Professional Documents

Culture Documents

Jis A5525 PDF

Jis A5525 PDF

Uploaded by

Tuanbk Nguyen0 ratings0% found this document useful (0 votes)

6 views30 pagesOriginal Title

JIS-A5525.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views30 pagesJis A5525 PDF

Jis A5525 PDF

Uploaded by

Tuanbk NguyenCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 30

n ruse on network prohibited (10135415).

Licensed to Me Tikman Utomo on 28 July 2010.1 user personal user cence ont. Storage, sstrbuon

JIS

JAPANESE

INDUSTRIAL

STANDARD

Translated and Published by

Japanese Standards Association

JIS A 5525 :2

(JISF)

Steel pipe piles

ICS 77,140.75; 93.020

Reference number : JIS A 5525 : 2009 (E)

PROTECTED BY COPYRIGHT 168

Licensed to Mr Tkman Ulomo on 2 July 2010 1 User personal user leence only. Storage, etibuton or use on network prohibited (10135415).

A.5525 : 2009

Date of Establishment: 1963-10-01

Date of Revision: 2009-06-20

Date of Public Notice in Official Gazette: 2009-06-22

Investigated by: Japanese Industrial Standards Committee

Standards Board

‘Technical Committee on Iron and Stee!

JIS A $525:2009, First English edition published in 2009-11

Translated and published by: Japanese Standards Association

41-24, Akasaka, Minato-ku, Tokyo, 107-8440 JAPAN

In the event of any doubts arising as to the contents,

the original JIS is to be the final authority

© J5A 2009

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or

Glitized in any form or by any means, electronic or mechanical, including photocopying and

microfilm, without permission in weiting from the publisher

Printed in Japan

KAT

PROTECTED BY COPYRIGHT

LUoensed ta Mr Tian Utomo on 28 ly 2010.1 user personal usr ence any. Storage, distibuton or use on network prohibited (10135415).

A.5525 : 2009

Contents

Page

Introduction: wd

1 Scope 1

Normative references -~ a= 2

Class symbol

Production method

‘Mechanical properties -

Shop circumferential weld.

2

3

4

5 Chemical component

6

7

8

Accessories, forming and painting/coating.

9 Shapes, dimensions, mass and their tolerances of single pipe

9.1 Shape of pipe end - c

9.2 Dimensions and unit mass

9.3 Shape and tolerances on dimension

10 Apparatus ~

11 Test

111 Analysis test

11.2 Mechanical test ~

11.8 Radiographic testing

12 Inspection and reinspection -

12,1 Inspection----

12.2. Reinspection

13 Marking--

14 Report.

Annex A (normative) Quality specification of the single pipe with rib--

Annex B (informative) Typical example of shape and dimensions of accessory-- 18

Annex C (informative) Forming, painting and coating

«@

PROTECTED BY COPYRIGHT

ence only. Storage, distribution or use on network prohibited (10135415).

EEE INENES ENG. as0¢ personal use

A.5525 : 2009

Foreword

‘This translation has been made based on the original Japanese Industrial Standard

revised by the Minister of Economy, Trade and Industry through deliberations at

the Japanese Industrial Standards Committee as the result of proposal for revision

of Japanese Industrial Standard submitted by The Japan Iron and Steel Federation

(JISF) with the draft being attached, based on the provision of Article 12 Clause 1

of the Industrial Standardization Law applicable to the case of revision by the provision

of Article 14,

Consequently JIS A 5525: 2004 is replaced with this Standard.

This JIS document is protected by the Copyright Law.

Attention is drawn to the possibility that some parts of this Standard may conflict

with a patent right, application for a patent after opening to the public, utility model

right or application for registration of utility model after opening to the publie which

have technical. properties. The relevant Minister and the Japanese Industrial Standards

Committee are not responsible for identifying the patent right, application for a patent

after opening to the public, utility model right or application for registration of utility

model after opening to the public which have the said technical properties.

Gi)

PROTECTED BY COPYRIGHT

Lcensod to Mr Tikman Utomo on 28 July 2010.1 user persona user ence only Storage, distribution or use on notworkprhibited (10135415),

JAPANESE INDUSTRIAL STANDARD. JIS A 5525: 2009

Steel pipe piles

Introduction

In this revision, the steel pipe piles with rib which have already taken root in the

market are added and the contents of accessories, forming and painting/coating are

revised corresponding to the current status.

1 Scope

This Japanese Industrial Standard specifies the single pipe of welded steel pipe piles

(hereafter referred to as “piles”) used in the foundation such as civil engineering works",

architecture and the like. The dimensional range, to which this Standard is applied,

is normally 318.5 mm to 2.000 mm in outside diameter.

Further, items other than those specified in the text, the quality specification of the

single pipe with rib, which the purchaser can specify upon the agreement with the

‘manufacturer, is shown in Annex A, the shape and dimension of typical accessories fitted

to single pipe is shown in Annex B and typical example of forming and painting/coat-

ing to be performed to single pipe is shown in Annex C.

NOTE 1 ‘The seamless steel pipes and the centrifugally cast steel pipes for land-

slip determent are specified in JIS G 3444 and JIS G 5201, respectively.

NOTE 2 The constitution of pile and the designation of each part shall be shown

in figure 1

A single pipe is defined as a blank pipe as it is or blank pipes jointed

by circumferential welding at shop and a pile is defined as a single pipe

or the combination of single pipes. When single pipes are to be welded

together on the site, the upper side, the middle side and the lower side

of single pipes are called the upper pile, the middle pile, and the lower

pile, respectively. In the case where the middle pile consists of two or

more, the lowest one is defined as the first middle pile, the one above

be the second middle pile and so on.

NOTE 3 Shop circumferential weld is defined as welding in which the blank pipe

and blank pipe are made to single pipe by circumferential weld by the

manufacturer, and site circumferential weld is defined as welding in

which the single pipe and single pipe are made to pile by cireumferen-

tial weld by the constructor.

Note " It includes piles for landslip determent.

PROTECTED BY COPYRIGHT

sensed to Me Tikman Utomo on 28 July 2010.1 user personal user icence ony. Storage, cistibuton or use on network prohibited (10135415),

2

‘A.5525 : 2009

Pipe |Site circumferential weld

Shop cieumferental weld ~ [FE] pack pipe

| sain

Site circumferential weld Blank pipe |

pte] mance | si ee

Shop circumferential weld ~_ [Ea |

} Single pipe

is"] Blank pipe

Shop cirumferental weld | Blank pipe

Blank pipe

Figure 1 Constitution of pipe

2 Normative references

‘The following standards contain provisions which, through reference in this text,

constitute provisions of this Standard. The most recent editions of the standards

(including amendments) indicated below shall be applied.

JIS G 0320

JIS G 0404

JIS G 0415

JIS G 3193

JIS Z 2201

JIS Z 2241

JIS Z 3104

JIS Z 3121

JIS Z 8211

JIS Z 3812

JIS Z 3313

JIS Z 3351

JIS Z 8352

Standard test method for heat analysis of steel products

Steel and steel products—General technical delivery requirements

Steel and steel products—Inspection documents

Dimensions, mass and permissible variations of hot rolled steel plates,

sheets and strips

Test pieces for tensile test for metallic materials

Method of tensile test for metallic materials

Methods of radiographic examination for welded joints in steel

Methods of tensile test for butt welded joints

Covered electrodes for mild steel, high tensile strength steel and low

temperature service steel

Solid wires for MAG and MIG welding of mild steel, high strength steel

and low temperature service steel

Flux cored wires for gas shielded and self-shielded metal are welding

of mild steel, high strength steel and low temperature service steel

Submerged are welding solid wires for carbon steel and low alloy steel

Submerged arc welding fluxes for carbon steel and low alloy steel

8. Class symbol

‘The piles shalll be classified into two classes and their symbols shall be as given in

table 1

PROTECTED BY COPYRIGHT

Licensed to Me Tikman Utomo on 28 July 2010.1 user personal user cence only. Storage, dstibuton or use on network profited (10135418).

3

A525 : 2009

Table 1 Class symbol

Class symbot

‘SKKA00

SKK490

4 Production method

‘The production method of piles shall be as follows.

fa) The blank pipe is produced by spiral seam welding or straight seam welding by

are welding or electric resistance welding.

‘Seam welded part of blank pipe in shop circumferential weld shall be staggered

1/8 or more in circumferential direction each other.

b) ‘The blank pipe with rib is produced by spiral seam welding of steel strip on which

rib has been set up continuously and parallel to the rolling direction so as rib is

laid on the inner side and/or outer side surface of the steel pipe,

©) Acsingle pipe is produced by circumferential welding of blank pipes at shop or a

blank pipe is used as a single pipe as it is.

5 Chemical component

‘The blank pipes shall be tested in accordance with 11.1 and their ladle analysis

values shall be as shown in table 2.

Table 2. Chemical component

Unit: %

Class symbol c Si Mn P s

SKKA00 | 0.25 max. = = (0.040 max, | 0.040 max.

SKKG00 | O18max. | 055 max. | 1.65max. | 0.035 max. | 0.035 max.

“Alloy elements other than those in this table may be added, as required,

6 Mechanical properties

‘The blank pipes shall be tested in accordance with 11.2 and their tensile strength,

yield point or proof stress, elongation, tensile strength of welds, and flattening resi

tance shall conform to table 3. As regards flattening resistance, the test piece shall

be free from flaws or cracks. However, the tensile strength of weld part is applied to

the blank pipe manufactured by are welding and the flattening resistance is applied

to the blank pipe produced by electric resistance welding.

PROTECTED BY COPYRIGHT

10138415),

LUconsed to Me Tikman Utomo on 28 July 2010 1 user personal user lcence only. Storage, dsrbtlon a use on network profi

4

‘A.5525 : 2009

Table 3 Mechanical properties

‘Tensile |] Yield point or Elongation | Tonsile strength | Flattening resistance

lane | tenets | pron tres % of weld Distance between

symbol Test pie No.8 a its

Pipe axis rightangled Beets

Nimm* | _Nimm® direction Nim!

‘SKKA00 | 400 min. | 235 min 18 min 400 min, 2p

KK490 | 490 min. | $15 min. 18 min 490 min, 3D

NOTE: 1 Nimm?=1MPa

7 Shop circumferential weld

‘The shop circumferential weld and its quality shall be as follows.

a) Welding materials Welding materials used for the shop circumferential weld

to joint blank pipes into a single pipe shall have a tensile strength not less than

that in the requirements of the materials for the blank pipes and shall be onc of

the followings or the combination.

SIS Z 8211, JIS Z 3812, JIS Z 3313, JIS Z 3351, JIS Z 3352

Further, welding material to be used for shop circumferential weld of differ-

ent types of blank pipes shall be equal or over to the specified tensile strength of

SKK400.

b) Quality For shop circumferential weld, the radiographic testing shall be per-

formed according to 11.8 and the flaw type shall be type 3 or over according to

the type of flaw of Annex 4 table 1 in JIS Z 3104.

8 Accessories, forming and painting/coating

‘The purchaser may specify the accessories attached to the pile, forming and paint-

ing/coating. Appearance, inspection, marking and so on in this case shall depend upon

the agreement between the manufacturer and the purchaser. Further, typical shape

and dimension of accessories are shown in Annox B, and typical example of forming

and painting/coating are shown in Annex C.

9 Shapes, dimensions, mass and their tolerances of single pipe

9.1 Shape of pipe end

The shapes of pipe-end geometry of the single pipe shall be as shown in figure 2.

When the pipes different in thickness are to be connected, they shall be preliminarily

worked at shop as shown in figure 3, as a rule. If especially required, reinforcement

or work may be determined by agreement between the purchaser and the supplier.

NOTE: Head end face is referred to as the top end of pile, and tip end face is

referred to as the bottom end of pile in figure 2.

PROTECTED BY COPYRIGHT

Licensed to Me Timan Utomo on 28 July 2010.1 user petsonal user cence only. Storage, distibuon or use on network prohibited (10135415).

5

A.5525 : 2009,

Head end face Upper pile

a Bnd face to form ae

site circumferential +

rp weld

‘Tip end face gh

a) Head part and tip part b) Site circumferential weld

Figure 2. Shape of both ends of single pipe and site circumferential weld

ao

| cat part”

Shep dreamt weld 7)

Site circumferential weld —S aie

A

Note *! The length of cut part inside the blank pipe shall be not less than 4 (¢,~

4). When (f,- tis not more than 2 mm, or when (f,~f2) is not more than

8 mm in the ease of both-side welding of the shop circumferential weld,

the cutting may be omitted,

Figure 3 Shapes of circumferential weld of pipes different in thickness

9.2 Dimensions and unit mass

‘The dimensions and unit mass of the single pipe shall be as follows.

a) The outside diameter, thickness, cross-sectional area and unit mass of the single

pipe shall be as given in table 4. However, it depends on the agreement between

the manufacturer and the purchaser concerned about dimensions other than

table 4.

b) The length of blank pipe shall be 2 m or more usually. The length of a single pipe

shall be usually 6 m or more in 0.5 m increments.

9.3 Shape and tolerances on dimension

The shape and tolerances on dimension shall be as follows.

a) The shape of single pipe and tolerance on dimension shall be as given in table 5.

b) In the case of site circumferential weld, the linear misalignment to connect two

single pipes (hereafter referred to as “linear misalignment in the site welding”)

shall be value of the difference of peripheral lengths of single pipes divided by «

and the tolerance shall be in accordance with table 6, where 1=3.141 6.

PROTECTED BY COPYRIGHT

or use on network prohibited (10136415).

12 aly. Storage, ests

LUcensed to Mr Tan Utama on 28 July 2010.1 user persona use

'A.5525 ; 2009

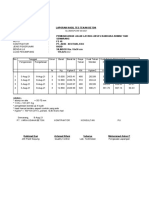

Table 4 Dimensions and unit mass

Dante | Tee | Gras | Varma Trias

diameter | “ness | ects! Gamera] Secion | ‘Radin | Ouida

onantatiseria| modu | grat etre | sve aren

pte lia ” 1 2 1

mm mm em? kgm cmt cm? cm tin

sas] 6s] ars] 0] a x0 ars xo) 10

wo3s_|_ 997 ms_| tis xit | r4axio_| 109 ao

36] 6a | 702 ssi] ior x10? | oa xi | 124 1

19 86.3 627 130 x10° 734 X10 123 42

ut_| nos xs |_imxie_| wosxio | 22 1

we} 9 | 0s ss] an xi] 05710] 8 126

a | wes | ons | a6 xe | sre xo | ae 126

wea] 9 [ime] 82am xia] ton xio | 8s 1a

| ver |r| ne xiot_| aario_| 40 128

cr ZT 1

nm 184.0 14 548 X10 29 X10 173, As?

te tons | ie | exe | ass xo | in us

sap [oP aut Pan] a9 1a Pins ono | 26 a

| aso | ot fos mat | ar xo | ons 10

te Las | im | es xi _| or xo | rs eo

wes] ten] is 30 to? | aes x10 J 209 1a

2 2217 114 988 x10? 319 x10 20.8 1.88,

“4 287.7 202 a x10 369 x10 20.7 1.88

te_| me | 0 | as xi _| ai xo | a0 ts

609.6 9 169.8 133, 766 X10? 251 X10 22 192

| ons | om | tae | 330 x | aa is

te | ao | 26 tne mir | st xt | at 1s

te_| oes | ae |i xi _| o_o _| ato i

wo] ase [ass] rio? a3 cro |e 220

fase | ae | ise ie | ae x10 | ons 220

4 3017 237 178 x10 507 x10 243 220

te | sas | zm | 2m xie@_| sos x0 | 242 220

mia] 9) 7s ise] ae anos ton 223

2 [owe | am | ice | as xi | 27 223

| 306 | on vas xi | se x10 | 247 223

ts _| see | 2 | on xi _| soa _xio_| nus 2s

wo [9 ae] 6 pris | ar a0] 280 B31

2 297.1 233 231 x 10° S17 x10. 27.9 251

we | ez fan fae xe | eos x0 | ars 21

io | sor | se | sos x1 | sr xo | an 251

8128 9 2273 178 184 x10 452 X10 284 255

2 3019 237 242 x10 596 x10 283 2.55

ve | sia | me | aso ior | 90 xio | a8 255

we | wos | sis xi’ _| rs2_xio_|__ 252 25s

900 12 334.8 263 330 X10 733 X10 34 2.83

te | 37 | 306 | ase xior | aso x10 | ois 28

ws | aus | ae] ase mit | 96s x10 | aia 283

19 $25.9 413 510_X10° 3 x10 312 2.83

PROTECTED BY COPYRIGHT

7

A.5525 : 2009

‘Table 4 (continued)

Outside | Thick | Grae | Uniram informative

esac | easll | eetine Geomeirial | Section | Rada? Outside

one rmomentofineria| modulus | gyratianofarea| urace area

> ' 4 w 1 2 :

om | om | ont kein ent em! em an

owa | 12 | 302 267 346 x10 | 758 x10 39) 2387

| 3960 x aor xi | 878 x10 38 2st

w | ass 354 436 x10 | 997 x10 ais 287

| sus 320 S36 xi | 07 x10! 37 287

Too | 2 | ars 22 45510" | 909 x10 349) 3

ue | 4337 340 sar xi | 10s x10 oo a4

ts | 4946 3a ss x10 | 120x108 Ma a

w | sess | 40 ros x10? | iat x10! 347 38

Towo | 2 | 378s 297 a7 xi? | 939 x10 385 3.9

14 | 407 396 ss3 x10 | 109 x10! 384 319

16 | sox | 398 ax x10 | a4 x0? 384 ais

19 | 595. er sao x0 _| 4s x08 383 a9

1100 f 2] s102 Er or xi” | 10 x10" 38S 36

4 | ane 375 ros x1o | 128 x10 384 346

6 | seas 8 00 x10 | 146 x? 383 Bas

w | oss 506 sas cio. | im xu? 382 346

rime | 2 | 4168 327 erie | ie x10 38.1 331

| aasa 381 ne xi | isa x10 380 a1

we | ss37 35 so x10? | 150 x10 390 3st

w | oss sis 950 x10 | 77 x10 3a 331

va [is | sane 409 a7 x10 iss xi a9 3m

16 | $98 467 os x10 | 174 x10? a9 am

19 | 089 583 123 xia | 205 x10! a8 am

| a2 639 rat xiot | ans x10? a7 an

vasa [14 | sor 416 963 x10" 158 x10 226 3a

16 | ota. as op x10 | 180 xc? 25 33

w | nea 562 19 xia | 212 x10! aa 33

zn | ws 630 was xiot_| 243 ict 423 3s

130 [4] 5656 6 17 x10" | 180 x10" 455 408

16 | ose sor 133 x10 | 205 x10! as 08

1 | 7686 600 ist xiot | 2a x1? 453 408

zn | sss 693 wo xo [278 x1? 452 408,

Tas] [sma 451 123 x1 | 186 x10 462 45

16 | 6859 sis yao xiot | an xi? 461 415

| mo 10 65 xiot | 299 x10? 460 aus

2 | er 70s go aot | 287 x1? 459 aus

1a | 1 | 06 | 978 146 x10" | 209 x10? $90 a0

we | 69s7 56 er x10 | 238 xc? 489 440

w | sa 637 197 x1at | 281 x10 88 440

22 | 9s 28 zs xiot_| 323 x10! 487 430

ras | | 19a 86 184 x10" | 216 x10" 98 447

16 | 7069 338 nis x10 | 246 x10? “97 4a7

w | a7 oss 206 x10! | 290 x10? 496 aa

z_| 9619 160 a7 xio'_| 335 x10? 495 ast

PROTECTED BY COPYRIGHT

ce only. Storage, istibuton oF use on network prohibited (10196815).

LUcensed ta Me Tkman Utomo on 28 July 2010, 1 user personal user l

8

A5525

2009

Table 4 (concluded)

Danie | Tia | Grom] Unitas Perr

aad es | eos Geoneireal | Secon | Radinat | Outnde

romentafineria| medulue | gyration of arn) surface rea

> 1 4 w 1 z i

mm mm cm? kg/m om’ cm om mim

1500 16 45.9 586 205 x10" 274 x10 S25 471

9 884.0 694 242 x10" 323 x10? $24 an

2 1021.5 802, 279 x10% 372 x10? 52.3 471

as | iisss | 9 | is xict_| a0 xi | 922 an

Tsao] is] sso] 9s] ais aot aa oP 479

9 898.3 105 254 x10" 334 x10? 53.2, 4.79

2 1038.1 815, 293 x10 384 x10? 33.1 479

25. 11773 924 331x108 434x108 53.0 4.79

Tao [is | 162 | as | 2soxi® | ain xie | 560 503

0 943.7 TAL 298 x10" 369 x10? 55.9 5.03

x | 1006 | as | 3a cit | ae xi | se $03

as_| izro | on | sua xiot_| aso xciot_| 557 5.03

Tass | 16 | 6001 Pes [ae xi | a x | 6 sa

19 959.0 183 309 x 10" 381 x10? 56.8 Su

2 1108.3. 870 356 x10" 438 x10 $6.7 su

25 257.1 987 403_x10* 49s X10" 56.6. SN

1800 9 1063.1 334 422 x10" 468 10? 63.0 5.65

2 1228.9 965 486 x10" 540 x10? a9 5.65

2s | issr | roe | suo x | sto | oe 565

2.000 2 1367.1 1073 669 x10" 669 X10? 69.9 6.28

as | issiz_ | ize | 750 xiot_| 56 x1? | os 628

NOTE? The numerical valuo of unit mavs is calculated from the following formula assuming 1 em of

steel to be 7,85 g and then it is rounded off ta three significant figures in accordance with rule A

of JIS Z 8401, “In the case of over 1.000 kg/m, it is rounded to the four digit integer.

W= 0.024 66¢(D 0)

where, W: unit mass of pipe (kg/m)

1: thickness of pipe (mm)

D: outside diameter of pipe (mm)

0.024 66: unit conversion coefficient to obtain W

PROTECTED BY COPYRIGHT

9

4.5525 : 2009

Table § Shape and tolerances on dimensions

Division Tolerances Remarks |

Outside [Pipe end part +05 % | For measurement of the outside diameter,

diameter circumferential length is used, and vither

o the measured value or its converted out

side diameter may be used. Conversion

between the outside diameter (D) and the

circumferential length () i ealeulated by

the following formula.

Delix

where, D: outside diameter,

1 circumferential length,

a: 81416

Thick | Thickness | Outside diameter | yet spied =

nos under | under 500 mm | ~0.6 mm

© 16mm | Outside diameter ++ not specified

500mm or over |'—0.7 mm

to and excl,

800 mm

Outside diameter | + not specified

800 mm or over | ~0.8 mn

up to and ine.

2000 mm

‘Thickness | Outside diameter | not specified

16mm | under 800 mm | ~O.8 non

er Outside diameter | yct epeciiad

800 mm or over | —1.0 min

up to and ine

2000 mm

Length (2) ' not specified

0 =

Warping (31) Within 0.1 %

of length (L),

In the case of

under 6 m in

length, 6 mm

or under

Flatness of end face forming the site

circumferential weld (2)

2mm or under

Ferpendicularity of end face forming the | Within 05 ©

site circumferential weld (c) of outside

diameter with

the maximum

of 4mm

PROTECTED BY CopyricHT

(10138415).

Licensed to Mr Tkmian Uomo on 28 July 2010.1 user personal usr cence ony. Storage, dstibuton or use on notwork prob

10

A525 : 2009

Table 6 Tolerances of dislocation of site circumferential weld":

Unit: mm

Outside diameter ‘Tolerance

Under 700 2or under

"700 oF over up to and inel, 1 016 ‘Sor under

‘Over 1 016 up to and inel. 2000, 4 or under

NOTE: Dislocation is referred to as the difference of outside diam-

eters of two single pipes at the pipe end (conversion value to

peripheral length) to perform site circumferential weld,

‘Notes ® The single pipe of an outside diameter exceeding 2000 mm

or of t/D less than 1.0 % shall be preliminarily agreed upon

between the purchaser and the supplier.

© When it is necessary to decide the combination of a part or

all of single pipes beforehand according to the agreement

between the purchaser and the supplier, the single pipes to

be combined shall be marked with a number or a symbol.

10 Apparatus

‘The single pipe shall be free from defects detrimental to use. However, the sur-

face discontinuities detrimental to use may be cleaned up by grinding or repaired by

welding in accordance with clause 7 of JIS G 3193.

11 Test

11.1 Analysis test

‘The analysis test shall be as follows.

a) The general items and sampling method of the analyte shall be as specified in

clause 8 of JIS G 0404.

b) The analysis method shall be in accordance with JIS G 0320.

11.2 Mechanical test

11.2.1 General matter for mechanical test

‘The general maters for mechanical test shall be performed in accordance with

clause 7 and clause 9 of JIS G 0404.

11.2.2 Tensile strength

The tensile strength test shall be performed for the parent material part and seam

welded part of arc welded steel pipe. The sampling method of test specimen and number

of test piece shall be as follows.

a) The sampling method of test specimen shall be in accordance with Class A of 7.6

in JIS G 0404.

b) The sampling method of test specimen and number of test pieces taken from each

test specimen shall be in accordance with table 7.

PROTECTED BY COPYRIGHT

Uconsed ta Me Tikman Utomo on 28 July 2010.1 user personal user lisnoe ony. Storage istibston or use on network probed (10136415).

) Test piece The test piece shall be as follows.

1) The tensile test piece shall be No. 5 test piece in JIS Z 2201 and the sam-

pling method shall conform to either of the following:

ul

A.5525 : 2009,

— for pipe which is not formed by pipe expanding, the test piece shall be

sampled from the pipe or the steel strip or steel plate which is used for

the pipe.

— for pipe which is formed by pipe expanding, the test piece shall be sampled

from the pipe.

2) Weld tensile test piece of are welded steel pipe shall be No. 1 test piece speci-

fied in JIS Z 3121, and shall be cut from the test specimen taken from the

end part welded under the same conditions as the blank pipe or blank pipe.

4) Test method The test method shall be in accordance with JIS Z 2241.

Table 7 Sampling method of test specimen and number of test piece

Division

‘Sampling method of specimen

‘Number of tet piece

obtained from one

test specimen

Tm the ease of taking the

sspocimen from blank pipe

‘Take one specimen from each blank pipe

‘equivalent 1 250 m or its fraction of the blank

pipes having the same dimensions”

Tensile test piece: 1

Weld tensile test piece: 1

Flattening test piece: 1

Tn the ease of taking the

‘spocimen for tensile tost

from steel plates or steel

steips

For steel plates, pat those belonging to the

same heat and having the maximum thickness

cf not more than twice the minimum thickness

together into a lot and take one specimen from

each lot of plates. Howover, in the case of the

‘mass of a lot exceeding 50 t, take one test pice

ceach from two test specimens,

For stool strips, take one test spocimen from

each lot belonging to the same heat and having

the same thickness. However, from mass of a

lot exceeding 50 t, take one test piece from each

‘wo test specimens.

“Tensile test piece: 1

In the case of taking the

tensile test pioce of weld

from the pipe end

specimen welded under

the same conditions as

the blank pipe in straight

seam weld steel pipe

‘Take one specimen from each blank pipe

equivalent 1 250 m or its fraction of the blank

pipes having the same dimensions

Weld tensile test picce: 1

NOTE: As for application of test items, soe clause 6.

Note*” The same dimensions means the same outside diameter and the same wall thickness.

11.2.3 Flattening test

The flattening test shall be as follows.

a) Test piece For the flattening test piece of electric resistance welded steel pipe,

sample a length of 50 mm or over from the end of the blank pipe to make a test

Piece.

PROTECTED BY COPYRIGHT

LUcensed to Mr Tkman Utomo on 28 July 2010. 1 user personal user cence only. Storage, dstibullon ar use an network prahiited (10135415)

12

A.5525 : 2009

b) Test method For the test method, put a test specimen between two flat plates

at ordinary temperature as it is, compress until the distance between flat plates

becomes the value given in table 3. When flattened, examine whether flaws and

clacks are generated on the wall of the test pieces. For the test piece, place it so

that the line connecting the centre and the weld of blank pipe gets into right angles

to the compressed direction as given in figure 4.

Compressing direction

KL

Figure 4 Flattening test

11.8, Radiographic testing

‘The radiographic testing for shop circumferential weld shall be as follows.

a) Test frequency and radiographic point Radiograph one photo of the cross-

over of seam weld and shop circumferential weld for every ten points of shop cir-

cumferential welds welded under the same condition and having the same

dimensions and its fraction,

b) Test method The test method shalll be in accordance with JIS Z $104,

12 Inspection and reinspection

12.1 Inspection

‘The inspection shall be as follows,

2) General items of inspection shall be as specified in JIS G 0404.

b) The chemical component of blank pipe shall conform to clause 5.

©) The mechanical properties of blank pipe shall conform to clause 6.

4) The part of shop circumferential weld shall conform to clause 7,

e) The inspection of shape, dimensions of single pipe shall be tested for each single

pipe and the results shall comply with the specified of clause 9.

) For the appearance, generally each single pipe is tested and the results shall

conform to clause 10.

12.2 Reinspection

‘The single pipe not accepted by tensile test or flattening test may be determined

for acceptance or not by retesting in accordance with 9.8 in JIS G 0404,

PROTECTED BY COPYRIGHT

tion or use on network prohibited (10135418),

LUcensed to Me Tkman Utoma on 28 July 2010, 1 user personal user cence only. Soxape

13,

A.5525 : 2009

13 Marking

‘The single pipe passed an inspection shall be marked indelibly with the following

items,

‘The order of arranging the items is not specified.

When blank pipes of different classes or different dimensions are jointed to one single

Pipe, all classes or all dimensions of the blank pipes shall be marked.

a) Class symbol

b) Manufacturer’s name or its abbreviation

¢) Serial number of manufacture

d) Dimensions (outside diameter, thickness and length)

14 Report

‘The report shall conform to clause 18 of JIS G 0404, and the manufacturer shall

submit an inspection certificate 3.1.B in JIS G 0415 to the purchaser. When requesting

inspection documents other than that, the purchaser shall request that to the manu-

facturer in ordering. However, for dimensions, report the test result (one for every

10 or its fraction) to the purchaser.

When the alloy element other than those in table 2 is added, the content of added

element shall be reported in the certificate,

PROTECTED BY COPYRIGHT

Licensed to Me Tikman Utomo on 28 July 2010.1 user personal user ficance oly. Storage, dstbuton or use on network probiited (10135418).

4

A.5525 : 2009

Annex A (normative)

Quality specification of the single pipe

with rib

Al Scope

‘This Annex specifies the quality specification of the single pipe with rib.

A2 Production method

‘The blank pipe with rib is produced by are welding after forming steel strip on which

the continuous and parallel rib to the rolling direction is attached with spiral seam

welder so that the rib is set to the inner side and/or outer side surface. However, when

the steel pipe with rib on inside and outside is applied for blank pipe, it shall depend

upon the agreement between the manufacturer and the purchaser.

Figure A.1 and figure A.2 show the examples of steel strip and its forming example.

Figure A.1_ Steel strip used for Figure A.2_ Forming of blank pipe

blank pipe with rib (example of outside

rib)

A3~ Shape, dimensions, unit mass and dimension tolerance of single pipe with

rib

AB.1 Shape of rib

‘The shape of rib shall be as follows.

a) Assingle pipe with rib inside and/or outside shall have rib on the inside and/or

outside surface of steel pipe.

b) Rib of the inside and/or outside of single pipe with rib may be eliminated in the

following cases if necessary.

1) The case where the backing ring, stopper and copper band interfere with rib

at the pipe end part of site circumferential weld.

2) The case where other accessory is attached.

3) The case where the agreement between the manufacturer and the purchaser

exists.

PROTECTED BY COPYRIGHT

15

A.5525 : 2009

8.2 Dimensions and unit mass

‘The outside diameter, thickness, cross sectional area and unit mass of single pipe

in the case of the blank pipe with rib shall be measured excluding rib and be in accor-

dance with table 4.

3.3 Shape and tolerance of dimensions

a) Shape and tolerance of dimensions shall be shown in table A.1.

b) Dimensional tolerance of rib shall be shown in table A.2.

Table A.1_ Shape and tolerance of dimensions

Division ‘Tolerance Remarks

Outside | Pipe end | +0.5% | Measurement of outside diameter shall be as follows.

diameter | part a) Single pipe with inside rib shall be as shown in table 5.

o b) Single pipe with outside rib shall be in accordance with

‘one of appropriate method of the followings. Unless

otherwise specified, the method shall be determined by

the manufecturer

VD De Lela~ hin 2

2) D=Lix

8) DeLiin 1x2

where, D : outside diameter, Ls: peripheral length

including rib, hy: height of protrusion (mean value of

the measured 3 points value), L: peripheral length

whore rib is excluded, Z,: inside peripheral length,

f: thickness of steel pipe (measured value), x: 8.141 6

©) In the case of single pipe with inside rib and outside rib,

shall conform to the case of b) single pipe with outside

lcance only Storage, cistbuton or use on network pohbited (10135415).

Table A.2 Dimensional tolerance of rib

Ttems Tolerance

Height of rib Go) 2.5 mm or over

Width of rib (B) “4'mm oF over up to and inel. 20 mm

Tnterval of rib) 30 mmm or over up to and inel. 40 mm

However, interval of rib including spiral sear

welding part (L’) shall be 280 mm or under.

‘Angle of rib direction (6) | 40" or under

Lense to Mr Tikman Utomo on 28 ly 2010, 1 user personal us

PROTECTED BY COPYRIGHT

Lense to Mr Tian Utomo on 28 July 2010, 1 user personal use ence ony, Storage, stibuton oF Use on network prohibited (10136415),

16

A.5525 : 2009

Interval Interval of rib including

‘of rib spiral seam welded part

Rib (4) (n'y

t t E Hight orb)

Acection [ I

wane / | Angle o ib

4 nit Spiral seam direction (6)

“eye, / aed pare r

Figure A.3 Height of rib and interval of rib

Ad Test

A4.1 Tensile test

a) Taking of test specimen and number of test pieces ‘The taking of test speci-

men and the number of test pieces shall be as specified in table 7.

b) Test piece Rib of tensile test piece obtained from single pipe with rib or steel

strip to be used for pipe shall be test piece after excluding rib.

A4.2 Measuring method of rib dimension

a) As for height of rib (4), one for the centre of coil width and two for the optional

near the both ends, total three points, shall be measured at the optional point in

the single pipe.

b) Select one pipe for each ten single pipes and its fraction and measure one optional

point.

AS Appearance

Any rib shall be free from harmful fault. However, harmful fault of rib may be

cleaned up by grinding or repaired by welding.

AG Inspection

Inspection of rib shall satisfy A.3.

Other inspection shall be performed in accordance with clause 12.

AT Marking

‘The single pipe passed the inspection shall be marked indelibly with the following

items,

‘The order of arranging the items is not specified,

a) Class symbol

b) Symbol of rib”

PROTECTED BY COPYRIGHT

LUconsed to Mr Tikman Utomo on 28 Jy 2010.1 user personal user cence only. Storage, dtbution or use on network prohibited (10135415),

°

a

°

7

A525 : 2009

‘Manufacturer's name or its abbreviation

Serial number of production

Dimensions (outside diameter, thickness and length)

Note ? Symbol of rib shall be as follows.

Symbol of inside rib: -IR

Symbol of outside rib: -OR

Hyphen, (~) may be vacant.

PROTECTED BY COPYRIGHT

or use on network prohiited (10135415)

Loensed to Me Tikman Utoma on 28 Jy 2010, + user personal user ence only. Storage, dst

18,

5525 : 2009

Annex B (informative)

Typical example of shape and dimensions

of accessory

Introduction

This Annex is to describe typical example of shape, dimensions and so on of acces-

sory attached to the single pipe specified by the purchaser and not to constitute the

provisions of this Standard.

NOTE: Accessories mean the temporally materials necessary for the pile execu-

tion temporally.

B.1 Materials of accessories and welding materials

‘The mechanical properties for materials of accessories should be equal to or better

than $8400 of JIS G 3101, and welding materials used to attach the accessories should

be any one or their combination of the following materials to obtain the specified ten-

sile strength or better than the specified tensile strength of accessories.

SIS Z 8211, JIS Z 3312, JIS Z 3313, JIS Z 3361, JIS Z 3352

When the strengths of blank pipe and accessory are not the same, use welding ma-

terial of specification value of lower strength specification or better than it should be

applied.

B.2 Appearance, inspection and marking of accessories

‘The appearance, inspection and marking of accessories are as follows.

a) Appearance There should be no harmful fault for use in the appearance of ac-

cessories.

b) Inspection Materials and welded part of accessories should be in accordance

with B.1, Appearance should be inspected visually and should satisfy a).

©) Marking Accessories not attached to the main body at shop should be marked

80 as the class and size are identifiable.

B.3_ Example of shape and dimensions of accessories

B.3.1 Reinforeing band

B.3.1.1 Shape of reinforeing band

‘The shape of reinforcing band is as shown in figure B.1

PROTECTED BY COPYRIGHT

LUcensed ta Me Tikman Utomo on 28 Ady 2010.1 user personal user Reence only. Storage, distribution or use on network prohibited (10135415),

19

A525 : 2009

{+—_,

Reinforcing

band

| 1: Thickness 9 mm

NM] fa, bes Length Ls 200 mm

(outside diameter

609.6 mm or under)

1,300 mm

(outside diameter

T over 609.6 mm)

‘Top of bottom pile

Figure B.1 Example of shape of reinforcing band

B.3.1,2 Attaching method

‘The attaching method should be as follow:

a) Fitting position (J,): 18 mm

b) Weld length (a): 6 mm (Welding is carried out by fillet weld.)

B.3.1.3 Dimensional tolerance

‘The dimensional tolerance of reinforcing band should be as specified in table B.1

Table B.1 Dimensional tolerance of reinforcing band

Division Thickness Length Fitting position

T Li 4

not specified | + not specified 0

09 mm 5mm 9mm

PROTECTED BY COPYRIGHT

Licensed to Mr Taman Utomo on28 July 2010.1 user personal user ence any. Sorage, deribuon or use on network probit (10135415).

20

‘A.5525 : 2009

B.3.2. Hanging hook

The shape and dimensions of hanging hook should be as given in figure B.2,

A x

Unit: mm

Maximum hangingload | Width | Height] Hole | Chamfer | Board | Hole | Weld leg

position | dimension | thickness | diameter | length

t ala c [ole Tr 6 e

3 max, 10 | 100 | 55 | 25 | 25 | 12 40 6

OverSuptoandine.§ | 120 [ 100 | 55 | 25 | 25 | 16 40 8

Over Suptoandine.10 | 200 | 150 | 90 | so | a0 | 22 65 15

Over 10uptoandinel 20] 00 | 250 | 150 | 50 | 50 | 22 80 18

Figure B.2 Shape and dimensions of hanging hook

PROTECTED BY COPYRIGHT

21

A.5525 : 2009

B.8.3 Backing ring and stopper

When a stopper is attached to backing ring of single pipe site welded part and middle

pile or bottom pile, the shape and dimensions should be as shown in figure B.3 unless

otherwise specified.

. ait: som osefen

: Peso qf

i he

: ‘ iS

i el i | \ lA 2 Tbe iterat

5 4 i cs keeping boad

: - a ; ‘ena

af sin | ane

3 Inside diameter of pipe ‘Backing PPE

naar ae a |i

:

a 1S shop assembly

i ato ple

i rasan ine

g ‘Thickness and height of backing ring Number of stopper

i eines

3 Camis dams [Cr [a [a nee ee

é 1.016 or under 45| 50 | 18 forH-50 609.6 or under 4

eI Over 1016 60 [70,80 | Bie-70| [Over soneuptoandines 1016| 6

a Tn the case of inner excavation, #=50 mm. Over 1 016 8

5 ) Backing ring ») Backing ring and stopper

& Figure B.3_ Example of shape and dimensions of backing ring

i and stopper

3

PROTECTED BY COPYRIGHT

jon or use on network probed (10135415).

Uconsod to Mr Tian Utomo 28 hy 2010.1 user personal use cence only. Storage, es

22,

5525 : 2009

B34 Auxiliary parts for execution

‘The auxiliary parts for execution, such as high strength steel, is attached to the

top of bottom pile as shown in figure B.4 to improve the penetration ability and to pre-

vent the damage of top of bottom pile at the penetration.

‘Top of bottom pile >, vralai

—“4

XC Auniliary parts

for exeestion

Figure B.4 Example of attaching the auxiliary parts for execution

PROTECTED BY COPYRIGHT

(10135415),

LUcensed to Me Tikman Utomo on 28 July 2010.1 user personal user lence ony. Storage, dtbution or use on network pri

23,

A.5525 : 2009

Annex C (informative)

Forming, painting and coating

Introduction

‘This Annex is to describe typical examples of forming, painting and coating on the

single pipe according to the specification of the purchaser and not to constitute the pro-

visions of this Standard,

NOTE: Forming means forming and painting, coating to exhibit the pile faculty

such as load transfer to concrete,

C.1_ Type of forming

‘Typical forming of single pipe is shown in table C.1

‘Table C.1 Representative forming example of single pipe

‘Type of forming Content of forming ‘Shape example

1) Ring type plane steel, stecl bar, weld bead

or rib of steel plate are attached to the

Fitting of bearing member or | inside or outside of single pipe (a) to d) of

ribband figure C.1), er

2) Ribband is attached to the inside or outside

cof top of single pipe la) of figure C.11

Fitting of blade to the top of | Cut the top part of bottom pile corresponding | piu oo

rotating pile to the shape of fitting part and weld blade ie

Weld the mechanical joint, instead of site .

Fitting of mechanical joint eee eee ar singe ripe Figure C3

NOTE: The bearing member means a part to transfer the load by bearing stress (com-

pression stress working on the partial area to the whole area) to concrete or cement

mortar, The ribband means a bearing member which is attached to either or both

of inside and outside surface of single pipe top part to transfer axial direction force

of single pipe to concrete securely.

C.2 Welding materials

Welding materials used for forming should be any one or the combination of the

followings, unless otherwise specified.

JIS Z 3211, JIS Z 3312, JIS Z 3313, JIS Z 3351, JIS Z 3352

When the strength of parts attached by forming and blank pipe is not the same,

the welding material having tensile strength of the same or better than the lower

strength level specification should be used.

PROTECTED BY COPYRIGHT

ted (10195415),

sion oF use on network pr

‘

Licensed to Mr Tikman Uomo on 28 July 2010. 1 user personal user cence nly. Stora

24

‘A.5625 : 2009

Flat Stoel waa

steel bead \

Weld

Steel

a plate

ae Steal pipe

‘Stee! pipe. Steet pipe Stool pipe pile

pile pile pile waa /

a) For flat steel b) Forsteelbar ¢) Forweld bead —d) For steel plate

Figure C.1 Shape examples of bearing member

‘Top pile or middle pile

Weld

Lower pile

‘Mechanical joint

Weld Weld

Midale pile or lower pile

Figure C.2 Shape examples of Figure C.3. Shape example of

blade at the top of mechanical joint

rotating pile top

©.3. Appearance, inspection and report of formed part

‘The appearance, inspection and report of formed part should be as follows.

a) Appearance There should be no harmful fault for use.

b) Inspection The appearance of formed part should be inspected visually and

should satisfy a).

©) Report The manufacturer should submit the certification letter to the purchaser

when the purchaser requested beforehand. In this case, the report should be in

accordance with clause 13 of JIS G 0404, When not specified at the time of or-

dering, the type of inspection report should be in accordance with an inspection

certificate 3.1.B of JIS G 0415.

C4 ‘Type of painting, coating and appearance

C.4.1 Type of painting and coating

‘The typical types of single pipe painting and coating are shown in table C.2,

PROTECTED BY COPYRIGHT

Uoensed to Mr Tikman Utomo on 28 tly 2010, 1 user personal user lence only. Storage, dstbution or use on network profited (1013541).

25.

4.5625 : 2009

Table C.2 Types of painting and coating

ee Classification ‘Types:

Tnorganie zine-rich + epoxy resin paint

Painting Tnorganie zine-rich + tar epoxy resin paint

Rust prevention Paint with glass fake

“Heavy corrosion protective | Polyethylene coating

come) Urethane clastomer coating

Reduce negative friction | SL compound painting | Primer + SL, compound + surface layer material

NOTE: The negative friction means, when pile is set on the ground sinking area, the downward

friction force generated to the surrounding of pile forced by ground sinking. By coating

SL compound (compound to agitate slip, slip layer), reduce the friction force,

C.4.2 Appearance

‘The appearance of painting and coating should be inspected visually and should have

no harmful defects.

PROTECTED BY COPYRIGHT

LUcensed to Me Tikman Utomo on 28 July 2010.1 user personal user Kcence only. Storage, cstibuton or use on network profited (10135418),

Errata for JIS (English edition) are printed in Standardization Journal, published monthly by

the Japanese Standards Association, and also provided to subscribers of JIS (English edition) in

Monthly Information.

Errata will be provided upon request, please contact

Standards Publishing Department, Japanese Standards Association

41-24, Akasaka, Minato-ku, Tokye, 107-8440 JAPAN

‘TEL, 03-3585-8002 FAX. 053580-0462

PROTECTED BY COPYRIGHT

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pertamina Pak IndraDocument1 pagePertamina Pak IndraBudhi Kurniawan100% (1)

- Penjelasan Teknis Komparasi Produk Membran Tensil Merek AGTEX Dengan Merek Serge FerrariDocument8 pagesPenjelasan Teknis Komparasi Produk Membran Tensil Merek AGTEX Dengan Merek Serge FerrariBudhi KurniawanNo ratings yet

- Price & Approval DesignDocument4 pagesPrice & Approval DesignBudhi KurniawanNo ratings yet

- PVC Spek 2017Document1 pagePVC Spek 2017Budhi KurniawanNo ratings yet

- Theoretical Maximum Specific Gravity and Density of Hot Mix Asphalt (HMA)Document3 pagesTheoretical Maximum Specific Gravity and Density of Hot Mix Asphalt (HMA)Budhi Kurniawan100% (1)

- Astm D6690-15Document4 pagesAstm D6690-15Budhi KurniawanNo ratings yet

- Undangan Wawancara Calon IP 20220204 ADocument2 pagesUndangan Wawancara Calon IP 20220204 ABudhi KurniawanNo ratings yet

- MarshallDocument10 pagesMarshallBudhi KurniawanNo ratings yet

- Gradasi Combine AC WCDocument1 pageGradasi Combine AC WCBudhi KurniawanNo ratings yet

- Pipa BerlubangDocument2 pagesPipa BerlubangBudhi KurniawanNo ratings yet

- Cek Drained LayerDocument12 pagesCek Drained LayerBudhi KurniawanNo ratings yet

- T20-10400 Original Result Complete Consol Cure E White ASTM C309Document7 pagesT20-10400 Original Result Complete Consol Cure E White ASTM C309Budhi KurniawanNo ratings yet

- Brosure Colflex (PMB) 100Document2 pagesBrosure Colflex (PMB) 100Budhi Kurniawan100% (1)

- Jis A7201Document13 pagesJis A7201Budhi KurniawanNo ratings yet

- Tes Beam 2 Tumpuan VubDocument9 pagesTes Beam 2 Tumpuan VubBudhi KurniawanNo ratings yet

- Spek Lpa LPBDocument2 pagesSpek Lpa LPBBudhi KurniawanNo ratings yet

- Sni 1976 2008Document18 pagesSni 1976 2008Budhi KurniawanNo ratings yet

- Tolok Ukur Penilaian IP Badan Kejuruan PII Agustinus 12 Januari 2017Document42 pagesTolok Ukur Penilaian IP Badan Kejuruan PII Agustinus 12 Januari 2017Budhi KurniawanNo ratings yet