Professional Documents

Culture Documents

50Hz Pump Catalog PDF

50Hz Pump Catalog PDF

Uploaded by

kiki2709770 ratings0% found this document useful (0 votes)

2 views132 pagesOriginal Title

50Hz_Pump_Catalog.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views132 pages50Hz Pump Catalog PDF

50Hz Pump Catalog PDF

Uploaded by

kiki270977Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 132

PUMPING LIFE

SUBMERSIBLE PUMPS

‘CONTENT PAGE NO. CONTENT PAGE NO.

GENERAL DATA a4 PUMPS

Performance RANg@rnrmnnennennee 2 ‘SSP General Data. 102

23 Pump Range.. 1403

3 Motor Range.rcncncsnsrnanennnenncn 408

4 ‘Type Key. 403

4 Pumped Liquids. 403

4 Operating Conditions. 403

4 Features & Benefits. 104

Curve Conditions... 4 Performance Range

Material Spectication &

‘SUBMERSIBLE PUMPS ‘Sectional view of SSP 271

Performance Curve & Technical Data

87 ‘SSP 270.

8 ‘SSP 300.

‘SSP 360.

SUBMERSIBLE MOTORS.

‘SUBMERSIBLE MOTORS

Features and Benefits. 10

“Material Specification & Sectional View ‘Single Phase Performance Data 50 Hz 119

3" MOTOR .. a 4° Premium 400/101..

4" PREMIUM 100, 4° PREMIUM 10, 1243 ‘Three Phase Performance Data 50 Hz 120

4" MCIP 100, 4" MCIP 104. 1445 4" Premium 400/404.

BE MTSE 18 MTSF 6" Rewindable Motors 424

i a7 Performance Data 50 Hz.

8° MTSI 18 MTSF 8" Rewindable Motors 422

10" MSF 49 Performance Data 50 Hz.

'SML 6" Rewindable Motors 123

PERFORMANCE CURVES / TECHNICAL DATA Performance Data 50 Hz.

MTSF 10" Rewindable Motors 124

(OF SUBMERSIBLE PUMPS.

Performance Data 50 Hr.

‘TABLE OF HEAD LOSSES

S88

Head Losses in Plastic Pipes.

CABLE SIZING

‘Submersible pumps SP A, SI 128.130

o

CO SHAKT.

GENERAL DATA ‘PUMPING UE

PERFORMANCE RANGE

fey tml

SOHz

2000 | 499 2 |

A ce

1300 | 400 : ee

300 100 I" |

230 | ala

200 | 80 ) -lelala

J ate &| Al slab ¢ Ayala

A 3 518] alubehl ’ 4) 5} 2)8) &

©

0

so

20

|

wo!

8 10 2 40 60 60100 «200 500 400. 500 cin /n}

as 06 08 1 2 46 80 2 4 6080 100 120 a /4]

02

CO SHAKTI

GENERAL DATA

PUMP RANGE

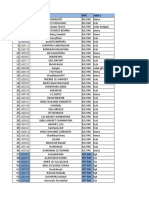

Te a aoe a a aa a | ara] are aro | rs [oro [ar arma

me eee eae epee Pe

tes: OHS]

nd “lelelelel? ele lela tele (ats l-l-lelele

NPT Thread mlelaetfvel 2 tate] 2f2fafs]} 2]? 8 a}s]e6 6

ats

re z pete

MOTOR RANGE

QU joasrg.a|ss]aa]s0|ao] [7a] oa] 21] 2a saa 2a [an] v0] =|] |=] vs] zai]

aewomes P= [>to [=| f=

Direct-on-Line starting is recommended up to 7.5 kW.

Soft starter or auto transformer is recommended above 7.5 kW.

03

GENERAL DATA

CO SHAKTI

APPLICATIONS

‘The pumps are suitable forthe following applications :

+ Raw water supply

+ Inrigation systems

+ Groundwater lowering

+ Pressure boosting

‘+ Industrial applications

TYPE KEY

Example

QF 210-5 -A

Type range

Nominal ow rate x 40 In

Number of impellers

First impeller with reduced diameter (A.8 oF

‘Second impeller

ith reduced diameter (A,B or )

PUMPED LIQUIDS

Clean, thin, non-aggressive liquids without solid particles

or fibres.

OPERATING CONDITIONS:

Flow rate,Q: 0.1-280 m'/h.

Head, | Maximum 670m,

Maximum Liquid Temperature:

Installation

Motor | Flow velocity-] Vertical | Horizontal

ast motor

‘Shakti

syarerast| ot5nvs | 40% 4o'c

Operating pressure: Maximum 0.67m (67 bar)

CURVE CONDITIONS

‘The conditions below apply to the curves shown on the

following pages :

GENERAL,

+ Curve tolerance accordingto1SO 9906, Annex.

‘The performance curves show pump performance at

actual speed cf. standard motor range.

‘The speed of the motors s approximately:

‘3 motors, ‘n=2850 min*

4" motors. ‘n=2870min*

6" motors ‘n=2870min*

8"to12" motors: n=2900min*

+ The measurements were made with airless water at a

temperature of 20% The curves apply to a kinematic

iscosity of ¢mm’/s. When pumping liquids with a density

higher than that of water, mators with correspondingly

higher outputs mustbe used.

+ The bold curves indicate the recommended performance

range.

+ The performance curves are inclusive of possible losses

suchasnon-return valveloss.

, OF, OF2, OFS, FS, QF12, QF20, QF25 CURVE

+ Q/H: The curves are inclusive of valve and inlet losses at,

the actualspeed.

+ Power Curve : BPkW/Stage shows pump power input per

stage.

+ Efficiency Curve: Efficiencyshows pump stage efficiency.

QF40, OF15, QF30, QF5O, QF75, QF100, QF125, QF160,

QF2410, QF270, QF360 CURVE

+ Q/H: The curves are inclusive of valve and inlet losses at,

theactual speed.

Operation without non-return valve will increase the

actual head at nominal performance by0.5to1.0m.

+ NPSH The curve is inclusive of suction case and shows.

required inlet pressure.

+ Power Curve: It shows pump power Input at the actual

speed foreach individual pumpsize.

+ Effleleney Curve : Efficiency shows pump stage

efficiency.

o4

SUBMERSIBLE PUMPS

GO SHAKTI

FEATURES AND BENEFITS

AWIDE PUMP RANGE.

We offers submersible pumps with energy efficient duty

points ranging from 0.1 to 335 m’/h. The pump range

consists of many pump sizes and each pump size Is

avallable with an optional number of stages to match any

duty point.

HIGH PUMPS EFFICIENCY

Often pump efficiency is a neglected factor compared to

the price however, the observant user will notice that price

variations are without importance to water supply

‘economics compared to the importance of pump and

motorefficiencies.

EXAMPLE:

‘When pumping 125 m'/nwith ahead of 200m fora period

‘of 10 years $ 60,000 will be saved if a pumps and motors

having a 10% higher efficiency is chosen and the price Is.

$0.40 perkWh.

(

100

90

50

70

60 s

oo woe

6 48 5B

40 wg =

Se

30 h

&

20

10

0

01 1 2 4 6810 2

oF 30

‘APPLICATIONS

We offers a complete range of pumps and motors which as

a standard are made completely of stainless stee! AISI -

‘304, This provides for good wear resistance and a reduced

risk of corrosion when pumping ordinary cold water with a

‘minorcontent of chloride.

LOWINSTALLATIONCOSTS

Stainless steel means low weight facilitating the handling

‘of pumps and resulting in low equipment costs and

reduced Installation and service time. In addition pumps.

willbe as new after service due to the high wear resistance

ofstainlesssteel.

SOHz

oF 360

F125

OF 160

oF 210

OF 370

oF 50

oF

GF too

40 60 80 100 200 O[m3/n]

05

SHAKTT

[BEARINGS WITH SAND CHANNELS.

All bearings are water- lubricated and have a square shape, enabling sand particles, if any, to leave the pump

together with the pumped liquid.

INLET STRAINER

‘The inlet strainer prevents particles aver a certain size from entering the pump.

NON - RETURN VALVE

‘All pumps are equipped with a rellable non-return valve In the valve casing preventing back flow In connection

with pump stoppage. Furthermore , the short closing time of the non-zetum valve means that the risk of

destructive water hammer Is reduced to a minimum. The valve casing Is designed for optimum hydraulle

properties to minimize the pressure loss across the valve and thus contributes to the high efficiency of the pump.

SHA,

SUBMERSIBLE PUMPS Leedaintel

[AIF and QF 30 pumps are fitted witha priming screw. Consequently, dry running Is prevented because the priming

‘serew will make sure that pump bearing are always lubricated. Due to the sembaxal Impellers of large QF pumps

{except for QF 30) this priming is automatically provided. However, it applies to all purnp types that if the water table

| lowered to a level below the pump Inlet neither pump nor motor will be protected against dry running,

‘STOP RING

‘The stop ring prevents damage to the pump during transport and in case of uphrust in connection with start-up.

‘The stop ring, which Is designed as a thrust bearing limits axlal movements of the pump shaft.

EXAMPLE: QF 125,

‘The stationary part ofthe stop ring (A) is secured in the top bow! (Upper intermediate chamber). The rotating part (B)

Is fitted above the collet [spit cone (C).

SUBMERSIBLE PUMPS

MATERIAL SPECIFICATION EXAMPLE : QF - 125

3a_[ Onna nam

2 [WANE Sear SANLESSSTen [04 36

| UPPER BEARING ‘SANLESS STE | 308 a6

7 NEocRNa NUP

‘es | WASHER FORSTOP RNG | cARBOWGRIPHTE

9 | oumper SONESSSTER__| 904 36

a2 | SAUT ONE SUNLESS SER | 08 ae

15 sTRANER SANLESS Ten. 208 26

19_[ NuTFoRSTRAP ‘SANLESSsTER | 308 a6

70 vAve cue ‘snmuesssrea | 304 26

rawr ‘STuNLeSs grea | 308 316

08

‘SUBMERSIBLE MOTORS

© SHAK

z

FEATURES AND BENEFITS

‘A COMPLETE MOTOR RANGE

We offer a complete submersible motor range nat

motors, single phase up to 2.5 HW (ewindeble)

‘+ ‘tmotors, single phase up to 4 KW. (Encapsulated & Rowndable)

+ @°moters,threephaee upto 75 KW. (Encapsulated & Rewindsbe)

“+ B'motors,throe-phaso rom 2.2 KW to 37 KW. (Rowindoblo)

‘+ Brmotor, three-phase from 44 KW to 220 KW. (Rewindable)

HIGH MOTOR EFFICIENCY

Within the area of high motor efficiency Staris a market leader. This

1s due to newly developed motor concept which Is introduced with

the Premium 400, Premium 403 and Premium 450.

SHAFT SEAL

The cholce of material Is ceremle/ tungsten carbide providing

‘optimum sealing, optimum wear resistance andlonglite.

‘The spring loaded shat seal Is designed witha large surface and @

snd shield, The result is a minimum exchange of pumped and

‘motor liquids and no penetration of particies.

PROTECTION AGAINST UPTHRUST

‘Incase ota very smal counter pressure In connectton wit start.up there

|e x ak thatthe entre pump body may rise, Tis Ws called upthrust

Upthrust may damage both pump and motor. Therefore, both pumps

‘and motors are protocted against upthrust ss standar, provonting

tupthrust from eccuring In the critical startup phese. The protection

‘consist of ether ulin stop rng or hydraulcbalancing.

BUILT 4N COOLING CHAMBERS

Inall submersible motors an efficient cooling Is ensured by cooling

‘chambers at the top and at the bottom of the motor, and by an

Internal creulation of motor quid. AS long as the requlred flow

‘yelocity cooling ofthe motor willbe efficient.

SUBMERSIBLE MOTORS

FEATURES AND BENEFITS

(OVER TEMPERATURE PROTECTION

For Shakti submersible motors accessories Pt100 for

protection against over temperature Is available. When the

temperature becomes too high, the protection device wil

cut-out and damage to the pump and motor be avoided.

PROTECTION AGAINST UPTHRUST

Incase of a very small counter pressure in connection with

start-up there Isa risk that the entire pump body may rise.

‘This is caller upthrust. Upthrust may damage both pump

‘and motor. Therefore both Shakti pumps and motors are

protected against upthrust as standard, preventing upthrust

form occurring In the critical startup phase. The protection

consists of a bulltin upthrust ring.

EXAMPLE : 6” MTSF

10

SUBMERSIBLE MOTORS

MATERIAL SPECIFICATION 3 INCH MOTOR

[SRO] PART MATERIAL

4 [SAND SUNGER NR

2 [SEAL COVER PPS

ol seat NOR SSAISIG04

4 [T0P END BELL c1F6260

5 |UPTHRUST WASHER | PP

6 [BUSH ‘CARBON WITH RESIGN

IMPREGATED

7 [ROTOR SHAFT SS AISI 420

8 ROTOR SUB ASSLY NA

9 __|rop Fiance Ms

20 _ [STATOR PIPE $5 ASI308

11 [STATOR SUB ASSIY | W/A

22 [THRUST BEARING PLATE_| ci F260

3 [THRUST PAD SSAISi420

[4 [REVOLVING PLATE ASSLY | NA

15 [BOTTOMEND BELL | c1FG260,

5 [MOTOR BASE c1F6-260

[7 [DIAPHRAGM NBR

[48 [BOTTOM FLANGE MS

19 [ADJUSTING STUD ‘SS AISI-410 + MAX DIA 73

}——)

8) 5)

8) 4)

3)

9) 2)

D D

i

SUBMERSIBLE MOTORS

C SHAKTI

MATERIAL SPECIFICATION 4” PREMIUM-100

SECTIONAL VIEW OF 4” PREMIUM 100

[SRO] PART MATERIAL

ja |[SANDSLINGER NBR

[2 |SEAL COVER PPS

son SEAL EPDM + SS AISI 304

[4 |TOP END BELL COVER | SS AISI304

[S_|TOP END BELL C1FG-260

(6 |SHAFT BUSH NYLON 30% GLASS FILLED

7 [Bush ‘CARBON WITH RESIGN

IMPREGATED

8 |ROTOR SHAFT ‘SS (STAINLESS STEEL

| SPECIAL GRADE)

9 |ROTORSUBASSLY [N/A

[40__|TOP FLANGE MS

[a4 |STATOR PIPE [SS AISI304

[a2 [STATOR SUB ASSLY_[N/A

[a3_| THRUST DISC [ANTIMONY CARBON

[a4 |THRUST PAD SS AISI420

15 [LEVELING DISC ‘MS+ HARD CHROM.

16 [BOTTOM END BELL _|cIFG-260

[a7 [DIAPHRAGM EPDM.

jas [BOTTOM FLANGE [MS

19 [BOTTOM END BELL covER|SS AISI304

SUBMERSIBLE MOTORS

@ SHAKTI

MATERIAL SPECIFICATION 4” PREMIUM-101.

‘SECTIONAL VIEW OF 4” PREMIUM 101

SRNO] PART MATERIAL

[1 |SAND SLINGER NBR

2 |SEAL COVER PPS:

3 [Ou SEAL EPDM + 88 AISI 304

4 |TOP END BELL COVER |$S AISL304

5 __|TOPEND BELL (ClFG-260,

6 (BUSH ‘CARBON WITH RESIGN

IMPREGATED

7 |ROTOR SHAFT ‘SS (STAINLESS STEEL

‘SPECIAL GRADE)

(8___|ROTOR SUBASSLY__[N/A

9 |TOP FLANGE MS:

10 _| STATOR PIPE [SS AISI304

11 |STATOR SUB ASSLY_|N/A

12 |THRUSTHOUSING __|ciFG-260

123 |THRUSTPIPE [SS AISIS04

[a4 |THRUSTDISC (clFG-260

[25 [CARBON PLATE REGIN IMPREGNATED.

[16 [LEVELING DISC 'SS AISI 420

27 [ADJUSTING STUD __|SSAISL410

18 |BOTTOMEND BELL |CIFG-260

19 [DIAPHRAGM EPDM

20__|BOTTOM FLANGE [MS

21 [DIAPHRAGM COVER |S AISL304

3

SUBMERSIBLE MOTORS

CG SHAKTI

MATERIAL SPECIFICATION 4” MCIP-100

‘SECTIONAL VIEW OF 4” MCIP 100

[SR.NO.[ COMPONENT MATERIAL

‘1_ | SEND SLINGER Nar

2 __| SEAL COVER PPS:

3 | stu ‘SS AISTSO4

4 | OWSEAL EPDM+ SS AISI304

S| UPPER HOUSING | CIFG-260

6 | BUSH ‘CARBON WITH RESIN

IMPREGNATED

7_| SHAFT BUSH NYLON 30% GLASS FILLED

3 | ROTORSUBASSY | N/A

‘9 | STATOR SUB ASSY_| N/A

0_| THRUST DISK "ANTIMONY CARBON

T1_| THRUST PAD ‘SS AISH420

22 _| LEVELING DISK HIGH GRADE

13__| BOTTOM END BELL | CIFG-260

14_| DIAPHRAGM EPDM.

25 | ENDBELL COVER | SSAISIS04

287.25

Fry

SUBMERSIBLE MOTORS

GO SHAKTT

MATERIAL SPECIFICATION 4” MCIP-101.

‘SECTIONAL VIEW OF 4” MCIP 101.

[SR.NO.| COMPONENT MATERIAL

1_| SEND SLINGER NBR

2_| SEAL COVER PPS

3 STUD ‘SS AISTSO4

4_| O1L SEAL EPDM# SS AISI 304

S| UPPERHOUSING | CIFG260

6 | BUSH ‘CARBON WITH RESIN

IMPREGNATED

7__| ROTOR SUBASSY | N/A

@ | STATORSUBASSY_| N/A

9 | BOTTOM END BELL | CIFG260

0_| THRUST DISK "ANTIMONY CARBON

24_| THRUSTHOUSING | CIFG260

22_| THRUST SEGMENT | SSAISI420

13 _| LEVELING DISK SSAISI304

24 _| ADJUSTING STUD | SSAISI410

25 _| DIAPHRAGM. EPDM.

16 | DIAPHRAGM SPRING SPRING STEEL

“27_| DIAPHRAGM COVER | STAINLESS STEEL

12.7 MIN

|.FULL SPLINE

15

SUBMERSIBLE MOTORS

CO SHAKTI

MATERIAL SPECIFICATION 6” MTSF ‘SECTIONAL VIEW OF 6” MTSF

$ MATERIAL

No, | COMPONENT i 30

cira2co | ssaisi3zoa | ssaisi3ie 35 gun

Z| SAND SLINGER [NBR NBR NBR «3

2 [stu c1Fe260 | ssaisia0a | ssaisiai6 i

3_[MECHSEAL_[SiC/sic SI0/SIC SIC/SIC wal

eee ee ied

5 [BUSH RESIN RESIN RESIN

IMPREGANTED| IMPREGANTED| IMPREGANTED

carson | CARBON ‘CARBON

© [uPTaRUST NYLONSO® | NYLON3O% | NYLONSO%

GLASS FILLED| GLASS FILLED | GLASS FILLED

7_[ROTOR SUB ASSY [N/A WA. WA.

| STATOR SUB ASSY [N/A MA. NA,

‘9 [END BELL LOWER [c1FG-260 | SSAISI304 | _SS.AISI3I6

10" | REVOLVING PLATE

ASSY N/A NA, MA.

Z| THRUST HOUSING ese

BEARING cire2so | ssaisizo¢ | ssaisiais

72 [DIAPHRAGM [EPDM EPDM EPDM

3 | DIAPHRAGM

‘SPRING ‘SPRING STEEL| SPRING STEEL| SPRING STEEL

ia [moron Base _[circ-260 | Ssaisi304 | SSAIsi316

16

SUBMERSIBLE MOTORS

omar

MATERIAL SPECIFICATION 6” SML

‘SECTIONAL VIEW OF 6” SML

[SR.No| COMPONENT MATERIAL

1_| SAND SLINGER NBR

2 [stu [ss AISI 304

3 | OL SEAL EPDM + 55304

“4 _ | UPPER HOUSING (clFG-260,

5 _| END BELL UPPER [clFG-260

6 | BUSH RESIN IMPREGNATED

jCARBON

7 [UP THRUST BEARING | NYLON 30% GLASS

FILLED

B_| ROTOR SUB ASSY NA tI

‘@ _| STATOR SUB ASSY N/A

20_| END BELL LOWER (erFe-260

“Z| REVOLVING PLATE ASSY [N/A

2_| THRUST SEGMENT [ss Aisi 304

T3_| THRUSTING BEARING PLATE Cl FG-260

44_[ ADJUSTING STUD DUPLEX

45_| DIAPHRAGM [EPDM

46 | DIAPHRAGM SPRING [SPRING STEEL

17_[ MOTOR BASE [clFG-260

2000 @

24MIN.

77

73.03,

/

oe

So ©

3)

|

®

/

b

/

@

S

Fy

CO SHAKTI

SUBMERSIBLE MOTORS:

MATERIAL SPECIFICATION 8” MTSF SECTION VIEW 8” MTSF

[SRNo| —coMPONENT MATERIAL

[SAND SUNGER aR 4 fa ye

2 [BUST COVER c1Fe360 oui 1

cae oreaor e4

4 | MECH SEAL S10 :

3 [UPPER HOUSING C1FERBO

6 [ENO BELL UPPER 16260

7 BUSH METAL IMPREGNATED

ANT:MONY

3 [ENO TAMNATION PPS

3 | STATOR SUB ASSY WA

0 | ROTOR SUB ASSY NAR

+E [END BELL LOWER c1FGzBD

+2 [REVOLVING PLATE ASSY —[ W/A

4 [THRUST HOUSING BEARING| ci FO-260

74_[ THRUST BEARING SUPPORT ciFG-260

35 [ADIUSTING STUD DUPLEX

36 | DAPHRAGM POM

[DIAPHRAGM SPRING | SPRING STEEL

48 [ MOTOR BASE 16-260

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- 4G Site DetailsDocument615 pages4G Site DetailsZahoor WaniNo ratings yet

- CGMT REVIEW REPORT OctDocument10 pagesCGMT REVIEW REPORT OctZahoor WaniNo ratings yet

- Budgam Site DetailsDocument1 pageBudgam Site DetailsZahoor WaniNo ratings yet

- Budgam BillDocument2 pagesBudgam BillZahoor WaniNo ratings yet

- Cluster2 Dockets HardwareDocument2 pagesCluster2 Dockets HardwareZahoor WaniNo ratings yet

- BZL - HPT Node BDocument2 pagesBZL - HPT Node BZahoor WaniNo ratings yet

- IPfication Plan NewDocument15 pagesIPfication Plan NewZahoor WaniNo ratings yet

- VAS DeactivationDocument2 pagesVAS DeactivationZahoor WaniNo ratings yet