Professional Documents

Culture Documents

Case Studies

Uploaded by

Rishabh Soni0 ratings0% found this document useful (0 votes)

17 views2 pagesOriginal Title

15. CASE STUDIES

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views2 pagesCase Studies

Uploaded by

Rishabh SoniCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

Case1.

Tasty Noodles Company

Study the following case and answer the question given at

the end of case study. …………………………………….………………..……….[20]

Tasty Noodles Company was planning to introduce 100 grams pack of noodles into

Indian market at Rs.8/- per pack during the test marketing period of one month. During

this period the company wanted to flood the market with their noodles.

In the subsequent month, Tasty Noodles Company planned to increase the price to

Rs.12/- and change the packaging to 120 grams with a free toy car attached to the pack.

One month before the product introduction , marketing department brought out

advertisement in the print, FM radio and television media. There were also competitions

arranged for children with prizes sponsored by Tasty Noodles Company.

Production for the introduction phase was to be started two months in advance. Demand

for the product was estimated to be one lakh packs for the first month and 1.2 lakhs in the

second month. Production had to be started earlier in order to meet the estimated demand,

as also to account for the change over in the pack size for the second month.

Questions:

1. What coordination is required between the marketing, production, and logistics

departments to integrate the activities towards the success of the introductory

campaign?

2. Explain the role of logistics department in the introductory phase.

3. Explain the information sharing that needs to take place between marketing,

production, and logistics departments for efficient and effective results.

4. Explain the role of logistics department in the change over to the new packaging in

the second month?

Case 2. Plastic furniture Ltd.[FPL]

Study the following case and answer the question given at

the end of case study. …………………………………….………………….[20]

Plastic furniture Ltd.[FPL] manufacture a range of plastic furniture for home as well as

office use. PFL have increased their sales to large retail outlets in last few years. Today

almost all their products are sold to large retail out lets in major cities. Without these

customers PFL would be in the category of a small manufacturer.

However theses large retailers have been demanding. PFL have had to install EDI for

connectivity and provide access to the retailers to their inventory data for stock

availability information. PFL are also needed to provide shipment status of all orders to

retailers at regular intervals.

The latest requirement from the retailers has been the reduction of delivery lead time

from 10 days 5 days. This has created problems in consolidation for full truck load

shipments in transportation for logistics. LTL [less than truck load] transportation will

result in increased transportation costs. Also PFL has been utilizing a centralized

distribution warehouse untill this time which is a constraint for the new requirement from

the retail stores.

Questions:

1. explain the logistical implications of the new requirements of the retail stores.

2. Suggest logistical solutions to PFL to meet the new requirement of the retail stores

Case 3. M/s XYZ Ltd.

Study the following case and answer the question given at the end of case study.…….20

M/s XYZ Ltd. are a consumer goods manufacturing company. They have outsourced

their logistical operations [inbound as well as out bound] to M/S ABC Ltd. Competition

has forced M/s XYZ Ltd. to drop their price in the market. Hence there is strong cost

reduction drive in M/s XYZ Ltd. M/S ABC Ltd. Have been informed by M/s XYZ Ltd

that they will have to drop their rate. The president of M/S ABC Ltd. Spoke to the senior

managers about the impending rate reduction. To keep the profit in tact cost of logistics

are to be reduced. What is your advice as student of logistical management to M/S ABC

Ltd. Please out line your strategy

You might also like

- Case Studies in LogisticsDocument21 pagesCase Studies in LogisticsAnand Khisti.82% (66)

- Logistic Case StudiesDocument28 pagesLogistic Case Studiessuhas_pr50% (2)

- Logistics Problems and SolutionsDocument11 pagesLogistics Problems and SolutionsSailpoint CourseNo ratings yet

- AssignmentDocument5 pagesAssignmentteeba ShreeNo ratings yet

- BB Bakery's Wedding Cake ProfitsDocument4 pagesBB Bakery's Wedding Cake ProfitsSahil ThadaniNo ratings yet

- Case Studies in Logistics - AlingDocument4 pagesCase Studies in Logistics - Alingmizbuziey30% (10)

- Documento - MX Case Study Logistics ManagementDocument8 pagesDocumento - MX Case Study Logistics ManagementEmmanuel IsangoNo ratings yet

- Case Study No. 1Document17 pagesCase Study No. 1Rajni jhamaniNo ratings yet

- London 2011Document32 pagesLondon 2011Amandine JayéNo ratings yet

- Chapter 1: IntroductionDocument22 pagesChapter 1: IntroductionsimranNo ratings yet

- Logistic Management - Case - Ms Ador Electrodes Limited (AEL)Document5 pagesLogistic Management - Case - Ms Ador Electrodes Limited (AEL)Jay KrishnaNo ratings yet

- Business Plan For 5star PaintDocument20 pagesBusiness Plan For 5star Paintracecomedy4lifeNo ratings yet

- Case Study No2Document2 pagesCase Study No2Merwin DsouzaNo ratings yet

- Tazmir Mobile Company Ltd. (TMCL) : Sample Marketing PlanDocument5 pagesTazmir Mobile Company Ltd. (TMCL) : Sample Marketing PlanSohel KhanNo ratings yet

- To Study The Impact of Promotional Activities On The Sale of Mobile Handset in Doaba RegionDocument67 pagesTo Study The Impact of Promotional Activities On The Sale of Mobile Handset in Doaba RegionashirockNo ratings yet

- Retailing Issues and ApplicationsDocument12 pagesRetailing Issues and ApplicationsMeghna BatraNo ratings yet

- Market Prices SCB Plastics Limited, Inc. Has Conducted A Survey of Plastic Chair andDocument6 pagesMarket Prices SCB Plastics Limited, Inc. Has Conducted A Survey of Plastic Chair andAJ BantayNo ratings yet

- Dragon Bathroom Fittings distribution challengesDocument4 pagesDragon Bathroom Fittings distribution challengeslakshaykalraNo ratings yet

- How external forces impact business strategiesDocument7 pagesHow external forces impact business strategiesRevati MenghaniNo ratings yet

- Case Studies CHAPTER 3Document16 pagesCase Studies CHAPTER 3akankasha thakurNo ratings yet

- Mid Term Transportation Sec A SubjectiveDocument5 pagesMid Term Transportation Sec A SubjectiveYASIRNo ratings yet

- International Commercial TermsDocument17 pagesInternational Commercial TermsLucien KouadioNo ratings yet

- Dsiopma Final PaperDocument50 pagesDsiopma Final PaperNevan NovaNo ratings yet

- Ambuja Cement Market Survey ReportDocument16 pagesAmbuja Cement Market Survey ReportAkshay MahajanNo ratings yet

- S.B.Patil Institute of ManagementDocument10 pagesS.B.Patil Institute of ManagementyashkakadeNo ratings yet

- Discuss Any Business Issue in Malaysia Industries and Give ExampleDocument5 pagesDiscuss Any Business Issue in Malaysia Industries and Give ExampleMohamad NajmiNo ratings yet

- Fastgo Case Study: Made By:-Vikram Gupta E-04 Manas Chafekar E-12Document20 pagesFastgo Case Study: Made By:-Vikram Gupta E-04 Manas Chafekar E-12Aditi BhandariNo ratings yet

- Strategy& PwC Booz Casebook Consulting Case Interview Book思略特 - 博斯 - 普华永道咨询案例面试Document14 pagesStrategy& PwC Booz Casebook Consulting Case Interview Book思略特 - 博斯 - 普华永道咨询案例面试issac li100% (3)

- Case Study On Yummy NoodlesDocument2 pagesCase Study On Yummy NoodlesGanesh Chindanuru100% (3)

- Marketing functions and strategiesDocument3 pagesMarketing functions and strategiesFathan AryadiNo ratings yet

- MM02Document7 pagesMM02Pratulya SinghNo ratings yet

- SCM - Subhradeep HazraDocument22 pagesSCM - Subhradeep HazraSubhradeep HazraNo ratings yet

- London Casebook 2011 For Case Interview Practice - MasterTheCaseDocument32 pagesLondon Casebook 2011 For Case Interview Practice - MasterTheCaseMasterTheCase.com100% (1)

- How Coca Cola India Quenched Its Thirst of The Indian Rural MarketDocument9 pagesHow Coca Cola India Quenched Its Thirst of The Indian Rural MarketKishore MuppaneniNo ratings yet

- Supply Chain Management NotesDocument35 pagesSupply Chain Management NotesRazin GajiwalaNo ratings yet

- ME - Case StudiesDocument19 pagesME - Case StudiesABINAYANo ratings yet

- Growthink's Ultimate Marketing Plan TemplateDocument46 pagesGrowthink's Ultimate Marketing Plan TemplateDarrel Magno33% (3)

- Packaging Solutions History, Products, Supply ChainDocument11 pagesPackaging Solutions History, Products, Supply Chainnoreenjajja007No ratings yet

- The Comfort Zone: Strategy For Survival and Growth of The BusinessDocument16 pagesThe Comfort Zone: Strategy For Survival and Growth of The BusinessPUTTU GURU PRASAD SENGUNTHA MUDALIARNo ratings yet

- Case StudyDocument2 pagesCase StudyWaqar KhalidNo ratings yet

- Bench Marking FMCG SectorDocument47 pagesBench Marking FMCG SectorShashank Chauhan100% (2)

- Assignment - Business Environment (Case Studies)Document3 pagesAssignment - Business Environment (Case Studies)KOMAL AGGARWALNo ratings yet

- Chapter 3Document10 pagesChapter 3Anushka ChauhanNo ratings yet

- Consumer Behaviour 1Document2 pagesConsumer Behaviour 1baby0310No ratings yet

- Where Profit BFL Food LogisticsDocument2 pagesWhere Profit BFL Food Logisticssukumaran3210% (1)

- SalesDocument3 pagesSalesEdgardo MartinezNo ratings yet

- Sep 2020 Solved NMIMS 1st and 2nd Year Assignment Call 9025810064Document59 pagesSep 2020 Solved NMIMS 1st and 2nd Year Assignment Call 9025810064Palaniappan NNo ratings yet

- Pdfjoiner PDFDocument86 pagesPdfjoiner PDFvictor saikiaNo ratings yet

- MKTG 12 Case Study MidtermsDocument5 pagesMKTG 12 Case Study MidtermsMaria Charise TongolNo ratings yet

- SMU Assignment Paper - MB046Document7 pagesSMU Assignment Paper - MB046Pankaj RaajNo ratings yet

- Aptitude Test ADocument6 pagesAptitude Test AraedahamedNo ratings yet

- BIT Pilani Supply Chain Management Comprehensive Exam QuestionsDocument2 pagesBIT Pilani Supply Chain Management Comprehensive Exam QuestionsPradeep MishraNo ratings yet

- Brunswick Distribution CaseDocument6 pagesBrunswick Distribution CaseAmeenii Mukhlis100% (1)

- Model Answer: Launch of a laundry liquid detergent in Sri LankaFrom EverandModel Answer: Launch of a laundry liquid detergent in Sri LankaNo ratings yet

- Marketbusters (Review and Analysis of Mcgrath and Macmillan's Book)From EverandMarketbusters (Review and Analysis of Mcgrath and Macmillan's Book)No ratings yet

- Lean Solutions: How Companies and Customers Can Create Value and Wealth TogetherFrom EverandLean Solutions: How Companies and Customers Can Create Value and Wealth TogetherRating: 3.5 out of 5 stars3.5/5 (16)

- Inventory Management Volume 2: And Some Observations About the Future of the Automotive AftermarketFrom EverandInventory Management Volume 2: And Some Observations About the Future of the Automotive AftermarketNo ratings yet

- Source BibliographyDocument2 pagesSource BibliographyManasa G NNo ratings yet

- Z TableDocument2 pagesZ TableRishabh SoniNo ratings yet

- DifferencesDocument1 pageDifferencesRishabh SoniNo ratings yet

- Kotler Krasher 2019Document69 pagesKotler Krasher 2019U Aakash 23No ratings yet

- Scuba Certification Lesson Price ListDocument1 pageScuba Certification Lesson Price ListSiddharth DasNo ratings yet

- Data Red Banjo BrewingDocument7 pagesData Red Banjo BrewingRishabh SoniNo ratings yet

- Top Canadian Online Brokers, Screeners, News ProvidersDocument194 pagesTop Canadian Online Brokers, Screeners, News ProvidersRishabh SoniNo ratings yet

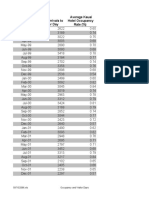

- Month Average Arrivals To Kauai Per Day Average Kauai Hotel Occupancy Rate (%)Document1 pageMonth Average Arrivals To Kauai Per Day Average Kauai Hotel Occupancy Rate (%)Rishabh SoniNo ratings yet

- 200 0 225 1 250 0 275 3 300 6 325 2 350 3 375 1 400 1 425 1 450 1 475 0 More 1Document1 page200 0 225 1 250 0 275 3 300 6 325 2 350 3 375 1 400 1 425 1 450 1 475 0 More 1Rishabh SoniNo ratings yet

- Data BrahmintonDocument3 pagesData BrahmintonMuhammad GulfamNo ratings yet

- Propreturns - Yield Sheet: Parameter DetailsDocument1 pagePropreturns - Yield Sheet: Parameter DetailsRishabh SoniNo ratings yet

- Scuba GuestsDocument6 pagesScuba GuestsArjun BalajiNo ratings yet

- Puma T&CDocument1 pagePuma T&CRishabh SoniNo ratings yet

- How To Retire Before 30 - Ankur WarikooDocument7 pagesHow To Retire Before 30 - Ankur WarikooJAYA BALDEV DasNo ratings yet

- Value Research Fund Performance Scheme Name Benchmark Riskometer Scheme Riskometer BenchmarkDocument6 pagesValue Research Fund Performance Scheme Name Benchmark Riskometer Scheme Riskometer BenchmarkRishabh SoniNo ratings yet

- Group 2 PDFDocument58 pagesGroup 2 PDFRishabh SoniNo ratings yet

- Case Interviews CrackedDocument208 pagesCase Interviews CrackedSaurabhYadav100% (11)

- Claims and performance of top insurers in IndiaDocument7 pagesClaims and performance of top insurers in IndiaRishabh SoniNo ratings yet

- Group 3 PDFDocument59 pagesGroup 3 PDFRishabh SoniNo ratings yet

- CamScanner Scans PDF DocsDocument7 pagesCamScanner Scans PDF DocsRishabh SoniNo ratings yet

- Terms and ConceptsDocument23 pagesTerms and ConceptsRishabh SoniNo ratings yet

- SYLLABUSDocument1 pageSYLLABUSRishabh SoniNo ratings yet

- ZS Associates ExperianceDocument3 pagesZS Associates ExperianceRahul Jolly100% (2)

- Case Interview FrameworksDocument6 pagesCase Interview Frameworkserika KNo ratings yet

- Solution To The Problems & How Mechanical Engineers Can ContributeDocument10 pagesSolution To The Problems & How Mechanical Engineers Can ContributeRishabh SoniNo ratings yet

- NTPC's Satellite Communication and MPLS ProtocolDocument16 pagesNTPC's Satellite Communication and MPLS ProtocolRishabh SoniNo ratings yet

- DOM Exp. 2Document7 pagesDOM Exp. 2Rishabh SoniNo ratings yet

- Rishabh Soni ReportDocument40 pagesRishabh Soni ReportRishabh SoniNo ratings yet

- GateDocument6 pagesGateParveen SwamiNo ratings yet

- P150EDocument4 pagesP150EMauro L. KieferNo ratings yet

- MBA Regular Part-I (Sem I)Document17 pagesMBA Regular Part-I (Sem I)Jasdeep SinghNo ratings yet

- Giáo Trình LPTD 2Document40 pagesGiáo Trình LPTD 2Hưng Trịnh TrọngNo ratings yet

- Problem solving and decision making in nutrition postgraduate studiesDocument55 pagesProblem solving and decision making in nutrition postgraduate studiesteklayNo ratings yet

- FLG 212 Study GuideDocument19 pagesFLG 212 Study GuidecynthiaNo ratings yet

- Course 4Document3 pagesCourse 4Ibrahim SalahudinNo ratings yet

- Façade Lift PerformanceDocument2 pagesFaçade Lift PerformanceIgor DzuklevskiNo ratings yet

- GRL+Prosp - EDocument2 pagesGRL+Prosp - Ethoma111sNo ratings yet

- Examen TSMDocument4 pagesExamen TSMKaryna VeraNo ratings yet

- H2 Physic 2010 A Level SolutionsDocument32 pagesH2 Physic 2010 A Level Solutionsonnoez50% (4)

- Hps40 Tech Doc ScreenDocument20 pagesHps40 Tech Doc ScreenAnonymous oyUAtpKNo ratings yet

- Bajaj Internship ReportDocument69 pagesBajaj Internship ReportCoordinator ABS100% (2)

- EPON ONU with 4FE+WiFi EONU-04WDocument4 pagesEPON ONU with 4FE+WiFi EONU-04WAndres Alberto ParraNo ratings yet

- Eliminator ® Liquid Line Fi Lter Driers: DML and DCLDocument12 pagesEliminator ® Liquid Line Fi Lter Driers: DML and DCLbracaNSNo ratings yet

- CFPA E Guideline No 2 2013 FDocument39 pagesCFPA E Guideline No 2 2013 Fmexo62No ratings yet

- 00001Document20 pages00001Maggie ZhuNo ratings yet

- TC-21FJ30LA: Service ManualDocument33 pagesTC-21FJ30LA: Service ManualRajo Peto alamNo ratings yet

- Lesson Plan in ESPDocument4 pagesLesson Plan in ESPkaren daculaNo ratings yet

- Invoice Request for Digitize Global InovasiDocument1 pageInvoice Request for Digitize Global InovasiAsa Arya SudarmanNo ratings yet

- Fraud Ebook Latest - Databricks PDFDocument14 pagesFraud Ebook Latest - Databricks PDFmohitbguptaNo ratings yet

- Air Brake System For Railway CoachesDocument40 pagesAir Brake System For Railway CoachesShashwat SamdekarNo ratings yet

- NView NNM (V5) Operation Guide PDFDocument436 pagesNView NNM (V5) Operation Guide PDFAgoez100% (1)

- Consumer Behaviour of Titan WatchesDocument57 pagesConsumer Behaviour of Titan Watchesmanu100% (1)

- Barcode BasicsDocument3 pagesBarcode Basicsnikhilbajpai_88No ratings yet

- Microsoft Security Product Roadmap Brief All Invitations-2023 AprilDocument5 pagesMicrosoft Security Product Roadmap Brief All Invitations-2023 Apriltsai wen yenNo ratings yet

- Project Report On Stock ExchangeDocument11 pagesProject Report On Stock Exchangebhawna33% (3)

- Configuration Management and ISO 9001Document7 pagesConfiguration Management and ISO 9001Simone MeschinoNo ratings yet

- Rguhs Dissertation PharmacyDocument6 pagesRguhs Dissertation PharmacyWhatAreTheBestPaperWritingServicesSingapore100% (1)

- The Three Pillars of The ASEANDocument13 pagesThe Three Pillars of The ASEANLouwell Abejo RiñoNo ratings yet

- Gec-Art Art Appreciation: Course Code: Course Title: Course DescriptionsDocument14 pagesGec-Art Art Appreciation: Course Code: Course Title: Course Descriptionspoleene de leonNo ratings yet