Professional Documents

Culture Documents

Ecu (Engine Control Unit - DSL) : 5-8 Electrical Wiring Diagrams

Uploaded by

Juan Sebastian Hernandez SolanoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ecu (Engine Control Unit - DSL) : 5-8 Electrical Wiring Diagrams

Uploaded by

Juan Sebastian Hernandez SolanoCopyright:

Available Formats

5-8 1491 Electrical Wiring Diagrams

3. ECU (ENGINE CONTROL UNIT - DSL) 1491

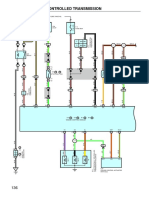

1) ENG MAIN RELAY, PEDAL MODULE, HFM SENSOR, VALVE, CRUISE CONTROL SW

Electrical Wiring Diagram (LHD)

Electrical Wiring Diagrams 1491 5-9

A. CONNECTOR INFORMATION

01

Connector Number Connecting Wiring

(Pin Number, Color) Harness Connector Position Remark

C101 (18Pin, White) W/H Floor - Eng Room Fuse & Relay Box Eng Room Fuse & Relay Box

C102 (4Pin, White) W/H Floor - Eng Room Fuse & Relay Box Eng Room Fuse & Relay Box

02

C106 (20Pin, White) W/H Floor - Eng Room Fuse & Relay Box Eng Room Fuse & Relay Box

C115 (42Pin, Black) W/H Floor - W/H Eng Control Right Eng Room Dash PNL

C202 (39Pin, Black) W/H Main - W/H Floor Driver Cowl Side C/Holder

C206 (39Pin, Black) W/H Main - W/H Floor Upper the Driver Legroom C/Holder 03

C212 (20Pin, L/Green) W/H Main - W/H Floor Passenger Cowl Side C/Holder

C213 (20Pin, Red) W/H Main - W/H Floor Passenger Cowl Side C/Holder

C214 (20Pin, Yellow) W/H Main - W/H Floor Passenger Cowl Side C/Holder

G201 W/H Floor Under the Driver Cowl Side PNL Under C/Holder 04

S302 (14Pin, Black) W/H Main Beside RR LH Seat W/H Protector

B. CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION 05

Electrical Wiring Diagram (LHD)

5-10 1491 Electrical Wiring Diagrams

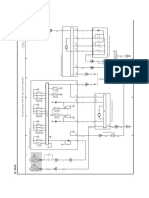

2) FUEL FILTER WARNING LAMP, IMMOBILIZER, SENSOR CIRCUIT (FUEL PRESSURE, CAM SHAFT,

BOOSTER PRESSURE, CRANK SHAFT, KNOCK, COOLANT TEMP., FUEL TEMP.)

Electrical Wiring Diagram (LHD)

Electrical Wiring Diagrams 1491 5-11

A. CONNECTOR INFORMATION

01

Connector Number Connecting Wiring

(Pin Number, Color) Harness Connector Position Remark

C101 (18Pin, White) W/H Floor - Eng Room Fuse & Relay Box Eng Room Fuse & Relay Box

C103 (16Pin, White) W/H Floor - Eng Room Fuse & Relay Box Eng Room Fuse & Relay Box

02

C104 (14Pin, White) W/H Floor - Eng Room Fuse & Relay Box Eng Room Fuse & Relay Box

C106 (20Pin, White) W/H Floor - Eng Room Fuse & Relay Box Eng Room Fuse & Relay Box

C108 (18Pin, White) W/H Eng - Eng Room Fuse & Relay Box Eng Room Fuse & Relay Box

C113 (16Pin, Black) W/H Eng - W/H Floor Inside RH Fender PNL 03

C115 (42Pin, Black) W/H Floor - W/H Eng Control Right Eng Room Dash PNL

C202 (39Pin, Black) W/H Main - W/H Floor Driver Cowl Side C/Holder

C203 (18Pin, White) W/H Main - W/H Floor Driver Cowl Side C/Holder

C206 (39Pin, Black) W/H Main - W/H Floor Upper the Driver Legroom C/Holder 04

C212 (20Pin, L/Green) W/H Main - W/H Floor Passenger Cowl Side C/Holder

G103 W/H Eng Room LH FRT END PNL (LH Head Lamp Side)

G201 W/H Floor Under the Driver Cowl Side PNL Under C/Holder

G207 W/H Main Inner the Passenger Cowl Side PNL 05

S201 (14Pin, Black) W/H Main RH Protector of the Driver Legroom

S205 (14Pin, Black) W/H Main Upper the PTC Protector GND

B. CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION

Electrical Wiring Diagram (LHD)

5-12 1491 Electrical Wiring Diagrams

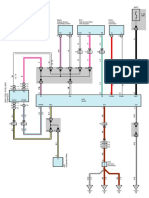

3) INJECTOR, CAN LINE

Electrical Wiring Diagram (LHD)

Electrical Wiring Diagrams 1491 5-13

A. CONNECTOR INFORMATION

01

Connector Number Connecting Wiring

(Pin Number, Color) Harness Connector Position Remark

C103 (16Pin, White) W/H Floor - Eng Room Fuse & Relay Box Eng Room Fuse & Relay Box

C105 (10Pin, White) W/H Floor - Eng Room Fuse & Relay Box Eng Room Fuse & Relay Box .

02

C113 (16Pin, Black) W/H Eng - W/H Floor Inside RH Fender PNL

C115 (42Pin, Black) W/H Floor - W/H Eng Control Right Eng Room Dash PNL

C203 (18Pin, White) W/H Main - W/H Floor Driver Cowl Side C/Holder

C210 (16Pin, White) W/H Main - W/H A/Con Inside the Middle I/P (Right PTC) 03

C212 (20Pin, L/Green) W/H Main - W/H Floor Passenger Cowl Side C/Holder

G205 W/H Main RH Eng ECU ECU

S301 (14Pin, Black) W/H Main Beside Driver Seat W/H Protector CAN

04

B. CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION

05

Electrical Wiring Diagram (LHD)

5-14 1491 Electrical Wiring Diagrams

C. CIRCUIT DESCRIPTION

INPUT SIGNAL OF ECU

According to input signals from various sensors, engine ECU calculates driver’s demand (position of the acceleratorpedal)

and then controls overall operating performance of engine and vehicle on that time. ECU receives signals from sensors

through data line and then performs effective engine air-fuel ratio controls based onthose signals.

Engine speed is measured by crankshaft speed (position) sensor and camshaft speed (position) sensor

determinesinjection order and ECU detects driver’s pedal position (driver’s demand) through electrical signal

that generated byvariable resistance changes in accelerator pedal sensor.

Air flow (hot film) sensor detects intake air volume and then transmits to ECU. Especially, the engine ECU

controls theair-fuel ratio by recognizing instant air volume changes through air flow sensor to pursue low

emission gases (EGR valvecontrol). Furthermore, the ECU uses signals from coolant temperature and air

temperature sensor, booster pressuresensor and atmospheric pressure sensor as compensation signal to

respond to injection start and pilot injection setvalues and to various operations and variables.

CONTROL FUNCTION OF ECU

1. Controls by operating stages:

To make optimum combustion under every operating stage, ECU should calculate proper injection volume

ineach stage by considering various factors.

2. Starting injection volume control:

During initial starting, injecting fuel volume will be calculated by function of temperature and engine

crankingspeed.

Starting injection continues from when the ignition switch is turned to ignition position to till the engine

reachesto allowable minimum speed.

3. Driving mode control:

If the vehicle runs normally, fuel injection volume will be calculated by accelerator pedal travel and engine

rpmand the drive map will be used to match the drivers inputs with optimum engine power.

ECU INPUTS·OUTPUTS

Inputs Control Outputs

Booster pressure sensor

Atmospheric pressure sensor Injector

(Built-in ECU) EGR system

Air flow sensor (HFM) Fuel pressure regulating valve (IMV)

Coolant temperature sensor Electrical fan control (Low/High-speed)

Fuel temperature sensor E A/C compressor relay

Fuel pressure sensor Glow plug relay

Fuel filter water sensor Immobilizer

Knock sensor C Warning lights

crankshaft position sensor (Water warning light, glow plug

camshaft position sensor

Accelerator sensor

U indicator light, engine warning light)

Preheater (auxiliary heater)

Vehicle speed sensor K - line

Switch input signal CAN communication

(IG, brake, clutch, A/C signal, A/C Self-diagnosis

compressor)

Electrical Wiring Diagram (LHD)

Electrical Wiring Diagrams 1491 5-15

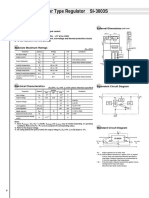

STRUCTURE AND FUNCTION OF ECU

ECU receives and analyzes signals from various sensors and then modifies those signals into permissible

voltage levels and analyzes to control respective actuators. 01

ECU microprocessor calculates injection period and injection timing proper for engine piston speed and crank-

shaft angle based on input data and stored specific map to control the engine power and emission gas.

Output signal of the ECU microprocessor drives pressure control valve to control the rail pressure and activates

injector solenoid valve to control the fuel injection period and injection timing; so controls various actuators

in response to engine changes. Auxiliary function of ECU has adopted to reduce emission gas, improve fuel 02

economy and enhance safety, comforts and conveniences. For example, there are EGR, booster pressure

control, autocruise (export only) and immobilizer and adopted CAN communication to exchange data among

electrical systems (automatic T/M and brake system) in the vehicle fluently. And Scanner can be used to

diagnose vehicle status and defectives.

Operating temperature range of ECU is normally -40 ~ +85°C and protected from factors like oil, water and 03

electromagnetism and there should be no mechanical shocks.

To control the fuel volume precisely under repeated injections, high current should be applied instantly so

there is injector drive circuit in the ECU to generate necessary current during injector drive stages.

Current control circuit divides current applying time (injection time) into full-in-current-phase and hold-cur-

rent-phase and then the injectors should work very correctly under every working condition. 04

05

Electrical Wiring Diagram (LHD)

You might also like

- Nissan Patrol ATDocument15 pagesNissan Patrol ATxgrapherNo ratings yet

- gx160 HondaDocument1 pagegx160 Hondamatt1985200967% (3)

- 4AGEDocument4 pages4AGEAl-Ameen MohammedNo ratings yet

- System CircuitsDocument234 pagesSystem CircuitsEme Elibe Johnson EmestarNo ratings yet

- Ford Escort 1.6l 97-98Document2 pagesFord Escort 1.6l 97-98Miguel ruizNo ratings yet

- Toyota RAV4 SIS/CAS vehicle diagnosis and control unit pin assignmentDocument3 pagesToyota RAV4 SIS/CAS vehicle diagnosis and control unit pin assignmentnicamarcosNo ratings yet

- Zd30 ecu pinouts guideDocument10 pagesZd30 ecu pinouts guideKinaryoNo ratings yet

- Electrical Wiring Diagram: TOYOTA: Hilux Sport RiderDocument60 pagesElectrical Wiring Diagram: TOYOTA: Hilux Sport RiderThiri HlaingNo ratings yet

- Electronically controlled transmission system overviewDocument6 pagesElectronically controlled transmission system overviewOliver leal100% (1)

- Technic Auto Car Engine Control Module Isuzu D-Max (4jj1-Tc) Part 1Document1 pageTechnic Auto Car Engine Control Module Isuzu D-Max (4jj1-Tc) Part 1Miguel Esteban Betancourt CelisNo ratings yet

- Wiring Toyota Rav4 1AZFEDocument1 pageWiring Toyota Rav4 1AZFEAutomotriz HercaNo ratings yet

- 2005 MKV Fuse Diagram - VW Vortex - Volkswagen ForumDocument11 pages2005 MKV Fuse Diagram - VW Vortex - Volkswagen ForumMarco Antonio Ortiz RomeroNo ratings yet

- Honda AbbreviationsDocument5 pagesHonda AbbreviationsCrescentrisingNo ratings yet

- Electrochemi Toyota Land Cruiser Prado 2004 DemoDocument15 pagesElectrochemi Toyota Land Cruiser Prado 2004 DemoVinsensius Agus Priyono100% (1)

- Toyota Fortuner (EM3275E) - Relay LocationsDocument37 pagesToyota Fortuner (EM3275E) - Relay Locationsyudianto sugyty100% (2)

- Diagnosing ABS Solenoid Relay IssuesDocument3 pagesDiagnosing ABS Solenoid Relay IssuesAdasson BravoNo ratings yet

- 5 - 12 Section 5 - Diagnosis J-1 ECM Connector Identification (1 of 2 J-1)Document8 pages5 - 12 Section 5 - Diagnosis J-1 ECM Connector Identification (1 of 2 J-1)MyBriggsNo ratings yet

- 4WD ECU Connector DiagramDocument1 page4WD ECU Connector Diagramcartronix2010No ratings yet

- SM 1Document87 pagesSM 1Gilberto BerdealNo ratings yet

- Daewoo Fault CodesDocument3 pagesDaewoo Fault CodesCatalin MariusNo ratings yet

- CRDB Konnect - Test StrategyDocument31 pagesCRDB Konnect - Test StrategymsvinuNo ratings yet

- EWD of Zace DR077W (VN)Document41 pagesEWD of Zace DR077W (VN)Binh Binh100% (1)

- DTC P0121 Throttle / Pedal Position Sensor / Switch "A" Circuit Range / Performance ProblemDocument2 pagesDTC P0121 Throttle / Pedal Position Sensor / Switch "A" Circuit Range / Performance Problempeter_nicks5441No ratings yet

- Howo Electrical DiagramDocument22 pagesHowo Electrical DiagramTagapag LinawNo ratings yet

- Landcruiser 200 Engine & Transmission CodesDocument9 pagesLandcruiser 200 Engine & Transmission Codesmarran almarranyNo ratings yet

- ECT-Engine Coolant TempDocument4 pagesECT-Engine Coolant TempĐức HòangNo ratings yet

- Power Steering PDFDocument93 pagesPower Steering PDFWaldo Fuentes100% (1)

- Data List/Active Test: DiagnosticsDocument1 pageData List/Active Test: DiagnosticsClodoaldo BiassioNo ratings yet

- Zabbix Starter Week Day 2Document44 pagesZabbix Starter Week Day 2Erik CavalheiroNo ratings yet

- Embedded Software Testing SyllabusDocument5 pagesEmbedded Software Testing Syllabusp chaitanyathejaNo ratings yet

- P5000 (At3502064) 98725-45100 Cat Engine (1) (K21 and K25) (Upto March 2018) Engine Mechanical 102-01 Engine Gasket KitDocument243 pagesP5000 (At3502064) 98725-45100 Cat Engine (1) (K21 and K25) (Upto March 2018) Engine Mechanical 102-01 Engine Gasket Kit2119100146No ratings yet

- Schematy Daewoo Nubira All Models PDFDocument97 pagesSchematy Daewoo Nubira All Models PDF8014000% (1)

- Porsche ECU Pins....Document4 pagesPorsche ECU Pins....José BenavidesNo ratings yet

- F Electrical Wiring Diagram (System Circuits) : LAND CRUISER Station Wagon (EWD342F) LAND CRUISER Station Wagon (EWD342F)Document1 pageF Electrical Wiring Diagram (System Circuits) : LAND CRUISER Station Wagon (EWD342F) LAND CRUISER Station Wagon (EWD342F)وليدمطهر الشجاعNo ratings yet

- Toyota Hilux 2018 Overall EWD Vehicle Exterior Power Window (RHD All Door Jam Protection)Document2 pagesToyota Hilux 2018 Overall EWD Vehicle Exterior Power Window (RHD All Door Jam Protection)gabrielzinho43No ratings yet

- 2006 ls430 Suspension Ecu Terminals PDFDocument4 pages2006 ls430 Suspension Ecu Terminals PDFbob loblawNo ratings yet

- DTC C1267/67 Brake Pedal Load Sensing Switch: DescriptionDocument4 pagesDTC C1267/67 Brake Pedal Load Sensing Switch: DescriptionbakriramziNo ratings yet

- 428L2 PDFDocument13 pages428L2 PDFesquisofNo ratings yet

- Toyota 1nz Trasnsmision AutomaticaDocument3 pagesToyota 1nz Trasnsmision AutomaticaCristhian Cazas100% (2)

- Overall Electrical Wiring DiagramDocument1 pageOverall Electrical Wiring Diagramallaucaamor100% (1)

- 2014 D4CB (A2) Schematic Diagrams Body Electrical System Immobilizer System Schematic DiagramsDocument1 page2014 D4CB (A2) Schematic Diagrams Body Electrical System Immobilizer System Schematic DiagramsMarcioMartinhoFerreiraNo ratings yet

- 27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)Document8 pages27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)autocomtrucksNo ratings yet

- 2gr-Fse Emission Control - Emission Control System - System Diagram PDFDocument4 pages2gr-Fse Emission Control - Emission Control System - System Diagram PDFJohn LockeNo ratings yet

- Hazard Light Circuit DiagramDocument1 pageHazard Light Circuit DiagramariboroNo ratings yet

- Toyota Mil CodeDocument3 pagesToyota Mil CodeinayyerNo ratings yet

- D15/D16/D17/K20 2001-2007 Honda/Acura Connector GuideDocument2 pagesD15/D16/D17/K20 2001-2007 Honda/Acura Connector GuidesurajNo ratings yet

- 50 Hilux (Cont. Next Page) : Power Source Combination Meter (From Jun. 2011 Production)Document4 pages50 Hilux (Cont. Next Page) : Power Source Combination Meter (From Jun. 2011 Production)Ichsan KurniawanNo ratings yet

- ABS and Brake Assist Systems DiagramDocument12 pagesABS and Brake Assist Systems DiagramAlbert BriceñoNo ratings yet

- 4 Toyota Fortuner (Cont. Next Page) : Power SourceDocument4 pages4 Toyota Fortuner (Cont. Next Page) : Power Sourcealexander pinto100% (1)

- Toyota Mark X 2006Document19 pagesToyota Mark X 2006Rodrigo Mogro100% (1)

- VW Polo 1.4D Year 2003 9N1 Car Computer Network Got Crazy Repair ManualDocument10 pagesVW Polo 1.4D Year 2003 9N1 Car Computer Network Got Crazy Repair ManualLucio OliveiraNo ratings yet

- DLC3 01 01Document1 pageDLC3 01 01kaka100% (1)

- Suzuki ECC 3-Speed Electronic ControlsDocument18 pagesSuzuki ECC 3-Speed Electronic ControlsJose PichinteNo ratings yet

- SK 3003 SDocument2 pagesSK 3003 SAhmad MahrojiNo ratings yet

- BSD104DV H3axDocument21 pagesBSD104DV H3axTiborNo ratings yet

- d2fee44ce3373b7c092a008235dbd2f5Document153 pagesd2fee44ce3373b7c092a008235dbd2f5Ovvc100% (2)

- Data List For Active TestDocument5 pagesData List For Active Testjeremih alhegnNo ratings yet

- Common Connector List: Back To Chapter IndexDocument1 pageCommon Connector List: Back To Chapter Indexstaff055No ratings yet

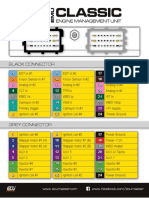

- EMU Classic PinoutDocument2 pagesEMU Classic PinoutTeerajet ChumrunworakiatNo ratings yet

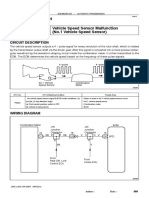

- Ci P0500Document2 pagesCi P0500David BenazeraNo ratings yet

- Diagnosis With Blink Code - Edc7 - 2002 - 01Document10 pagesDiagnosis With Blink Code - Edc7 - 2002 - 01Jason KozminskaNo ratings yet

- Peugeot Engine Management Fault CodesDocument1 pagePeugeot Engine Management Fault CodesIoan NovacNo ratings yet

- 1.4 l/55 KW - 4AV, Engine Codes AHW, AKQ: Current Flow DiagramDocument9 pages1.4 l/55 KW - 4AV, Engine Codes AHW, AKQ: Current Flow DiagramSaul CalderónNo ratings yet

- Electrical Wiring Diagram GuideDocument6 pagesElectrical Wiring Diagram GuideNajuwa AbrahamsNo ratings yet

- EWD ActyonC0104004 PDFDocument6 pagesEWD ActyonC0104004 PDFAnderson BombistaNo ratings yet

- Disturbance vs. Setpoint ControllersDocument5 pagesDisturbance vs. Setpoint ControllersravaraeNo ratings yet

- Cause and Effect - Ig541 System at Pre-Treatment BuildingDocument2 pagesCause and Effect - Ig541 System at Pre-Treatment BuildingWaseem SiddiqueNo ratings yet

- Classification of Adaptive Control TechniquesDocument3 pagesClassification of Adaptive Control TechniquesLOKESHWARAN K CHEM-UG- 2017 BATCHNo ratings yet

- Boosted Gasoline Engine Concept For BS VI and Beyond: Presented at GT India Conference 2019Document24 pagesBoosted Gasoline Engine Concept For BS VI and Beyond: Presented at GT India Conference 2019Santosh TrimbakeNo ratings yet

- PosixDocument20 pagesPosixadeel akramNo ratings yet

- LAB Ecomm 2023Document12 pagesLAB Ecomm 2023omar.khotabiNo ratings yet

- How To Make An ExtensionDocument3 pagesHow To Make An Extensionاميرة TVNo ratings yet

- Managed Detection & Response Service OverviewDocument77 pagesManaged Detection & Response Service OverviewJoker ViperNo ratings yet

- Honda Passport 2000, Check Engine Light Flashing. Manual Says Its An Indication of A Misfire. Just Rebuilt The Engine.Document12 pagesHonda Passport 2000, Check Engine Light Flashing. Manual Says Its An Indication of A Misfire. Just Rebuilt The Engine.ikperha jomafuvweNo ratings yet

- JSA PSV Recalibration 2006Document3 pagesJSA PSV Recalibration 2006Iksan Adityo MulyoNo ratings yet

- Traka Key ManagementDocument8 pagesTraka Key ManagementSamastha Nair SamajamNo ratings yet

- Security/Hacking: 2 Short CoursesDocument1 pageSecurity/Hacking: 2 Short Coursesabdel_lakNo ratings yet

- 3rd Title Project Proposal OCRS of Woliso CityDocument17 pages3rd Title Project Proposal OCRS of Woliso CityTolosa TafeseNo ratings yet

- System Analysis QuestionnsDocument8 pagesSystem Analysis QuestionnsAnupam GyawaliNo ratings yet

- Object Oriented SEDocument73 pagesObject Oriented SEBibhuti boraNo ratings yet

- Introduction to Lean Manufacturing PrinciplesDocument16 pagesIntroduction to Lean Manufacturing PrinciplesTaucean IlieNo ratings yet

- Split Cycle EnginesDocument28 pagesSplit Cycle Enginesthy7rexNo ratings yet

- Certified Automation Engineer (CAE) : SyllabusDocument4 pagesCertified Automation Engineer (CAE) : SyllabusSMEClabsNo ratings yet

- Thesis On Java ProgrammingDocument4 pagesThesis On Java Programmingfj8e4mc7100% (2)

- ISO 27k Framework Secures Information SystemsDocument5 pagesISO 27k Framework Secures Information SystemsRandyGallegosJr.No ratings yet

- FILE 20220714 232825 ASM2 1644 NguyenMinhNghia GCC200100Document35 pagesFILE 20220714 232825 ASM2 1644 NguyenMinhNghia GCC200100(FGW CT) Hoàng Minh TânNo ratings yet

- 8 Ways Monitor Measure Marine Engine PerformanceDocument3 pages8 Ways Monitor Measure Marine Engine PerformanceDwein Ocampo AguilarNo ratings yet

- Ankit PYTHON LABDocument17 pagesAnkit PYTHON LABMic CavNo ratings yet

- Carnegie Mellon University Practical Software Engineering Series Introduction To Software Engineering Homework Assignment 2 ObjectiveDocument2 pagesCarnegie Mellon University Practical Software Engineering Series Introduction To Software Engineering Homework Assignment 2 ObjectiveTruc PhanNo ratings yet

- Modern System Analysis and Design Chapter 7 DFD GuideDocument39 pagesModern System Analysis and Design Chapter 7 DFD GuideIlham J.ENo ratings yet