Professional Documents

Culture Documents

Desulfation Device and Desulfation Method

Desulfation Device and Desulfation Method

Uploaded by

Boulos Nassar0 ratings0% found this document useful (0 votes)

17 views11 pagesOriginal Title

Desulfation_device_and_desulfation_method

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views11 pagesDesulfation Device and Desulfation Method

Desulfation Device and Desulfation Method

Uploaded by

Boulos NassarCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 11

2) United States Patent (10) Patent No: US 8,519,672 B2

Kondo (45) Date of Patent: Aug. 27, 2013

(S!) DESULFATION DEVICE AND DESULEATION. 6) References Cited

METHOD

US. PSTENT DOCUMENTS

(71). Applicant T&K Coy Lt, Nagoya UP) 420810 A+ SIDR Kolbowlh 392

‘onda 4S Sloat Kottows ts

(72) Inventor: Toshihike Kondo, Nagoya (JP) 2001/0019257 Al 912001 Bynum etal

Sivoclosss Ale 112004 Balt a wos

Or) Aviano: TAK Cooled Nowy OP Sniioisoo Ale ‘73011 Nses erry

FOREIGN PATENT DOCUMENTS

(4) Notice: Subject to any dlaier.thetem ofthis sp Wosooms yee

pute is etéded or aijued under 35. JP 2olbtamt ‘82010

° Wo toce2 7200

USC. 1540) by 0 day wo. 20040030137 42004

wo amoissoy—— Launo

(21) Appl. Nos 13788367 Wo Houionot S00

OTHER PUBLICATIONS

(22) Filed: Jan, 29, 2013,

Seach Rept Os. 25,201 fom Inno Apion

(65) Prior Publication Data ‘No. PCTSP201 1/004406.

US20130141059.A1 Jun. 6.2013, * cited by examiner

Primary Examiner — Bia Too

Related US. Application Data (74) Attorney, Agent, or Firm — Beyer Law Group LLP

(63) Continuation of application No. PCT/5P2011/004406, (57) ABSTRACT

fed on Avg 3,201 A denilftion device 10 dvs is switching circuit 140 by

Using pulse wave ere sual ving ple wih of 18

0) Foreign Application Priority Data tsscand frequen of 20000 Fz The switching ici 140

ts withed onto allow extaction of elect cuent of 500

Aug. 25,2010 OP) 2010-188043 mA froma batey vina resistor, while being switched off

to sop the extaction of eli ure When he itching

(st) mc, Gieut 140 is sich ofa tck setomotve fore anda

MUM 1044 —— 200601) revere erent of 500 mA are supplied the bate. The

ows in4s (0801) tupplied reverse curet is eeatve current in the form of

(52) US.CL spikes. This electric current acts on electrodes ofthe battery

Usie sania and hereby enbles removal ofsultion onthe electrodes of

the ine, while redacig «temper cease of the

(58) Field of Classification Search

Fil nSearcl 3 135,biG. 16 lision device 10 dring its operation

See application file for complete search history

cencaating |

oRcuT |

ons

ae

| er

-150

PROTECTIVE

‘oRCUT

[waverorn |

SHAPING

| encur

swoon

10 Claims, § Drawing Sheets

= 1

"ro garteay

| oteunais.

pe _|

saree

‘oRCuT

US 8,519,672 B2

Sheet 1 of 5

Aug. 27, 2013

US. Patent

4LINOYIO

SNIHOLIMS:

| aunowto LI

ob ONIAYHS 4

Ss

oer

| ainouto

4 oniLvasN30 |} —~

amod legos

a =

4 oz

o1--7

US. Patent Aug. 27, 2013 Sheet 2 of 5 US 8,519,672 B2

Fig.2

ELEOTRIC CURRENT

a

ca

eS

ELECTRIC CURRENT

bP \

-

|

___\

US 8,519,672 B2

Sheet 3 of 5

Aug. 27, 2013

US. Patent

Fig.6

(yu) LNSHIND OLOTTS

US. Patent Aug. 27, 2013 Sheet 4 of 5 US 8,519,672 B2

ye

INITIAL | AFTER LAPSE, i AFTER LAPSE

VALUE | OF 34 DAYS | OF 87 DAYS

1,255 | 1.266

MAXIMUM SPEGIFIG GRAVITY | 1.27 | 1.28

MINIMUM SPECIFIC GRAVITY

SPECIFIC GRAVITY DIFFERENCE)

TOTAL VOLTAGE

ff

INCREASE RATE OF SPECIFIC GRAVITY) 1. 0087

INITIAL | AFTER LAPSE

VALUE | OF 20 DAYS

MAXIMUM SPEGIFIG GRAVITY

MINIMUM SPECIFIC GRAVITY

| SPECIFIC GRAVITY DIFFERENCE

TOTAL VOLTAGE

“TEMPERATURE 38.2

—— - na

INCREASE RATE OF SPECIFIC GRAVITY | 1.040 |

US. Patent Aug. 27, 2013 Sheet 5 of 5 US 8,519,672 B2

Fig.9

etecTrc | AMBIENT | AMBIENT | TEMPERATURE]

CURRENT | TEMPERATURE|TEMPERATURE| INCREASE

(mA) Coy eo) |

26 34

27 40

BATTERY AMBIENT CASING CASING

VOLTAGE | TEMPERATURE | TEMPERATURE | TEMPERATURE

(vy) i (°C) (cy (°C)

36 25 31

200mA,

MBO DIMENT] COMPARISON

500mA

US 8,519,672 B2

1

DESULFATION DEVICE AND DESULFATION

METHOD

cro

REFERENCE TO RELATED

“APPLICATIONS: s

‘This application is 2 Continuation of Iteration Appl

cation No, PCT/P2011/04406 filed Aug. 3, 2011, which

‘lin benefit of riety to Japanese Apliaton No, 2010-

188083 fled Aug, 25,2010, both of which are hereby incor 10

porated by reference.

‘TECHNICAL FIELD

“The present invention relates to technology of removing.

sulfation (Gesulfation} on eletrodes of a lead-acid battery.

BACKGROUND ART

Sulfation ona positive electrode anda negativeelectmde of 29

lead-acid battery is known as one reason of degrading the

performances ofthe lead-acidbatery. The sulfation occurson

oth the electrodes by the following electrochemical reac-

tions ofa diluted sulfuri acd electrolyte solution withthe

positive electrode (lead oxide electrode) nd withthe negative

electrode (lead electrode) during operation (discharging) of|

the lead-acid battery: The electrochemical eactions proceed

in the revere dioction during charging

Fa

Po,st80,126-¥PSO SILA ;

tr) ‘

P8480, 80,42e ae ede)

Sulfation (lead sulfation) om the surfaces ofthe postive

electrode and the negative clectrode (electrode suriaces 5

inolved in charging) inerferes with the desired electro-

‘chemical reactions between the respective electrodes and the

‘lectroyte solution and thereby degrades the charging per

formance and the discharging performance of the lead-acid

batory

Application of a pulse curent to the lead-acid battery is

known asthe technique of ecavering the performances ofthe

lead-acid battery which are depraded by sulfation

‘This known fechnigue takes account of reduction of per-

formance degradation of the lead-acid battery during dis-

‘charging but des consider removal of sulfation onthe elec-

trodes of the used lead-acid battery or recovery of

performances ofthe lead-acid battery. This known technique

‘also does not take account of shortening a period of time

requied for removal of sulfation or reducing a temperature

increase ofa removal apparatus daring removal of silfation,

‘There is accordingly a requirement to shorten a period of

time requited for removal of sulfation, while reducing heat

regeneration during removal of te sulfation inthe lead-acid

batery.

‘SUMMARY OF INVENTION

I order to achieve atleast part of the above roguzemeat,

the invention provides various aspects described below. 60

Acconding to frst aspect, there is provided a desolation

device applicable to a lead-acid battery, The desulfiton

‘device of the frst aspect includes: an electrode coanector

‘connected with an electrode ofthe lead-acid battory a drive

signal generator configured to generate a pulse wave dive

signal byusingeletic cutent extracted from the electrode of

the lead-acid hatery via the electrode connector; resistor

s

2

configured wo regulate the eletic current extracted from the

electrode ofthe lead-acid batery via the electrode connector

to oletric curent of not less than 300 mA; and a switcher

connected with the deve signal peneratorand withthe resistor

and operated in response to the generated pulse wave dive

signal to supply a back electromotive force and a reverse

current to te lead-acid bantery in synchronism with a falling

edge ofthe pulse wave drive sil

‘The desulfation device ofthe ist aspoct supplies a hack

clectromotive force and a reverse current to the lead-acid

battery in synchronism with a falling edge ofthe pulse wave

drive signal, thus shortening the period of time required for

removal of sulfation

Inthe deslfation device ofthe first aspect, the drive signal

generator may generate the pulse wave drive signal of a

specific pulse width that causes a temperature increase of the

desuliation device to be equal tof less tan a predetermined

temperature value. This aspect shorten the period of time

equred for removal ofsulfition, while reducing heat gene

eration during removal of sulfation in the lead-acid battery.

Inthe desulfation device ofthe fist aspect, the drive signal

generator may generate the pulse wave drive signal ofa pulse

‘wid that is equal to or less than a pulse width Pwmax.

calculated by an equation given below when Thase represents

a known temperature increase corresponding to a known

pulse widkh Pwhase and Tmax represen an allowable tem-

erature increase

Pree

Pre Tx

This spect causes the temperature increase ofthe desullation

device to be equal oof less than the allowable temperature

Inthe deslfation device ofthe fist aspect, the drive signal

‘zenerator may generate the pulse wave drive signal having 8

smaller pulse wid with an increase in output voltage ofthe

lead-acid battery. This aspect effectively reduces heat zenera-

tion during removal of sulfation in the lex-acid battery

sccording tothe output voltage of the lead-acid battery

‘The desulfation device of the first aspoct may further

include wave shaper configured to generatea sawtooth wave

Arve signal from the pulse wave drive signal generated bythe

Arve signal generator. This aspect improves the efficiency of

removal of sulfation,

Inthe deslfation device ofthe first aspect, the drive signal

enerator may generate the pulse wave drive signal having 2

Trequency of 15000 Hz w 20000 Hand a pulse width of 1

see to 2 yee, and the resistor may regulate the electric

current extracted from te electrode a thelead-acid battery

electric curent of 300 to $00 mA. This aspect effectively

shoctens the period af time required for removal of sulfation,

While reducing bea generation during removal of sulfationin

the lead-acid batery.

“According toa second aspect, there is provided a desu

tion method fora lead-acid battery. The desulfation method of

the second aspoct includes the steps of: generating a pulse

wave drive signal by using electric curren extracted from an

electrode of the lead-acid barter: regulating the electiccur-

rent extracted from the eloctode ofthe lead-acid battory to

electric eneat of not fess than 300m; and supplying a back

electromotive force anda reverse current, which ar atributed

to theeletrccurentof not less than 300 mA, tothe lead-acid

US 8,519,672 B2

3

bare syncvonim wit fling eg ofthe pulse wave

dive sana, wherein the respective steps are performed

repataly

“Thedesltionmethadofthe second sspecthasthe ilar

fictions and advantages fart thowf the deoftion

device ofthe fist spect and may be implemented by any of

‘eros apts inthe desolation device ofthe fst sp

“The dessin methodafthessconnpet maybe imple

inened inthe form of aslltionrenoing program orn the

form of computer readable maium in which the ulfaton

snowing progam i Nore

BRIEF DESCRIPTION OF DRAWINGS

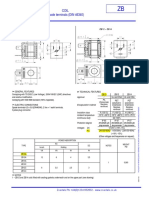

FIG. isa block diagram illustrating the fuetional circuit

structure of desulfation device according 10 one emibodi-

rent;

FIG. 2illustrates an equivalent circuit toa waveform shap-

ing circuit provided in the desullation device acconling to the

‘embodiment

FIG. 3 illustrates one example of pulse wave dive signal

‘generated by a pulse generating eireit provide ia the des

Ulfition device according tothe embodiment;

FIG. 4 illustrates one example of a sawtooth wave drive

signal peneate by the waveform shaping eieuit provided in

the desulfaton device sceording tothe embodiment

IG. 3 illustrates one exemplary connection mode of the

leslfation device ofthe embodiment with a lead-acid bat-

FIG. 6 schematically illustestes a variation in electric eur

rent between the desulfiton device ofthe embodiment and

the lead-acid battery,

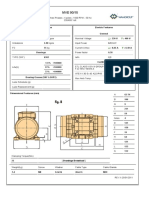

FIG. 7 illustrates the results ofa test with respect to the

performance recovery of the lead-acid battery by a desulia

tion device of a comparative example;

FIG. 8 illustrates the resulis ofa test with respect to the

performance recovery ofthe lead-acid batery bythe desulia-

tion device ofthe embodiment:

FIG. 9 illustrates temperature change during operation of

the desulfation device ofthe comparative example: and

FIG. 10ilustrtes a temperature change ding operation

‘ofthe desulftion device of to the embodiment.

DESCRIPTION OF THE EMBODIMENTS:

‘The following describes someemibodiments ofthe desl

tion device and the desufition method! according to the

invention with reference tothe accompanied drawings,

FIG. sa block diagram illustrating the fuetional circuit

structure ofa desulfition device (sulfation removal appara-

tus) according to one embodiment. The desulfaton device 10

‘of the embodiment includes a power circuit 110, 2 pulse

generating circuit 120, 2 waveform shaping cievit 130,

Switching eircuit 140, a protective circuit 180, an indication

light 11, a positive terminal TH and a negative terminal T2,

‘The positive terminal TL is connected with a positive le:

trode of lead-acid battery (not shown). The positive terminal

THis also connected with the power circuit 110 via a drive

signal curent ine Ld atranged to supply the electric current

‘extracted from the positive electrode of te lead-acid battery,

to the power circuit 110, while being connected with the

svtehing circuit 140 via a poser cureatline Lp aeranged 10

supply the electric eurent extracted from the positive elee-

trode ofthe lead-acidbatory, tothe switching circuit 140.The

drive signal current line Lal is provided with a diode DL

serving io prevent the reverse flow of electic cursent from the

power circuit 110 to the positive tenminal TI. The power

4

current line Lpis provided with a diode D2 serving prevent

the reverse flow of eletrc curent from the switching cieuit

£140 tthe positive terminal Land with resistor RU serving

‘o regulate the eletric curent that is to be supplied to the

switching circuit 140, to a predetermined value. The indiea-

tion light 11s it on during power supply (during operation)

of the desulfation device 10, For example, a light-emitting

diode may be used forthe indication light 1. The respective

circuits included inthe desulfation dove 10 ofthe emibi-

rent may be provided in the form ofan integrated circuit or

‘may sleratvely be provided in the form of discrete circuits

‘The power circuit 110 is connected with the pulse gener-

sing circuit 120 via a signal line, and te pulse generating

circuit 120 is connected with the waveforn shaping circuit

130 via a signal lie, The wavefomn shaping circuit 130 is

coanected withthe switching circuit L40viaa signal line, and

the switching circuit 140 is connected withthe power current

line Lp as deseribed above, The protective circuit 150 is

coanected to the waveform shaping circuit 130, The negative

terminal T2 is signal-grounded. Although signal-grounding

of only the switching circuit 140 is explicily illustrated in

FIG. 1, the respostve other circuits are similarly signal-

rounded

‘The power circuit 110 provided in he form of a DC-DC

coaverter serving « reduce the voltage level (12V to 48 V)

supplied from the lead-acid bartery to 10V that isthe voltage

far drive signal (contaleieuit voltage). The eurrent for drive

signal subjected tothe voltage step-downby the power circuit

‘10s supplied to the pulse generating czcut 120, The pulse

eneratng circuit 120 is provided as a cect serving to use

the current for drive signal supplied from the power eiruit

110 and thereby generate a pulse signal wave for driving the

switching circuit 140. The pulse generating circuit 120 inter-

nally hasan oscillator ad outputs « pulse wave drive signal

including a predetermined number of rectangular waves of 8

specified pulse width comresponding oa predetermined fre-

queney. In other words, the pulse generating circuit 120 con

tinually ouputs a rectangular wave signal of aspecified pulse

‘id at a predetemnined eyele (I/fequeney),

‘The pulse generating circuit 120 ofthis embodiment gen~

cratesa pulse wave drive sigaal ofa specitie pulse wid that

‘uses the temperature inerease of the desulltion device 10

to be equal io orfess than a predetermined temperature vale,

“More specifically, the pulse generating circuit 120 generates

a pulse wave deve sigal of a pulse width that is equal to.0r

Jess than a pulse width Pwwmax calculated by an equation

given below when Thase represen a known temperature

‘increase corresponding to aknowa pulse width Psbase at the

frequency of 15000 to 20000 Hz. aad Tmax represeats an

allowable temperature increase:

‘The pulse width ofthe generated pulse wave drive signals.

specifically 1 to 2 usec and is more specifically about 1.4 to

17sec. For example, the maximum allowable pulse widths.

shout 3.4 see when the known pose width Pwbase is qual

10 16, the known temperature increase Thase is equal to 28°

CC. and the allowable temperature increase Tmax is equal 19

arc.

‘The waveform shaping circuit 130 shapes the pulse wave

drive signal generated by the pulse generating circuit 120108

sawtooth waveform and outputs as a sawtooth wave dive

signal. FIG. lustrates an equivalent circuit tothe waveform,

US 8,519,672 B2

5

shaping circuit provided in the desullation device according

‘otheembodimeat. FIG. Sillustatesoaeexampleof the pulse

‘wave drive signal generated by the pulse generating circuit

provided in the desulation device according to the embodi-

‘meat, FIG, 4 illusates one example of the sawtooth wave

‘drive signal generated by the waveform shaping circuit pro-

Vid inthe deslfation device according tothe embodiment,

The waveloem shaping cieuit 130 sa known circuit and

includes, for example, two resistors R2A and R22 connected

in parallel o eachother, a capacitor C1 connected in parle)

to theresisior 822 anda diode D3 connectedin series withthe

resistor R22, The wavefoem shaping circuit 130 enables the

pulse vwavefonn shown in FIG. 3 tobe shapes the sawtooth

‘waveform shown inFIG. 4,5, waveform having gentle rises

and abzupt alls. Such wave shaping allows a quick switching

‘action of a circuit that is actuated at a falling edge as the

trigger, fr example, the switching cireuit 140.

‘The switching circuit 140 is provided asa cirouit switched

‘on and off in response to the shaped pulse wave dive signal

According this embodiment, the switching circuit 140 is

switched on to allow extraction of electric current from a

battery via the power cueent line Lp, while being switched

‘off to stop the extaction of electric eurent fom the battery.

‘The switching circuit 140 thus enables the pulse curentto be

flowed outof the battery: For example, a field-effect rasistor

(PET) or another switching element may be adopted for the

‘svitcingcieuit 14.

‘The protective circuit 180s provided asa circuit serving to

protect the resistor RI from a poteatial file, such as bura-

Ing-ou, when the pulse wave ceive signal output from the

waveform shaping creuit 130 is kept continuously a a high

level. signal eve! that provides instruction for switeh-on

‘oporation tothe switching cireuit 40), The protective eircuit

150may beiplemeated by acireuit using a Zener diodeand

«transistor as is known wo one skilled in the at.

‘The resistor RI is used to regulate the vale ofthe power

‘curzeat that sto be supplied to the switching circuit 140, The

resisiance value is selected according to the vollage of

battery BT as the processing object, in onder to regulate the

power current to a curent value of 300 t0 500 mA. The

following description is onthe assumption of using the eee

tric eurent of $00 mA,

‘The following describes the operations ofthe desulfation

device Wacconling to theembodiment. 1G, Silistetes one

‘exemplary connection mode of the desullation device ofthe

‘embodiment with 2 lead-zcid battery. FIG. 6 schematically

illustrates a variation in electric curent beeen the desulia-

tion device of the embodiment and the lead-acid batery. The

‘desulfation device 10 is used in connection witha batery BT.

More specifically, a positive cable L1 connected with the

positive terminal T1 ofthe desulfation device 10s connected

to-a positive electrode T+ ofthe battery BT, wheres a nega

tive cable L2 connected with the nogative terminal T2 is

‘connected to a negative electrode T- ofthe battery BT. The

sulfation device 10 operates with the electric curret sup-

plied from the battery BT. In alue Words, he electric current

‘extracted from the battery BT via the positive terminal Tis

‘suppl tothe respective circuits vi the ceive signal current

line La.

Asdescribod above the dosulfation device 10 sconfigured

te extract the electric current inthe form of pulses from the

battery BT in espouse 1 te pulse wave drive signal. More

specifically, the switching cieuit 140 is switched on in

response to the pulse wave drive signa to allow the electri

‘current regulate to 500 mA by the esstor RI to low from

the switching citcuit 140 into the ground. The switching

icuit 140 isswitched off in response othe pulse wave drive

6

signal to stop the flow of the electric current regulated 10 500

‘MA nto the ground. This series of operations enable the

clectrie current in the foam of pulses to be extracted from the

battery BT. Whea the desufation device 10 (switching circuit

140) stops the extraction ofelecticcurent ata falling edgeof

the pulse wave drive signal, there are a back electromotive

force anda reverse current, which areatibuted to inductance

components including the positive cable L1, the negative

cable 2 and te battery BT. The voltage and electric curent

in the form of spikes, which are negative with respect to the

desulfation device 10, are then applied wo the buttery BT (on

the assumption thatthe electric current extracted from the

battery BT is positive). For example, electric curent in the

Jarmo spikes as shown inF1G, 6is applied to de battery BT.

According to this embodiment, the pulse wave drive signal

input into the switching circuit 140 is shaped to have the

sawtooth wavefom bythe waveform shaping iruit 130. The

switching circuit 140 thus relatively gatly shifts to the ON

sate when being switched on, bu instantaneously’ shifting

the OFF state when being switched of. Asa result, the elec-

tei eurent and voltage in the form of spikes having the high

peak (large height) and the small width are provided to the

battery BT. The value ofthe reverse curent inthe form of

spikes supplied tothe battery BT is, for example, 203 And

‘increases with an increase in service current (power current),

The eurrent waveform shown in FIG, 6 s obiined by con

necting a esisior to an electrode ofthe battery BT in series

and measuring voltage waveforms at both ends ofthe resistor

‘The electric curzent and voltage inthe form of spikes acting

‘on the postive eleerode and the negative eletrode of the

battery enable sulfation or suite layers depositing on the

positive electrode and the negative electrode (lead sulfate

Jayers inthe lead-acid battery) to be moleculey peeled off

tnd separate from the respective lecrodes and recovers the

charging area involved in charging out of sulfste-covered

surface are of each ofthe electrodes to is initial charging

‘rca, The molecular sulfite layer separate into an electyte

solution is decomposed during charging ofthe lead-acid bat-

‘ery and is dissolved inthe form of lead ion and sulfate fon

into the electrolyte solution. Generation of H2O, whieh pro-

ceeds during discharging ofthe lead-acid battery, tops dur-

ing charging. Asa result te specie previty ofthe electroyte

in the battery BT, i, lead-acid battery, is recovered to

‘approach a fvorable value of 1.280,

Results of Verification

‘The following describes results of various tests using the

desuliation device 10 according to the embodiment ad 2

desulition device according to «comparative example.

Recovery of Battery Performances

FIG. 7 illustrates the results ofa test with respect to the

perlormunee recovery of the lead-acid battery by the desulfa-

tion device ofthe comparative example. FIG. 8 illustrates the

resulls of atest with respect to the performance recovery of

the lead-acid battery by the desulfaion device of the emiboi-

‘meat, The following conditions were adopted forthe ext

‘Comparative Example: pulse frequency: 20000 Hz, curent

value: 200 mA, batter: 48 volt battery manufactured by GS.

Yuasa Corporation

Embodiment: pulse frequeney: 20000 Hz, eurent valve:

500 mA, battery: 48 vot battery manufactured by GS Yuasa

Corporation

“The resuls ofthis test prove the recovery ofthe specific

rvity bythe deslfation devie 19 ofthe embodiment and

‘verify the mechanism of removing and dissolving the sulfate

layers by using the electric eurent inthe foam of spikes as

described above.

US 8,519,672 B2

1

According to the comparative example shown in FIG. 7,

the averge specific gravity of the elaeulyte solution was

1.28Sasitsntalvalueand waschangedto | 266afleralapse

‘of M4 days since the stat of connection and was fuer

‘hanged to 1280 alter lapse of 87 days since the start of 5

‘onnection. The favorable value ofthe speific rity the

Ieaaciattery is gnealy thought to beabout 1.28 which

‘wasachievedafterthe apse of 87 days. The impeovementrate

ofthe average specific pavity to the inal value, Le, the

inereaserateofthe specific aavity, was 1.0087 after the apse

‘of 3 days and was 1.0199 afer the lapse of $7 days. The

increase rate ofthe specific gravity accordingly remained at

the valve of 1.0199 alter a lapse of approximately three

months. According tothe emiboiment onthe oer hand the

sverage specific gravity ofthe eect solution was 1219 1s

‘sits intial value and as changed to | 268aftera lapse of 20,

days since the start of connection The improvement rate of

thoaverage specific gravity tothe initial value Was 1 O40 afer

the lapse of 20 days. The increase rate othe speci gravity

accordingly achieved the valve of 1.040 ater lapse of only

about hal a month

‘The primary dierence between th embodiment and the

comparative example the value of elec curent. The

Aeslfation device 10 of the embodiment using the lager

‘ureat value can reover the performances of te battery

‘within time period of about." of the recovery time by the

eslfation device othe comparative example. When slong,

period of time such as three to four months, required 10

schieve the sufficient improvement ofthe battery perfor

mance, is rather dificult forth user of the appara to 30

ceflectively very the improvement effet. The desolation

device 1 of the embodiment, onthe other hand allows veri

festion of the improvement effet in a relatively shorter

period of ine, such as about hal month to one month and

‘an thus mee the demand ofthe user ofthe apparatus. 38

‘Thesereslsoftheestprovethathelargerlevrc cument

applied tothe battery BT peovides the beter aspoversent

‘flect,The simple increase in value elect curent applied

tothebatiery BT, however causes apreblemo increasing the

‘operating temperature ofthe desulation device (that may

lanage the ict elements, uch es resister).

“Temperature Change

FIG. illstratesa temperature change during operation of

the desulition deve of the comparative example. FIG, 10

ilysttes temperature change diag operation othe des

ulation device ofthe embeliment. For the purpose of veri

fication, the temperature ofthe casing body f the destin

device and the temperature ofthe esistor far repuating the

‘leceiccureat were measured with an ifrrel themaoniler

FIG. 9 shows a tempertie change of the comparative

‘example obsained by ineressng the electric curzet supplied

totheswitchingceuitofthe deslation device rom 20004

to 500 mA under the conditions ofthe pulse frequency of

20000 Hz and the pase width of 4 yse ofthe pulse wave

‘deve signal. The esl of FIG. 9 show thatthe casing tem

perature increased withan increas in value of let eurrnt

an that the easing temperature reached 4° Cand the tem

perature inctese reached 19°C at 50 a. The temperature

‘ofthe sisi asthe heat source each 14° Ct $00 mu.

Inanapplicaion ofthe desulfation device in connection with 60

2 batry located in an engine room of an automobile the

‘operating envionment temperature is about 601 70°C. $0

thatthe temperate the resistor significa exceeds 150°

(C-Thereisaccontngly a igh possibility tht he resistor for

general purpse is damaged

“The destlfaion device 10 ofthe embodiment i, on the

‘otherand driven with he pulse wave drive signal having the

s

8

pulse wid of 1.6 usec andthe frequency of 20000 Hz, s0 as

‘oeliginate this problem, FIG. 10 shows the results of veri=

fication with respect tothe desulfation device 10 connected to

36 vot battery and toa 48 vot battery and measured at 200

‘A and 500 mA asthe valueofeectrccureat suppiedto the

switching circuit 14.

According tothe comparison using the electric current of

200mA, thecasing temperate w2s31°C. and 34°C.and the

temperature increase was 6° C. and 8° C. for the 36 volt

buttery and forthe 48 wot hatery, respectively According to

the embovdiment using the eletric current of $00 mA, om the

other hand, the casing temperature was 32" C,and 35° C.and

the temperature increase was 5° C.and 8° C. for the 36 volt

buttery and forthe 48 volt battery, respectively. The tempera~

tureinereaseof this embodiment is accoedingly reduced 08°

CC, compared with the temperature increase of 19°C. inthe

comparative example of FIG. 9. This level of temperature

increase is substantially equivalent to the temperature

increase ofthe comparative example sing the electric cuerent

f200 ma,

‘The pulse widthof 6 psec is selected only for the purpose

of reducing the temperature increase to level equivalent to

the conventional temperature increase, The smaller pulse

Wid shouldbe selected, in order to achieve a fuer reduc-

tion ofthe remperature increase, The larger pulse width may

beseleted, onthe other hand, fora requirement that satisfies

the less reduction ofthe temperature inerease. At the operat=

Jing curent that i ess than $00 mA, the resistor Rs the

Jess amount of heat generation, so thatthe larger pulse width

is allowable, At the operating current that i not less than $00

‘mA, on the other hand, the resistor RU as the greater amount

ofhet generation, sothat the smaller pulse wid is desirable,

Tho amount of heat generation by the resistor RI increases

with an increase in voltage ofthe battery BT, so thatthe

smaller pulse width may be used with an inereae in voiage

ofthe batery BT,

|As described above, the desulfation device 10 of the

embodiment increases the working current from the conven

tional level of 200 mA to $00 mA, so ast shorten the peti

of time required for recovery of the performances of the

battery BT to 14M of the conventionally required recovery

time. Inother word, the deslfation device 10 af the embei-

‘ment can remove the sullate layers depositing on the elec-

teodes of the batery BT more effectively than the cou

tional desulfation devie.

Increasing the working current to S00 mA causes poten-

til problem of temperature increase ofthe desullation device

410 (resistor RI). Reducing the pulse wid ofthe pulse wave

dive signal o 1.6 psec thts about 12.5 ofthe conventional

pulse width, however, advantageously reduces the tempera-

ture increase of the desulfation device 10 at the working

current of $00 mA to the level equivalent wo the temperature

increase atthe working curent of 200 m..

‘The desulfation device 10 of the embodiment can tans

shocten the period of time required for removal of sulfation,

while reducing heat generation during removal of sulfation.

Modifications

(1) The forgoing description ofthe embodiment includes

verification using the pulse wave drive signal having the

frequency of 20000 Hz. The frequency of the signal may.

however, be les than 20000 Hi or greater than 20000 Hz.

(2) The foregoing description ofthe embodiment includes

verification using the electri curret of S00 mA. The value of

cectriecurent used may, however. be ina range of 30010 500

‘mA or may be greater than 500 mA.

(G) According wo the above embodiment, the pulse wave

Arve signal generated by the pulse generating circuit 120 has

US 8,519,672 B2

9

fixed pulse width The pulse widih may, however, be vari-

‘bleamong a plurality of dtfeent vals by switching opera-

tion. According othe shove embodiment, the resistor RY has

‘fixed resistance value. The resistor RI may, however, be a

‘arable resistor whee te tesstance value is variable tong.

a plurality of different values by switching operations. In this

modification, varying the resistance value secording tothe

voltage ofthe battery BT enablesone deslfition device 1010

be applicable oa plurality of diferent battery voltages. This

also enables the value of electric current to be adequately

‘changed according tothe voltage ofthe battery BT and allows

the user to determine and set desired parameters suitable for

the operating environment, thus improving the convenience

‘of the dsulftion device 10

‘The foregoing has described the invention with reference

‘o theembodimentandsome modifications. Teembadiment

‘of the invention described above is only for the purpose of|

facilitating the understanding of the invention and is not

intended to limit the iaveaion at al. The invention may be

‘hanged or modified without departing from the ope ofthe

invention and includes such modifications and equivalents

‘The invention claimed is:

1A desuliation device applicable o a lead-acid batter,

‘comprising:

‘an electrode eomector connected with an electrode ofthe

lead-acid battery’

18 drive signal generator configured to generate @ pulse

‘wave drive sina with a specific pulse width that causes

4 temperature inerease ofthe deslfation device to be

‘equal oor less than a predetermined temperature value

by using electric current extracted from the electrode of

‘the lead-acid battery via the electrode connector;

resistor configured to regulate the electric current

‘extracted from the electrode of the lead-acid battery via

the elecode connector to eletrie current of not less

‘than 300 mA; and

‘ siteher connected withthe drive signal generator and

‘with the resistor and operated in response to the gener-

ated pulse wave drive signal to supply backeletromo-

tive foreeand a reverse current othe leased battery in

syachronism witha falling edge of the pulse wave drive

signal

2. The desulftion device ecording to claim 1, wherein

the drive signal generator generates the pulse wave drive

‘signal ofa pulse width that sequal tocrless than pulse

‘width Prymax calculated by an equation given below

‘when Thase represents @ known temperature increase

corresponding to a known pulse widlh Pwhate and

“Tmax represents an allowable temperature increase,

3. The destlfation device according to elaimn 2, wherein

the drive signal generator generates the pulse wave drive

signal having a smaller pulse wiih with an increase in

‘ouput voltage ofthe lead-acid battery.

4. The dosulfation device according to claim 1, furer

‘comprising:

Fa

»

10

‘a wave shaper configured to generate a sawtooth wave

clive signal from the pulse wave drive signal generated

by the drive signal generator

'5, The desullation device according to claim 1, wherein

the drive signal generator generates the pulse wave drive

signal having a fequency of 15000 Fizto 20000 Fz and

a pulse width of 1 psec to 2 psec, and

the resistor regulates the electric current extracted fom the

‘lectrode ofthe Tead-acid battery to electric eurent of

300 to $00 mA,

6, 8 desulfation method for a lead-tcid battery using @

Aesulfation device, comprising the step of

‘generating a pulse wave dive signal witha specific pulse

ida hat causes temperature increase ofthe desu.

tion device tobe equal to or less than a predetertined

temperature value by using electric current extracted

from an electode ofthe lead-acid battery:

‘regulating the electric current extracted fom the electode

‘ofthe lead-acid battery to electeiceurrentof notes than

300 mA; and

supplying a back electromotive force anda reverse current,

‘which are atteibuted tothe eloctic current of not less

than 300 ma, to the lead-acid battery in synchronism

‘with a falling edge of the pulse wave drive signal,

wherein

the respective steps are performed repeatedly.

7. The desulfation method according to any one of esi

whersin

the stepof generating the pulse wave drive signal generates

the pulse wave drive signal havinga frequency of 15000

Hto 2000012 anda pulse width of | psec to 2ysee, and

thestepof regulating the clecticeurent extaeted trom the

‘elecrode ofthe lead-acid batery regulates the eleteie

‘eurtent extracted from the electrode of the lead-acid

buatery to electric current of 300 to $00 mA.

£8, Tho desullation method aecording to claim 6, wherein

thestepof generating the pulse wave drive signal generates

the pulse wave drive signal of pulse wid that is equal

to or less than a pulse width Pama calculated by a

‘equation given below when Thase represents a kaown

lemperatize increase corresponding To a known pulbe

‘width Pwbase and Tmax represents an allowable tem

petature increase

6

49. The desullation method according to claim 8, wherein

thestepof generating the pulse wave deve signal generates

the pulse wave drive signal having smaller pulse with

‘with an increase in output voltae ofthe lead-acid bat-

tery.

10, The desulfaion method aocording to claim 6, further

comprising the sep of

‘generating savitooth wave die signal rom the generated

pulse wave deve signal

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Main Vehicle SpecificationsDocument3 pagesMain Vehicle SpecificationsBoulos NassarNo ratings yet

- Effects of Parameters On Nrel Solar Position Algorithm (Spa) and Simatic S7-1200 Spa - Calc - Sunvector Library AccuracyDocument18 pagesEffects of Parameters On Nrel Solar Position Algorithm (Spa) and Simatic S7-1200 Spa - Calc - Sunvector Library AccuracyBoulos NassarNo ratings yet

- Spade Terminals (DIN 46340) : ZB10 ZB12 - ZB14Document1 pageSpade Terminals (DIN 46340) : ZB10 ZB12 - ZB14Boulos NassarNo ratings yet

- Wiring PDFDocument13 pagesWiring PDFBoulos NassarNo ratings yet

- Efficiency Package For Solar TrackerDocument2 pagesEfficiency Package For Solar TrackerBoulos NassarNo ratings yet

- PCB PDFDocument1 pagePCB PDFBoulos NassarNo ratings yet

- Battery Desulphator: John Drake Services, IncDocument3 pagesBattery Desulphator: John Drake Services, IncBoulos NassarNo ratings yet

- Abb Acs 355: Access Parameter ListDocument3 pagesAbb Acs 355: Access Parameter ListBoulos NassarNo ratings yet

- Sadelmi Power: List of ReferencesDocument24 pagesSadelmi Power: List of ReferencesBoulos NassarNo ratings yet

- 3GAA112312 BSE M3aa 112mb 4Document2 pages3GAA112312 BSE M3aa 112mb 4Boulos NassarNo ratings yet

- 3gaa112312 BseDocument2 pages3gaa112312 BseBoulos NassarNo ratings yet

- Leaching of Spent Batteries Powder With Sodium Carbonate and Carbon DioxideDocument6 pagesLeaching of Spent Batteries Powder With Sodium Carbonate and Carbon DioxideBoulos NassarNo ratings yet

- 19A00142Document1 page19A00142Boulos NassarNo ratings yet

- Silica Gel Emitter PreparationDocument2 pagesSilica Gel Emitter PreparationBoulos NassarNo ratings yet

- Mve90 15Document1 pageMve90 15Boulos NassarNo ratings yet

- Section VI.M: Waste Oil RefineriesDocument25 pagesSection VI.M: Waste Oil RefineriesBoulos NassarNo ratings yet

- Battery 101 TrainingDocument2 pagesBattery 101 TrainingBoulos NassarNo ratings yet