Professional Documents

Culture Documents

Banner SM312CV2 Datasheet

Uploaded by

Marlon MorelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Banner SM312CV2 Datasheet

Uploaded by

Marlon MorelCopyright:

Available Formats

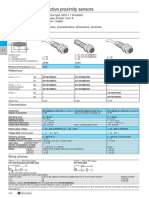

MINI-BEAM® SM312CV and SM312CV2

Self-contained DC-operated Convergent Mode Sensors

• Compact, modulated, self-contained convergent mode sensors for

10-30V dc operation

• Produces a precise 1.3 mm (0.05") diameter sensing spot at a

focus point 16 mm (0.65") from the lens surface (model SM312CV)

or a 3.0 mm (0.12") sensing spot at 43 mm (1.70") focus (model

SM312CV2)

• Switch-selectable for light operate or dark operate

• Includes Banner’s exclusive AID™ alignment system*

• Highly repeatable 1 millisecond response

• Both sourcing and sinking outputs (150 mA max. each); continuous

overload and short-circuit protected

• Rugged, epoxy-encapsulated construction: meets NEMA standards

1, 2, 3, 3S, 4, 4X, 6, 12 and 13; IEC IP67

• Physically and electrically interchangeable with 18 mm barrel-type

photoelectrics

*US patent number 4356393

Visible red, 650 nm

MINI-BEAM Convergent Mode Models

Supply Output Excess Gain Beam Pattern

Models Range Cable Voltage Type

Performance based on 90% reflectance white test card

1000

SM312CV

16 mm E 3.0 mm

SM312CV 0.12 in

X Convergent Mode

(0.65 in) C

Convergent Mode 2.0 mm 0.08 in

100

E 1.0 mm 0.04 in

S 0 0

SM312CV Spot 2 m (6.5 ft) Bipolar S

10-30V dc 1.0 mm 0.04 in

SM312CVQD Size 4-Pin Euro QD NPN/PNP G 10 2.0 mm 0.08 in

A

at Focus: I

3.0 mm 0.12 in

N

1.3 mm 1

0 7.5 mm

0.3 in

15 mm 22.5 mm 30 mm 37.5 mm

0.6 in 0.9 in 1.2 in 1.5 in

(0.05 in) 1 mm

.04 in

10 mm

.4 in

100 mm

4 in

1000 mm

40 in DISTANCE

DISTANCE

1000

43 mm E

SM312CV2

SM312CV2

(1.7 in) X

C

Convergent Mode 3.0 mm

Convergent Mode

0.12 in

100 2.0 mm 0.08 in

E

S 1.0 mm 0.04 in

SM312CV2 Spot 2 m (6.5 ft) Bipolar S 0 0

10-30V dc

SM312CV2QD Size 4-Pin Euro QD NPN/PNP G 10 1.0 mm 0.04 in

A 2.0 mm 0.08 in

at Focus: I 3.0 mm 0.12 in

N

3.0 mm 1 0 25 mm 50 mm 75 mm 100 mm 125 mm

(0.12 in) 1 mm

.04 in

10 mm

.4 in

100 mm

4 in

1000 mm

40 in

1 in 2 in 3 in 4 in 5 in

DISTANCE

DISTANCE

For Standard MINI-BEAMs:

i) 9 m (30 ft) cables are available by adding suffix “W/30” to the model number of any cabled sensor (e.g. - SM312CV W/30).

ii) A 150 mm (6 in.) long pigtail cable with attached QD connector is available by adding suffix “QDP” to the model number of any

MINI-BEAM sensor (e.g. - SM312CVQDP). See page 5 for more information.

iii) A model with a QD connector requires an accessory mating cable. See page 8 for more information.

iv) May be ordered with 0.3 millisecond on/off response by adding suffix “MHS” to the model numbers (e.g. - SM312CVMHS). This

modification reduces sensing range (and excess gain).

Printed in USA 05/01 P/N 03365 rev. D

MINI-BEAM® Sensors SM312CV and SM312CV2

MINI-BEAM Installation and Alignment

Proper operation of the SM312CV or SM312CV2 sensor requires that it be mounted

securely and aligned properly. In some applications, excessive movement or CONVERGENT MODE ALIGNMENT

vibration can result in intermittent or false operation caused by loss of alignment. nd

rou

For best results, final-mount the sensor in an 18mm-hole by its threaded barrel or Bac

kg

v ity

use a mounting bracket (see page 6). fle

cti

Re

w

Lo

Begin with the sensor at the approximate position where it will be mounted. With

power applied to the circuit and with the sensor set for “light operate”, direct the jec

t

Ob

sensor’s visible red spot at the object approximately 16 mm (0.65 in) (for model SM312CV

SM312CV) or 43 mm (1.7 in) (for model SM312CV2) directly in front of the lens. or

SM312CV2

Move the sensor very slightly toward or away from the object while observing the

red LED indicator on the back of the sensor. Note the near and far points at which

sensing occurs (the range of distance over which the LED remains lit). Mount the Up

sensor at a point approximately midway in the range. This should correspond to the t

gh

Ri

point at which the red sensing spot on the object appears most sharply defined on

the object surface. Mount the sensor at this position and distance.

ft

Le

wn

Do

Distance from Sensor lens to object:

16 mm (0.65 in) for SM312CV

43 mm (1.7 in) for SM312CV2

* Note regarding Light/Dark operate switch:

• Turn switch fully clockwise for light operate (sensor outputs conduct when 15 Turn

Gain

sensing light is received) Adjustment

• Turn switch fully counterclockwise for dark operate (sensor outputs conduct and Light/Dark

Operate Switch*

when sensing light is not received)

Gasketed

Acrylic Cover

“AID” Indicator LED Lights when the

sensor sees its own modulated

light and pulses at a rate proportional to the

strength of the received light signal.

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

page 2

MINI-BEAM® Sensors SM312CV and SM312CV2

MINI-BEAM DC Sensor Specifications

Supply Voltage and Current 10 to 30V dc (10% maximum ripple) at less than 25 mA (exclusive of load)

Supply Protection Circuitry Protected against reverse polarity and transient voltages

Output Configuration Bipolar: One current sourcing (PNP) and one current sinking (NPN) open-collector transistor

Output Rating 150mA maximum each output at 25°C, derated to 100 mA at 70°C (derate ≈1 mA per °C)

Off-state leakage current less than 1 microamp

Output saturation voltage (PNP output) less than 1 volt at 10 mA and less than 2 volts at 150 mA

Output saturation voltage (NPN output) less than 200 millivolts at 10 mA and less than 1 volt at 150 mA

Output Protection Circuitry Protected against false pulse on power-up and continuous overload or short-circuit of outputs

Output Response Time Sensors will respond to either a "light" or a "dark" signal of 1 millisecond or longer duration, 500 Hz max.

0.3 millisecond response modification is available. See note below.

100 millisecond delay on power-up: outputs do not conduct during this time.

Repeatability 0.3 milliseconds. Response time and repeatability specifications are independent of signal strength.

Adjustments LIGHT/DARK OPERATE select switch, and 15-turn slotted brass screw GAIN (sensitivity) adjustment

potentiometer (clutched at both ends of travel). Both controls are located on rear panel of sensor and

protected by a gasketed, clear acrylic cover.

Indicators Exclusive, patented Alignment Indicating Device system (AID™, US patent #4356393) lights a rear-panel

mounted red LED indicator whenever the sensor sees a "light" condition, with a superimposed pulse rate

proportional to the light signal strength (the stronger the signal, the faster the pulse rate).

Construction Reinforced PBT thermoplastic polyester housing, totally encapsulated, o-ring sealing, acrylic lenses, and

stainless steel screws.

Environmental Rating Meets NEMA standards 1, 2, 3, 3S, 4, 4X, 6, 12, and 13; IEC IP67

Connections PVC-jacketed 4-conductor 2 m (6.5 ft) or 9 m (30 ft) cables, or 4-pin euro-style quick disconnect (QD)

fitting are available. QD cables are ordered separately. See page 5.

Operating Temperature Temperature: -20° to +70°C (-4° to +158°F)

Maximum relative humidity: 90% at 50°C (non-condensing)

Application Notes The NPN (current sinking) output of dc MINI-BEAM sensors is directly compatible as an input to Banner

logic modules, including all non-amplified MAXI-AMP and MICRO-AMP modules. MINI-BEAMs are

TTL compatible.

Certifications

NOTE: DC MINI-BEAMs may be ordered with 0.3 millisecond on/off response by adding suffix “MHS” to the model numbers

(e.g. - SM312CVMHS). This modification reduces sensing range (and excess gain).

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

page 3

MINI-BEAM® Sensors SM312CV and SM312CV2

MINI-BEAM DC Hookup Diagrams

DC Sensors with Attached Cable DC Sensors with Quick Disconnect

(4-Pin Euro-Style)

bn bn

+ +

bu 10-30V dc bu 10-30V dc

– –

wh wh

Load Load

bk bk

Load Load

4-Pin Euro-Style Pin-out

(Cable Connector Shown)

White Wire

Quick Disconnect (QD) Option

Brown Wire DC MINI-BEAM sensors are sold with either a 2 m (6.5 ft)

Blue Wire

or a 9 m (30 ft) attached PVC-covered cable, or with a 4-pin

Black Wire euro-style QD cable fitting.

DC QD sensors are identified by the letters “QD” in their

model number suffix. For more information on mating QD

cables, see page 5.

MINI-BEAM Dimension Information

MINI-BEAM DC Sensor with Integral Cable MINI-BEAM DC Sensor with Quick-Disconnect

3.2 mm (0.13 in)

12.2 mm (0.48 in)

30.7 mm

(1.21 in)

24.1 mm

ø 3 mm Clearance (2)

(0.95 in)

M18 x 1 x 15 mm Thread

(Mounting Nut Supplied)

M12 x 1 Thread

2 m (6.5 ft) Cable Quick Disconnect

Mounting Peg

(ø 6.3 mm x 2.5 mm)

19.1 mm (0.75 in)

27.4 mm (1.08 in) 72.2 mm (2.84 in)

53.3 mm (2.10 in)

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

page 4

MINI-BEAM® Sensors SM312CV and SM312CV2

MINI-BEAM MODIFICATIONS

Example of Model

Model Suffix Modification Description

Number

All MINI-BEAM sensors may be ordered with an integral 9 m (30 ft)

W/30 9 meter (30 ft) cable SM312CV W/30

cable in place of the standard 2 m (6.5 ft) cable

Standard dc MINI-BEAM sensors with 1 millisecond output response may

Modified for High be modified for 0.3 millisecond (300 µs) response.

MHS SM312CVMHS

Speed NOTE: Faster response comes at the expense of lower excess gain.

Also, operating temperature range becomes -20º to +50ºC (-4º to +122ºF)

All MINI-BEAMs may be built

with a 150 mm (6 in) long

Pigtail Quick

QDP integral cable which is SM312CVQDP

Disconnect

terminated with the

appropriate QD connector.

Replacement Lens Assemblies

MINI-BEAM lens assemblies are field-replaceable.

Model Description

UC-300C.7 Replacement lens for CV

UC-300C2 Replacement lens for CV2

Euro-Style Quick Disconnect Cables

Cable: PVC jacket, polyurethane connector body, nickel-plated brass coupling nut

Conductors: 22 or 20 AWG high-flex stranded, PVC insulation, gold-plated contacts

Temperature: -40 to +90°C (-40 to +194°F)

Voltage Rating: 250V ac/300V dc

Style Model Length Dimensions: Pin-out

MQDC-406 2 m (6.5 ft) ø15 mm

4-Pin

MQDC-415 5 m (15 ft) (0.6 in)

Straight

MQDC-430 9 m (30 ft) M12 x 1

44 mm max.

(1.7 in)

White Wire

38 mm max. Brown Wire

(1.5 in)

Blue Wire

Black Wire

MQDC-406RA 2 m (6.5 ft) 38 mm max.

4-Pin

MQDC-415RA 5 m (15 ft) (1.5 in)

Right-angle

MQDC-430RA 9 m (30 ft)

M12 x 1

ø15 mm

(0.6 in)

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

page 5

MINI-BEAM® Sensors SM312CV and SM312CV2

Extension Cables (without connectors)

The following cables are available for extending the length of existing sensor cable. These are 30 m (100 ft) lengths of MINI-BEAM cable.

This cable may be spliced to existing cable. Connectors, if used, must be customer-supplied.

Model Type Used with:

EC312-100 4-conductor All MINI-BEAM SM312 dc models

Mounting Brackets

Model Description

R 24.1 mm

R 5.1 mm (0.95 in)

(0.20 in) 10° (TYP)

15° 4.32 mm

(2)

CL 31.8 mm (0.170 in) 20.3 mm

(1.25 in) Slot (2) (0.80 in)

20°

Stainless steel 2-axis, side ø 3.05 mm Slot

SMB312S ø 3.05 mm (0.120 in)

R 3.1 mm

mounting bracket (0.120 in) (0.12 in) (2)

90° 20.1 mm

(0.79 in)

2.5 mm

(0.10 in) 45.5 mm

(1.79 in)

R 24.1 mm 15.2 mm

R 5.1 mm (0.95 in) (0.60 in)

(0.20 in)

15°

(2)

CL 31.8 mm

(1.25 in)

20°

Stainless steel 18 mm barrel- ø 4.6 mm Slot

SMB312PD ø 4.6 mm (0.18 in)

R 3.1 mm

mounting bracket (0.18 in) (0.12 in) (2)

18.42 mm

(0.725 in)

40.6 mm

90° (1.60 in)

2.5 mm

(0.10 in) 45.5 mm

(1.79 in)

4.3 mm Slot (2)

(0.17 in)

10° (2) 24.1 mm

90° (0.95 in)

9.1 mm

10° (2) (0.36 in)

2.5 mm 3.1 mm 8.6 mm (2)

(0.10 in) Slot (2) (0.34 in)

Stainless steel 2-axis, bottom (0.12 in)

SMB312B 17.3 mm (2)

mounting bracket (0.68 in)

ø 6.9 mm

(0.27 in)

23.4 mm

11.4 mm (0.92 in)

(0.45 in)

35.0 mm (2)

(1.38 in)

50.8 mm

(2.00 in)

CL

6 mm

(0.2 in) 15 mm

(0.6 in)

6 mm

(0.2 in) ø36 mm (1.4 in)

5 mm (0.2 in) 8 mm

ø6.5 mm (0.26 in) (6x)

(2x) (0.3 in) 16 mm

(0.6 in)

• “L” bracket

SMB46L

• 14 ga 316 stainless steel 65 mm

(2.6 in)

54 mm 2 mm 27 mm

(2.1 in) (.1 in) (1.1 in)

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

page 6

MINI-BEAM® Sensors SM312CV and SM312CV2

Mounting Brackets

Model Description Dimensions

34 mm

(1.3 in)

10 mm CL

17 mm

(0.4 in) (0.7 in)

3.5 mm

(0.14 in)

6 mm

(0.2 in) 15 mm

(0.6 in)

6 mm

(0.2 in) ø36 mm (1.4 in)

8 mm ø6.5 mm (0.26 in) (6x)

5 mm (0.2 in) (0.3 in)

• “S” bracket (4x) 16 mm

SMB46S (0.6 in)

• 14 ga 316 stainless steel

65 mm

(2.6 in)

54 mm 2 mm 27 mm 16 mm

(2.1 in) (.1 in) (1.1 in) (0.6 in)

34 mm

(1.3 in)

CL

17 mm

(0.7 in)

13 mm

(0.5 in) 3.5 mm

(0.14 in)

6 mm

(0.2 in) 15 mm

(0.6 in)

• “U” bracket 6 mm

(0.2 in) ø36 mm (1.4 in)

SMB46U 5 mm (0.2 in)

8 mm

(0.3 in) 16 mm ø6.5 mm (0.26 in) (6x) 16 mm

• 14 ga 316 stainless steel (4x) (0.6 in) (0.6 in)

65 mm

(2.6 in)

2 mm 27 mm

54 mm (1.1 in)

(.1 in) 70 mm

(2.1 in)

(2.8 in)

40.0 mm

(1.60 in) 13 mm

(0.5 in)

• 18 mm split clamp black

VALOX® bracket 42.4 mm

SMB18C (1.67 in) 21.1 mm

• Stainless steel mounting (0.83 in)

hardware included 14.0 mm

(0.55 in) Nut Plate

2.5 mm

(0.10 in)

30.0 mm M5 x 0.8

(1.18 in) x 60 mm

Screw (2)

46.0 mm

(1.81 in) 10.9 mm

(0.43 in)

• 18 mm swivel, black VALOX®

bracket 44.5 mm

(1.75 in)

SMB18S 25.4 mm

(1.00 in)

Spacer

(If Required)

• Stainless steel mounting

hardware included 13.0 mm (0.50 in)

Nut Plate

6.4 mm

(0.25 in)

2.5 mm

36.0 mm (0.10 in) M5 x 0.8

(1.42 in) x 60 mm

Screw (2)

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

page 7

MINI-BEAM® Sensors SM312CV and SM312CV2

WARNING . . . Not To Be Used for Personnel Protection

! Never use this product as a sensing device for personnel protection. Doing so could lead to serious injury or death.

This product does NOT include the self-checking redundant circuitry necessary to allow its use in personnel safety applications. A

sensor failure or malfunction can cause either an energized or de-energized sensor output condition. Consult your current Banner Safety Products

catalog for safety products which meet OSHA, ANSI and IEC standards for personnel protection.

WARRANTY: Banner Engineering Corp. warrants its products to be free from defects for one year. Banner Engineering Corp. will repair or

replace, free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the warranty

period. This warranty does not cover damage or liability for the improper application of Banner products. This warranty is in lieu of any

other warranty either expressed or implied.

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN 55441 • Phone: 763.544.3164 • www.bannerengineering.com • E-mail: sensors@baneng.com

You might also like

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Banner SM312D Datasheet PDFDocument8 pagesBanner SM312D Datasheet PDFMarlon MorelNo ratings yet

- SE Current Monitoring Series H721LC-S6: DangerDocument3 pagesSE Current Monitoring Series H721LC-S6: DangerBijay KumarNo ratings yet

- Slo 30Document4 pagesSlo 30Jean RaminhoNo ratings yet

- SE Current Monitoring Series H708-S6: DangerDocument3 pagesSE Current Monitoring Series H708-S6: DangerIsrael AldabaNo ratings yet

- SKF CMSS2200 PDFDocument2 pagesSKF CMSS2200 PDFSANTIAGONo ratings yet

- Accelerometer - SKF CMSS 2200 Data Sheet of CurveDocument2 pagesAccelerometer - SKF CMSS 2200 Data Sheet of Curveaal_shurafa0% (1)

- Measure Coating Thickness with M2s, C2s, M6s ModelsDocument1 pageMeasure Coating Thickness with M2s, C2s, M6s Modelsarhamscientific coNo ratings yet

- SE Current Monitoring Series H908-S6: DangerDocument3 pagesSE Current Monitoring Series H908-S6: DangerIsrael AldabaNo ratings yet

- Datasheet VK Serie Micro DetectorsDocument5 pagesDatasheet VK Serie Micro DetectorsschortboghNo ratings yet

- Delta Smart Sensors Guide to Industrial AutomationDocument32 pagesDelta Smart Sensors Guide to Industrial AutomationchichialinNo ratings yet

- Ica220 72MDocument1 pageIca220 72MAlexander ZulqarnainNo ratings yet

- NMOS Linear Image Sensors for Multichannel SpectroscopyDocument8 pagesNMOS Linear Image Sensors for Multichannel SpectroscopyFabián RamírezNo ratings yet

- High-Performance Pushbutton Switch With Built-In Subminiature Basic SwitchDocument3 pagesHigh-Performance Pushbutton Switch With Built-In Subminiature Basic Switchkasim leeNo ratings yet

- Vishay 357Document3 pagesVishay 357Rudy DaneseNo ratings yet

- Speed Monitor PDFDocument4 pagesSpeed Monitor PDFTony IbraNo ratings yet

- Electronic Sensor E-ProxDocument8 pagesElectronic Sensor E-ProxSINU0607IITEEENo ratings yet

- MP1 Series MagnetoPotDocument4 pagesMP1 Series MagnetoPotyayaNo ratings yet

- CO2 and Temperature Transmitter User's GuideDocument4 pagesCO2 and Temperature Transmitter User's GuideAFNo ratings yet

- Rocker Switch PDFDocument2 pagesRocker Switch PDFJoshua ForbesNo ratings yet

- Manual de ZSCDocument108 pagesManual de ZSCteresaNo ratings yet

- sh460 20160718 LCN7700 FinLRDocument2 pagessh460 20160718 LCN7700 FinLRJo HydeNo ratings yet

- pusbutton-switches-serie-AV-19 22 NcnoDocument6 pagespusbutton-switches-serie-AV-19 22 NcnoPaolo TestaNo ratings yet

- S18 Series Retroreflective Sensors S18 Series Retroreflective SensorsDocument4 pagesS18 Series Retroreflective Sensors S18 Series Retroreflective Sensorsplasticos_jfm6580No ratings yet

- Inductive Sensors GuideDocument20 pagesInductive Sensors GuideCsaba VargaNo ratings yet

- OTDC16F3 DC Switch-DisconnectorDocument3 pagesOTDC16F3 DC Switch-DisconnectorLance DineroNo ratings yet

- Engine Electrical Service Limits Chart Item Measurement Qualification Standard or New Service LimitDocument86 pagesEngine Electrical Service Limits Chart Item Measurement Qualification Standard or New Service LimitWSMengine WSMengine100% (1)

- OsiSense XC XCKMR54D1H29Document2 pagesOsiSense XC XCKMR54D1H29Joseph VillamarNo ratings yet

- LY2N RelaysDocument3 pagesLY2N RelaysAnh PhamNo ratings yet

- Ica100 36MDocument1 pageIca100 36Mvian_anawagis_12345No ratings yet

- Manual ASISYS UKDocument4 pagesManual ASISYS UKjoel porro seclenNo ratings yet

- Prox td001 - en PDocument102 pagesProx td001 - en PaldoNo ratings yet

- 210 Dial Bore GaugeDocument1 page210 Dial Bore Gaugeajay upadhyayNo ratings yet

- Mini-Beam sm312cv2qdDocument14 pagesMini-Beam sm312cv2qdedgar rdzNo ratings yet

- E2ec Ds e 9 3 csm447Document9 pagesE2ec Ds e 9 3 csm447Bambang otomasiNo ratings yet

- PRD DOC PRO HSS-210-Speed-Sensor SEN AIN V1Document2 pagesPRD DOC PRO HSS-210-Speed-Sensor SEN AIN V1richard sanromaNo ratings yet

- Mini-Beam 2 - QS12 Series Mini-Beam: FeaturesDocument8 pagesMini-Beam 2 - QS12 Series Mini-Beam: Featuresviernes06No ratings yet

- 63-9229 Rev-H Puck - Datasheet Web-1Document2 pages63-9229 Rev-H Puck - Datasheet Web-1Supriyo PNo ratings yet

- DS S8 - Series Ena4 PDFDocument8 pagesDS S8 - Series Ena4 PDFPritish SinghNo ratings yet

- Sensor Catallogue HoneywellDocument8 pagesSensor Catallogue Honeywellfalah nihaNo ratings yet

- Rectilinear Displacement Transducer With Magnetic Drag: Technical Data Mechanical DimensionDocument4 pagesRectilinear Displacement Transducer With Magnetic Drag: Technical Data Mechanical DimensionSathish J EceNo ratings yet

- Inductive Proximity SensorsDocument2 pagesInductive Proximity SensorsJair Juárez ZavaletaNo ratings yet

- Prox td001 - en P PDFDocument102 pagesProx td001 - en P PDFdwi nugrohoNo ratings yet

- Rectilinear Displacement Transducer With Magnetic Drag: Mechanical Dimension Technical DataDocument2 pagesRectilinear Displacement Transducer With Magnetic Drag: Mechanical Dimension Technical DataEBNo ratings yet

- 1SVR730774R1300 CM Pas 31sDocument4 pages1SVR730774R1300 CM Pas 31sCanh NguyenNo ratings yet

- M30 Series AC 2-Wire/AC-DC 2-Wire SN 10/16mm: Inductive Sensors FeaturesDocument1 pageM30 Series AC 2-Wire/AC-DC 2-Wire SN 10/16mm: Inductive Sensors Featuresany3000No ratings yet

- Product Features: Image ImageDocument2 pagesProduct Features: Image ImageFallo SusiloNo ratings yet

- Baumer BDK Ds enDocument4 pagesBaumer BDK Ds enMehdi Houari ZaidNo ratings yet

- Quantum IkeDocument1 pageQuantum IkeMedoBoudyNo ratings yet

- PME Pneumatic cylinders-DATA SheetDocument2 pagesPME Pneumatic cylinders-DATA SheetGopal HegdeNo ratings yet

- Model 357 Vishay Potentiometer SpecsDocument3 pagesModel 357 Vishay Potentiometer SpecsMarco Antonio Esquivel BarretoNo ratings yet

- Velodyne VLP 16 Puck LiteDocument2 pagesVelodyne VLP 16 Puck LiteVictor MedranoNo ratings yet

- WCM2012F2S Series Wire Wound Common Mode Filter Supresses NoiseDocument4 pagesWCM2012F2S Series Wire Wound Common Mode Filter Supresses Noisegoogi7No ratings yet

- Banner QS30LDQ Datasheet PDFDocument12 pagesBanner QS30LDQ Datasheet PDFSanket IchakeNo ratings yet

- Omron proximity sensor specsDocument6 pagesOmron proximity sensor specsRonald Paul Torrejon InfanteNo ratings yet

- DS MP20 21 enDocument5 pagesDS MP20 21 enrudirstNo ratings yet

- Double Articulated Linear Position TransducersDocument3 pagesDouble Articulated Linear Position TransducersANKURNo ratings yet

- Cardiagn Specs SheetDocument24 pagesCardiagn Specs SheetWSMengine WSMengineNo ratings yet

- Plastic Cylindrical Inductive Prox: Ordering InformationDocument10 pagesPlastic Cylindrical Inductive Prox: Ordering Informationmas madNo ratings yet

- Ab 872C-DH4NN12-D4 Sensor de Empuntado Robot 2-3-5 NPNDocument3 pagesAb 872C-DH4NN12-D4 Sensor de Empuntado Robot 2-3-5 NPNCesarFTANo ratings yet

- Ex820 UmDocument12 pagesEx820 UmMarlon MorelNo ratings yet

- sb371 PDFDocument116 pagessb371 PDFSevtunus BangunNo ratings yet

- Clutch and Brake Motors PDFDocument10 pagesClutch and Brake Motors PDFMarlon MorelNo ratings yet

- Positionservo: Users ManualDocument75 pagesPositionservo: Users ManualMarlon MorelNo ratings yet

- Motores Panasonic PDFDocument293 pagesMotores Panasonic PDFMarlon MorelNo ratings yet

- GB4003 2013-09 GNB SCR200 Charger Tech Data SheetDocument4 pagesGB4003 2013-09 GNB SCR200 Charger Tech Data SheetMarlon MorelNo ratings yet

- W150: Miniature Photoelectric Switch Series With Completely Integrated ElectronicsDocument16 pagesW150: Miniature Photoelectric Switch Series With Completely Integrated ElectronicsMarlon MorelNo ratings yet

- Blower and Motor CalculationsDocument9 pagesBlower and Motor CalculationsChris LaytonNo ratings yet

- 1609 Um009 - en PDocument34 pages1609 Um009 - en PAnonymous VKBlWeyNo ratings yet

- Operator's Manual: Heavy-Duty Commercial Microwave Oven With Manual ControlsDocument12 pagesOperator's Manual: Heavy-Duty Commercial Microwave Oven With Manual ControlsMarlon MorelNo ratings yet

- Ze500 4 Parts Catalog en UsDocument9 pagesZe500 4 Parts Catalog en UsClaudia LopezNo ratings yet

- 940 Simple Servo Manual PDFDocument140 pages940 Simple Servo Manual PDFarmandoNo ratings yet

- SILD845160UKDocument5 pagesSILD845160UKMarlon MorelNo ratings yet

- Rexroth Indradrive Supply Units and Power Sections: Project Planning ManualDocument326 pagesRexroth Indradrive Supply Units and Power Sections: Project Planning ManualVenkataramanaaNo ratings yet

- VX-261 Om en Ec128u101Document24 pagesVX-261 Om en Ec128u101Setec SrlNo ratings yet

- Doran Service PDFDocument42 pagesDoran Service PDFMarlon MorelNo ratings yet

- Rexroth HMV Troubleshooting Guide PDFDocument604 pagesRexroth HMV Troubleshooting Guide PDFMarlon MorelNo ratings yet

- Rexroth IndraDrive Mi KCU01, KMS01, KSM01 Project Planning Manual R911320924 - 04Document182 pagesRexroth IndraDrive Mi KCU01, KMS01, KSM01 Project Planning Manual R911320924 - 04Marlon MorelNo ratings yet

- Rexroth Servo Drives Programming:: Page 1 of 56Document56 pagesRexroth Servo Drives Programming:: Page 1 of 56Marlon MorelNo ratings yet

- FbcsDocument344 pagesFbcskomal bandleNo ratings yet

- High Voltage Ignition Coil Driver Power I.C.: VB921ZVFI VB921ZVSPDocument7 pagesHigh Voltage Ignition Coil Driver Power I.C.: VB921ZVFI VB921ZVSPNgoc AnNo ratings yet

- Ece131l Exp7Document4 pagesEce131l Exp7Carmela SapalaranNo ratings yet

- Instruction Manual: Kistler GPS Sensor Compact Travel Sensors Type CGPSSADocument46 pagesInstruction Manual: Kistler GPS Sensor Compact Travel Sensors Type CGPSSATranNo ratings yet

- SMA Off-Grid ConfiguratorDocument2 pagesSMA Off-Grid Configuratorrocco1No ratings yet

- SEL-849 Fail-Safe and Nonfail-Safe Tripping: Application Note AN2021-01Document6 pagesSEL-849 Fail-Safe and Nonfail-Safe Tripping: Application Note AN2021-01bonginkosibrutusNo ratings yet

- 2013-14 Ns2 Project Titles - ME / MtechDocument3 pages2013-14 Ns2 Project Titles - ME / MtechPantech Proed Pvt Ltd.,No ratings yet

- MC2000™ Advanced Deskset: Tone Control L3216 Operator and Installation ManualDocument112 pagesMC2000™ Advanced Deskset: Tone Control L3216 Operator and Installation ManualAlex Gomez50% (2)

- Circuit Breaker Performance Analysis PDFDocument10 pagesCircuit Breaker Performance Analysis PDFInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Catalogue-FRANKE GMKP LV PFC SystemDocument23 pagesCatalogue-FRANKE GMKP LV PFC Systemdaniloiwamoto100% (1)

- 70L02GHDocument8 pages70L02GHJtzabalaNo ratings yet

- OISD STD 180-Lightning-ProtectionDocument33 pagesOISD STD 180-Lightning-ProtectionNanu PatelNo ratings yet

- Checkfire MP-N Electric Detection and Actuation System: Data/SpecificationsDocument3 pagesCheckfire MP-N Electric Detection and Actuation System: Data/Specificationsclaudio garciaNo ratings yet

- Service Report Form Completed B20e16-000005 PDFDocument1 pageService Report Form Completed B20e16-000005 PDFBPE Gauri ShankarNo ratings yet

- Simulation Set 2Document4 pagesSimulation Set 2Harsh ThakurNo ratings yet

- Variable Speed Drive For Converter Fed Synchronous Machine - PCS 8000 Variable-Speed Converter - (Converters For Pumped Storage Plants - ) - ABBDocument3 pagesVariable Speed Drive For Converter Fed Synchronous Machine - PCS 8000 Variable-Speed Converter - (Converters For Pumped Storage Plants - ) - ABBDeepak GehlotNo ratings yet

- PLC Mid SyllabusDocument2 pagesPLC Mid SyllabusHardik PatelNo ratings yet

- Victron Freedom Won Lifepo4 Batteries - Freedom Won Lite and EtowerDocument16 pagesVictron Freedom Won Lifepo4 Batteries - Freedom Won Lite and EtowerAmer AlmansoryNo ratings yet

- Cascadia HVAC Operation Part OneDocument1 pageCascadia HVAC Operation Part OneDonald Charles FernoughtyNo ratings yet

- Photovoltaic Inverter White PaperDocument10 pagesPhotovoltaic Inverter White PapergubiliNo ratings yet

- Mentorpaper 102410Document7 pagesMentorpaper 102410Sandesh Kumar B VNo ratings yet

- New S7 series high performance switch-disconnectorDocument6 pagesNew S7 series high performance switch-disconnectorMostafa ShannaNo ratings yet

- Panasonic TX 29PM11PDocument32 pagesPanasonic TX 29PM11PCarlos Delgado0% (1)

- Auto Grid ProDocument95 pagesAuto Grid ProIngenieroSinTitulo100% (1)

- Service Manual: NX-240, NX-240 (V)Document42 pagesService Manual: NX-240, NX-240 (V)A&A LABORATORIONo ratings yet

- Ethernet Cables and Transceivers Tech GuideDocument8 pagesEthernet Cables and Transceivers Tech Guidematthew_mk_au2271No ratings yet

- HP Pavilion DV5 (Inventec ST145a-UMA)Document52 pagesHP Pavilion DV5 (Inventec ST145a-UMA)Brahim TelliNo ratings yet

- Patient Monitor User Manual-ES 82-01.54.455782-1.5 Im8 M8 Series PDFDocument191 pagesPatient Monitor User Manual-ES 82-01.54.455782-1.5 Im8 M8 Series PDFAlia PopaNo ratings yet

- Chapter 2Document20 pagesChapter 2Saman Brookhim100% (4)

- JERC Manipur Tariff Order 2014-15Document124 pagesJERC Manipur Tariff Order 2014-15Anil KumarNo ratings yet