Professional Documents

Culture Documents

Tender No. PLT-20-001

Tender No. PLT-20-001

Uploaded by

Mohammed Shoaib0 ratings0% found this document useful (0 votes)

23 views28 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views28 pagesTender No. PLT-20-001

Tender No. PLT-20-001

Uploaded by

Mohammed ShoaibCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 28

HEAVY MECHANICAL COMPLEX

Government Of Pakistan

bail C7

TENDER ENQUIRY

Iwo. PLT-20-001 Joate 08-01-2020

loue on : 22-01-2020

Please eure to Wale YOU Ofer ls

‘Schadule. in cage of shortage of space, you

‘may use your letiarbesd bul this ectedul is

1 be returned duly ila in& signe.

| Weta yur sealed td on FOR FO Tada or Frew Detvery, HMC, Taxa base for he suptly of folowng stor (6) resey

[| seeuedegto heforma epee blow. Ed mus rach Purchase Dewey 1400 repens publ 1eSONerS eas

Manufacturing, Supply, Installation, Erection, Commi

FOR Delivery of Transformers & other Spare Parts

As er specifications & other details attached es Annexure-A( Pages 1/5 ~5/5)

ning,

|General Site Con:

ions are attached as Annexure-8 (Pages 1122 - 22/22)

- Transportation charges upto Jagran-il Hydel Power Project Site-Distric

Muzaffarabad-AJK:

|. Complate Erection Install

ionlCommissioning charges:

Notes:

1- Validity: The offer validity should not be less than 50 days.

2- The supplier may quote for Transformer, Accesscries, Consumables &

[spares for Main Step-Up Transformers at Serial 1.1 of Annexure-A & Station

| Supply Transformers at Serial No, 1.2, 1.3 & 1.4 with relevant Accessories,

[Consumebles & spares separately or in one package

3- The supplier wil be responsible for complete Erection/ Installation’

Commissioning of quated Package(s)

[4 Only Local Authorized Manufacturer with complete manutactiring set up

can participate in Tencer

5- Supply reference list with acceptance & successful Commissioning

(Ceitifcate of suppied/instaled Transformers must be attached with quotation.

'7- 2% Bid securty is essential to be submitted with Quotation.

|& Quantity can te increased, decreased or deleted alter Tender cpeninig

required.

Fox and othr Gov. levies pease reed cause 7 (2) of Terms and Cendtions, overeal

Terme of Datwory: FOTIFOR Tania -Proe Detvery NG Tal

Your eff No.2 date Vales upto

{ pe

‘Aetna Requirements —— SSS Ee

1 TECLANATION

sue 8 We cory tat we naveread ne terms and condtions of the

tender enquty overleaf and he sara are ful accent to

is. We ther agree to prevce prormance bon. irequted

Siraue'

ve

03" ° Ful Nome,

baad Prose Departnert

Heavy Mehul Cones, Tax, Soa ote Fen

‘Tenia 47080 Patieian Phones: (+0263) 9270563 (@ Lines), (79291) SUTA16H)

Fax (202.5) #314260, 102-51) 8914229

Email: imcenga@hme.compk, marketing@hme-com.pk, procarementimc@gmalicom & sem@he.con. pk

‘We Ste itp me hne.com.pk

a

1

iL

1a

au

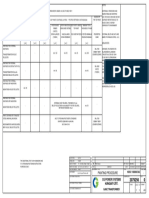

S.No,

~Folect 148 Mur IAGGRAN I Hydro Power Project

projCode: 811701

SS.COpE : Supply , Manufacturing, Installation, Erection , commissior

delivery to Project site of the following items

Description

Transformers

‘Main step-up trnaformers (Single Phase) 11/132KV, 4OMVA,

\ ONAF, Voltage control -On-Load tap

Glhanger (+1 242.5% Range) MK, HV and LV oushing

otection and cartel devices

1. AuRiiry Panels for 10 MA Transformers

‘Stetion supnly wanstonmers 11704KV, BOOKY

[contre devees

tntane Aucvay transformer (at wor Site) 110 44V. 200KVA, CNAN, DY tJ, MK HV and WV bushing,

Protection ane contol devices

{Transtomer fr wlage supoly 11/44, 8308VA, ONAN, OYA 1, Nx, HV anc LV Bushing, Potacion

jad centol devices

z

Transformer Tools, Accessorive £ Conoumables and Spare Parts

[Tools and Application accossories

1

[Oi] Rurfrog uritisluding Oil storage tant, fitraton machina (2000 Liter, vacuum purr. pipes,

valves and recossary pressure guages and adaoters)

Bushing ofeach tne used complate vith gastole and accnesorion

“ANNEX:

s

oA

20-Dec-19

Qty.

ano.

|

[Comte tiree-ohate tes of elampe

{A fallout oftecls end seeeiaitoote, for assemtiing and dismanting the transformers with

ve Dare forthe tap changer {On-Loag)

[2+ Special Tons Icading Torgua Wrench, Soca vrench

3. Liting Sing for Tan Changer

11 on) engi of acigpa

13,Memratinoge Tan desc A ep roar conga wi ecco

210 |Contact ype thamometers ci each wpe

231 [Ot eve gauges of heaton 2o.

[F02% inweunna wae quan sone lice i dohyaatng wahow Wed WUS '

24? ransfomers. _ zm

aay [Eonar Seater ge Pe aa Bea ny IG Tame

Iconet euneni nites sas temo

Trensterer a inacaion othe oe amount ocued wtve voroomue 200

215 [Gauge glasses of eech type used. 2 Nos.

216 [es jar scat ornbers “Nos

27 [Bopha rth xposon vers tappnabe anos

2:2 | Sonventontenpertueatactrs or laa ofeach ype wees, cnpous van ccnores 2 Nos

ia [Vanes ot ech oped Des

>

: 2

wre

Powe

1-76

partie:

|

Suter 10%

2.44 [Set of sonware programs forthe contol unk for Power Tralonne

r 4 Pdlect aan iacanan -1 hydro Power Project ANNEX-A + |

Proj Code:811701

“Scope :Supply, Manufacturing, installation , Erection, commissioning & ‘

delivery to Project site of the following Item: 20088

anh en eae

nel Description ay.

‘2a Other spare parts.consumables.test instruments & maintenance ‘equipment as per manufacturer -

20 Grandad ecansumebies teat insrmen ee tor

1 No.

2 > Buterty Valves

‘9 ~ Special Tacs for Transformer Irstalltion

1,

— oat : Me

2.2, Maintenance accessories, including test rigs. exender arse, teat cables, stionustors ele Hot,

[2 [eerste ae of any specter cute maintenancs and adcnent the supaied equipment, Let.

1Set

| Notes

‘ai jdder shail provide the followings with supply

1 The sure ef epere pets shal te cakulted considering a perodoftive yeas of normal peralion af he power

ransiorers, Th supply shall cons ofa east bit nl teailed to

i 2 jim Annid. On ator the approval of rawings /decumets the sar con -

jan fs — Als a

3._All ranstomers wih thar accessoine mvs be eutable or aie, abet and atc cantons 1660 m ASL

4 Basic parame of Main Transformer -¢ dimensions! Oi sapaiy or others 30 thet design of Oi ok cud cary oxt

§5 Silver to cont toprovide alongwith the oe aleisive krargonen: Oring wasp mouneng Getais Ga, weigh

|

|

|

for elvsecrartal won st |

{Manso qu ts mentoring wih mansacuar Prod Gove wi uote vena

peesenes ees _

7 [Tranaporatonot at step up and step down transformers to site.

[Bidcler mist hive experience of suppy & vetataton unto ‘commissioring the stich type of pojects in Hycko Power Plants

3 with eclid references with name of customers ‘description

{Scubrredspind seid be ‘tc aang tom anv naar wari Waly SOBd Wed WBA! Te

uring nection italatin/commaionng soe Baer shalbeessomule br lscenea eee tae

|. Soempuy come tse rat oar maar ey wasn esos! sna fon |

[the cate of commasioning

}

z

ALE Pap als

Pow

Lu fol- 17

Project : 48 MW JAGGRAN - Il HYDROPOWER PROJECT

Subject : Scope of supply & Technical Requirement

Proj Gode:8 14704

4. POWER TRANSFORMERS +=+07 Nos.

Single Ph. 11/132kV, 10MVA, ONAF, Voltage control - On-Lead tap Changer (+/- 2x2.5% Range)

With all requirement as per Specs of Annex-B -

4.2. Accessories - All accessories as méntioned in section 1.2 of Annex-8

1.3 Insulation - Dearated / Adapted design required for an installation height of 1600 Mtr

1.4 Connection - ary-type three core XLPE cable with plug-in MV terminale.

4.5 Tramsport- Ail transformers ( power + distribuion) shall be Guivered at site.

1.6 installation & Its Accessories — As per Specs of Annex-B

1.7 Technical Recommendations and Standards

‘Standards of listed items shall be applicable as per Annex-B :

- Power Transformers - | EC 60076

- Power Transformer Auyiliaries - IEC Standards.

- Voltage Controllers - 1 recommendations 60244 end 60244-2

+ iinsulaung Mineral Oil - iE recommendations 60296.

= Steel Core Platas - Latest versions of applicable IEC Standards.

+ Bushings - Latest versions of applicable IEC Standards.

- Noise Level -IEC Recommendations 60076-10 (2016) and 61672-1/ 61672-2.

1.74 Construction Transformer Tank

Elecirically welded, manholes, oolted covers, flanged joints, Jacking pads, pressure relief device,

drain valve and othe: requirements as per Annex-B.

1.7.2 Transformer Cores

shall be in accordance with IEC standards as mentioned in Annex.B

1.7.3, Windings

All MV and LV windings fully insulated. Effects of short circult under conditions as specifies in IEC

60076-5, Power Transformers.

1.7.4 Voltage Regulation

ON-oad Tap change . Other requirements as per Specs of Annex-B

1.7.5 Bushings

Creepage distance mm / KV based on plant location. Material may be OIL PAPER capacitor

and shall be possible to replace the bushings without lifting or dismantting the transformer cover.

Other requirements shall be as per Specs of Annex-B.

1.7.6 Gontrol and Monitoring

MCBs and all auxiliary devices shall be in marshaling kiosk. Control equipments shail be fited with

110 V DC throw-over switches. Other requirements shall be as per Specs of Annex-B

1.7.7 Gas-operated Relays

02 contacts shall be for alarm Temp & level, and 02 for tripping Temp & over pressure

1.7.8 Cooling Systom

Transformer shall be of ONAF system. Pipe systems & radiators shall be perfect airfoil tight (hot

oil). Other requirements shall be as per Specs of Annex-B

2 Page 1 of 3

Page 3157

Pile -07

1.7.9 Rating Plates

All the plates shall be approved by the Client before manufacturing and installation Other

requirements shall be as Per'SHRSS ot Antisied.

1.7.49 Valves - Each transformer shall be with valves for +=

Tank draining, oll sampling, at tank bottom fier press connections (upper and lower), isolating each

Cooling unit, draining each cooling unit, air venting of tank coolers, isolating conservator from

transformer and so forth. Other requirements shall be as per Specs of Annex-B

4.8 Guarantees

The equipment shall be designed according to the loading guide IEC 60076-7 (Latest version

2018). Other requirements shall be as per Specs of Annex-B

1.9 Ternperatures rises

cd by IEC €0076-7

4.10 Marshalling Kiosk

shall house tho local Temp Indicators & the control gear for Cooler Control. I PS5 or better, Al!

Other requirements & Scope shall bo as per Specs of Annex-B

4.11 Shipment

Each transformer when prepared for shipment shall be fitied with IMPACT RECORDER to measure

and record the shocks / jerks during jeurney, also shail remain in situation until the transformer is

GeiWere ‘lig. Giher req: n

4.42 Transformer Oil

First filing of all insulating olls required for operation. Other requirements shall be as per Specs of

Annex-B

4.43 Oi Treatment Plant

Cil treatment, including equipment such as oil fitretion machine, pumps, vacuum pump and

Pressure gauges. Other requirements shall be as. per Specs of Annex-8

2 Documentation:

Documentation & drawings as listed in Annex-B shall be submitted for approval before the

manufacturing the Transformers. Only after the approval of the drawings Manufacturing & the FAT can

be conducted.

3 Tests & Inspection (Must be in accordance with applicable IEC standards)

Specific & Routine tests & measurements as menticned in Annex-B of this section will be performed

on each transformer at the factory.

4 STATION AUXILIARY TRANSFORMERS

4.2.1 Station Supply Transformers -----------+.-+05 o++se00+02Nos,

3Phase , 110.4kV, 800kVA, ONAN, DYnt 1, with all requirement as per Specs of Annex-B

Village Supply Transformer -- - +==01No.

3-Phase, 11/0.4KV, 630KVA, ONAN, DYN11, with all requirement as per Specs of Annex-B

4.2.2 Intake Supply Transformer - 01No

3-Phase, 11/0.4kV, 200KVA, ONAN, DYn11, with all requirement as per Specs of Annex-B

4.2.3 Accessories

In adeition to other protection relays, each transformer shall be supplied with a protection relay

with 2 contacts for temperature and oil level alarm and 2 contacts for temperature and oll over

pressure tripping.

5 INSTRUMENT TRANSFORMERS

@ Current and voltage transformers. all requirement as per Specs of Annex-B

Spov of Annex3

ner 30 as por Specs of Annex’

ets . SU Te) - nie

6 STANDARDS AND ENVIRONMENTAL CONDITIONS

61 Standards

3. Design and manufacture of all electrical equipment shall comply with relevant standard /

Dumber of the IEC Recommendations, particularly the electrical equipments as listed in Annex-B,

b. In case an IEC Regulation does not exist or cover the scope of supply, National Standards,

at least equivalent to ANSI and / or IEEE Standards shall be appied

© 01 Nos set (official complete, unebridged & in English language) of all relevant standarcie

' specications according to which the equipment is manufactured shall be provided

6.2 Standard Voltages

a. Rated values & requirements for high and low voltages shall be applied as per Annex-B.

7 Prevtection of Transformore

i. Both inside and outside of metallic parts shall be corrosion protected.

il Exterior surfaces shall be protected with one coat of chromates of zinc primer and two coat of

glycerolphtalic paint.

i Interior surfaces shall be protected with chromate of zine primer or equivalent, Bolts and screws

Shall be olectrotytic zinc and biechromate coated. Washers shall be oither in tinned bronze or

stainless steel,

uhor ye

adopted accordingly as per standards.

ous uf puiniingvayers snail Le

7.1. Inspection Before Shipments - Requirement of inspection shall be as defined in Annox-B

7.2 Shipment

Zhe Bieler shall take all reasonable precautions to ensure that the protective cealings are not

Gamaged during handling in the factory, during transport or during erection. in particular. he chal

ensure thal no damage Is caused through the use of inappropriate packing systems,

In the event of damage, the Bidder shall make good the existing protective coatings using the same

Products and under the same conditions of applications.

8 GENERAL REQUIREMENTS

8.1 Equipment

Requir of ali accessories mestioned in the section of Annes-5 sivaii be the same. And work

shall be as per requirements of IEG Standards

8.2 Other requirements:

Manuals, Drawings, Documents, Test Schedule, Tools, Soft / Hard Copies and other requirement

shall be same as montioned in Annex-B.

9 Tools , Spare Parts , Accessories & Consumables

Mentioned in ANNEX-A item No-2

Page 3 of 3

SU ol 1

481 WJAGGRAN II HYDRO POWER PROJECT

TECH NICAL SPECIFICATIONS POWER TRANSFORMER ANNEX 2B —

General Site Conditions

Ambient Temp Maximum 45°C

Ambient Temp Minimum - 5°

Altitude 1600 m ASL

1 POWER TRANSFORMERS

14 General

The works include the design, supply, supervision and factory testing of 07 Nos. single

phase step-up transformers of 11/132/V3 kV, 10MVA & shall mest the generator output

ents ambient u

oat a

bank for a Wye-Delta connection.

Bidder stall provide all information's with guideline drawings / instruction manuals for

rector

12 ' Scope of Supply

1.2.1 Main Transformers

Six (6) power transformers, single phase type, have to be provided and shall be

supplied for the connection with 11 KV bus-bars, and shall be located outside the

Power plant in the switchyard as per the drawing. One (1) power transformer shell be

‘supplied as spare.

1.2.2 General Characteristics

Type: Single phase, step-up. Oil Filled

Installation: Outdoor, roller mounted

Duty: Continuous

Dielectric; Mineral oil conforming to IEC 60296

Nominal frequency: 50 Hz

Rated nominal power at 1600m above sea level: 10 MVA,

Page 1 of 22

i

SS

Ss

ne) MIob 1H,

Nes

48 M1 WV JAGGRAN II HYDRO POWER PROJECT

TECH NICAL SPECIFICATIONS POWER TRANSFORME Rage ANNEX - 8 .

Rated high voltage: 132 kV

Connection: As per Clause 1.4 on Page 3 of 25

Voltage control: On-load, tap changer 192/V3 (+2,-

2)2.5%

Impedance: 10% (Approx)

Cooling: ONAF ~ The indicated climatic condition up

to 45°C as well as the decreased cooling

capacity at 1660m ASL

Connection: Ynd 11

The neutral of the transformers shall be solidly earthed.

NOTEs :-

1- Bidder to take into account Grid short circuit levels as per WAPDA standards

2. Bidaer to aiso indicate the transtorniers overivading capabilities.

1.2.3 Bidder to ensure that each transformer shall be equipped with at east the

following accessories :-

> Oil conservator with level gauge

~ Dehydrating breather with silica get

- Bucholz relay

- Resistance-type temperature detectors for oil and winding temperatures

- Contact thermometers for ail and winding temperatures

~ Aladder with protective cage for access to top of the transformer

~ Jacking system

> Surge arresters

- Bushings

- Transformer bushing CT's

- Oil sampling valve

~ Pressure relief device

- Fall protection on top (safety)

- Name plates mentioning with complete detail

- Set of Isolating valves between tank and cooling 1 Set

- lifting lugs. 4 Nos

= Pulling eyes and jacking pads. 4 Nos

- _ Earthing terminals. 2 Nos

Page 2 of 22

=

Serres ff

age eet

4g 4 WJAGGRAN IIHYDRO POWER PROJECT

TécH NICAL SPECIFICATIONS POWER TRANSFORMER ANNEX - 8

~ _ Ughtning Arresters on 132 KV side with Power Transformers, 01 No for each.

- 1 (one) relay with 2 contacts for alarm temperature and oil level and

2.Nos contacts for trip- ping temperature and overpressure. 1 Set

- Flanged type wheels for cross-wise travel of the transformer. 4 Nos

= Free thermometer pocket. 1. Nos

- Schematic diagram plate 1 Nos

= Setof terminals of each type 1 set

- HY Bushing fo si former 1 Set

- _ MVSide connection with 2 Plug-in Cable connectors For Each

Transformer

1.3. Insulation

Primary — Secondary

Nominal system voltage {kV} u 132"

Highest voltage for equipment (kV) 15 145

Rated power frequoncy curation withstand 50 275

Min volt (1min, kv rms)

Rated lightning imputse withstand

voltage (KV peak) 110 650

Ocarated / Adapted design required for an installation height of 1600 Mtz

NOTE:

Insulation Values may change as per manufacturer standard / design for the

altitude as mentioned above

44 Connection

‘The 132kV main power transformers are to be installed outside power house. Fire

resistant walls shall be placed on each side of the transformers.

On the 11 KV side, the connection with the 11 kV phase cubicles of the generator shall

be made by means of dry-type three core XLPE cable with plug-in MV terminals.

4.5 Transport

‘The main power transformers shall be transported to the Site pressurized with nitrogen

and the Bidder shall be responsible for ensuring that the nitrogen pressure is

‘maintained within the limits stated by the manufacturer. Each transformer shall be

Page3 of 22

48 V1W JAGGRAN II HYDRO POWER PROJECT

STO —Y

: —_ae

TECH FEAL SPECIFICATIONS POWER TRANSFORMER ANNEX -B

1.6

unloaded from the road transporter and mounted on the rails for transfer to the

transformer bay for erection by the Bidder.

Installation

Each transformer shall be lowered on to anti-vibretion pads and secured 19

Prevent movement’ under the earthquake conditions. The Bidder shall provide the

pulling apparatus and other apparatus such as spacial erection tools and jacks.

The transformer shall be designed, delivered and erecied with ali the tools

accessories and associated services required until the scheme is put into industrial

operation, such as: sufficient oil for the first filing, the electrical control cabinet, the

rollers, primary and secondary voltage bushings and lugs for lifting and handling.

The following moving and handling facilities shall be provided for each transformer:

Four (4) jack siti

oil by means of hydraulic jacks.

Lugs for lifting the complete transformer.

Pulling eyes for moving the transformers in any direction.

Minimum four (4) bi-directional wheels, as required by the maximum permissible point

toad. The individual wheel positions shall be marked clearly on the carrisge.

‘One (1) tank cover access ladder.

The scope of supply shall include all material required for fixing of the transformers

in their service position. Ralls shall be provided up to the related roads to ellow easy

un- loading, loading and movement.

luge te enable raisin

Technical Recommendations and Standards

The late of the followin

the design, manufacture, testing and erect

Power Transformers

ahail be followed

ransformers,

Intemational Electrotechnical Commission (IEC) Recommendation 60076:

Part-4 - General

Part 2 - Temperature rise

Part 3 - Insulating level and dielectric tests

Part 4 - Tappings and Connections

Part § * Ability to withstand short circuit

Power Transformer Auxiliaries

Page 4 of 22

Gute! WI

48/1 WJAGGRAN 11 HYDRO POWER PROJECT

TECH NICAL SPECIFICATIONS POWER TRANSFORMER ANNEX -B

17.4

required t

Latest versions of applicable IEC Standards.

Voltage Controllers

IEC recommendations 60214 and 60214-2

Insulating Mineral Oil

IEG recommendations 60296.

Sieet Core Plates

Latest versions of applicable IEC Standards.

Bushings

Latest versions of applicable IEC Standards.

Noise Level

IEC Race

Construction Transformer Tank

‘The transformer tanks shall be the classical type and electrically welded. The tank

shall be constructed of heavy mild siesi plates and shall withstand filling with oil at full

vacuum without permanent distortion. All seams or joints other than those which may

have to be broken shall be welded both inside and outside to assure strong leak-proof

joints.

Heavy structural steel members shall be welded to the bottom of the tank to form a

rigid under-supporting base.

Suitable dimensioned manholes, with bolted covers, shall be provided wherever

afford easy access to the lower ends of the bushings, terminals, ete. All

fianged joints shell be provided with gaskets, preferably set in grooves or hald in

Position by stops to prevent over compression of the gaskets. Pulling eyes shall be

provided so as to allow for the attachment of a pulling tig and moving the transiormer

horizontally on wheels or rollers in either direction.

Jacking pads shall be available at convenient locations on the transformer tanks to

allow the jacking of the completely filled transformer, The same set of jacks shall be

used for all the main transformers.

The tansformer tank shall be equipped with the necessary quantity of lifing lugs to

permit lifting of the assembled, completely fillod transformer, as well as the

sore/winding assembly.

Each transformer tank shall have at least two earthing terminals of adequate

Page 5 of 22

2

=

. Wein,

43,4 W JAGGRAN 1 HYDRO Power PROJECT

Te¢H NICAL SPECIFICATIONS POWER TRANSFORMER ANNEX - 8

dimensions. These shall be welded near the tank bottom, at opposite sides,

'n order to prevent tank deformations during operation, a pressure relief device of

Sufficient size shall be provided for rapid release of any pressure that might be

Senerated within the tank, and which might result in damage to the equipment. The ‘

Gevice shall operate at a static pressure of less than the hydraulic test pressure of

the tank, Means shail be provided to prevent the ingress of rain or dust. Exhausting

Ol shall be directed downwards into the transformer's ol collecting pit. A drain valve

at the lowest point of the transformer tank shail be provided.

As required the tank shall be provided with suitable flanges or other approved means

for connection of the sealed cable end boxes

17.2 Transformer Cores

Transformer cores shall be made from extra-high quality high-flux steel sheeting

Adin: lous ere lose. in aocatden-= +

Adequate and carefully connocted copper earth conductors shall link all parts of the

core to an earth terminal.

The core, framework, clamping arrangements and generel structure of the

wransformers shall be of robust design, capable of withstanding ny shock to which

they may be subject during transpon., installation or service.

1.7.3 Windings

Transformer windings shall be of high conductivity electrolytic copper. All due

Precautions shall be taken to ensure that the windings are assembled tight against

the core so that winding movement does not compromise shortcircuit resistance

they shall be tightly secured and efficiently connected to their bushings to avoid

Short-ctroult displacement. a i

insulation of windings and connections shall be free from insulation compositions

likely to soften, shrink or to collapse during service. None of the materials used shall

shrink, disintegrate, carbonize or become brittle under the action of hot oil at any load

condition.

The transformers shall be designed and constructed to withstand, without damage or

mechanicel movement, the effects of extemal short circuit under the conditions as

Specified in IEC 60076-5, Power Transformers.

be f

1.7.4 Voltage Regulation

On-load Tap changer Head shall consist of Head Flange, Head Cover, Head Worm

Gear Pair, Blasting Cap, oil Chamber View window, Oil Overflow Vent Screw and

Page 6 of 22

=

43 1 WJAGGRAN IIHYORO POWER PROJECT

TECHNICAL SPECIFICATIONS POWER TRANSFORMER ANNEX - B

ete,

17-5 Bushings

‘The HV bushings shall be suitable for interface between the transformer and nude

Conductor. On the LV-side, cables shall be connected. Final design details shall be

elaborated by the Bidder at a later stage, and be subject to approval by the Client.

The transformer bushings shall withstand accidental arcing or flashover without

damage te seats of other vital parts. Sultahie connecting aiamps shall he =

absorb shocks due to vibration of the connecting jumpers. The bushings shail be

able to withstand internal vacuum in the transformer tank.

Bushings shall be free from defects and thoroughly vitrified, The glaze shall not form a

dependence factor from insulation and shall be of uniform shade of brown, covering

completely all exposed parts of the insulator.

The sutton. 7

dust or rapid changes in air temperature. The creepage distance shall be 60%

increase compared with those normally suitable for the appropriate nominal voltage

and insulation strength

Sidder to assume creepage distance mm/KV based on plant location at Jagran

Valley , AJK.

Also to find poilution ciass of jagran-ll for suitable vaiue of creepage distance.

Bushings shall be erranged to facilitate easy access for mounting and dismounting

Built-in current transformers nave to be provided the bushings shall be arranged to

permit their removal without interfering with the pertinent current transformer, A

transformer bushing current transformer is mounted below the bushing and is rot

integrated in it.

Sushings material may be OIL PAPER capacitor and shall be designed to

withstand stresses resulting from their weight and from electro-dynamis and

mechanical conductor loads caused by short-circuit. It shall be possible to replace the

bushings without lifting or dismantling the transformer covor.

1.7.6 Control and Monitoring

‘The oloctrical and / or mechanical control and monitoring equipment shall be complete

in every respect, the associated equipment including contactors MCB and all auxiliary

de- vices shall be accommodated in the marshaling kiosk as specified,

Control equipment shall be fitted with 110 V DC throw-over switches.

1.7.7 Gas-operated Relays

Page 7 of 22

48M WJAGGRAN II HYDRO POWER PROJECT

TECH NICAL SPECIFICATIONS POWER TRANSFORMER ANNEX - B

17.8

17.9

A relay shall be installed to protect the transformer. In a transformer liquid

dielectric, an internal incident always creates a more or less important release of gas

Gue to the decomposition of insulating oil under the action of heat and electric arc

The first function of the system shall be to detect this gas. The sysiem shall also

indicate accidental fall of dielectric level. The system shall indicate all excessive

Pressure which might hap- pen inside the tank. Increase of temperature of the

ric shall bo alse indicated.

Two contacts shall be provided for alarm temperature and level, and two contacts

for tripping temperature and over pressure.

Cooling System

stem),

performance of air)

The heat exchangers shall be connected to the top and bottom of the tank, with

Provision made for connection from either side of the tank. Suitable valves shail be

‘mounted directly on the tank for closure of lines on each side when the other side is

connected,

Pipe systems and racistors shail be perfectly airfoil fight (hot cil)

3

3

oS

s

3

8

g

ee

s

g

2

3

3

€

a

2.

=

6

g

&

o

2

eS

ee

Rating Plates

Stainless steel plates with engraved data shall be provided on each transformer, as

follows:

1) Arraling plate oearing the data specified in IEC 60076, Part 1. This plate shall

also include @ space for the Employer's serial number.

2) A diagram plate showing in an approved manner, the intemal connections and

the voltage vector relationship of the windings, in accordance with IEC 60076.

Part 1, with tho transformer voltege ratio for each tap and, in addition, a plan

view of the transformer giving the correct physical relationship of the terminals.

3) Valve location plate drawing, showing the location and function of all valves and

air release plugs. This plate shall also warn operators to refer to the

maintenance instructions before applying the vacuum,

All the plates shall be approved by the Client before manufacturing and installation.

Cc) Pages of 22

D

er.

48 1 W JAGGRAN HYDRO POWER PROJECT -

TecHt ICAL SPECIFICATIONS POWER TRANSFORMER ANNEX - B

18

19

1.1.10 Valves

Each transformer shall be equipped with the required number of valves for:

Tank draining, oll sampling at tank bottom filter press connections (upper and lower),

isolating each cooling unit, draining each cooling unit, air venting of tank coolers,

isolating conservator from transformer and so forth,

Flanges, valves, etc., shall corfu to etundu

Fittings. All minor fittings required shall be impervious to water and hot oil.

Control boxes and switch cabinets shall be fitted with heating elements on a

‘Separate circuil so that the equipment can be kept at the correct temperature both

during operation and shutdown. No wiring shail be routed through steel tubing and

neither shall rubber-insulated conductors be used.

Guarantees:

The equipment is intended to be operated at constant loads but shall be designed to

withstand overloads according to the loading guide IEC 0076-7 (Latesi version

2018).

All. electrical performance figures apply to the rated voltage ratio (principal tap),

rated current, rated frequency and to the reference temperature of 75°C, except

otherwise stated. Tolerances ara in accordance with the reference standard,

Temperatures rises

Following values should be verified by IEC 60076-7 latest version of 2018 --

Top oii (measured by thermometer) 60°C

Windings (measured by resistance method 65°C

No-Load Losses “KW

Load Losses at 10 MVA “KW

Total Losses “KW

Impedance voltage HV/ LV at 10 MVA *%

No-load current *%

Acoustic sound level 65 dba (g)

* The Bidder to provide above values in Technical Data sheets of Transformers.

Page 9 of 22

43 A WSRGGRAN II HYORO POWER PROJECT

“TECH NICAL SPECIFICATIONS POWER TRANSFORKIER ANNEX SB |

140 Narshalling Kidsk

Marshaliing Kiosk shall house the local Temperature Indicators (OT I/WT1) & the

contol gear for Cooler Control. All wiring from the various accessories mounted on the

transformer

The MK shall be of robust construction and shell be assembled to the transformer using

anti-vibration mountings. It shall have a degree of protection of IP5S or belter. The

fotlowing points shall be taken care of :

Door locking arrangement of Marshalling kiosk shall be proper and lock shall be of

integral handle type, Pogket for keening the scheme drawinas shall be made inside the .

Marshaiiing K __ Aleomponents inside the Marshalling kiosk shall be stitably and sufficiently spaced

apart considering the site ambient conditions. Minimum 200 mm clearance between

terminal blocks shall be kept. Terminal blocks are to be fixed at least 200 mm above the

cable entry.

~ The components in the marshalling kiosk shall be suitable for site ambient conditions

and easily accessible.

~ Each motor shal be provided wiil: averioas and short cireuit protuciisn wad earthing

connections should be foreseen

- _ Allwiring shail be neatly arranged in trunking.

~ Trip and alarm wires shall be terminated in terminal blocks having isolating facility.

- _ Allltrip wires shall be provided with red ferrules and marked ‘Trip!

~ _ Anfi condensation heater controlled by thermostat & hygrostat with contral switch &

‘HEATER-ON indication lamp shall be provided in the marshalling kiosk.

~ Minimum 20% of terminals shall be kept as spere in each type.

* _ A250V, 13/152, single phase, Industrial type 3 pin plug socket with suitable plug pin

Shall be provided inside the Marshalling Kiosk. Separate MCB control shall be provided

for this circu,

Page 10 of 22

48 V1 WJAGGRAN II HYDRO POWER PROJECT

‘TECH NICAL SPECIFICATIONS POWER TRANSFORMER ANNEX B

4441

112

1.13

All wiring for the control gear accommodated in the marshalling kiosk together with

ailnecessary cable boxes and terminations and all wiring between the marshaling

kiosk and the motors shail be included in the Bidder scope.

Shipment

Each transformer when prepared for shipment shall be fitted with IMPACT RECORDER

to measure and record the shocks / jerks during journey, also shall remain in situation

intl the red fe. in the e S

have been subjected to excessive shock in transit, such examination as is necessary

Shall be made in the presence of HMC.

Where practicable, transformers shall be shipped with oil filling to cover core and

windings but when shipped under pressure of gas shall be fitted for the duration of

delivery (o Site and for such time thereafter as is necessary, with a gauge and gas

Zio

Transformer Oil

The Bidder shall supply the first filing of all insulating oils técuired for operation. The

new

oil Intended for final filing shail be degassed properiy in separate tank having sufficient

Size and prior to filing into any part of transformer, degassed oil shalll be tested for water

content, BDV and tangent delta, After complete installation work nacessary treatment

shall be done for the transformer. After complete processing at site oil shall be tested to

meet all requirements as per IEC 60296 reference oil prior to filling and IEC 60422 after

filing in to the transformer. The method of degassing/treetment shall be submitted to the

Client for approval and shall be included in the O&M manual. The dissolvad gas analysis

‘shall be carried out after complete testing from the main tank and OLTC.

Oil Treatment Plant

‘The Bidder shall provide his own plant for the treatment of insulating oil provided and

Used for the initial filing of transformers. Strict control shall be applied while selecting

the treatment plant so that there is no cross contamination by moisture, particle and

PCB. To ensure this, healthiness of the purifier shall be verified by treating oil in a

Separate tank using the proposed purifier before using for the new transformers at

site and the results shall meet the following requirements

Moisture - § ppm

Particles - Low as per B.1 of IEC 60296

QO Page 11 of 22

A

gee

e=5

481 W JAGGRAN II HYDRO POWER PROJECT

TECH NICAL SPECIFICATIONS POWER TRANSFORMER ANNEX-B ~

2

PCB - Not detectable

The above step shall be prior to any oil treatment before commissioning and during

warranty period.

The Bidder is deemed to have included in his Tender, the cost of oll treatment,

including equipment such as oil filtration machine, pumps, vacuum pump and

pressure gauges.

Documentation:

The following drawings should be submitted for approval before the manufacturing of the

power transformer can proceed. Only aiter the approval of the drawings the FAT can be

conducted

Z.1- Outine of the transformer

2.2 Shipsing dimensions drawing

2.5. Oetai gS & Accesso drawing shows the

& part number of the accessories used on transformer such as radiator, valves, tap-

changer, Instrumentations etc)

2.4- Marshalling Kiosk Outline and schematic drawing

2.5- Valve location piete drawing

2.6- Rating plate drawing

2.7- Earthing of core and clamping arrangement drawing

2.8- LV cable box drawing

2.9- HV Bushing drawing

2.10- LV bushing drawing

2.11- HV neutral bushing drawing

2.12- Schematic and Wiring diagrams

2.13- An O&M manuel, complete in all respects, shall be provides!

2.14.Three (3) additiena! copies of Bidder’s Drawings

2.15- Programme for design, manufacture, delivery, erection, testing & commissioning.

2.16- List of standards to be employed

2.17- List of Contractor's Drawings

2.18- Copies of approved standards

2.19- List of design notes and calculations

2.20- Quality Manual and detailod inspection and test plan for ali mejor items,

2.21- Manufacturer's catalogues, technical literature and brochures showing types,

performance, design and constructional details of all equipment and devices

2.22- O&M manuals & Site As-built drawings, interface drawings / Schematics for each item

2.23- G A drawings for all equipment complete with list of devices & accessories

2.24- All essential civil Engg data, such as floor penetrations, loads, transport weights etc

arawing ti

Page 12 of 22

Sous

ea

Loe

asm

‘\WJAGGRAN II HYDRO POWER PROJECT

TicH NICAL SPECIFICATIONS POWER TRANSFORNER ANNEX - B

3

2.25- Connection & wiring diagrams including terminal strip drawings

2.26- Lubricant lists 2s applicable

2.27- Dimension transformer drawings showing main dimensions, weights, arrangement of

Control and monitoring cubicles/ marshaling kiosks, terminals, etc

2.28- Erection, test and commissioning instructions including oil filling and dehydration

instruction

2.29- Water spray system and oil piping layouts with flow diagrams

2.30- Plan showing arrangement of the oil pit for the generator transformer

2.1- 's of fap changer of transformers

2.32- Schematics showing instrumentation, control and monitoring of related systems

2.33- Typical sections of bushings showing the internal construction

‘2.34- Details of gasket material and anti-vibration pads

2.35- Complete description of oil conservation system with dimensions of conservation

tank

2.36- Connection / wiring diagrams of marshaling kiosks & all other electrical equipment

2.37- Transformers loading and unloading instructions and mounting details

2.38 ORM manuals

Tests & Inspection (Must be in accordance with applicable IEC standards)

Following routine iesis & measurements will be performed on each transformer at the factory

3.-

3.2

3.3

34

35

3.6-

3.7-

3.8-

3.9-

Measurement of winding resistance

Voltage ratio measurement and check of voltage vector relationship.

Measurement of impedance voltage (principal tapping).

Measurement of load loss,

Measurement of no-load loss and current.

Induead over

Tan-delta test

Separate-source power frequency voltage withstand test.

Power-requency withstand test on the auxiliary circuits according to IEC 60076-3, 2013

ar. § (all accessories shall be tested according to IEC standards).

3.10- Atsite the transformers shalt undergo a check program as per manufacturer's practice.

At least the following tests shall be performed :

Rene

Visual inspection.

Oil quality verification as follows:

dielectric strength

purity

Page 13 of 22

ee

4611 WJAGGRAN HYDRO POWER PROJECT

TecH NICAL SPECIFICATIONS POWER TRANSFORMER ANNEX - B

26.

27.

28.

29.

particle content

gas analysis

insulation resistance.

water content

temperature stability

flash point

$H value

The oil quality verification shall he repeated after one morth normal operation,

as well as at the and of the gu. veri,

Megger test (all windings against each other and against earth)

Winding resistance measurement

Ratio check on all taps

Functional test of all contro! and protection equipment.

A static pressure test of the complete assembly, tank and accessories.

SFRA, TAN-Delta

Phase relationship and vector group test

a FY wk a ts>

Calibration of OT! and WTI

Operation of cooling apparatus and alarm

Pressure test on tank

Deluge test

Tho Employer or their designated representatives shall be eniltled 10 attend the aforesaid

lest and/or inspection, provided that the Employer shall bear all costs & expences

incurred in connection with such attendance including, but not limited to, al traveling and

boaid and lodging expenses. ~

Whenever the Bidder is ready to carry out any such test and/or inspection, the Bidder

shall give 8 reasonable advance notice of such tests and/or inspection and of the place

and time thereof to the Employer. The Bidder shall obtain from any relevant third party or

manufacturer any necessary permission or Consent to enable the Employer or their

Designated Representatives to attend the test and/or inspection.

‘The bidder shall provide the Employer with a certified report of the results of any such

test and/or inspecton. ii the Employer or their designated representatives falls to

attend the test and/or inspection. or ifit is agreed between the partios that ouch person

shall not do so, then the Bidder may proceed with the Test and/or inspection in the

absence of such persons, and may provide the Employer with a certified report of the

result thereof.

If any item or part of the item faile to pass eny test and/or Inspection, the Bidder shall

either rectify or replace such item or part of the item and shall repeat the Test and/or

Inspection as specified in tender documents.

The Bidder shall at its own expense carry out at the place of Manufacture and /or on

site all such tests and /or Inspections of the items and any part of the items as are

Specified in the tender document as per Clause 3 (Pg No.13 of 22 in Annax-B)

pi 1 of 22

48 MWV JAGGRAN II HYDRO POWER PROJECT

TECHIN'

4

44

42

42.4

422

ICAL SPECIFICATIONS POWER TRANSFORMER ANNEX -B

STATION AUXILIARY TRANSFORMERS

General

Two idehtical auxitary transformers 71 / .4 KV, 8U0 KVA, for the respeciive units sna

be located in the Powerhouse, they shall be ONAN type. rated and shall supply low

voltage to auxiliary switchgear. Each transformer will supply to the respective LV bus

bar. Bus Bar No. 1 & Bus Bar No. 2 will be provided with normally open 11 KV bus

coupler. But it must have synchronizing capability, In case of closed bus coupler.

Adequate protection relays to provide comprehensive protected system, measuring

Insinuments, iovai & remote odhiltol musi be avalladie. Cac 630 KYA tranciormer will bo

installed for village supply. One 200kVA transformer will be placed at the intake. The

Bidder shall submit transformer sizing calculations for Client approval

Generai Characteristics

Station Supply Transformers

Type, operation

Instatlation

Dielectric

Rated frequency

Rated power (continuous duty)

Rated primary voltage

Rated secondary voltage

Tap changing

Cooling

Connection

Windings

Village Supply Transformer

Type, operation

Three phases, step down

Indoor

Derating required with a Max Temp of 43°C as

well with the installation height of 1600m ASL

lL

50 Hz

800 KVA (at 1600m ASL)

1k

oak

Offload (4 2 x 2.5%)

ONAN

Dynt1

Copper

Three phases, step down

2 Page 15 of 22

48 VW JAGGRAN II HYDRO POWER PROJECT

TECH NICAL SPECIFICATIONS POWER TRANSFORMER

ANNEX - B

Indoor/outdoor ( as per site requirement)

Derating required with a Max Temp of 45°C as

well with the installation height of 1600m ASL.

Installation

Dielectric OL

Rated frequency 50 Hz

Rated power (continuous duty)

Rated primary voltage

Rated secondary voltage

Tap changing

11kV

Oak

Cooling ONAN

Connection Dynt1

Windings Copper

4.2.3 Intake Supply Transformer

630 KVA (at 1600m ASL)

Off load (t 2x 2.5%)

1 (one) thres-phese, OIL Type transformer for outdoor use, ONAN-cooléd, with data

as specified below.

Rated power

Rated voltage, MV winding

Rated voltage, LV winding

Frequency

Vector group

Tap changer on HV winding

Tapping range

impedance voltage at rated current,

principal tapping, not less than

The transformer shall be equipped with

Oil conservator with level gauge

Valve for oil samples

Offoad tap changer

200 kVA (at 1600m ASL)

it kV

400 V

50 Hz

Dyn14

Oft-loaa

£2% 2.5%

4%

42.4 Accessories

In addition to other protection relays, each transformer shall be supplied with a

Protection relay with 2 contacts for temperature and oll level alarm and 2 contacts for

temperature and oil over pressure tripping.

5 INSTRUMENT TRANSFORMERS

tet

es

4g W JAGGRAN ll HYDRO POWER PROJECT

TECH NICAL SPECIFICATIONS POWER TRANSFORMER ANNEX -B

a. Current and voltage transformers are to be housed or accommodated to suit their

Particular duties. They shall meet the requirements of the latest relevant approved

standard specification for metering and for protection and be capable of

withstanding the maximum circuit currents at their plece of installation, without any

demage or deterioration.

b. The current transformers shall have sepa ring, measuring ancl

Protection. They shall at least comply with the following classes:

|, For metering: 0.2 in case for Tariff

i. For protection: 5P20

¢. The voltage transformers shall have an accuracy of 0.5%. (In case of energy

metering class 0.2, fault margin shall be 0.2 %)

U. Tie seconaary’s of VTs shaii be protected by MCBs. All VTs shall be provided

with an open delta winding and loading resistors.

@. The secondarys of CTs shall be earthed by means of a heavy copper conductor,

Such earth connection shall be easliy accessible.

Unless otherwise approved all CT secondary windings shall be rated for 1 ampere

and the VT secondary windings for 110 V.

g. The Bidder shall determine the burdens and required capacities of the various

secondary circuits taking into consideration the most unfavorable conditions. Secondary

windings shall be wired to suitable terminal boards and earthed at one point in the circuit.

h. Allinstrument transformers shail be provided with an identifying table giving type,

mmber, and conneciions =

rao, class, output. serizi

1, The Bidder shail supply manufacturer's test certificates on tests and measurements

tobe performed in accordance with applicable standards. Tha CTs and their associated

‘cacuiis shall be tested on site by the primary injection method.

6 STANDARDS AND ENVIRONMENTAL CONDITIONS

6.1 Standards

a. Design and manufacture of all electrical equipment shall comply with number of the

JEC Recommendations, particularly the following to select the electrical equipment:

IEC 60034 Recommendation for rotating electrical machinery

(O) Page 27 of 22

Yo

POs

4811 W JAGGRAN ll HYDRO POWER PROJECT

TEcH NICAL SPECIFICATIONS POWER TRANSFORMER - ANNEX -8 |

IEC 60056 HV AC circult-breakers (IEC 62271-100 + AMD1 + AMD2)

IEC 60072 Dimensions and output rating of electrical machines

1EC 60076 Recommendations for power transformers

IEC 60079 — Recommendations for the construction of flameproof enclosure

- of electrical apparatus

IFC AONE Primary cells and tsalteries

1EC 60123 | Recommendations on sound level meters (IE 61672-2)

1EC 60129 AC Isolators

1EC 60137 AC Bushings above 1000 V

IEC 60141 Tests on oil-filled and gas pressure cable and their accessories

IEC 60144 Degree of protection of enclosure for LVIEC 60157 LV Distribution

‘switchgear

IEC 60158 LV Control gear

JEC 60182 Lighting fittings for tubular fluorescent lamps

IEC 60214 — On-load tap changers

EC 60228 Conductors of insulated cables

IEC 60269 — Low-voltage fusas with high breaking capacity

IEC 60287 Calculation of the continuous current rating of cables

IEC 60292 —_ LV motor starters.

JEC 60298 HV metatenclosed switchgear and control gear

b. In case an IEC Regulation does not exist or cover the scope of supply,

National Standards, at least equivalent to ANSI and / or IEEE Standards shall be

applied.

The Bidder shall provide the Client with one set (official, complete, unabridged and in

the English language) of all relevant standards / specifications according to which the

equipment is manufactured.

6.2 Standard Voltages

a. The following rated values for high and low voltages are applied:

i Transmission voltage: 132 kV

ii, Generator voltage 1Wkv

Page 18 of 22

E

er

+ 4g vi WJAGGRAN II HYDRO POWER PROJECT

Tec

NICAL SPECIFICATIONS POWER TRANSFORMER ANNEX - B

ili, Low voltage (3-phase, 4.wire system) 400/230 V

lv. Main DG voltage 10 Vv

b. The rated frequency of the AC voltages is 50 HZ. The steady state operation

©. The AC ope:

frequency variation range is + 5%. The frequency during transient conditions, how-

ever, may vary within the range of + 10% of the rated value.

lary nt shal! be capable of operating

correctly within the supply linits of plus oF minus 10 % ofthe rated voltage.

Gd. The neutral point of the AG power supplies shall be solidly grounded.

©. The DC operating device or auxiliary equipment shall be capable of operating

f.

7

7A

correctly within the supply limits of + 10% and - 15 % of the rated voltage.

However, the tripping circuits shall function correctly for a variation in DC supply of -

23% afd the closing and span s

10% and - 20%.

renga of t

The DC system shall be un-grounded two wire system, equipped with suitable

ground detector (high resistive supervision system connected to different buses).

Protection of Transformers -

i. Both inside and outside of metallic parts shall be corrosion protected.

i, Exterior surtaces shall be protected with one coat of chromate of zine primer and

two coat of glycerolphtalic paint

li, Interior surfaces shall be protected with chromate of zinc primer or equivalent.

Bolts and screws shall be electrolytic zinc and bi-chromate coated. Washers

shall be elther in tinned bronze or stainless steel.

iv- No of corrosion protection years to be indicated by BIDDERS and thickness of

painting layers to be adopted accordingly as per standards,

Inspection Before Delivery

The Client may inspect the paint application facilities in the Bidders workshops and to

ensure that they comply with the prescribed standards and painting procedure.

The number of coats of paint will be checked, together with the thickness of individual

coats and the total thickness of the coating. The Bidder shall supply the measuring

apparatus, which shall be of the electronic detection type (Brand Posit Ector or similar),

2. Page 19 of 22

Za

48) /AWPIAGGRAN II HYORO POWER PROIECT

TECH NICAL SPECIFICATIONS POWER TRANSFORMER ANNEX - B

Giving readings accurate to within 1 micrometer. One measurement shall be taken every

0.5 m2 or every 0.5 linear meters.

Adhesion test shall be performed on submerged and partially submerged equipment, in

accordance with standard ASME D 3359. The instruments required, in accordance with

the same standard, shall be supplied by the Bidder, Results must not be lower than No,

38 classification of standard ASME D 3359.

All power transformers must be tested for their transformation ration at every tap,

insulation resistance, operation of gas protection devices, oil and temperature alarming

and tripping devices, cooling system, tap changer operation, silica gel breathers,

dielectric strength & pH level of insulating oil, indoor & outdoor controlling devices, etc

The Bidder shall take all reasonable precautions te ensure that the protective coatings

are not damaged during handling in the factory, during transport of during erection. In

Particular, he shall ensure that no damage is caused through the use of inappronrial

packing systems,

In the event of damage, the Bidder shall make good the existing protective coatings

using the same products and under the same conditions of apy

8 GENERAL REQUIREMENTS

at

Equipment

a. All components of the electric equipment shall be new and of a proven and reliable

design with adequate factor of safety. The highesi extent of uniformity and inter-

changeability shall be reached. The design shall facilitate an easy maintenance and

‘epair of ine companonts. *

b. The equipment shail be pre-assembled to the highest possible extent in the Bidder

workshop, €.g. wiring completely up to the terminal blocks of boards, panels, consoles

etc,, including installation of internals shall be carried out.

©. All equipment shali be suitable for the prevailing climatic conditions. Open air

installed parts shall be protected against sun radiation by means of adequate steel

covers.

G. !f not mentioned otherwise, all power cables and control cables shall be included and

laid up to the common terminal boxes.

© All required equipment for control, protection and instrumentation needed in the

installation shall be supplied and connected by the Bidder.

we Page 20 of ZZ

ear

43 MW JAGGRAN II HYDRO POWER PROJECT

TECH NICAL SPECIFICATIONS POWER TRANSFORMER ANNEX - B

8.2

f If not agreed otherwise, the nominal capacity of the electrical equipment, selected or

proposed by the Bidder, shall include a safety margin of ten percont (10%) under the

Worst conditions of operation. Before the final approval of the basic figures are given,

the Bidder shall submit all information as list of loads, calculation of short circuit, rating

factors and other data required by the Client.

9 The calculations of the short circuit shail provide full evidence that all electrical

with maximum voltages during the fault cond

components will resist the current n

within the specified duration.

h. In case of the failure of the main protection, the back-up protection shall clear the

fault.

i. When installing parts of the clectrical equipment in open air conditions, an adequate

protection against sun radiation and heavy rainfall shall be provided.

i. Equipment, materials and the various electrical systems shall be-assembled and

installed in accordance with the provisions, as applicable, supplemented by such

additional requirements as may be specified elsewhere in these Specifications. The

work shall conform to the requirements of IEC Standards

Other requirements:

@. The Bidder shall submit all the site-as built drawings for the approval of the Client. All

the legends shall be in English language and complete in all respect. Upon approval of

the Client three(3) set of copies of the as-built drawings shall be handed over as Hard

copy and three (3) in the form of CD's/DVD's.

b. The O&M manuals shall be s:

equipment in English Language. Upon approval three (3) set of Hard and Soft copy

each shall be handed over.

©. During the Testing and commissioning phase, Bidder shall inform the Client one week

in advance for any testing scheduled at the site and submit complete test protocol. The

testing shall be witnessed by the Client representative and signed by each party. After

completion of the site testing, Bidder shall submit (3) copies of all the test reports.

d. The back-up of all the softwares including firmware and loading configuration in the

plant shall be handed over.

©. Tools used by the Bidder for erection, testing and commissioning of the electro-

Mechanical equipment should be handed over to client for future maintenance.

\ ) Page 21 of 22

for the approval of the

POWER PROJECT

; POWER TRANSFORMER

ANNEX -B

a. The Bidder is obliged to review the dimensions of rooms housing the electrical

equipment and installations, bearing in mind the equipment he plans to install in each

particular place.

». Not only shall the rooms should be of sufficient size to house the gears, but there

shall also be ample space to allow the operators and maintenance crews to perform

their tasks without difficulty.

9 Transformer Spare Parts , Accessories & Consumables.

Mentioned in ANNEX-A item No-2.

a ge =

a Poge 22 of 22

ae

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- 4000 34.5 11.5 Dyn11 (Core)Document1 page4000 34.5 11.5 Dyn11 (Core)Mohammed ShoaibNo ratings yet

- Po Box 15410 Dubai, United Arab Amirates: Commercial InvoiceDocument1 pagePo Box 15410 Dubai, United Arab Amirates: Commercial InvoiceMohammed ShoaibNo ratings yet

- 10 MVA METCO (KSA) - Dimensional SketchDocument1 page10 MVA METCO (KSA) - Dimensional SketchMohammed ShoaibNo ratings yet

- A View "A": Bushing Din 42533 30NF/1000ADocument1 pageA View "A": Bushing Din 42533 30NF/1000AMohammed ShoaibNo ratings yet

- F-Service and InstallationDocument2 pagesF-Service and InstallationMohammed ShoaibNo ratings yet

- SheetsDocument42 pagesSheetsMohammed ShoaibNo ratings yet

- SheetsDocument42 pagesSheetsMohammed ShoaibNo ratings yet

- Application For Issuance of Letter of Credit (LC) / Back To Back Letter of Credit (B2BLC)Document5 pagesApplication For Issuance of Letter of Credit (LC) / Back To Back Letter of Credit (B2BLC)Mohammed ShoaibNo ratings yet

- Thickness of Paint Coatings Layers / Festési Rétegek VastagságaiDocument1 pageThickness of Paint Coatings Layers / Festési Rétegek VastagságaiMohammed ShoaibNo ratings yet

- Order Sheet For Ventilator: CG Electric Systems Hungary ZRTDocument1 pageOrder Sheet For Ventilator: CG Electric Systems Hungary ZRTMohammed ShoaibNo ratings yet

- 01-03 A A4Document3 pages01-03 A A4Mohammed ShoaibNo ratings yet

- Material List: GANZ TransformerDocument3 pagesMaterial List: GANZ TransformerMohammed ShoaibNo ratings yet

- Despt User GuideDocument48 pagesDespt User GuideMohammed ShoaibNo ratings yet

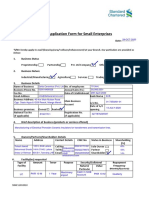

- Finance Application Form For Small EnterprisesDocument2 pagesFinance Application Form For Small EnterprisesMohammed ShoaibNo ratings yet

- Pi JugeDocument1 pagePi JugeMohammed ShoaibNo ratings yet

- BBFS (R-3)Document4 pagesBBFS (R-3)Mohammed ShoaibNo ratings yet

- Sillicon 7225.1100Document49 pagesSillicon 7225.1100Mohammed ShoaibNo ratings yet

- HV Connectors Test Report PDFDocument21 pagesHV Connectors Test Report PDFMohammed ShoaibNo ratings yet