Professional Documents

Culture Documents

Document PDF

Uploaded by

MSc Kostic MilosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Document PDF

Uploaded by

MSc Kostic MilosCopyright:

Available Formats

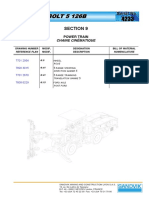

Product information

Guided Wave Radar

Level and interface measurement in liquids

VEGAFLEX 81

VEGAFLEX 83

VEGAFLEX 86

Document ID: 46597

Contents

Contents

1 Measuring principle................................................................................................................................................................................................ 3

2 Type overview.......................................................................................................................................................................................................... 5

3 Instrument selection............................................................................................................................................................................................... 8

4 Selection criteria................................................................................................................................................................................................... 11

5 Housing overview................................................................................................................................................................................................. 12

6 Mounting................................................................................................................................................................................................................ 13

7 Electronics - 4 … 20 mA/HART - two-wire.......................................................................................................................................................... 14

8 Electronics - 4 … 20 mA/HART - four-wire......................................................................................................................................................... 15

9 Electronics - Profibus PA..................................................................................................................................................................................... 16

10 Electronics - Foundation Fieldbus...................................................................................................................................................................... 17

11 Electronics, Modbus, Levelmaster protocol...................................................................................................................................................... 18

12 Adjustment............................................................................................................................................................................................................ 19

13 Dimensions............................................................................................................................................................................................................ 21

Take note of safety instructions for Ex applications

46597-EN-160921

Please note the Ex specific safety information that you can find at www.vega.com and that comes with each instrument. In hazardous areas

you should take note of the appropriate regulations, conformity and type approval certificates of the sensors and power supply units. The sen-

sors must only be operated on intrinsically safe circuits. The permissible electrical values are stated in the certificate.

2 Guided Wave Radar - Level and interface measurement in liquids

Measuring principle

1 Measuring principle

Measuring principle

High frequency microwave pulses are coupled onto a cable or rod and

guided along the probe. The pulse is reflected by the product surface.

The time from emission to reception of the signals is proportional to the

distance of the level.

The instrument is supplied with the probe length (0 % and 100 %)

already adjusted. In most cases setup on site is not required. In any case,

you set up VEGAFLEX without medium. The shortenable, bare cable and 1 1

rod versions can be simply adapted to the local requirements, if neces-

sary. 4 4

Level measurement in liquids

Density fluctuations, steam generation or strong pressure and tempera-

ture fluctuations do not influence the measuring result. Also buildup on

the probe or the vessel wall do not influence the measurement. This

makes VEGAFLEX simple in planning. 2 2

An ideal application is level measurement in a bypass tube or standpipe,

because even products with a dielectric constant below 1.6 can be reli- 3 3

ably measured. Weld seams, buildup and corrosion inside the tube do

not influence the accuracy of the level measurement. Even if overfilling

up to the process fitting occurs, the measurement is reliable. VEGAFLEX

81 also offers a special solution for ammonia applications.

Different probes are available 5 5

• Cable probes for applications in high vessels up to 75 m (246 ft)

• Rod probes for applications in vessels up to 6 m (20 ft)

• Coax probes for application in low viscosity liquids, with vessel instal- Fig. 2: Measuring ranges of VEGAFLEX - coax version

lations, in vessels up to 6 m (20 ft) high 1 Reference plane

2 Probe length (L)

The measured quantity is the distance between process fitting of the sen- 3 Measuring range

sor and product surface. Depending on the sensor version, the reference 4 Upper dead band

plane is the seal surface on the hexagon or the lower side of the flange. 5 Lower dead band

Interface measurement in liquids

Non-conductive products only partly reflect the energy of microwaves.

The non-reflected energy passes through the medium and is reflected

at the phase boundary to a second liquid. Interface measurement takes

advantage of this effect. You can select this function on VEGAFLEX via

the adjustment tools.

1 1 You thus get a reliable total level as well as the level of the lower medium

in your vessel.

Typical applications are interface measurements in storage tanks,

4 4 separators and pump sumps. VEGAFLEX normally determines the level

of water underneath a non-conductive medium. Since the instrument is

independent of the density of the medium, a reliable, maintenance-free

and precise measurement can be realised.

3 By simply switching over, the instruments can be used for interface

2 2

measurement of liquids.

3 Thanks to its guide tube, the coax version is not influenced by vessel

installations and reliably measures products with low dielectric constant.

Therefore this instrument version is be preferred.

5

Prerequisites for interface measurement

Upper medium (L2)

5

• The upper medium must not be conductive

• The dielectric constant of the upper medium must be known

Fig. 1: Measuring ranges of the VEGAFLEX cable and rod versions • The composition of the upper medium must be stable, no varying

products or mixtures

1 Reference plane

2 Probe length (L) • The upper medium must be homogeneous, no stratifications within

3 Measuring range the medium

4 Upper dead band • The layer can only be measured if it has a thickness ≥ 100 mm (4 in)

5 Lower dead band • Clear separation from the lower medium, no emulsion phase, no

detritus layer

• If possible, no foam on the surface

Lower medium (L1)

• The dielectric constant must be 10 higher than the dielectric constant

46597-EN-160921

of the upper medium, preferably electrically conductive. Example:

upper medium dielectric constant 2, lower medium at least dielectric

constant 12

Guided Wave Radar - Level and interface measurement in liquids 3

Measuring principle

1

d2

d1

L2 TS

h2 L1

h1

Fig. 3: Interface measurement

1 Reference plane

d1 Distance to the interface (HART value 1 or Primary Value)

d2 Distance to the level (HART value 3 or Third Value)

TS Thickness of the upper medium (d1 - d2)

h1 Height - Interface

h2 Height - Level

L1 Lower medium

L2 Upper medium

46597-EN-160921

4 Guided Wave Radar - Level and interface measurement in liquids

Type overview

2 Type overview

VEGAFLEX 81 VEGAFLEX 81 VEGAFLEX 81

Cable version Rod version Coax version

Applications Storage tanks, liquids with agitated sur- Storage tanks, liquids with smooth sur- Storage tanks, liquids with low dielectric

face face constant, vessel with installations

Max. measuring range 75 m (246 ft) 6 m (19.69 ft) 6 m (19.69 ft)

Probe Cable probe Rod probe Coax probe

ø 2 mm ø 8 mm ø 21.1 mm

ø 4 mm ø 12 mm ø 42.2 mm

Process fitting Thread from G¾, ¾ NPT Thread from G¾, ¾ NPT Thread from G¾, ¾ NPT

Flanges from DN 25, 1" Flanges from DN 25, 1" Flanges from DN 25, 1"

Process temperature -40 … +200 °C (-40 … +392 °F) -40 … +200 °C (-40 … +392 °F) -40 … +200 °C (-40 … +392 °F)

Process pressure -1 … +40 bar/-100 … +4000 kPa (- -1 … +40 bar/-100 … +4000 kPa (- -1 … +40 bar/-100 … +4000 kPa (-

14.5 … +580 psig) 14.5 … +580 psig) 14.5 … +580 psig)

Measuring accuracy ±2 mm ±2 mm ±2 mm

Signal output • 4 … 20 mA/HART - two-wire

• 4 … 20 mA/HART - four-wire

• Profibus PA

• Foundation Fieldbus

• Modbus and Levelmaster protocol

Indication/Adjustment • PLICSCOM

• PACTware

• VEGADIS 81

• VEGADIS 62

Approvals • ATEX

• IEC

• Shipbuilding

• Overfill protection

• FM

• CSA

• EAC (GOST)

46597-EN-160921

Guided Wave Radar - Level and interface measurement in liquids 5

Type overview

VEGAFLEX 83 VEGAFLEX 83 VEGAFLEX 83

Cable version Rod version Rod version - Foodstuffs

Applications Aggressive and corrosive liquids Aggressive and corrosive liquids Hygienic applications in the food process-

ing and pharmaceutical industry

Max. measuring range 32 m (105 ft) 4 m (13.12 ft) 4 m (13.12 ft)

Probe Cable probe Rod probe Rod probe

ø 4 mm ø 10 mm ø 8 mm

PFA coated PFA coated Polished version (Basle Standard)

Process fitting/Material Flanges from DN 25, 1" Flanges from DN 25, 1" Hygienic fittings

Hygienic fittings Hygienic fittings

PTFE-TFM 1600 PTFE-TFM 1600

Process temperature -40 … +150 °C (-40 … +392 °F) -40 … +150 °C (-40 … +302 °F) -20 … +150 °C (-4 … +302 °F)

Process pressure -0.5 … +16 bar/-50 … +1600 kPa (- -0.5 … +16 bar/-50 … +1600 kPa (- -1 … +40 bar/-100 … +4000 kPa (-

7.3 … +232 psig) 7.3 … +232 psig) 14.5 … +580 psig)

Deviation ±2 mm ±2 mm ±2 mm

Signal output • 4 … 20 mA/HART - two-wire

• 4 … 20 mA/HART - four-wire

• Profibus PA

• Foundation Fieldbus

• Modbus and Levelmaster protocol

Indication/Adjustment • PLICSCOM

• PACTware

• VEGADIS 81

• VEGADIS 62

Approvals • ATEX

• IEC

• Shipbuilding

• Overfill protection

• FM

• CSA

• EAC (GOST)

46597-EN-160921

6 Guided Wave Radar - Level and interface measurement in liquids

Type overview

VEGAFLEX 86 VEGAFLEX 86 VEGAFLEX 86

Cable version Rod version Coax version

Applications High temperature applications High temperature applications High temperature applications

Max. measuring range 75 m (246 ft) 6 m (19.69 ft) 6 m (19.69 ft)

Probe Cable probe Rod probe Coax probe

ø 2 mm ø 16 mm ø 42.2 mm

ø 4 mm

Process fitting Thread G1½ Thread G1½ Thread G1½

Flanges from DN 40, 2" Flanges from DN 40, 2" Flanges from DN 40, 2"

Process temperature -196 … +450 °C (-321 … +842 °F) -196 … +450 °C (-321 … +842 °F) -196 … +450 °C (-321 … +842 °F)

Process pressure -1 … +400 bar/-100 … +40000 kPa (- -1 … +400 bar/-100 … +40000 kPa (- -1 … +400 bar/-100 … +40000 kPa (-

14.5 … +5800 psig) 14.5 … +5800 psig) 14.5 … +5800 psig)

Deviation ±2 mm ±2 mm ±2 mm

Signal output • 4 … 20 mA/HART - two-wire

• 4 … 20 mA/HART - four-wire

• Profibus PA

• Foundation Fieldbus

• Modbus and Levelmaster protocol

Indication/Adjustment • PLICSCOM

• PACTware

• VEGADIS 81

• VEGADIS 62

Approvals • ATEX

• IEC

• Shipbuilding

• Overfill protection

• FM

• CSA

• EAC (GOST)

46597-EN-160921

Guided Wave Radar - Level and interface measurement in liquids 7

Instrument selection

3 Instrument selection

Application areas

VEGAFLEX 81

VEGAFLEX 81 is suitable for applications with liquids in small vessels

under ordinary process conditions. There are application possibilities in

nearly all areas of industry.

Through a large selection of gravity weights, the VEGAFLEX 81 can be

also used in standpipes and bypass tubes.

VEGAFLEX 83

The PFA-coated VEGAFLEX 83 is suitable for measurement in aggres-

sive liquids or applications with special hygienic requirements. Applica-

tion possibilities can be found in the chemical industry as well as in the

food processing and pharmaceutical sector.

The polished version of VEGAFLEX 83 is particularly suitable for level

measurement under hygienic conditions in, for example, vessels with

foodstuffs.

VEGAFLEX 86 1

VEGAPULS 86 is suitable for high temperature applicatons in liquids, e.g.

in storage tanks and process vessels. The application possibilities can be

Fig. 14: Position of the spacer

found in the chemical industry, the environmental and recycling technol-

ogy as well as in the petrochemical industry. 1 Spacer

Note:

Applications

Measurement in a standpipe is not recommended for extremely

Level measurement in conical vessels adhesive products.

During operation, the probe must not touch any installations or the vessel

wall. If necessary, fasten the probe end. Interface measurement

In vessels with conical bottom it can be advantageous to mount the sen- Through simple switching, all instruments of the VEGAFLEX 80 series

sor in the center of the vessel, as measurement is then possible down to can also measure liquid interfaces. Typical applications are the measure-

the lowest point of the vessel bottom. ment of oil or solvents on water. The measuring principle is maintenance-

free because no moving parts are used. VEGAFLEX operates completely

independent of the density of the product. This means reliable measured

values without additional effort for correction.

Prerequisites for interface measurement

• The upper medium must not be conductive

• The dielectric constant of the upper medium must be known (input

required). Min. dielectric constant: rod version 1.7.

• The composition of the upper medium must be stable, no varying

products or mixtures

• The upper medium must be homogeneous, no stratifications within

the medium

• Min. thickness of the upper medium 100 mm

• Clear separation from the lower medium, no emulsion phase, no

detritus layer

• If possible, no foam on the surface

Lower medium (L1)

Fig. 13: Vessel with conical bottom • The dielectric constant must be 10 higher than the dielectric constant

of the upper medium, preferably electrically conductive. Example:

upper medium dielectric constant 2, lower medium at least dielectric

Measurement in a standpipe or bypass tube constant 12

When a standpipe or bypass tube is used in a vessel, the influences from

vessel installations and turbulence can be excluded. In such case, meas-

urement of products with low dielectric values (εr value ≥ 1.6) is possible.

In very adhesive products, measurement in a standpipe or bypass tube is

not recommended.

If VEGAFLEX is used in standpipes or bypass tubes, contact with the

tube wall should be avoided. We offer spacers as accessories for fasten-

ing the probe in the middle of the tube.

If chemical resistance is not a problem, we recommend using a metal

tube to improve measurement reliability.

46597-EN-160921

8 Guided Wave Radar - Level and interface measurement in liquids

Instrument selection

1

d2

d1

L2 TS

h2 L1

h1 1 2

Fig. 17: Socket must be installed flush

Fig. 15: Interface measurement 1 Unfavourable installation

1 Reference plane 2 Socket flush - optimum installation

d1 Distance to the interface (HART value 1)

d2 Distance to the level (HART value 3)

Plastic vessel/Glass vessel

TS Thickness of the upper medium (d1 - d2)

h1 Height - Interface The guided microwave principle requires a metallic surface on the

h2 Height - Level process fitting. Therefore, in plastic vessels, etc., use an instrument ver-

L1 Lower medium sion with flange (from DN 50) or place a metal sheet (ø > 200 mm/8 in)

L2 Upper medium beneath the process fitting when screwing it in.

Make sure that the plate has direct contact with the process fitting.

Mounting socket When installing rod or cable probes in vessels without metal walls, e.g. in

If possible, avoid sockets. Mount the sensor flush with the vessel top. If plastic vessels, the measured value can be influenced by strong electro-

this is not possible, use short sockets with small diameter. magnetic fields (emitted interference according to EN 61326: class A). In

Higher sockets or sockets with a bigger diameter can generally be used. this case, use a probe with coaxial version.

They can, however, increase the upper blocking distance (dead band).

Check if this is relevant for your measurement.

In such cases, always carry out a false signal suppression after installa-

tion. You can find further information under "Setup procedure".

1 2

d h

DN25 ... DN150 ≤ 150 mm (5.91")

> DN150 ... DN200 ≤ 100 mm (3.94")

d

h

Fig. 18: Installation in non-metallic vessel

1 Flange

2 Metal sheet

Fig. 16: Mounting socket

Ammonia applications

When welding the socket, make sure that the socket is flush with the For applications in ammonia, a special, gas-tight instrument version of

vessel top. VEGAFLEX 81 as coax probe is available.

For this special application, the instrument is equipped with high resistant

seals of elastomer-free materials. The instrument seal and the "Second

Line of Defense" are made of borosilicate glass GPC 540.

Steam boiler applications

Vapours, superimposed gases, high pressures and temperature differ-

ences can change the spreading speed of radar impulses.

For automatic correction of these deviations, the VEGAFLEX can be

optionally equipped with a running time correction over the reference

distance. Hence the probe can execute an automatic running time cor-

rection.

The reference point must hence not be overfilled. The upper dead band is

hence 450 mm (17.7 in).

46597-EN-160921

Guided Wave Radar - Level and interface measurement in liquids 9

Instrument selection

1 1

112 mm

(4.84")

65,3 mm

(2.57")

183 mm

(7.20")

ø 54 mm

(2.13") 3

6 6

2 1

øw

4 4

2 2

L

3

øw

5

DIN DN25 DN32 DN40 / 1" 1 1/2" ø 50,5

5 DIN DN50 / 2" ø 64

DIN DN65 / 3" ø 91

Fig. 20: Autoclaved version

Fig. 19: Measuring ranges - VEGAFLEX with steam compensation

1 Groove nut

1 Reference plane

2 Process fitting

2 Probe length (L)

3 Cover with groove nut

3 Measuring range

4 Upper dead band

5 Lower dead band

6 Additional upper dead band by steam compensation

7 Reference measurement distance to steam compensation

Autoclaved version

For use in an autoclave, e.g. for sterilization, the polished version of

VEGAFLEX is available as autoclavable version.

Hence you can separate the housing from the process fitting.

The side of the process fitting is provided with a cover after the housing

is removed.

After autoclaving, attach the housing again and the instrument is immedi-

ately ready for operation.

46597-EN-160921

10 Guided Wave Radar - Level and interface measurement in liquids

Selection criteria

4 Selection criteria

VEGAFLEX 81 VEGAFLEX 83 VEGAFLEX 86

Cable Rod Coax Cable Rod Polished Cable Rod Coax

rod

Vessel Vessels < 6 m ● ● ● ● ● ● ● ● ●

High vessels > 6 m ● – – ● – – ● – –

Non-metallic vessels ○ ○ ○ ○ ○ ○ ○ ○ ○

Measurement in a standpipe or bypass tube ● ● ○ – ○ ● ● ● ○

Process Aggressive liquids – – – ● ● – – – –

Bubble or foam generation ● ● ● ● ● ● ● ● ●

Wave movements at the surface ● ● ● ● ● ● ● ● ●

Steam or condensation ● ● ● ● ● ● ● ● ●

Buildup ● ● – ● ● ● ● ● –

Changing density ● ● ● ● ● ● ● ● ●

Ammonia application – – ● – – – – – –

High temperatures > 200 °C – – – – – – ● ● ●

Pressures up to 400 bar – – – – – – ● ● ●

Hygienic applications – – – ○ ○ ● – – –

Narrow space above the vessel ● ○ – ● – – ● ○ –

Steam boiler application – – – – – – – – ●

Process fitting Threaded fittings ● ● ● – – – ● ● ●

Flange connections ● ● ● ● ● ● ● ● ●

Hygienic fittings – – – ● ● ● – – –

Probe Stainless steel ● ● ● – – ● ● ● ●

PFA coating – – – ● ● – – – –

Polished (Basel Standard) – – – – – ● – – –

Probe can be shortened ● ● – – – – ● ● –

Chemical ● ● ● ● ● ● ● ● ●

Power generation ● ● ● ○ ○ – ● ● ●

Foodstuffs – – – ● ● ● – – –

Offshore ● ● ● ○ ○ – ● ● ●

Petrochemical ● ● ● ○ ○ – ● ● ●

Industry

Pharmaceutical – – – ● ● ● – – –

Shipbuilding ● ○ ○ – – – ● ○ ○

Environment and recycling industry ● ● ● ● ● ● ● ● ●

Water ● ● ○ ● ● ● ○ ○ ○

Waste water ○ ○ – ○ ○ ○ ○ ○ –

– not recommended

○ possible with limitations

● optimum suitability

46597-EN-160921

Guided Wave Radar - Level and interface measurement in liquids 11

Housing overview

5 Housing overview

Plastic PBT

Protection rating IP 66/IP 67 IP 66/IP 67

Version Single chamber Double chamber

Application area Industrial environment Industrial environment

Aluminium

Protection rating IP 66/IP 67, IP 66/IP 68 (1 bar) IP 66/IP 67, IP 66/IP 68 (1 bar)

Version Single chamber Double chamber

Application area Industrial environment with increased me- Industrial environment with increased me-

chanical stress chanical stress

Stainless steel 316L

Protection rating IP 66/IP 67 IP 66/IP 67, IP 66/IP 68 (1 bar) IP 66/IP 67, IP 66/IP 68 (1 bar)

Version Single chamber, electropolished Single chamber, precision casting Double chamber, precision casting

Application area Aggressive environment, food processing, Aggressive environment, extreme mechani- Aggressive environment, extreme mechani-

pharmaceutical cal stress cal stress

46597-EN-160921

12 Guided Wave Radar - Level and interface measurement in liquids

Mounting

6 Mounting

Mounting examples The fully PFA insulated VEGAFLEX 83 is ideal for level measurement

in vessels in the food processing and pharmaceutical industries. The

The following illustrations show mounting examples and measurement

sensor can be set up without filling or adjustment with medium. Fully

setups.

insulated rod probes are available in lengths up to 4 m (13 ft) and cable

Storage vessels probes up to 32 m (105 ft).

The wetted parts are made of the food safe plastics PFA and TFM-PTFE.

The measurement is unaffected by product characteristics such as

density, temperature or overpressure. Even foam and buildup do not influ-

ence the measurement.

Different, as well as frequently changing products and mixtures can be

measured.

Bypass tube

Fig. 28: Level measurement in a storage vessel with VEGAFLEX 81

The guided microwave principle is ideal for level measurement in stor- Fig. 30: Level measurement in a bypass tube

age vessels. The sensor can be set up without filling or adjustment with

medium. Standpipes or bypass tubes are often used in distillation columns, e.g. in

the petrochemical industry. Also in this environment, measurement with

Cable and rod probes are available for different lengths and loads.

guided microwaves has many advantages.

The coax version is especially suitable for low viscosity liquids with low

The configuration of the standpipe or bypass tube does not influence the

dielectric constant. This also applies when the requirements on the ac-

measurement. Lateral tube connections, mixing holes, buildup or corro-

curacy of the measurement are very high.

sion in the tube do not influence the measuring result.

The measurement is independent of product characteristics such as den-

Product temperatures up to 400 °C (752 °F) can be measured, up to

sity, temperature, overpressure, foam, dielectric constant and buildup.

150 °C (302 °F) even with standard versions.

Different, as well as frequently changing products and mixtures can be

The sensor utilises nearly the entire vessel height, and can measure with

measured.

high accuracy up to approx. 30 mm (1.181 in) below the process fitting. A

possible overfilling even in this range is detected reliably.

Tanks with foodstuffs

VEGAFLEX sensors are also available with SIL2.

46597-EN-160921

Fig. 29: Level measurement in a vessel with foodstuffs with VEGAFLEX 83

Guided Wave Radar - Level and interface measurement in liquids 13

Electronics - 4 … 20 mA/HART - two-wire

7 Electronics - 4 … 20 mA/HART - two-wire

Configuration of the electronics Connection

The plug-in electronics is mounted in the electronics compartment of the

instrument and can be exchanged by the user when servicing is required.

Single chamber housing

The electronics is completely encapsulated to protect against vibration 2

and moisture.

The terminals for voltage supply as well as the contact pins with I²C

interface for parameter adjustment are located on the upper side of the

electronics. In the double-chamber housing, the terminals are located in 4...20mA

3

the separate terminal compartment.

Voltage supply (+)1 2(-) 5 6 7 8

Power supply and current signal are carried on the same two-wire cable.

4

The operating voltage can differ depending on the instrument version. 1

You can find the data of the voltage supply in chapter "Technical data" in

the operating instructions manual of the respective instrument. Fig. 31: Electronics and terminal compartment, single chamber housing

Provide a reliable separation between the supply circuit and the mains 1 Voltage supply/Signal output

circuits according to DIN EN 61140 VDE 0140-1. 2 For display and adjustment module or interface adapter

3 For external display and adjustment unit

Specifications of the voltage supply: 4 Ground terminal for connection of the cable screen

• Operating voltage

–– 9.6 … 35 V DC Double chamber housing

–– 12 … 35 V DC

• Permissible residual ripple - Non-Ex, Ex-ia instrument 2

–– for 9.6 V< UN < 14 V: ≤ 0.7 Veff (16 … 400 Hz)

–– for 18 V< UN < 35 V: ≤ 1.0 Veff (16 … 400 Hz)

Keep in mind the following additional factors that influence the operating 4...20mA

voltage:

• Lower output voltage of the power supply unit under nominal load

(e.g. with a sensor current of 20.5 mA or 22 mA in case of fault)

• Influence of additional instruments in the circuit (see load values in

(+)1 2(-) 3

chapter "Technical data" of the operating instructions of the respec-

tive instrument) 1

Fig. 32: Terminal compartment, double chamber housing

Connection cable

1 Voltage supply/Signal output

The instrument is connected with standard two-wire cable without 2 For display and adjustment module or interface adapter

screen. If electromagnetic interference is expected which is above the 3 Ground terminal for connection of the cable screen

test values of EN 61326-1 for industrial areas, screened cable should be

used. Wire assignment, connection cable with version IP 66/IP 68, 1 bar

We generally recommend the use of screened cable for HART multidrop

mode.

1

Cable screening and grounding

If screened cable is required, we recommend connecting the cable

2

screen on both ends to ground potential. In the sensor, the screen must

be connected directly to the internal ground terminal. The ground terminal Fig. 33: Wire assignment in permanently connected connection cable

on the outside of the housing must be connected to the ground potential 1 Brown (+) and blue (-) to power supply or to the processing system

(low impedance). 2 Shielding

46597-EN-160921

14 Guided Wave Radar - Level and interface measurement in liquids

Electronics - 4 … 20 mA/HART - four-wire

8 Electronics - 4 … 20 mA/HART - four-wire

Configuration of the electronics

The plug-in electronics is mounted in the electronics compartment of the

instrument and can be exchanged by the user when servicing is required.

The electronics is completely encapsulated to protect against vibration

and moisture.

The contact pins with I²C interface for parameter adjustment are located

on the upper side of the electronics. The terminals for the power supply

are located in the separate connection compartment.

Voltage supply

If a reliable separation is required, the power supply and the current

output are transmitted over separate two-wire connection cables.

• Operating voltage with version for low voltage

–– 9.6 … 48 V DC, 20 … 42 V AC, 50/60 Hz

• Operating voltage with version for mains voltage

–– 90 … 253 V AC, 50/60 Hz

Connection cable

The 4 … 20 mA current output is connected with standard two-wire

cable without screen. If electromagnetic interference is expected which

is above the test values of EN 61326 for industrial areas, screened cable

should be used.

For power supply, an approved installation cable with PE conductor is

required.

Cable screening and grounding

If screened cable is required, we recommend connecting the cable

screen on both ends to ground potential. In the sensor, the screen must

be connected directly to the internal ground terminal. The ground terminal

on the outside of the housing must be connected to the ground potential

(low impedance).

Connection, double chamber housing

4...20mA

common

IS GND

passive

active

power supply

(+)1 2(-) 5 6 7 8

/L

/N

PE

Fig. 34: Terminal compartment, double chamber housing

1 Voltage supply

2 4 … 20 mA signal output active

3 4 … 20 mA signal output passive

Terminal Function Polarity

1 Voltage supply +/L

2 Voltage supply -/N

5 4 … 20 mA output (active) +

6 4 … 20 mA output (passive) +

7 Mass - output -

8 Functional ground with installa-

tion according to CSA

46597-EN-160921

Guided Wave Radar - Level and interface measurement in liquids 15

Electronics - Profibus PA

9 Electronics - Profibus PA

Configuration of the electronics Double chamber housing

The plug-in electronics is mounted in the electronics compartment of the 2

instrument and can be exchanged by the user when servicing is required.

The electronics is completely encapsulated to protect against vibration

and moisture.

The terminals for voltage supply as well as the plug with I²C interface for Bus

3

parameter adjustment are located on the upper side of the electronics. In

the double-chamber housing, these connection elements are located in

the separate terminal compartment.

(+)1 2(-) 5 6 7 8 4

Voltage supply

1

The voltage supply is provided by a Profibus DP /PA segment coupler.

Specifications of the voltage supply: Fig. 36: Terminal compartment, double chamber housing

• Operating voltage 1 Voltage supply, signal output

–– 9 … 32 V DC 2 For display and adjustment module or interface adapter

• Max. number of sensors per DP/PA segment coupler 3

4

For external display and adjustment unit

Ground terminal for connection of the cable screen

–– 32

Wire assignment, connection cable with version IP 66/IP 68, 1 bar

Connection cable

Connection is carried out with screened cable according to Profibus

specification. 1

Make sure that the entire installation is carried out according to the Profi-

bus specification. In particular, make sure that the bus is terminated with

suitable terminating resistors. 2

Fig. 37: Wire assignment in permanently connected connection cable

Cable screening and grounding

1 Brown (+) and blue (-) to power supply or to the processing system

In systems with potential equalisation, connect the cable screen directly 2 Shielding

to ground potential at the power supply unit, in the connection box and

at the sensor. The screen in the sensor must be connected directly to

the internal ground terminal. The ground terminal outside on the housing

must be connected to the potential equalisation (low impedance).

In systems without potential equalisation, connect the cable screen di-

rectly to ground potential on the power supply unit and the sensor. In the

connection box or T-distributor, the screen of the short stub to the sensor

may not be connected to ground potential or to another cable screen.

Connection

Single chamber housing

2

3

0 901 901

78

78

23

23

4

1

0 45 6 45 6

Bus

(+)1 2(-) 5 6 7 8 5

1

Fig. 35: Electronics and terminal compartment, single chamber housing

1 Voltage supply/Signal output

2 For display and adjustment module or interface adapter

3 Selection switch for bus address

4 For external display and adjustment unit

5 Ground terminal for connection of the cable screen

46597-EN-160921

16 Guided Wave Radar - Level and interface measurement in liquids

Electronics - Foundation Fieldbus

10 Electronics - Foundation Fieldbus

Configuration of the electronics Double chamber housing

The plug-in electronics is mounted in the electronics compartment of the 2

instrument and can be exchanged by the user when servicing is required.

The electronics is completely encapsulated to protect against vibration

and moisture.

The terminals for voltage supply as well as the contact pins with I²C Bus

3

interface for parameter adjustment are located on the upper side of the

electronics. In the double-chamber housing, the terminals are located in

the separate terminal compartment.

(+)1 2(-) 5 6 7 8 4

Voltage supply

1

Power supply via the H1 Fieldbus cable.

Specifications of the voltage supply: Fig. 39: Terminal compartment, double chamber housing

• Operating voltage 1 Voltage supply, signal output

–– 9 … 32 V DC 2 For display and adjustment module or interface adapter

• max. number of sensors 3

4

For external display and adjustment unit

Ground terminal for connection of the cable screen

–– 32

Wire assignment, connection cable with version IP 66/IP 68, 1 bar

Connection cable

Connection is carried out with screened cable according to Fieldbus

specification. 1

Make sure that the entire installation is carried out according to the Field-

bus specification. In particular, make sure that the bus is terminated with

suitable terminating resistors. 2

Fig. 40: Wire assignment in permanently connected connection cable

Cable screening and grounding

1 Brown (+) and blue (-) to power supply or to the processing system

In systems with potential equalisation, connect the cable screen directly 2 Shielding

to ground potential at the power supply unit, in the connection box and

at the sensor. The screen in the sensor must be connected directly to

the internal ground terminal. The ground terminal outside on the housing

must be connected to the potential equalisation (low impedance).

In systems without potential equalisation, connect the cable screen di-

rectly to ground potential on the power supply unit and the sensor. In the

connection box or T-distributor, the screen of the short stub to the sensor

may not be connected to ground potential or to another cable screen.

Connection

Single chamber housing

2

3

0

4

1

0

Bus

(+)1 2(-) 5 6 7 8 5

1

Fig. 38: Electronics and terminal compartment, single chamber housing

1 Voltage supply/Signal output

2 Contact pins for the display and adjustment module or interface adapter

3 Selection switch for bus address

4 For external display and adjustment unit

5 Ground terminal for connection of the cable screen

46597-EN-160921

Guided Wave Radar - Level and interface measurement in liquids 17

Electronics, Modbus, Levelmaster protocol

11 Electronics, Modbus, Levelmaster protocol

Configuration of the electronics

The plug-in electronics is mounted in the electronics compartment of the

instrument and can be exchanged by the user when servicing is required.

The electronics is completely encapsulated to protect against vibration

and moisture.

The contact pins with I²C interface for parameter adjustment are located

on the upper side of the electronics. The terminals for the power supply

are located in the separate connection compartment.

Voltage supply

Power supply via the Modbus host (RTU)

• Operating voltage

–– 8 … 30 V DC

• max. number of sensors

–– 32

Connection cable

Connection is carried out with screened cable according to Fieldbus

specification.

For power supply, a separate two-wire cable is required.

In the product configurator of VEGAFLEX, different cable glands can

be selected. They cover all cable diameters in the range of 4 … 12 mm

(0.16 … 0.47 in).

Make sure that the entire installation is carried out according to the Field-

bus specification. In particular, make sure that the bus is terminated with

suitable terminating resistors.

Cable screening and grounding

In systems with potential equalisation, connect the cable screen directly

to ground potential at the power supply unit, in the connection box and

at the sensor. The screen in the sensor must be connected directly to

the internal ground terminal. The ground terminal outside on the housing

must be connected to the potential equalisation (low impedance).

In systems without potential equalisation, connect the cable screen di-

rectly to ground potential on the power supply unit and the sensor. In the

connection box or T-distributor, the screen of the short stub to the sensor

may not be connected to ground potential or to another cable screen.

Connection

Double chamber housing

1

USB MODBUS

IS GND

D1 (-)

D0 (+)

power supply

(+)1 2(-) off on 3 4 5

4 3

Fig. 41: Terminal compartment

1 USB interface

2 Slide switch for integrated termination resistor (120 Ω)

3 Voltage supply

4 Modbus signal

46597-EN-160921

18 Guided Wave Radar - Level and interface measurement in liquids

Adjustment

12 Adjustment

12.1 Adjustment on the measurement loop PACTware is an adjustment software for configuration, parameter adjust-

ment, documentation and diagnosis of field devices. The corresponding

Via the display and adjustment module through keys device drivers are called DTMs.

The plug-in display and adjustment module is used for measured value

indication, adjustment and diagnosis. It is equipped with an illuminated 12.2 Operation in the measurement loop environ-

full dot matrix as well as four keys for adjustment.

ment - wireless via Bluetooth

Via a smartphone/tablet

The display and adjustment module with integrated Bluetooth functional-

ity allows wireless connection to smartphones/tablets with iOS or Android

operating system. The adjustment is carried out via the VEGA Tools app

from the Apple App Store or Google Play Store.

Fig. 42: Display and adjustment module with single chamber housing

Via the display and adjustment module through magnetic pen

With the Bluetooth version of the display and adjustment module, the

sensor can also be adjusted with the magnetic pen. This is done right 2

through the closed lid (with inspection window) of the sensor housing. 3

Fig. 45: Wireless connection to smartphones/tables

1 Display and adjustment module

2 Sensor

3 Smartphone/Tablet

Via a PC with PACTware/DTM

The wireless connection from the PC to the sensor is carried out via

the Bluetooth USB adapter and a display and adjustment module with

integrated Bluetooth function. The adjustment is carried out via the PC

with PACtware/DTM.

Fig. 43: Display and adjustment module - with adjustment via magnetic pen 2

Via a PC with PACTware/DTM 4

The interface converter VEGACONNECT is required for connection of

the PC. The converter is placed on the sensor instead of the display and

adjustment module and connected to the USB interface of the PC. 3

1 Fig. 46: Connection of the PC via Bluetooth adapter

1 Display and adjustment module

2 Sensor

3 Bluetooth USB adapter

4 PC with PACTware/DTM

2

12.3 Adjustment carried out at position remote from

4

the measuring point - wired

Via external display and adjustment units

For this, the external display and adjustment units VEGADIS 81 and 82

3

are available. The adjustment is carried out via the keys of the built-in

Fig. 44: Connection of the PC via VEGACONNECT and USB display and adjustment module.

1 VEGACONNECT The VEGADIS 81 is mounted at a distance of 50 m from the sensor and

46597-EN-160921

2 Sensor directly to the sensor electronics. VEGADIS 82 is looped directly into the

3 USB cable to the PC signal cable at any point.

4 PC with PACTware/DTM

Guided Wave Radar - Level and interface measurement in liquids 19

Adjustment

3

4

5

Fig. 50: Transmission of measured values and remote parameter adjustment of the

sensor via mobile phone network.

4

1

12.5 Alternative adjustment programs

Fig. 47: Connection of VEGADIS 81 to the sensor

1 Voltage supply/Signal output sensor

DD adjustment programs

2 Sensor Device descriptions as Enhanced Device Description (EDD) are available

3 Connection cable sensor - external display and adjustment unit for DD adjustment programs such as, for example, AMS™ and PDM.

4 External display and adjustment unit The files can be downloaded at www.vega.com/downloads under "Soft-

5 Display and adjustment module

ware".

5 Field Communicator 375, 475

Device descriptions for the instrument are available as EDD for param-

eter adjustment with the Field Communicator 375 or 475.

For the integration of the EDD in the Field Communicator 375 or 475, the

4 software "Easy Upgrade Utility" is required which is available from the

manufacturer. This software is updated via the Internet and new EDDs

3 are automatically taken over into the device catalogue of this software

after they are released by the manufacturer. They can then be transferred

2 to a Field Communicator.

1

Fig. 48: Connection of VEGADIS 82 to the sensor

1 Voltage supply/Signal output sensor

2 External display and adjustment unit

3 Display and adjustment module

4 4 … 20 mA/HART signal cable

5 Sensor

Via a PC with PACTware/DTM

The sensor adjustment is carried out via a PC with PACTware/DTM.

4

3

2

6

1

Fig. 49: Connection of VEGADIS 82 to the sensor, adjustment via PC with PACT-

ware

1 Voltage supply/Signal output sensor

2 External display and adjustment unit

3 VEGACONNECT

4 4 … 20 mA/HART signal cable

5 Sensor

6 PC with PACTware/DTM

12.4 Adjustment carried out at position remote from

the measuring point - wireless through mobile

network

As an option, the radio module PLICSMOBILE can be mounted into a

46597-EN-160921

plics® sensor with double chamber housing. It is used for transmission of

measured values and for remote parameter adjustment of the sensor.

20 Guided Wave Radar - Level and interface measurement in liquids

Dimensions

13 Dimensions

Plastic housing VEGAFLEX 81, cable and rod version

~ 69 mm ~ 84 mm

(2.72") (3.31")

ø 79 mm ø 79 mm

(3.11") (3.11")

M16x1,5

112 mm

112 mm

(4.41")

(4.41")

SW 55 mm

(2.17")

M20x1,5/

½ NPT

M20x1,5/ SW 36 mm

68 mm

51 mm

(2.68")

(2.01")

1 ½ NPT 2 (1.42")

96 mm

(3.78")

1 Single chamber housing

G1 ½

2 Double chamber housing

30 mm

(1.18")

G¾

Aluminium housing

22 mm

(0.87")

~ 116 mm ~ 87 mm

(4.57") (3.43")

ø 86 mm ø 86 mm

(3.39") (3.39")

ø 12 mm ø 8 mm

M16x1,5 (0.47") (0.32")

116 mm

(4.57")

120 mm

L

(4.72")

L

L

M20x1,5/ M20x1,5

½ NPT

M20x1,5/ ø 4 mm

1 ½ NPT 2 (0.16")

1 Single chamber housing

2 Double chamber housing

100 mm (3.94")

ø 20 mm

(0.79")

Stainless steel housing

~ 59 mm ~ 69 mm ~ 87 mm

(2.32") (2.72") (3.43")

ø 80 mm ø 86 mm

ø 79 mm

(3.15") (3.39")

(3.11")

1 2 3

M16x1,5

Fig. 54: VEGAFLEX 81, cable and rod version

117 mm

120 mm

112 mm

(4.61")

(4.72")

(4.41")

1 Cable version, ø 4 mm (0.16 in) with threaded fitting

M20x1,5/ 2 Rod version, ø 12 mm (0.47 in) with threaded fitting

M20x1,5/

½ NPT

3 Rod version, ø 8 mm (0.32 in) with flange connection

M20x1,5/

½ NPT 1 2 ½ NPT 3 L Sensor length, see chapter "Technical data"

1 Single chamber housing, electropolished

2 Single chamber housing, precision casting

2 Double chamber housing, precision casting

46597-EN-160921

Guided Wave Radar - Level and interface measurement in liquids 21

Dimensions

VEGAFLEX 81, Coax version VEGAFLEX 83, PFA coated version

SW 55 mm

(2.17")

SW 36 mm

(1.42")

46 mm

(1.81")

51 mm

(2.01")

69,4 mm

81 mm

(3.19")

(2.73")

70 mm

(2.76")

G¾

G1 ½

22 mm

(0.86")

L

L

L

ø 4 mm

(0.16")

120 mm (4.72")

ø 21,3 mm ø 10 mm ø 20 mm

(0.84") (0.39") (0.79")

ø 42,2 mm

(1.66")

1 2 1 2

Fig. 56: VEGAFLEX 83, PFA coated version

Fig. 55: VEGAFLEX 81, Coax version

1 Rod version, ø 10 mm (0.39 in) with flange connection

1 Coax version, ø 21.3 mm (0.84 in) with threaded fitting 2 Cable version, ø 4 mm (0.16 in) with Clamp connection

2 Coax version, ø 42.2 mm (1.66 in) with threaded fitting L Sensor length, see chapter "Technical data"

3 Coax version, ø 42.2 mm (1.66 in) with flange connection

L Sensor length, see chapter "Technical data"

46597-EN-160921

22 Guided Wave Radar - Level and interface measurement in liquids

Dimensions

VEGAFLEX 83, polished version VEGAFLEX 86, cable and rod version

56 mm

(2.20")

312 mm (12.28")

237 mm (9.33")

L

45 mm

(1.77")

L

L

ø 4 mm ø 4 mm

(0.16") (0.16")

ø 10 mm

(0.39")

100 mm

(3.94")

ø 16 mm ø 20 mm

(0.63") (0.79")

Fig. 57: VEGAFLEX 83, polished version (Basle Standard), rod version ø 10 mm

(0.39 in) with Clamp connection

1 2 3 4

L Sensor length, see chapter "Technical data"

Fig. 58: VEGAFLEX 86, cable and rod version with threaded fitting

1 Rod version, ø 16 mm (0.63 in), -20 … +250 °C/-4 … +482 °F

2 Cable version, ø 4 mm (0.16 in), -20 … +250 °C/-4 … +482 °F

3 Rod version ø 16 mm (0.63 in), -200 … +400 °C/-328 … +752 °F

4 Cable version, ø 4 mm (0.16 in), -200 … +400 °C/-328 … +752 °F

L Sensor length, see chapter "Technical data"

46597-EN-160921

Guided Wave Radar - Level and interface measurement in liquids 23

Dimensions

VEGAFLEX 86, Coax version

312 mm (12.28")

237 mm (9.33")

35 mm

(1.38")

57 mm

(2.24")

L

ø 42,2 mm

(1.66")

1 2

Fig. 59: VEGAFLEX 86, coax version with threaded fitting

1 Coax version, ø 42.2 mm (1.66 in), -20 … +250 °C/-4 … +482 °F

2 Coax version, ø 42.2 mm (1.66 in), -200 … +400 °C/-328 … +752 °F

L Sensor length, see chapter "Technical data"

The listed drawings are only an excerpt of the available process fittings.

You can find more drawings on our homepage www.vega.com » Down-

loads » Drawings.

46597-EN-160921

24 Guided Wave Radar - Level and interface measurement in liquids

Notes

46597-EN-160921

Guided Wave Radar - Level and interface measurement in liquids 25

Notes

46597-EN-160921

26 Guided Wave Radar - Level and interface measurement in liquids

Notes

46597-EN-160921

Guided Wave Radar - Level and interface measurement in liquids 27

All statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems correspond to the information

available at the time of printing.

Subject to change without prior notice

© VEGA Grieshaber KG, Schiltach/Germany 2016

46597-EN-160921

VEGA Grieshaber KG Phone +49 7836 50-0

Am Hohenstein 113 Fax +49 7836 50-201

77761 Schiltach E-mail: info.de@vega.com

Germany www.vega.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Brigada Pagbasa Action Plan SY 2021 - 2022Document3 pagesBrigada Pagbasa Action Plan SY 2021 - 2022Jazzele Longno95% (20)

- Review Test Submission: Test 2 - CIST1305-Program Design...Document7 pagesReview Test Submission: Test 2 - CIST1305-Program Design...Rahsaan JahiNo ratings yet

- Pressure Gauge - Isolator Valve Type AF 6: Nominal Size 6 Series 4X Maximum Operating Pressure 300 BarDocument4 pagesPressure Gauge - Isolator Valve Type AF 6: Nominal Size 6 Series 4X Maximum Operating Pressure 300 BarMSc Kostic MilosNo ratings yet

- KR 32 - 20210922Document4 pagesKR 32 - 20210922MSc Kostic MilosNo ratings yet

- General Catalogue: Cod. 9910204 - 10/2015 Stampa: Euroteam (BS)Document1,222 pagesGeneral Catalogue: Cod. 9910204 - 10/2015 Stampa: Euroteam (BS)MSc Kostic MilosNo ratings yet

- iwsh (Lzzpal P (Owvy (Punwh ( (Lyu (V +05MVYT (HUK0:6: 9, 9Lwshjlz!Document4 pagesiwsh (Lzzpal P (Owvy (Punwh ( (Lyu (V +05MVYT (HUK0:6: 9, 9Lwshjlz!MSc Kostic MilosNo ratings yet

- Merkel Omegat Oms-Mr: Value To The CustomerDocument3 pagesMerkel Omegat Oms-Mr: Value To The CustomerMSc Kostic MilosNo ratings yet

- Re27551 - 2020 11 04Document12 pagesRe27551 - 2020 11 04MSc Kostic MilosNo ratings yet

- Hoses English Imperial E329Document2 pagesHoses English Imperial E329MSc Kostic MilosNo ratings yet

- Load Sensing ControlDocument2 pagesLoad Sensing ControlMSc Kostic MilosNo ratings yet

- Tapr... U PDFDocument1 pageTapr... U PDFMSc Kostic MilosNo ratings yet

- Quality 1.2080 Chemical Composition: Lucefin GroupDocument1 pageQuality 1.2080 Chemical Composition: Lucefin GroupMSc Kostic MilosNo ratings yet

- CHAPTER 4: ISO Symbols: Family of Graphic SymbolsDocument14 pagesCHAPTER 4: ISO Symbols: Family of Graphic SymbolsMSc Kostic MilosNo ratings yet

- 6603C45Document8 pages6603C45MSc Kostic MilosNo ratings yet

- GGB DU BearingsDocument52 pagesGGB DU BearingsMSc Kostic MilosNo ratings yet

- List of Items Which Key Is Not Available in The DepartmentDocument1 pageList of Items Which Key Is Not Available in The DepartmentninupgNo ratings yet

- Adm2 FR Operating Manual 15 07 02Document160 pagesAdm2 FR Operating Manual 15 07 02Avs Electron100% (2)

- MR 222 Trafic 2Document116 pagesMR 222 Trafic 2RobertNo ratings yet

- Text Classification To Predict Skin Concerns Over Skincare Using Bidirectional Mechanism in Long Short-Term MemoryDocument11 pagesText Classification To Predict Skin Concerns Over Skincare Using Bidirectional Mechanism in Long Short-Term MemoryCSIT iaesprimeNo ratings yet

- Terastandard - Bsi Bs Iso 5597 267Document26 pagesTerastandard - Bsi Bs Iso 5597 267baladiroyaNo ratings yet

- DS PPTDocument221 pagesDS PPTanilperfectNo ratings yet

- Test Bank For Purchasing and Supply Management 14th Edition P Fraser JohnsonDocument6 pagesTest Bank For Purchasing and Supply Management 14th Edition P Fraser JohnsontostoillyoqiNo ratings yet

- Effect of Computers On Internal ControlDocument13 pagesEffect of Computers On Internal ControlAyessa Marie AngelesNo ratings yet

- Sap PP Configuration DocumentDocument75 pagesSap PP Configuration DocumentRafaelCasagrandeNo ratings yet

- Filed Work 2 On DemocracyDocument2 pagesFiled Work 2 On DemocracyNaveed AhmedNo ratings yet

- S09 Power TrainDocument90 pagesS09 Power TrainPLANEAMIENTO MDRILLNo ratings yet

- Compactlogix 5370 Controllers, Revision 21: Release NotesDocument22 pagesCompactlogix 5370 Controllers, Revision 21: Release NotesMarcosNo ratings yet

- Medical Equipment Laboratory ManualDocument59 pagesMedical Equipment Laboratory ManualDelcides NunesNo ratings yet

- Thesis On Higher Education in PakistanDocument7 pagesThesis On Higher Education in Pakistanpattybuckleyomaha100% (2)

- Komatsu Parts Numbering System: Call The ExpertsDocument30 pagesKomatsu Parts Numbering System: Call The ExpertsChristian MorenoNo ratings yet

- A330 AMM ch06Document170 pagesA330 AMM ch06Larry BoguesNo ratings yet

- Offer Summary - 17 August 2021: Ultra Fast Broadband - Naked Fibremax You Choose OfferDocument4 pagesOffer Summary - 17 August 2021: Ultra Fast Broadband - Naked Fibremax You Choose OfferRegan RidgeNo ratings yet

- KSP UI ManualDocument61 pagesKSP UI ManualHadi HosriNo ratings yet

- Gabriel 2020Document2 pagesGabriel 2020robin rajanNo ratings yet

- Math-102-Section-8.5-L52-with SolutionDocument16 pagesMath-102-Section-8.5-L52-with SolutionGharsellaoui MuhamedNo ratings yet

- Annual Report 2020 PDFDocument165 pagesAnnual Report 2020 PDFNRNo ratings yet

- Lista Motor 3066 (Exc. 320c)Document5 pagesLista Motor 3066 (Exc. 320c)enrique chavezNo ratings yet

- (A305) Otomatik Kontrol Ders Notu (Slayt)Document27 pages(A305) Otomatik Kontrol Ders Notu (Slayt)Mücahit Ezel100% (1)

- ABENDI & ASME Workshop - N Finney W Hembree - Section VDocument114 pagesABENDI & ASME Workshop - N Finney W Hembree - Section VMarciel AmorimNo ratings yet

- EGA Pipa ConduitDocument2 pagesEGA Pipa ConduitDerahamaniNo ratings yet

- Matlab Homework SolutionsDocument10 pagesMatlab Homework Solutionsewbp4y3sNo ratings yet

- RT 200Document50 pagesRT 200Memo PáezNo ratings yet

- Contribuição de Alguns Sites de Estudos.Document5 pagesContribuição de Alguns Sites de Estudos.ruben adrielNo ratings yet