Professional Documents

Culture Documents

Ac 4

Uploaded by

swarna ravi0 ratings0% found this document useful (0 votes)

9 views9 pagesOriginal Title

ac4

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views9 pagesAc 4

Uploaded by

swarna raviCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 9

AR 302

Air handling unit system

and its types in building

CH.GOWTHAM

101117006

Air Handling Units

An air handling unit (AHU) is a machine that conditions i.e., heats, cools,

cleans or humidifies and circulates air in a house or building. AHUs are

components of complete HVAC systems.

+ AHUs are large metallic boxes comprising of a blower, filter racks,

sound attenuators (to reduce noise), and cooling and/or heating

coils. Connected to the HVAC’s ductwork, AHUs are installed inside

and outside of buildings, with the rooftop being common for the

latter.

+ While commonly known as large machines, it should be noted that

AHUs come in different sizes and with a range of configurations. In

terms of size, you can get internal AHUs for houses too — these are

known as terminal units.

+ However, those with multi-unit buildings will look at large air

handlers, such as makeup air units (MAU)

Components Of An AHU

+ Filters

* Heating and/or cooling elements

+ Humidifier

* Mixing chamber

* Blower/fan

* Balancing

* Heat recovery device

* Controls

* Vibration isolators

* Sound Attenuators

uct humidity sensor RH

(accessory) heat exchanger

extract filter

supply filter

INTAKE AIR

EXTRACT AIR

EXHAUST AIR

SUPPLY AIR

condensate

duct temperature ‘drain pips

sensor TES

exhaust fan

control unit celactric heater

froaze protection

temperature sensor

Function of Blower

An important component of every air handling unit is the blower which

performs the function of recycling the air present in the building. The air

collected by the blower is conditioned (heated or cooled) and then released

into the building. Air handling units at commercial buildings may have multiple

blowers or fans for better functionality

rect)

Function of Conditioning Elements

The second important components of an air handling unit are the elements

that help in heating or cooling the air. For heating systems, there are heating

coils used for this purpose. Cooling coils are used to cool the oil in the air-

conditioning systems. Hot water, steam and cold water are among other

conditioning elements used for this purpose.

Function of Humi r

Humidifiers present in the air handling units perform the function of maintaining

the quality of air in cold climate areas. In the absence of these components,

the air may become extremely dry due to constant heating. Different types of

humidifiers, including vaporizers and ultrasonic humidifiers are present in

different units

Function of Dampers and Mixing Chambers

Dampers are installed inside the mixing chamber of an air handling unit and

they perform another important function. This whole arrangement is used to mix

air from the outside of the building and exhaust air from the inside of the

building in order to condition the air more easily and quickly.

eee

Function of Filters

One of the most important components of AHUs is the filter. Apart from

conditioning the air, it is extremely important to clean the air present in a

building. Air handling units are fitted with filters that perform the function of

removing dust and other undesirable components of air to make it clean and

fresh. Remember that filters function to increase the overall life of an air

handling unit

Types Of AHU

Draw-Through

The fan is placed after the burner.

The AHU’s fan pulls in the air and the air is then put through

the AHU’s internal system (mixing box, filters and, its cooling

coil) before reaching the air-conditioned room or area

Blow-Through

The fan is put before the burner.

The AHU fan pushes the air through its internal system before

entering the air-conditioned area or room.

Ei tl

foo J

1 2 3 1 2 3

Draw through configuration Blow through configuration

1: AHU inlet = On-coil condition 1: AHU inlet = Fan upstream

2: Off-coil condition = Fan upstream 2°: Fan downstream = On-coil condition

3: Fan downstream = Supply condition _3: Off-coil condition = Supply condition

Energy recovery

Run around coil - Air handling unit

LOU e er kel]

If the supply and extract AHU’s are located in different areas then a

common way to recover some of the thermal energy is to use a run

around coil. This uses a coil within both supply and return AHU’s

which are connected via pipework. A pump circulates water between

the two. This will pickup waste heat from the extract AHU and add

this to the supply AHU. As the pump will consume electricity, it is

only cost effective to turn on if the energy saved is more than the

pump would consume

AHU air economizer

Another very common version we'll come across is to have a duct

sit in between the exhaust and the fresh air intake. This allows

some of the exhaust air to be recirculated back into the fresh air

intake, to offset the heating or cooling demand. This is safe and

healthy to do but you will need to ensure the exhaust air has a

low Co2 count so we need some Co2 sensors to monitor that.

If the Co2 level is too high then the air can’t be re-used, the

mixing damper will close and the all the return air will be rejected

from the building.

AHU heat wheel, thermal wheel

Bia atasYel a1

Marea aC)

Rion

+ Another variation we might come across, is the heat wheel. This

is very common in newer compact AHU’s. This uses a large

rotating wheel, half of it sits within the exhaust air stream and

half of it sits within the fresh air intake.

+ The wheel will rotate, driven by a small induction motor, as it

rotates it picks up unwanted heat from the exhaust stream and

absorbs this into the wheels material. The wheel then rotates into

the fresh air intake stream, this air is at a lower temperature than

the exhaust stream so the heat will transfer from the wheel and

into the fresh air stream which obviously heats this incoming air

stream up and thus reduces the demand on the heating coil.

+ This is very effective but some air will leak from the exhaust into

the fresh air stream so this can not be used in all buildings.

AHU plate heat exchange

ary

+ Another version we might come across is the air plate heat

exchanger. This uses thin sheets of metal to separate the two

streams of air so they do not come into contact or mix at all, the

temperature difference between the two air streams will cause heat!

to transfer over from the hot exhaust stream through the metal

walls of the heat exchanger and into the cold intake stream.

Location of AHU’s in

buildings

Roof Basement Floors

Air handling units, which usually have the acronym of A.H.U are

found in medium to large commercial and industrial buildings.

They are usually located in the basement, on the roof or on the

floors of a building. AHU’s will serve a specified area or zone

within a building such as the east side, or floors 1 - 10 or perhaps

a single purpose such as just the buildings toilets. Therefore, it’s

very common to find multiple AHU’s around a building.

Some buildings, particularly old high rise building, will have just

one large AHU, usually located on the roof. These will supply the

entire building. They might not have a return duct, some older

designs rely on the air just leaking out of the building. This design

isn’t so common anymore in new buildings because it’s very

inefficient, now its most common to have multiple smaller AHU’s

supplying different zones. The buildings are also more air tight so

we need to have a return duct to regulate the pressure inside the

building.

You might also like

- Aluminum Extrusion ProcessDocument4 pagesAluminum Extrusion Processswarna raviNo ratings yet

- Functional Checklist For Exterior LightingDocument16 pagesFunctional Checklist For Exterior Lightingswarna raviNo ratings yet

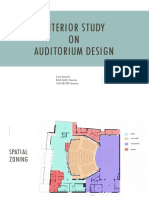

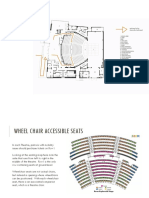

- Interior Study ON Auditorium Design: Zach Theatre BLUE BARN Theatre CHICHESTER TheatreDocument4 pagesInterior Study ON Auditorium Design: Zach Theatre BLUE BARN Theatre CHICHESTER Theatreswarna raviNo ratings yet

- AssignmentDocument10 pagesAssignmentswarna raviNo ratings yet

- 2.1 Acoustical Design ConsiderationsDocument5 pages2.1 Acoustical Design Considerationsswarna raviNo ratings yet

- Interior StudyDocument6 pagesInterior Studyswarna raviNo ratings yet

- Laurie Baker Brief - 62nd Year - 2019-2020Document5 pagesLaurie Baker Brief - 62nd Year - 2019-2020swarna raviNo ratings yet

- Acoustics PDFDocument2 pagesAcoustics PDFswarna raviNo ratings yet

- AR 308 Building Construction &materials - VDocument23 pagesAR 308 Building Construction &materials - Vswarna raviNo ratings yet

- Lobby SpaceDocument4 pagesLobby Spaceswarna raviNo ratings yet

- False Ceiling: Types and Methods of ConstructionDocument26 pagesFalse Ceiling: Types and Methods of Constructionswarna ravi100% (1)

- Stage: Area of The Stage Is 105 SQ.MDocument8 pagesStage: Area of The Stage Is 105 SQ.Mswarna ravi100% (1)

- Ac & Mechanical Services: National Building Code FOR ACDocument14 pagesAc & Mechanical Services: National Building Code FOR ACswarna raviNo ratings yet

- VernacularDocument9 pagesVernacularswarna raviNo ratings yet

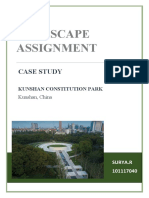

- KUNSHAN CONSTITUTION PARK Landscape Case StudyDocument14 pagesKUNSHAN CONSTITUTION PARK Landscape Case Studyswarna raviNo ratings yet

- Vernacular ArchitectureDocument9 pagesVernacular Architectureswarna raviNo ratings yet

- KUNSHAN CONSTITUTION PARK Landscape Case StudyDocument14 pagesKUNSHAN CONSTITUTION PARK Landscape Case Studyswarna raviNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)