Professional Documents

Culture Documents

1434699443

1434699443

Uploaded by

Ronildo - Hydrapar0 ratings0% found this document useful (0 votes)

10 views25 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views25 pages1434699443

1434699443

Uploaded by

Ronildo - HydraparCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 25

www.grhpower.com

GRA POWER

a

°

3

3

5

<

5

Z

=

3

8

4

TROON AMEE, ITH EOLU MISS, GRHH NOES SMETSIARSNMD.

FRO AURA CIRCA ATT

‘TS T0040FUISOTMOODESIREEGAHIN TEAC

ALOGRAWMGELGHABTRSNFHLATE

GRHQHHET: RESOR/ HAS / SSSA LASER (ARAREREDIME) /RESES

ik/PEANSA, BSAA T LIU ONE Tenet RWWA. CRHRAR REPS

UMA LOARRA MASE. RTCMGHERLOES, CHESS HCMINFRERERA

SRAMRDE, SPTMRGRHE ART RELL SEEM NCRHEA ERATIONS. GRY

ADSFRMSRERGRMOUERE, ATURE, GERMS T CARA COBE CAKES

a7.

SRE Le) AHO ONRN,

ORR GIG) — GAH A OMAHA,

GRHS LER RAAA A RARE EAMRADE

GRHE A SAERE-R, SRBKK 4) MRED

BRAM, RLZ+FEORHAMSBH

GRH is specialized in providing hydraulic components and solutions for hydraulic systems,

With continuous improvement and enthusiasm over the past 30 years, GRH has developed into an emerging

‘power in the fluid power industry since it was established in 1986.

Research and development are the driving force that facilitates GRH’s ability to create new products, Stan-

dards of TS16949 and 15014000 are our guiding principles. Employees’ capabilities and ereativity are ma-

{or factors that differentiate GRH from our competitors.

GRH designs and produces Hydraulic Gear Pumps & Motors, Monoblock Valves, Sectional Stack Valves,

Proportional Valves and Flow Dividers. ‘These products are uscd on industrial machinery, construction

‘equipment, agricultural equipment and material handling applications. GRH is also willing to work with

‘ur customers to develop specialized products for their special needs. Our customers ean count on GRH’S

‘extensive system design and application experience when they are designing their hydraulic systems.

‘GRH has designed and developed a series of load sensing proportional stackable valves which provides an

improvement in valve operating performance and system efficiency.

GRH (Shanghai) - International Sales Office

GRH (Jiangsu) - Manufacturing Facility & Domestic Sales Office

GRU will work together with the customers to create a better future,

Over 30 years in the design and manufacture of hydraulic equipment

ones = 2

Introduction of Gear Motor - i 43 4

Specitieations - BIN isHHt

Performance Curve carts - tf shite

Ordering Code TH HES

IMF/IAMF Bi-directional Gear Motor- IME/IAMF Ali WS 45

2MF Bi-diretional Gear Motor -2MP 34 #8 53,

2MF-B-OGear Motor With Outboard Bearing -2MF-B-O ff -rRi8b #42:

2.SME/3MF Bidirectional Gear Motor 2.SME/AMF Syl i

3.SMF Bi-directional Gear Motor -3.5MF St 88 Si

Introduction of Flow Divider 142/422 157

LEDF Flow Divider LFDE ti #230088

IAPDE Flow Divider LAFDF tbs }t 2

2FDF Flow Divider -2FDF th 80 C2

SEDE Flow Divider - SFP #858 088

PENIS GSE

iB

Gear motors from GRH Hydraulic have a floating bushing feature with automatic axial elearance compensa-

tion. The bushings are made with special abrasion resistant material providing improved service life. Pre-

cisely machined gears ensure our units provide excellent low noise characteristics. Our cold extrusion motor

bodies can endure pressures above 30Mpa, High strength cast iron front & rear covers also enhance our

reliability. Our units are widely used in the industrial, mobile, marine and aerospace industries

GRH has 5 series of gear motors — group 1, 2, 25, 3 and 3.5. They can be divided into two types. One is the

single direction gear motors, the other is the bi-directional gear motors, Normally the design of the single

direction gear motor is similar to that ofthe single direction gear pump with some slight design differences,

‘Therefore, all GRH pumps have a corresponding single direction gear motor. When placing your order,

please refer to the ordering code.

‘We now focus on the bi-directional gear motors. This motor has a diferent sealing structure to the single

Drain

=

a

EAR MOTOR eae Ss

Specifications -#2ES80 iu

Pt

Fa

a=, 5. EES i

IMFLAMF L105

MIA |simns oi a oo wn :

2M tis 200-280-250 4000 «ao ;

2M Sio1s 200 2502803500 «ao =

OME 1510 20 200 250 280 3000 600 20, 94 8s s

eae :

2M 261030 200-250-280 2000 S00 Retero a

cen iO) | aD cen) en ‘ela

25MF -—«201030-«200-=« 2302503600 SD ww SAL

2.5MF 301040 180 230 250-3000 500 ay

SM mw 200-280-250 3000 400

aMP 4317 200-220-250 2500 0S 6

aM rows 200 © 230-250 2200 300

35MF -«S21073.170=—200—210—3600.— 500

3.9MF 7310100 150 165 180 3000 500, 82 8 6

35MF 10010115 1201501402500 —500

Formulas - +5883

Q2V.n 10m

T M= p-¥nm/ 62.83

p Pep. V.n.mt/ 600-1000

¥V Comair] Q Cumin] p [bar] n [omin] P CW] M [Nm]

Characteristics - 18 FAS

Direction of rotation -f&¢T]= bi-reton and singleiection- 0 FU)

Permisible ambient temperature range - PERE: min =-20°C -max = +.60°C

Operating pressures ~ #21 int side iE PY max = refer above data ~ $8401. oulet side» th P2 max = 3 bar

Drain pressure i112): pmax =2 bar, Interhitent- {BFP Pd max ~ Shar

Fluid temperature range iL BLIEAEIE: max ~90 °C for NBR rotary shaft Fiptype seal - ALAS Tun aRR EE

100°C for FKM rotary shaft p-type sal - AF aA AY

Viscosity range IE (IH: nin = 10 mms ~ max = 600 mais

Fitration - 2238:

Recommended: Viscosity range -AEZPAHNE (IM + V=30.. 45 mm2is

Recommended hydraulic ids use - #87738: GBILLI8-94;_L-HMAG or equate NFE-603/DINSIS24 I-85

Characteristic curves referto pages - AYE HIER BAYH: paged to 7 ~ 4 $1 7 HE

ao BE

i

3

I

:

3

All motors canbe combined with relief valve, proportional valve or thermostatic valve.

As ESSN, HE, ATT.

{In most cases, Known: Torque output M at speed n Unknown: Pressure difference Ap and the required Input flow ;

Example: D M-=40 Nm; @)1 = 1000 pm; 0 The Intersection of ) and @ i the motor opersing point with: Ap 123 bar @)

Q=213 Yimin

AS SNGH rt, CASON AL FA LAH HTHEM RHE) Aap ER AEH

AbKcc4n DM=4ONm, @n= 1000 ym; D AID AMO MAT Ls Ap= 123 bar Ds

Torque ouputM Ne =

8 8 6°38 8

3

(min)

time

$00 1000 te00 2000 2e00 2000 set0 dono

"E00 2200 1800 2000 2800 e000 #8c0 4020

i

3

I

i

3

em

PeCtw ae yaaa

m|| Boge *

# =

* »

Py Fy

Gt

2

. 0

he,

.

‘ °

s

:

(9 Bea 1000 808 Seco 25003000 S800 400

nmin)

2 ae T°

33 a o

eT A |

a .

13] oT rt

:

10] = ae

;

oe

: \

‘

=

:

(© 50) s000 1800 2000 2600 ston 5500 done

(me)

CURE) Ween (AW) Remmmny

8 g 8 3 & 3 & ° 8

4 j

j ie s i aye

tt ° ti i

FN at u

2 AE ID | fe I

| SOU GE

i a i t 4

: :

8 a a s ° 8 a 0 °

(wn) a ee mie?

FT PT

. i

- t aif -

oy Rot

iS Bio

= BF jz FF

iy got A

= a

* ae

le

* =

: O

js

i

3

I

i

3

2300

2000

1500

FR max(N)

1000

500

FRmaxiN)

[n= 2000 ‘/min|

iimin]

FR maxi)

2MP BLDIRECTIONAL. GEAR MOTOR 2 ered

‘Ordering code - is "A815

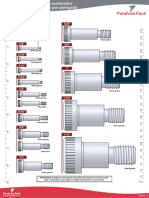

Shaft extension and flange combination - iti-AN = 4108:

Z03:1:8shai + European rectangle flange; $02:SAE 16/32 spline 11 tooth+SAE-A flange:

803:SAE 16/32 spline 9 tooth+SAE-A flange; S04: SAE 16/32 spline 10 tooth*SAE-A flange;

PO2:5/8 key shafl +SAE-A flange; P21: 3/4 key shafl+SAE-A flange;

More reference accessory 2- 2 & fei LiNS SIND i

A: Cation cover = RHF In/Out positon combination =i (REA i

Omit - 4 Aluminum cover - fifi ai BF: Back inlet and front outlet - aE tH) es

BBB: Back inlet and back outlet - J 71h =

Ghana BS: Back inlet and side outlet - FEM :

‘SB: Side inlet and back outlet - {Mite tlh

F: Continuous work pressure -

SEBE THEIR: 200 bar

Semmes

Rotation direction - lie #77]

B: Bi-directional - Li

Motor displacement - "yidpits | Li CCW ~ tm4t

4/6/8/10/12/14/16118/20/23/25 2 CW = AIEEE

Inlet/outlet combination - EH) 0414s

F06: inlet=940\M8\920;outlet=930\M6\9 13 Mode of drain - jt 7730

F85: inlet=35\M6\915;outlet=935\M6\p15 I: Inner drain - "il

MF52: inlet=935\M6\915;outlet=940\M6\p20

L04;inlet=G1/2; outlet=G1/2;

L46:inlet=G3/4; outlet=G3/4;

L76:inlet=1-5/16-12; outlet=1-5/16-12;

More reference accessory 1 - Wi % ri ALIS BI 2

Omi

lutside drain - batt

O: Outboard bearing - ‘74h 7%

1: Group 1 - 14 Omit - 471%: Without outboard bearing - 4b 7k

2: Group 2 - 241 Fe FKM seal - SaASibei

3: Group 3 - 341 Omit - #1: NBR seal - TUHAGBE

1 762401

L_ngpi—]

RIESE / low divider

x

8

s

&

2

g

130 20 27 34 41 SA LSS

2 & 4 4 4 87S SDSS 8

2 HK]

—s

ra ut 23/18

AR MOTOR = Ts wae:

TYPE: 2MF**L04P02-B-1

6

6 8 © 2 w 6 w % 2 2

a7 50 st 3 SS 56D

i

Lu “4s

a 96 98 to? tsk tok

TYPE: 2MF**F**Z11-R-V

a Lape

47s

sn

E

Ae ee

i

3

I

i

3

mB

sw

mos

in prt O18

mB

ss

6 us

—hede 1

ae aN, Geel

i

F

a, a a

So ae a

a aL se i

=

s

[saree | 3

ee

# Na kit

?

ee

we Le ola

aa: i

SOPINP MOU | REID

nto

is

a

95

163

7

120

160)

s4

118

ow

3

156

st

116

8

153

an

16

130

107

1

137

46

103.5

2

4

985

10

40

8

965

137

41

x05:

1M

1

w

2

29

0

i

ca 30 32 36 a 2

eee. 4 |

Pas)

ho}

!

Q tS}

us

219

268

us

219

100

132

28

108

a3

2s

direction C

ore

ae

QUIS

|

avin

8 on

288 a

‘@e

na ee :

i

JOPINP MOU | REID

‘Two or several gear motors can be combined to flow divider after being connected by coupling. It guaran-

tees synchronous operation and accuracy of power element like cylinder (Its principle drawing is as fol-

lows), hydraulic liquid from the pipe is input into the inlet port and the same amount liquid is distributed 10

‘the oullet port by the rotation of gears that with same specification . Obviously, accuracy of flow divider is

up to accuracy of gears and relative spare parts.

‘GRH has two series for flow divider IFDF and 2FDF.

Flow accuracy and pressure loss are as follows:

IT / gear motor

a

2

x

Es

It should be noted that flow accuracy is also related to the factors below:

System pressure, viscosity of hydraulic liquid, load that each power unit bears and overall flow. These fac-

tors should be taken into account at tine of application.

Flow divider can be integrated with relief valve, check valve and governor valve, protecting system pressure

and filling the oil. For specific requirements, please contact GRH,

DAA SIL a AOI PLANE. “EMT UL ERAT EAE CA LD Lb

J2tT. TREAD RINE, “EMO FI: MGdba Ak ERC, SLR EA

i AI 30 J sr eh UATE, TT Wy RE

De FAG LR AALS HHL»

GRH AAP ASTI: PDE, QPF, APH AE RH dO Ps

£15% 412% 16-19bar

15% 42% 11-14bar

BER EAP RONAN FT ABA RRA ALERT ART BLN

ALIN ASAPH SAA a RF Am Bo I OP

Dm id HT LATA. SL. SR, LABRET ANWAE UNE, SUMO

‘ARIGRIUER »

% *

FLAN DIVID!

3

i Specification Dimensions - HEHE STAIN RT

: = Se ar Be

We | Go inlet Outlet Gpm tp Gp Ipm Ph Bakar

Q09T 1.60 SAEG SAG 0.8 3.0 re 64 18001283500 240

m9 213 “SAES SAR 12,045, 25,95 180k 3500200,

0194 318 SAFES SAEG 17 64 4s 132 18001283500 240

025 424 SAEIO. SAEIO. «25°95 S189 1800128500240,

033 529° SAEIO. SAEIO. «30014027 tROD. 283500240,

0388 636 SAEIO. SAEIO. «35132, 70263160010 350240.

04s) 742 SAEIO. SAEIO. 40 © isd. 8030339038000

OSIT 842 SAEIO. SAEIO. | 45 17090. 3411200833800 240,

oe

DRAWING OF pRINCPILM DRAWING OF PRINCIPIUM

ae ee oe

‘#808 | gear motor

Cet]

4ELOW DIVIDER ~3¥

i ‘Speification Dimensions - #286 BRIER

#

a

#

5

in? em? tet Drain Bar

ea ‘ eed ter aa ean suc dee moat a

er soy ss ma moa

oon Gaza sss masa

ost ak on men 90 M87

a fo ook am aaa

ins 8 @E ina ee

ML GAR GID GR 37140 aS 2a tT

ourent_ourete

ey [I

os Sy ta ums

0s TAs

mer mers nacre

a |

a |

40, 1378 [

50 6364 024 as 1028

60. 668.4 4d 1515 l 106.8,

ai a 2) Ee

‘#804 | gear motor

Cee]

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- M 108ea7cf748bfaeDocument1 pageM 108ea7cf748bfaeRonildo - HydraparNo ratings yet

- M 108ea7cf748bfaeDocument1 pageM 108ea7cf748bfaeRonildo - HydraparNo ratings yet

- Telhados e Coberturas 02.05.17Document98 pagesTelhados e Coberturas 02.05.17Ronildo - Hydrapar100% (1)

- Folha QuadriculadaDocument1 pageFolha QuadriculadaRonildo - HydraparNo ratings yet

- Aula 18 Construção 2 Coberturas 2018 1Document76 pagesAula 18 Construção 2 Coberturas 2018 1Ronildo - HydraparNo ratings yet

- Parker HDA Visor de Nivel VIDocument2 pagesParker HDA Visor de Nivel VIRonildo - HydraparNo ratings yet

- Iberital Cocinas PDFDocument651 pagesIberital Cocinas PDFRonildo - HydraparNo ratings yet

- Model Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveDocument1 pageModel Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveRonildo - HydraparNo ratings yet

- HF ProductGuide Portuguese-2016 PDFDocument28 pagesHF ProductGuide Portuguese-2016 PDFRonildo - HydraparNo ratings yet

- Model ISO 08: On B, Port 3 To A and Port 4 ExternalDocument1 pageModel ISO 08: On B, Port 3 To A and Port 4 ExternalRonildo - HydraparNo ratings yet

- Filtro de Ar Com Sílica Gel - TriceptorDocument3 pagesFiltro de Ar Com Sílica Gel - TriceptorRonildo - HydraparNo ratings yet

- Model Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveDocument2 pagesModel Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveRonildo - HydraparNo ratings yet

- Model Direct Mount, Cross Pilot: Cavity: T-11ADocument1 pageModel Direct Mount, Cross Pilot: Cavity: T-11ARonildo - HydraparNo ratings yet