Professional Documents

Culture Documents

Hazardous Locations Poster - 2014 PDF

Uploaded by

Werner SchulzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazardous Locations Poster - 2014 PDF

Uploaded by

Werner SchulzCopyright:

Available Formats

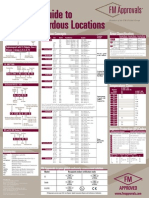

Hazardous Locations & Explosive Atmospheres

Guide to Equipment Certification Requirements

NORTH AMERICA ATEX & IECEx

Typical North American Marking Standards by Product Types Typical ATEX and IECEx Marking

Standard(s)

II 2 G Ex d IIC T4 Gb

Division Scheme Zone Scheme Product Category Class & Division

Luminaires UL 844 “Luminaires for use in Class I, Divisions 1 & 2 0359

Class I Division 1 Groups A&B T4 Class I Zone 0 AEx ia IIC T4 Ga Hazardous (Classified) Locations” Class II, Divisions 1 & 2

Class I, Zones 1 & 2

Class II, Zones 20, 21, 22

Area Protection Temperature Class III Complies Explosion

Hazard Area Gas Temperature Classification Class with Specific Equipment Protection

Hazard Concept Type of Gas Group Temperature Equipment

Class Classification Group Class Code European Marking for Category*

Class Equipment CSA C22.2 No. 137 “Electric Class I, Divisions 1 & 2 Protection Class (T1-T6) Protection

Approved to Directive* Explosion

Protection luminaires for use in hazardous Class II, Divisions 1 & 2 Protection* Level

US Standards Gas Group Level Equipment Environment* (EPL)

locations” Notified Body Group*

Number* *ATEX only

Motors and UL 674 “Electric motors and Class I, Division 1, Groups B,C,D

Generators generators for use in hazardous Class I, Zone 1, Groups IIA, IIB, IIB+H2

(Explosion-proof & (classified) locations” 3 Class II, Division 1, Groups E,F,G

Protection Concepts [NEC & CEC ]

® ®

Dust-ignition proof) Class II, Zones 20, 21 Protection Concepts [ATEX and IECEx]

CSA C22.2 No. 145 “Electric motors

Type of Basic Concept and generators for use in hazardous Typical Typical Basic Concept of

Code (EPL) Country Class Division/Zone Standard Type of Protection Symbol IEC Standard

Protection of Protection (classified) locations” 3 IEC EPL Zone(s) Protection

Electrical Equipment for Flammable Gas, Vapors and Mist - Class I Electrical Equipment for Gases, Vapors and Mists (G)

Industrial UL 698A “Industrial control panels Associated apparatus for the following

_ Control Panels relating to hazardous (classified) hazardous (classified) locations: General Requirements - - 0,1,2 IEC 60079-0

US Class I Division 1 & 2 FM 3600

General locations” Class I, Division 1

AEx US Class I Division 1 & 2 ISA 60079-0 Op pr Gb 1,2 IEC 60079-28

Requirements Class I, Zone 0 and Zone 1 Inherently safe

Ex CA Class I Division 1 & 2 CSA C22.2 No. 60079-0 Class II, Division 1 Optical Radiation Op sh Ga 0,1,2 IEC 60079-28

protected by shutdown

Class III, Division 1 Op is Ga 0,1,2 IEC 60079-28

Increased AEx e (Gb) US Class I Zone 1 ISA 60079-7 Class II, Zone 20 and Zone 21

No arcs, sparks or hot

Safety Ex e (Gb) CA Class I Zone 1 CSA C22.2 No. 60079-7 Increased Safety e Gb 1,2 IEC 60079-7

CSA C22.2 No. 14 “Industrial control Control panels located in ordinary surfaces

Type ‘n’ (Non-Sparking) nA Gc 2 IEC 60079-15

NI US Class I Division 2 ISA 12.12.01/FM 3611 No arcs, sparks equipment” Section 4.18 locations with intrinsically safe barriers: Enclosure IP54 or better

Non-Incendive Class I, Division 1

NI CA Class I Division 2 CSA C22.2 No. 213 or hot surfaces

Class I, Zone 0 and Zone 1 Flame-proof d Gb 1,2 IEC 60079-1 Contain the explosion,

AEx nA (Gc) US Class I Zone 2 ISA 60079-15 Class II, Division 1 quench the flame

Non-Sparking Type ‘n’ (Enclosed Break) nC Gc 2 IEC 60079-15

Ex nA (Gc) CA Class I Zone 2 CSA C22.2 No. 60079-15

Flashlights UL 783 “Electric flashlights and Class I, Divisions 1 & 2 Quartz/Sand Filled q Gb 1,2 IEC 60079-5 Quench the flame

XP US Class I Division 1 UL 1203 Class II, Divisions 1 & 2

Explosion-proof lanterns for use in hazardous ia Ga 0,1,2 IEC 60079-11

XP CA Class I Division 1 CSA C22.2 No. 30 Class I, Zones 1 & 2 Limit the energy of

(classified) locations”

Intrinsic Safety ib Gb 1,2 IEC 60079-11 sparks and surface

AEx d (Gb) US Class I Zone 1 ISA 60079-1 Contain the temperatures

Flame-proof Heaters UL 823 “Electric heaters for use in Class I, Divisions 1 & 2 ic Gc 2 IEC 60079-11

Ex d (Gb) CA Class I Zone 1 CSA C22.2 No. 60079-1 explosion and Class II, Divisions 1 & 2

hazardous (classified) locations” px Gb 1,2 IEC 60079-2

AEx q (Gb) US Class I Zone 1 ISA 60079-5 extinguish the Class III, Divisions 1 & 2 Purged /

Powder Filled flame Class I, Zone 1 Pressurized py Gb 1,2 IEC 60079-2

Ex q (Gb) CA Class I Zone 1 CSA C22.2 No. 60079-5

Class II, Zones 20, 21, and 22 pz Gc 2 IEC 60079-2

AEx nC (Gc) US Class I Zone 2 ISA 60079-15

Enclosed Break Fuel Dispensing UL 87 “Power-operated dispensing Type ‘n’ (Sealing & Hermetically nC Gc 2 IEC 60079-15

Ex nC (Gc) CA Class I Zone 2 CSA C22.2 No. 60079-15 devices for petroleum products” Sealed)

Equipment Keep the

IS US Class I Division 1 UL 913 / FM 3610 UL 87A Dispensers for gasoline and Type ‘n’ (Restricted Breathing) nR Gc 2 IEC 60079-15 flammable gas out

IS CA Class I Division 1 CSA C22.2 No. 157 ethonol blends, E0 to E85 ma Ga 0,1,2 IEC 60079-18

AEx ia (Ga) US Class I Zone 0 ISA 60079-11 Limit energy of Encapsulation mb Gb 1,2 IEC 60079-18

UL 87B Dispensers for diesel fuel, bio

Intrinsic Safety 1 AEx ib (Gb) US Class I Zone 1 ISA 60079-11 sparks and diesel blends to B20, kerosene and mc Gc 2 IEC 60079-18

AEx ic (Gc) US Class I Zone 2 ISA 60079-11 surface fuel oil

Areas classified for fuel dispensing Oil Immersion o Gb 1,2 IEC 60079-6

Ex ia (Ga) CA Class I Zone 0 CSA C22.2 No. 60079-11 temperature UL 87C Dispensers for diesel exhaust equipment per national and local codes

Ex ib (Gb) CA Class I Zone 1 CSA C22.2 No. 60079-11 fluids Electrical Equipment for Combustible Dusts (D)

Limited Energy Ex nL (Gc) CA Class I Zone 2 CSA C22.2 No. 60079-15 General Requirements - - 20,21,22 IEC 60079-0

UL 1238 “Control equipment for use

Type X US Class I Division 1 NFPA 496 (FM 3620) with flammable liquid dispensing ta Da 20 Standard protection

Type X CA Class I Division 1 NFPA 496 devices”

Enclosure tb Db 21 IEC 60079-31 for dusts, rugged tight

Type Y US Class I Division 1 NFPA 496 (FM 3620) CSA C22.2 No. 22 “Electrical tc Dc 22 enclosure

Type Y CA Class I Division 1 NFPA 496 equipment for flammable and

combustible fuel dispensers” Similar to enclosure, but

Type Z US Class I Division 2 NFPA 496 (FM 3620) ia Da 20

with some relaxations

Type Z CA Class I Division 2 NFPA 496 Intrinsic Safety ib Db 21 IEC 60079-11

Pressurized Note 3: UL 674 and CSA 145 are harmonized standards. if circuit inside is

AEx px (Gb) US Class I Zone 1 ISA 60079-2 ic Dc 22

intrinsically safe

Ex px (Gb) CA Class I Zone 1 CSA C22.2 No. 60079-2

ma Da 20 Protection by

AEx py (Gb) US Class I Zone 1 ISA 60079-2

Encapsulation mb Db 21 IEC 60079-18 encapsulation of

Ex py (Gb)

AEx pz (Gc)

CA

US

Class I

Class I

Zone 1

Zone 2

CSA C22.2 No. 60079-2

ISA 60079-2

Keep

flammable gas NORTH AMERICA and ATEX & IECEx mc Dc 22 incendive parts

Ex pz (Gc) CA Class I Zone 2 CSA C22.2 No. 60079-2 out Db 21,22 Protection by

Pressurized pD IEC 61241-4 pressurization of

Restricted AEx nR (Gc) US Class I Zone 2 ISA 60079-15 Dc 22

Breathing Ex nR (Gc) CA Class I Zone 2 CSA C22.2 No. 60079-15

Atmosphere Groups enclosure

Substance Hazard Class Division Groups Zone Groups Non-Electrical Equipment

AEx ma (Ga) US Class I Zone 0 ISA 60079-18

AEx mb (Gb) US Class I Zone 1 ISA 60079-18 Acetylene Group A IIC 0,1,2,

Encapsulation General Requirements - - EN 13463-1 Low potential energy

AEx mc (Gc) US Class I Zone 2 ISA 60079-18 20,21,22

Ex m CA Class I Zone 1 CSA C22.2 No. 60079-18 Hydrogen Group B IIC

Class I

Ethylene Group C IIB Relies on tight seals,

AEx o (Gb) US Class I Zone 1 ISA 60079-6 Flammable Gases

Oil Immersion Propane Group D IIA closely matched joints

Ex o (Gb) CA Class I Zone 1 CSA C22.2 No. 60079-6 Flow Restricted Enclosure fr - 2,22 EN 13463-2

and tough enclosures to

Electrical Equipment for Combustible Dust - Class II & Class III Methane Group D IIA5 Flame-proof Enclosure d - 1,2,21,22 EN 13463-3

restrict the breathing of

_ US Class II Division 1 & 2 FM 3600 Combustible Metal Dusts Group E 4 IIIC 6 the enclosure

_ CA Class II Division 1 & 2 CSA C22.2 No. 25 Combustible Carbonaceous Dusts Class II Group F IIIB6 Ignition hazards

General 0,1,2,

_ US Class III Division 1 & 2 FM 3600 Combustible Dusts Constructional Safety c - EN 13463-5 eliminated by good

Requirements _ Combustible Dusts not in Group E or F 20,21,22

Ex US Zone 20, 21, 22 ISA 60079-0 Group G IIIB 6 engineering methods

(Flour, Grain, Wood, Plastics, Chemicals)

Control equipment

US Class III 6 0,1,2,

Dust-Ignition DIP Class II Division 1 UL 1203 Combustible Fibers and Flyings Not Applicable IIIA Control of Ignition Sources b - EN 13463-6 fitted to detect

proof Fibers and Flyings 20,21,22

CA Class II Division 1 CSA C22.2 No. 25 malfunctions

Note 4: Group E is applicable to Class II, Division 1 only.

NI US Class II Division 2 ISA 12.12.01 / FM 3611 Note 5: Metane is a Group IIA Gas for non-mining applications. Enclosure is purged and

Note 6: Groups IIIA, IIIB and IIIC have not been adopted by the Canadian Electrical Code.

Dust Protected Purged / - 1,2, EN 60079-2 pressurized to prevent

CA Class II Division 2 CSA C22.2 No. 25 p

Pressurized 21,22 EN 61241-4 ignition sources from

Enclosure AEx ta (Da) US Class II Zone 20 2 ISA 60079-31 arising

2

AEx tb (Db) US Class II Zone 21

2

ISA 60079-31 Classification of Divisions and Zones Enclosure uses liquid to

AEx tc (Dc) US Class II Zone 22 ISA 60079-31 0,1,2,

Liquid Immersion k - EN 13463-8 prevent contact with

Ex ta CA Class II Division 1 CSA C22.2 No. 60079-31 Hazard Level Division Scheme Zone Scheme Definitions 20,21,22

explosive atmosphere

Ex ta CA Class III Division 1 CSA C22.2 No. 60079-31 Continuous A place in which an explosive atmosphere is

Ex tb CA Class II Division 1 CSA C22.2 No. 60079-31 Zone 0 / Zone 20

Hazard continually present

Ex tb CA Class III Division 1 CSA C22.2 No. 60079-31 Division 1

Ex tc CA Class II Division 2 CSA C22.2 No. 60079-31 Keep Intermittent A place in which an explosive atmosphere is

Ex tc CA Class III Division 2 CSA C22.2 No. 60079-31 combustible Hazard

Zone 1 / Zone 21

likely to occur in normal operation Ingress Protection Codes Atmosphere Groups

Fiber & Flying _ US Class III Division 1 & 2 UL 1203 / ISA 12.12.01 dust out Hazard Under A place in which an explosive atmosphere is [IEC 60529] [ATEX & IECEx]

Protection _ CA Class III Division 1 & 2 CSA C22.2 No. 25 Abnormal Division 2 Zone 2 / Zone 22 not likely to occur in normal operation, but First Number (protect Second Number (protect Group Environment Location Typical Substance

Conditions may occur for short periods from solid bodies) from water)

AEx maD US Class II Zone 20 ISA 61241-18 Coal Methane

Class II I

AEx mbD US Zone 21 ISA 61241-18 0 No Protection 0 No protection Mining (Fire damp)

Ex ma CA Class II Division 1 CSA C22.2 No. 60079-18

Ex ma CA Class III Division 1 CSA C22.2 No. 60079-18

Temperature Classification 7 1 Objects > 50mm 1 Vertical drip

IIA Gases, Methane,

Vapors and Surface Propane, etc.

Encapsulation 2 Objects > 12.5mm 2 Angled drip

Ex mb CA Class II Division 1 CSA C22.2 No. 60079-18 Max. Surface Temperature NEC® 500 CEC® NEC® 505 / IEC - Group II Mists and

IIB Ethylene

Ex mb CA Class III Division 1 CSA C22.2 No. 60079-18 3 Objects > 2.5mm 3 Spraying Other

450º C (842ºF) T1 T1

Locations Hydrogen,

Ex mc CA Class II Division 2 CSA C22.2 No. 60079-18 4 Objects > 1.0mm 4 Splashing IIC

300º C (572ºF) T2 T2 Acetylene, etc.

Ex mc CA Class III Division 2 CSA C22.2 No. 60079-18 5 Dust-Protected 5 Jetting

280º C (536ºF) T2A Combustible

IIIA

Type X US Class II Division 1 NFPA 496 (FM 3620) 6 Dust-Tight 6 Powerful jetting Surface flyings

260º C (500ºF) T2B

Type X CA Class II Division 1 NFPA 496 Combustible and

7 Temporary immersion IIIB Non-conductive

230º C (446ºF) T2C Dusts Other

Type Y US Class II Division 1 NFPA 496 (FM 3620)

215º C (419ºF) T2D Locations Conductive

Type Y CA Class II Division 1 NFPA 496 8 Continuous immersion IIIC

Pressurization Type Z US Class II Division 2 NFPA 496 (FM 3620) 200º C (392ºF) T3 T3

Type Z CA Class II Division 2 NFPA 496 9 High pressure and

180º C (356ºF) T3A temperature water jet

AEx pD US Class II Zone 21 ISA 61241-2

165º C (329ºF) T3B

IS US Class II Division 1 UL 913 / FM 3610

Limit energy of 160º C (320ºF) T3C

AEx iaD US Class II Zone 20 ISA 61241-11

Intrinsic Safety AEx ibD US Class II Zone 21 ISA 61241-11

sparks and

135º C (275ºF) T4 T4

Equipment Groups [ATEX]

surface

IS US Class III Division 1 UL 913 / FM 3610 temperature ATEX Equipment

120º C (248ºF) T4A Required Protection

Equipment Group Equipment Atmosphere Protection

100º C (212ºF) T5 T5 Performance & Operation

Note 1: For associated intrinsically safe apparatus suitable for installation in a hazardous location, the symbol for the type of Category Level (EPL)

protection “ia” or “ib” are enclosed within square brackets on the marking, e.g. AEx d [ia] IIC T4.

For intrinsically safe apparatus not suitable for installation in a hazardous location, both the symbol “Ex” or “AEx” and the 85º C (185ºF) T6 T6 I (Mines with Two faults, Remain

symbol for the type of protection “ia” or “ib” are enclosed within the same square brackets on the marking, e.g. [AEx ia] IIC; Firedamp)

M1 Methane & Dust Very High Ma

Note 7: For Group I applications (ATEX and IECEx only), electrical apparatus has fixed temperature limits of 150ºC (where layers of coal dust can form) and energized and functioning

in this case, a temperature class is not included. 450ºC (where coal dust is not expected to form a layer).

Note 2: Zones 20-22 are not currently classified in the Canadian Electric Code (CEC ® ). Severe normal operation,

I (Mines with M2 Methane & Dust High Mb

Firedamp) De-energize in exp. atm.

® ®

II (All Other Areas) 1G, 1D Gas, Vapor, Mist, Dust Very High Two faults

Additional Market Access: IECEx Scheme

® ® II (All Other areas) 2G, 2D Gas, Vapor, Mist, Dust High One fault

Enclosure Type Ratings [NEC & CEC ] Manufacturers of Ex equipment can obtain certificates of conformity that will be

accepted at a national level in all countries that participate in the IECEx Scheme. II (All Other Areas) 3G, 3D Gas, Vapor, Mist, Dust Low Normal operation

Type Area Brief Definition

A certificate of conformity may be obtained from any certification body accepted into the Scheme.

1 Indoor General Purpose

2 Indoor Protection against angled dripping water

The certificate will attest that (1) the equipment design conforms to relevant IEC Standards and (2) the Equipment Categories & ATEX Categories vs. Zones

product is manufactured under a quality plan assessed by an Approved IECEx Certification Body (Ex CBs).

Protection Levels 8 of Use 8

Indoor / Manufacturers holding certificates of conformity may affix the IECEx Mark of Conformity to equipment

3, 3R, 3S Protection against rain, snow Equipment

Outdoor they have verified complies with the certified design. ATEX Typical Equipment Equipment Zone of Use

Protection

Indoor / Category Zone Suitability Category

Intertek is an IECEx Testing Laboratory and has IECEx Accepted Certification Body status. For more Levels Gas, Vapors,

4, 4X Protection against rain, snow, hose directed water and corrosion (X only) ATEX 94/9/EC Dust

Outdoor information on the IECEx Scheme, contact us at icenter@intertek.com or visit www.IECEx.com. & Mist

1G Ga Suitable for Zones 0,1,2

5 Indoor Protection against angled dripping water, dust, fibers, flyings Category 1 Zone 0, 1 & 2 Zone 20, 21 & 22

1D Da Suitable for Zones 20,21,22

Indoor / Category 2 Zone 1 & 2 Zone 21 & 22

6 Protection against temporary submersion

Outdoor Other CE Directives That May Be Applicable 2G Gb Suitable for Zones 1,2

Category 3 Zone 2 Zone 22

Indoor / 2D Db Suitable for Zones 21,22

6P Protection against prolonged submersion Electromagnetic Compatibility (EMC) Directive 2004/108/EC

Outdoor 3G Gc Suitable for Zone 2

Note 8: Unless the explosion protection risk assessment states

otherwise.

Machinery Directive 2006/42/EC

12, 12K Indoor Protection against circulating dust, fibers, flyings

3D Dc Suitable for Zone 22

13 Indoor Protection against circulating dust, fibers, flyings, seepage Pressure Equipment Directive 97/23/EC

Low Voltage (excludes equipment for use in explosive atmospheres - see Directive 2006/95/EC

ATEX Annex II 1.2.7)

Radio Equipment and Telecommunications Terminal Equipment (R&TTE) Directive 1999/5/EC

Contact Intertek with questions about Hazardous Locations & Explosive Atmospheres testing and certification

icenter@intertek.com 1-800-WORLDLAB (967-5352) www.intertek.com/hazardous-locations HZL 0314

You might also like

- North America: Hazardous Areas, Explosive Atmospheres and Equipment GroupDocument1 pageNorth America: Hazardous Areas, Explosive Atmospheres and Equipment GroupkazdanoNo ratings yet

- Haz Area ChatDocument1 pageHaz Area Chatmaniking1No ratings yet

- Hazardous Area ClassificationsDocument1 pageHazardous Area ClassificationsAndrew Bull100% (2)

- Hazardous Area Classification - Guidelines - Process and HSE EngineeringDocument30 pagesHazardous Area Classification - Guidelines - Process and HSE EngineeringSivapriya SamyNo ratings yet

- Cable Gland SelectionDocument31 pagesCable Gland SelectionSrikant SuruNo ratings yet

- techNOTE - Coding Principles of Beacons and Indicators PDFDocument1 pagetechNOTE - Coding Principles of Beacons and Indicators PDFŽarko MočnikNo ratings yet

- Cable Glands in Hazardous Areas CCG PresentationDocument59 pagesCable Glands in Hazardous Areas CCG PresentationAwotiku Abimbola100% (2)

- ISA Standard ListDocument3 pagesISA Standard ListAnonymous w5tvtuFNo ratings yet

- Z System - Zener Barrier ManualDocument32 pagesZ System - Zener Barrier ManualHernan PatarroyoNo ratings yet

- Hazardous Area Chart - E&H PDFDocument2 pagesHazardous Area Chart - E&H PDFBuddy EkoNo ratings yet

- ExtronicsWallchart 160708Document1 pageExtronicsWallchart 160708Shyam VarunNo ratings yet

- HPM - Specification and Technical DataDocument48 pagesHPM - Specification and Technical DataVitor Nunes BragaNo ratings yet

- Hazardous Area SH CourseDocument22 pagesHazardous Area SH CourseafnakshNo ratings yet

- Hazardous Area Classification 2022-10-30 04-37-13Document39 pagesHazardous Area Classification 2022-10-30 04-37-13Pitipong SunkhongNo ratings yet

- Iecex TCD 02 Scheme Ed 7.0Document103 pagesIecex TCD 02 Scheme Ed 7.0Bhavik PrajapatiNo ratings yet

- Mark Vies Control: Functional Safety ManualDocument238 pagesMark Vies Control: Functional Safety Manualazizi reNo ratings yet

- ExSilentia User GuideDocument0 pagesExSilentia User Guidejeeva4384No ratings yet

- Nec TablesDocument21 pagesNec TablesRichard Wiltsie100% (2)

- Control Valve Specification Sheet: Customer Application End User Tag No End DestinationDocument3 pagesControl Valve Specification Sheet: Customer Application End User Tag No End DestinationAnonymous oVRvsdWzfBNo ratings yet

- 000 in DTS 401Document6 pages000 in DTS 401zsmithNo ratings yet

- Sample of Hazardous Area ClassificationDocument35 pagesSample of Hazardous Area ClassificationMouath AlraoushNo ratings yet

- Hazardous Area Classification StandardsDocument50 pagesHazardous Area Classification StandardsashawishNo ratings yet

- Certifications d2p Ewp Circuit Breaker Panelboards Ul E84577 Appleton en 7120036Document1 pageCertifications d2p Ewp Circuit Breaker Panelboards Ul E84577 Appleton en 7120036Diego Betancourt MejiaNo ratings yet

- Area ClassificationDocument71 pagesArea ClassificationFaiqoh NahareyNo ratings yet

- FIELDBUS ENGINEER's Guide - Pepperl+Fuchs PDFDocument474 pagesFIELDBUS ENGINEER's Guide - Pepperl+Fuchs PDFMuhammad ImranNo ratings yet

- 4.1 DCS IO List PDFDocument16 pages4.1 DCS IO List PDFAhmad ShekhNo ratings yet

- HazLoc PosterDocument1 pageHazLoc PosterSteven MarksNo ratings yet

- SLC-Essential 2013 Catalogue (Introduction) FinalDocument8 pagesSLC-Essential 2013 Catalogue (Introduction) FinalWaleed Mohammed FekryNo ratings yet

- Hazardous Area ClassificationDocument9 pagesHazardous Area ClassificationyogitatanavadeNo ratings yet

- Comparison Exd Vs Exe Design EnclosuresDocument10 pagesComparison Exd Vs Exe Design EnclosuresHarpreet SutdharNo ratings yet

- Poster ATExDocument1 pagePoster ATExmarius_brkt6284No ratings yet

- A-Pdf Merger DemoDocument36 pagesA-Pdf Merger DemoAvulsedBRNo ratings yet

- Arc Flash ProtectionDocument11 pagesArc Flash ProtectionDvmc Zona TacubaNo ratings yet

- Is Loop Calculate TableDocument1 pageIs Loop Calculate Tablehafizi07No ratings yet

- MTL Product OverviewDocument56 pagesMTL Product OverviewAries dNo ratings yet

- Generator Capability Study For Offshore Oil PlatformDocument8 pagesGenerator Capability Study For Offshore Oil Platformmohammad mostajeranNo ratings yet

- Nonincendive Electrical Equipment For Use in Class I and II, Division 2 and Class III, Divisions 1 and 2 Hazardous (Classified) LocationsDocument46 pagesNonincendive Electrical Equipment For Use in Class I and II, Division 2 and Class III, Divisions 1 and 2 Hazardous (Classified) LocationsMahdy MazinyNo ratings yet

- Harmonics Analysis For Ships and Industrial Power Systems (HASIP) Version 1, March 17, 2004Document4 pagesHarmonics Analysis For Ships and Industrial Power Systems (HASIP) Version 1, March 17, 2004kgskgmNo ratings yet

- Safety Analysis Function Evaluation (S.A.F.E.) Chart: Project Document No. RevisionDocument19 pagesSafety Analysis Function Evaluation (S.A.F.E.) Chart: Project Document No. RevisionCandraNo ratings yet

- Total Plant Solutions Overview TP01100 PDFDocument64 pagesTotal Plant Solutions Overview TP01100 PDFEMC RoboticsNo ratings yet

- ANSIISA-TR12.24.01-1998 (IEC 60079-10 Mod) PDFDocument66 pagesANSIISA-TR12.24.01-1998 (IEC 60079-10 Mod) PDFRubén VélezNo ratings yet

- Test Report Iec 62040-1 PDFDocument172 pagesTest Report Iec 62040-1 PDFศิษย์เก่า ทีเจพีNo ratings yet

- IEC61285 Analyser HouseDocument34 pagesIEC61285 Analyser HouseLuigi SergiNo ratings yet

- WAGO Catalog (2015)Document723 pagesWAGO Catalog (2015)Jorge_Andril_5370100% (1)

- Intrinsic Safety Barriers IsolatorsDocument14 pagesIntrinsic Safety Barriers IsolatorsDijith Jhansi100% (2)

- Earthing in Industrial and Pharmaceutical PlantsDocument28 pagesEarthing in Industrial and Pharmaceutical PlantsBrayden Chetty100% (1)

- 02 - ABB Functional Safety Jargon Buster 2018Document64 pages02 - ABB Functional Safety Jargon Buster 2018dave chaudhuryNo ratings yet

- Pump Start-Up Backpressure - Industrial Professionals - Cheresources - Com CommunityDocument7 pagesPump Start-Up Backpressure - Industrial Professionals - Cheresources - Com Communityjayrolling dollazNo ratings yet

- CMGPP-FD-EL-LST-0001 - Electrical Load List - Rev.0Document11 pagesCMGPP-FD-EL-LST-0001 - Electrical Load List - Rev.0PHAM THANH TUNo ratings yet

- Process Instrumentation Terminology Performance CharaDocument12 pagesProcess Instrumentation Terminology Performance CharaPriNo ratings yet

- 60.30-069 - 1994specification For Differential PressureDocument5 pages60.30-069 - 1994specification For Differential PressurepradeepNo ratings yet

- WWW - schischek.com:pdf:ATEX Classification Labelling of Electric EquipmentDocument1 pageWWW - schischek.com:pdf:ATEX Classification Labelling of Electric EquipmentfrancisNo ratings yet

- ControlLogix For SIL 2 PDFDocument4 pagesControlLogix For SIL 2 PDFveerendraNo ratings yet

- TR - 84.00.02 Part1Document108 pagesTR - 84.00.02 Part1Sandra TiguaqueNo ratings yet

- FM EXGas HazardPosterDocument0 pagesFM EXGas HazardPosterFabio Emanuele BrandaNo ratings yet

- CSA Group WallchartDocument1 pageCSA Group WallchartMohd Lutfi MahaliNo ratings yet

- P 0296 Hazardous Locations 2Document1 pageP 0296 Hazardous Locations 2Louis ChenNo ratings yet

- WEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishDocument1 pageWEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishJohnNo ratings yet

- WEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishDocument1 pageWEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishDave CNo ratings yet

- FM EXGas HazardPosterDocument1 pageFM EXGas HazardPosterrocket-vtNo ratings yet

- FM 3600 - 2011 Approval Standard For Electrical Equipment For Use in Hazadous LocationDocument14 pagesFM 3600 - 2011 Approval Standard For Electrical Equipment For Use in Hazadous LocationIo HitachiNo ratings yet

- General SpecificationDocument327 pagesGeneral SpecificationmaymanyassinNo ratings yet

- Dehn Main Catalog Lightning Protection EarthingDocument300 pagesDehn Main Catalog Lightning Protection EarthingIo HitachiNo ratings yet

- Non Intrusive Signallers GD-1035Document2 pagesNon Intrusive Signallers GD-1035Io HitachiNo ratings yet

- 869290Document252 pages869290Dmitry VasilevNo ratings yet

- FL Comserver Basic DescriptionDocument15 pagesFL Comserver Basic DescriptionIo Hitachi100% (1)

- Manual Kubota m130xDocument654 pagesManual Kubota m130xRaul Soteras Esteban100% (6)

- Thesis 2014 IkyereveDocument222 pagesThesis 2014 Ikyerevethai avvaiNo ratings yet

- Codigos de Fallas S 40 IIDocument1 pageCodigos de Fallas S 40 IIRonald Rivera GoraNo ratings yet

- IEA - Oil Market Report MonthlyDocument68 pagesIEA - Oil Market Report Monthlyrryan123123No ratings yet

- DB Density-Standards en 1.0Document2 pagesDB Density-Standards en 1.0Ahmed IsmailNo ratings yet

- BunkeringDocument29 pagesBunkeringChirag Gupta100% (2)

- Fuel Injector Pump PDFDocument16 pagesFuel Injector Pump PDFHrishikesh BedekarNo ratings yet

- TempDocument1 pageTempgrwgNo ratings yet

- Air Conditionig Quiz A320 CBTDocument10 pagesAir Conditionig Quiz A320 CBTjoseanrodmaNo ratings yet

- TR-500EX: Tadano LTDDocument6 pagesTR-500EX: Tadano LTDMuhammadFaridNo ratings yet

- Perkings Manual RegenerationDocument26 pagesPerkings Manual RegenerationErik Martinez100% (4)

- Wirtgen - 2200 SMDocument22 pagesWirtgen - 2200 SMDanu Putra100% (2)

- UNIT-2 Battery TechnologyDocument25 pagesUNIT-2 Battery TechnologyVasudev GuptaNo ratings yet

- Catalogue New 2015Document88 pagesCatalogue New 2015Sherif AdelNo ratings yet

- Aqua Blend AB1 PDFDocument4 pagesAqua Blend AB1 PDFusaid saifullahNo ratings yet

- Engine Detroit S-60 PDFDocument76 pagesEngine Detroit S-60 PDFcarlosorizaba100% (1)

- Aircraft Propulsion and Gas Turbine Engines Second Edition PDF Cap 6Document66 pagesAircraft Propulsion and Gas Turbine Engines Second Edition PDF Cap 6JimmyNo ratings yet

- FR92516 FR92996 6LTAA8.9-G2 Datasheet - 01 enDocument4 pagesFR92516 FR92996 6LTAA8.9-G2 Datasheet - 01 enmunhNo ratings yet

- Farm Power and MachinaryDocument101 pagesFarm Power and MachinarySushant YadavNo ratings yet

- Fact Sheet: Engine D13K500, EU6SCRDocument3 pagesFact Sheet: Engine D13K500, EU6SCRfrank mutale100% (1)

- BC501-502 2015Document119 pagesBC501-502 2015CESARALARCON1No ratings yet

- BR2406 Containerized Generator2Document8 pagesBR2406 Containerized Generator2Juvencio MolinaNo ratings yet

- Air Breathing PropulsionDocument157 pagesAir Breathing PropulsionKrishna PremNo ratings yet

- Ge Seasmart Brochure 0Document7 pagesGe Seasmart Brochure 0Benjamin StricklandNo ratings yet

- Yamaha Parts Catalog All OutboardsDocument263 pagesYamaha Parts Catalog All OutboardsMermaid TanajibNo ratings yet

- Alarm and Alert CodesDocument4 pagesAlarm and Alert Codesramadan aliNo ratings yet

- Mentis Et Al 2015-A GIS Based Approach For Electrification Planning-A Case Study On NigeriaDocument9 pagesMentis Et Al 2015-A GIS Based Approach For Electrification Planning-A Case Study On NigeriaMarysol AyalaNo ratings yet

- Co2 RecoveryDocument10 pagesCo2 RecoveryvijayxmanNo ratings yet

- MIT PHD 232158310Document0 pagesMIT PHD 232158310azharzebNo ratings yet

- Fyp TurbochargerDocument5 pagesFyp TurbochargerEngr Jahanzaib KhanNo ratings yet