Professional Documents

Culture Documents

Zracni Ventil Za Radijator

Uploaded by

shadow_zeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zracni Ventil Za Radijator

Uploaded by

shadow_zeCopyright:

Available Formats

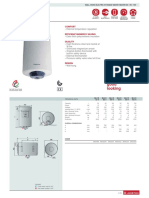

AERCAL

Automatic air vent for radiators

CALEFFI

series 504 cert. n° 0003

ISO 9001

01055/05 GB

Function

Automatic air vents with external float are designed to remove the

air that is released from the water when it is heated and which

accumulates at the top of radiators, limiting the normal heat

exchange process and giving rise to noise and corrosion.

The air vent has been constructed so that it can be installed on any

type of heating emitters ranging from the traditional cast iron

radiators to the thin steel panel radiators. All models are equipped

with a hygroscopic safety cap.

Product range

Series 504 Automatic air vent for radiators, chrome plated, with hygroscopic safety cap Sizes 1/2”, 3/4”, 1” right and left

Technical specification Dimensions

Materials:- Body and cover: brass EN 12165 CW617N, chrome plated

- Float: PP C

- Obturator stem: brass EN 12164 CW614N

- Spring: stainless steel

- Seals: EPDM

E

- Hygroscopic safety cap seal: NBR

D

F

- Hygroscopic safety cap discs: cellulose fibre

A

Medium: water and glycol solutions

Max. percentage of glycol: 30%

B

Max. working pressure: 10 bar G

Max. discharge pressure: 2,5 bar

Max. working temperature: 100°C

Code A B C D E F G Weight (kg)

Connections: 1/2” - 3/4” - 1”M right and left 504401 1/2” 51 48 37 63 76 88,5 0,28

504501 3/4” 51 48 34 60 76 88,5 0,27

504611 1” R 51 48 30 56 76 88,5 0,33

504621 1” L 51 48 30 56 76 88,5 0,33

Operating principle Flow curves

Air flow (when the system is being filled)

The accumulation of air bubbles in the valve body causes the float

to drop and thus the obturator to open. This phenomenon occurs,

Nl/s

1

and consequently the valve functions correctly, as long as the water 0,9

pressure remains below the maximum discharge pressure. 0,8

0,7

0,6

0,5

0,4

0,3

0,2

0,1

0

0,5 1,5 2,5 3,5 4,5 5,5 6,5

0 1 2 3 4 5 6 7 bar

(air)

Installation

The valve must be installed

in a vertical position.

The hygroscopic safety cap

must be screwed tight when

the system is operating.

Construction details

Hygroscopic cap

All models are equipped with a hygroscopic safety cap. Its

functionality is based on the properties of the cellulose fibre discs

that serve as the seal cartridge and whose volume increases by

50% as soon as they become wet and thus cause the valve to

close.

Cover Maintenance

The removable cover has a strong opening mechanism to vent the air.

The valve can be inspected as follows if the water contains

Float impurities that jeopardize the correct functioning of the system:

The location of the float and other internal parts means that the a) isolate the heating emitter by closing the valve and lockshield;

water never reaches the obturator, thus limiting the harmful effects

from the impurities contained in the liquid. b) unscrew the valve cover with the O-ring seal.

The valve has been constructed so that this operation can be

performed without leakage of water.

SPECIFICATION SUMMARIES

Series 504

Automatic air vent valve for radiators. Threaded connections, 1/2” M (3/4” M, 1” M right or 1” M left). Hygroscopic safety cap.

Chrome plated brass body and cover, stainless steel spring, PP float, EPDM O-ring seals. Hygroscopic safety cap seal in NBR.

Medium: water and glycol solutions. Maximum percentage of glycol 30%. Maximum operating pressure 10 bar. Maximum

discharge pressure 2,5 bar. Maximum working temperature 100°C.

We reserve the right to change our products and their relevant technical data, contained in this publication, at any time and without prior notice.

CALEFFI

CALEFFI S.P.A. · I · 28010 FONTANETO D’AGOGNA (NO) · S.R. 229, N.25 · TEL. +39 0322 8491 R.A. · FAX +39 0322 863723

· Http://www.caleffi.com · E-mail: info@caleffi.it ·

You might also like

- ITAPTECH AUTOMATIC-AIR-VENT EngDocument14 pagesITAPTECH AUTOMATIC-AIR-VENT EngCarlos EspNo ratings yet

- Automatic Air Vents Minical - Valcal: 5020 - 5021 - 5022 SeriesDocument2 pagesAutomatic Air Vents Minical - Valcal: 5020 - 5021 - 5022 SeriesGMSNo ratings yet

- Caleffi: Hydraulic Safety Groups For Hot Water Storage HeatersDocument2 pagesCaleffi: Hydraulic Safety Groups For Hot Water Storage HeatersMax.infoNo ratings yet

- Caleffi 250 Series Solar Automatic Air Vent SpecificationsDocument2 pagesCaleffi 250 Series Solar Automatic Air Vent Specificationse-ComfortUSANo ratings yet

- TOO Catalog File 2022 - 30.10.22Document6 pagesTOO Catalog File 2022 - 30.10.22Hen BenjaminNo ratings yet

- Mini Vitaq - 022858Document4 pagesMini Vitaq - 022858Ahmed SalemNo ratings yet

- ECO Heat Pump ENG 5Document16 pagesECO Heat Pump ENG 5Nano SalamNo ratings yet

- Valv Diluvio Claval Diafragma TubularDocument29 pagesValv Diluvio Claval Diafragma TubularDaniel ReyNo ratings yet

- Pressure Vacuum Relief Valve Flame Arrester 102Document3 pagesPressure Vacuum Relief Valve Flame Arrester 102vikramNo ratings yet

- Fire Deluge Valve: 800 Series (Tubular Diaphragm Valve)Document2 pagesFire Deluge Valve: 800 Series (Tubular Diaphragm Valve)dmitosNo ratings yet

- IM en 8 260 110 F68V F68YDocument2 pagesIM en 8 260 110 F68V F68Y2m8vzmsz5qNo ratings yet

- Seawater Fire Deluge Valve: 800 Series (Tubular Diaphragm Valve)Document2 pagesSeawater Fire Deluge Valve: 800 Series (Tubular Diaphragm Valve)dmitosNo ratings yet

- 2/2-Way Diaphragm Valve, Air Piloted: Type 174Document4 pages2/2-Way Diaphragm Valve, Air Piloted: Type 174Francisco Mones RuizNo ratings yet

- Bolaite (Atlas Copco) Screw Air CompressorDocument11 pagesBolaite (Atlas Copco) Screw Air CompressorJafarov VuqarNo ratings yet

- Ace CatalogueDocument8 pagesAce Catalogueosmanyildirim85No ratings yet

- CE BasicDocument28 pagesCE Basicpapbtm btm100% (1)

- 422-04026-05 OP Manual, SA-A (B, V, W)Document28 pages422-04026-05 OP Manual, SA-A (B, V, W)hung nguyen100% (1)

- Davey Xp350p8cDocument2 pagesDavey Xp350p8cNum470% (1)

- Calo-6 Spec B0mba AutomaticaDocument1 pageCalo-6 Spec B0mba AutomaticajmatallanaNo ratings yet

- Energy-Saving Free Float Steam Trap: FeaturesDocument2 pagesEnergy-Saving Free Float Steam Trap: FeaturesSebastian AcevedoNo ratings yet

- Indirect Fired Water Bath Heater Indirect Fired Water Bath Heater Flash Point - IfwbhDocument6 pagesIndirect Fired Water Bath Heater Indirect Fired Water Bath Heater Flash Point - IfwbhMuhammad AhsanNo ratings yet

- Evomax 2 30kW Spec Sheet 2020Document4 pagesEvomax 2 30kW Spec Sheet 2020SupyNo ratings yet

- Water Cooled Screw Chiller Brochure Final As 3 AsDocument16 pagesWater Cooled Screw Chiller Brochure Final As 3 AsSumon MahmudNo ratings yet

- Air Release Valve Cla-ValDocument4 pagesAir Release Valve Cla-Valventas2.fireproofcolNo ratings yet

- Series 34: Fire Protection System Air Release ValveDocument4 pagesSeries 34: Fire Protection System Air Release ValvecccNo ratings yet

- Valvula DesaireadoraDocument4 pagesValvula DesaireadoracccNo ratings yet

- Re-Circulated Hot Water Bath Vaporizer: For Chlorine, Sulphur Dioxide and AmmoniaDocument3 pagesRe-Circulated Hot Water Bath Vaporizer: For Chlorine, Sulphur Dioxide and AmmoniaNyandoro E-max MaxmoreNo ratings yet

- Pneumatically Operated With Manual Reset Deluge Valve For Freshwater and Seawater ServiceDocument2 pagesPneumatically Operated With Manual Reset Deluge Valve For Freshwater and Seawater ServicedmitosNo ratings yet

- Liquid - Gas Fuel Operated Steam Boilers With Opposite Pressure TS 497 - TS EN 303-1/2/3 High Fluid Cover Technology. Fire Concrete Problems Are OverDocument1 pageLiquid - Gas Fuel Operated Steam Boilers With Opposite Pressure TS 497 - TS EN 303-1/2/3 High Fluid Cover Technology. Fire Concrete Problems Are OverSharif MalekzadaNo ratings yet

- Twin Mac CQ ArcoDocument5 pagesTwin Mac CQ ArcoNitin SeenauthNo ratings yet

- Manual de Serviço Ar Sala LG CBN181QLA PDFDocument64 pagesManual de Serviço Ar Sala LG CBN181QLA PDFYuri GodoyNo ratings yet

- Water Cooled Water ChillerDocument28 pagesWater Cooled Water ChillerHENRYNo ratings yet

- Miniature Flowmeters For Analytical Process DK 700: Installation and Operating InstructionsDocument2 pagesMiniature Flowmeters For Analytical Process DK 700: Installation and Operating InstructionsMateusz SynowieckiNo ratings yet

- Informacion Valvula DesaireadoraDocument4 pagesInformacion Valvula DesaireadoraCesar GraterolNo ratings yet

- Thermopompe Hayward HPABG50Document18 pagesThermopompe Hayward HPABG50DanielNo ratings yet

- Pumps: Select The Optimum Model Between Two Different Types of PumpDocument2 pagesPumps: Select The Optimum Model Between Two Different Types of PumpLinh LeeNo ratings yet

- 40VMS CatalogDocument4 pages40VMS Catalognok.naingooNo ratings yet

- Alfa Laval Unique Mixproof Tank Outlet Valve Unique To Product LeafletDocument7 pagesAlfa Laval Unique Mixproof Tank Outlet Valve Unique To Product LeafletAnonymous KdnOsd9No ratings yet

- Almatec Manual CX 0806lDocument8 pagesAlmatec Manual CX 0806lpierre.franssenNo ratings yet

- Automatic Air Vents: For Hot and Cold Water SystemsDocument4 pagesAutomatic Air Vents: For Hot and Cold Water SystemsrameshNo ratings yet

- Automatic Air Release Valve For Low PressureDocument2 pagesAutomatic Air Release Valve For Low PressuresijilNo ratings yet

- Split System Cooling Product Data: 4TTB3018-060 1 - 5 TonsDocument12 pagesSplit System Cooling Product Data: 4TTB3018-060 1 - 5 TonsFernando CabreraNo ratings yet

- BLU R - ChinaDocument1 pageBLU R - ChinaShishan AhmadNo ratings yet

- On Line Self Cleaning Filter Operating Manual: Prepared: PM Verified: TM Controlled: QM Approved: MD IssuedDocument13 pagesOn Line Self Cleaning Filter Operating Manual: Prepared: PM Verified: TM Controlled: QM Approved: MD IssuedDaniel Touzet MalagaNo ratings yet

- Azeovaire Hot Water ASDI 1Document4 pagesAzeovaire Hot Water ASDI 1frank cevallosNo ratings yet

- Nicholson Thermostatic Steam TrapsDocument18 pagesNicholson Thermostatic Steam TrapsAli Fanani100% (1)

- Solar 1Document4 pagesSolar 1api-221502147No ratings yet

- Combination Air Eliminator-Strainer: OVAL CorporationDocument2 pagesCombination Air Eliminator-Strainer: OVAL CorporationChuong DongNo ratings yet

- R134a WC DX SCREW CHILLER USER MANUAL USER MANUAL 1 PDFDocument116 pagesR134a WC DX SCREW CHILLER USER MANUAL USER MANUAL 1 PDFSumit DasNo ratings yet

- 30HXCDocument2 pages30HXCvbharath21100% (1)

- ERHARD Air BEG ENDocument8 pagesERHARD Air BEG ENvladNo ratings yet

- Technical Specification of Dehumidifier ZLKD-2000FDocument4 pagesTechnical Specification of Dehumidifier ZLKD-2000Ffakir mohammadNo ratings yet

- Technical Data Sheet D6..NL: Type OverviewDocument4 pagesTechnical Data Sheet D6..NL: Type OverviewApetrii DoruNo ratings yet

- Air Cooled Screw Chiller R134aDocument12 pagesAir Cooled Screw Chiller R134aalkaf08No ratings yet

- Data Sheet-FIREMIKS-FM-3200-GP-F-Aut 2015-12-09Document3 pagesData Sheet-FIREMIKS-FM-3200-GP-F-Aut 2015-12-09appril26No ratings yet

- Air 2ADocument4 pagesAir 2AMoriyasu NguyenNo ratings yet

- LPHX Serie 4500 SIHIDocument11 pagesLPHX Serie 4500 SIHIJorge FernandezNo ratings yet

- Sihi lphx45000Document12 pagesSihi lphx45000jarivillasNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Reference GuideDocument48 pagesReference Guideshadow_zeNo ratings yet

- Samsung ManualsDocument24 pagesSamsung Manualsshadow_zeNo ratings yet

- Samsung ManualsDocument24 pagesSamsung Manualsshadow_zeNo ratings yet

- Bosancica Fonts PresentDocument30 pagesBosancica Fonts Presentshadow_zeNo ratings yet

- Bosancica Fonts PresentDocument30 pagesBosancica Fonts Presentshadow_zeNo ratings yet

- OP. Reflektori CjenovnikDocument2 pagesOP. Reflektori Cjenovnikshadow_zeNo ratings yet

- Matematika II-Materijal-II-dio - 102858Document16 pagesMatematika II-Materijal-II-dio - 102858shadow_zeNo ratings yet

- PL Food Journal PDFDocument1 pagePL Food Journal PDFshadow_zeNo ratings yet

- Matematika II-Materijal-I Dio - 102858Document40 pagesMatematika II-Materijal-I Dio - 102858shadow_zeNo ratings yet

- RH4 Guidance System User InfoDocument4 pagesRH4 Guidance System User Infoshadow_zeNo ratings yet

- TF April 2014 WebDocument20 pagesTF April 2014 Webjaskaran singhNo ratings yet

- D10RDocument24 pagesD10RAldo Cesar Mina Sosa100% (1)

- Service & Maintenance: 5.3 Maintenance of Cooling SystemDocument3 pagesService & Maintenance: 5.3 Maintenance of Cooling SystemNeeteshNo ratings yet

- LV Mitsubishi TritonDocument6 pagesLV Mitsubishi TritonAdie PranataNo ratings yet

- KC-AA014A Common All BussDocument272 pagesKC-AA014A Common All Busslocario10% (1)

- DGW400DM ANZ Owners Manual 1Document40 pagesDGW400DM ANZ Owners Manual 1Anonymous 4e7GNjzGWNo ratings yet

- 9600232dgdadgdb PDFDocument58 pages9600232dgdadgdb PDFJovanNo ratings yet

- General Characteristics: Power DefinitionDocument6 pagesGeneral Characteristics: Power Definitionaco bracoNo ratings yet

- Cooling SystemDocument61 pagesCooling SystemZalmiers SarterezNo ratings yet

- Heat TransferDocument9 pagesHeat TransferHectorCabzNo ratings yet

- Analysis of Heat Transfer Phenomena From Different Fin Geometries Using CFD Simulation in ANSYS® PDFDocument8 pagesAnalysis of Heat Transfer Phenomena From Different Fin Geometries Using CFD Simulation in ANSYS® PDFAMBUJ GUPTA 17BCM0060No ratings yet

- Module 1Document32 pagesModule 1kat johnsonNo ratings yet

- A Textbook of Automobile Engineering by Navy FerozDocument161 pagesA Textbook of Automobile Engineering by Navy Ferozumesh1374100% (2)

- General Characteristics: DescriptiveDocument5 pagesGeneral Characteristics: DescriptiveJovan KosticNo ratings yet

- New-Operation & Maintenance Manual S16r-Pta (-S)Document116 pagesNew-Operation & Maintenance Manual S16r-Pta (-S)Agus Tego100% (1)

- Diesel 1 - Hoja de Especificaciones - Kta50-G9Document4 pagesDiesel 1 - Hoja de Especificaciones - Kta50-G9Yonny TorradoNo ratings yet

- Atelier CollectionDocument39 pagesAtelier Collectioncristi_stoiciucNo ratings yet

- Test de RadiadorDocument10 pagesTest de RadiadorOmar Reinoso TigreNo ratings yet

- Effect of Nanofluids and Mass Flow Rate of Air On Heat Transfer Rate in Automobile Radiator by CFD AnalysisDocument6 pagesEffect of Nanofluids and Mass Flow Rate of Air On Heat Transfer Rate in Automobile Radiator by CFD AnalysisInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Sebp3815 61 01 All PDFDocument921 pagesSebp3815 61 01 All PDFpedroandres143No ratings yet

- Knowing Your Cooling SystemDocument119 pagesKnowing Your Cooling SystemDaniel Amanor100% (1)

- Engine Cooling Fan Rav 4 2001 2002Document11 pagesEngine Cooling Fan Rav 4 2001 2002mattkidoNo ratings yet

- KoraluxDocument52 pagesKoraluxҮүлэн СолонгоNo ratings yet

- 61.CFD Analysis On Radiator by Nano FluidDocument6 pages61.CFD Analysis On Radiator by Nano Fluidrs rawatNo ratings yet

- Cooling SystemDocument16 pagesCooling SystemWagner BernardinaNo ratings yet

- Nad 5986 DC enDocument3 pagesNad 5986 DC enmnezamiNo ratings yet

- OE Spec MTU12V1600DS730 3D 50Hz 2 14Document5 pagesOE Spec MTU12V1600DS730 3D 50Hz 2 14phuongNo ratings yet

- Claas CROP TIGER 30 Operator's Manual PDFDocument236 pagesClaas CROP TIGER 30 Operator's Manual PDFDmitry83% (6)

- Operation Manual x45Document116 pagesOperation Manual x45acalderon4596100% (1)

- GEP100Document6 pagesGEP100neton1No ratings yet