilNo ratings yet

- ShufaDocument132 pagesShufaTibzNo ratings yet

- Danish Viking SmokkrDocument16 pagesDanish Viking SmokkrMackenzie67% (3)

- Cave Art (Content)Document5 pagesCave Art (Content)Jemimah FVNo ratings yet

- Dries Van NotenDocument10 pagesDries Van Notenapi-246919300100% (1)

- LAW323 Cheat Sheet 5Document4 pagesLAW323 Cheat Sheet 5emilianoNo ratings yet

- The Play of Repetition in Andy Warhols Sleep PDFDocument33 pagesThe Play of Repetition in Andy Warhols Sleep PDFluisfgcNo ratings yet

- Week 1 EnrichmentDocument2 pagesWeek 1 EnrichmentStephanie Gwynette Almirol LalasNo ratings yet