Professional Documents

Culture Documents

Product Sticking To Conveying PDF

Uploaded by

Joao Henrique ZanettiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Sticking To Conveying PDF

Uploaded by

Joao Henrique ZanettiCopyright:

Available Formats

Product Sticking to Conveying Augers

Over Time

Question

I have a product that likes to stick to my conveying auger over time. Do you have a

solution for this problem?

Answer

Many bulk solids contain moisture and are very sticky. They become difficult to

convey because the bulk solid sticks to the flight surface of the screw and builds up.

Since you are processing polymers, the materials of construction of the conveying

equipment are typically stainless steel. The flight surfaces and complete screw can

be polished to a very fine finish and even electro-polished to achieve a mirror finish.

The bulk solid has less tendency to stick and will release from a smooth, polished

finish. The internal surfaces of the trough can also be polished or electo-polished.

Another option is to coat the conveying surfaces with non-stick coating such as

Teflon. The coatings can be engineered for your specific application. The flight

design of the screw conveyor can be modified to be a ribbon or even a shaftless

type. Ribbon and shaftless screw conveyors are designed specifically for conveying

sticky bulk solids. Sticky products adhere to the screw at the location where the

flight meets the center pipe. The ribbon flight is only attached to the center pipe

with thin posts located on 90° intervals. The shaftless flight has no center pipe and

only uses the flighting or spiral to convey the product. You may want to consider

these options.

KWS Manufacturing

3041 Conveyor Drive

Burleson, Texas 76028

Toll Free: (800) 543-6558

Phone: (817) 295-2247

Fax: (817) 447-8528

www.kwsmfg.com

You might also like

- Altium Rigid Flex GuidebookDocument40 pagesAltium Rigid Flex GuidebookGustavo Dallaqua100% (3)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Casting ProceduresDocument35 pagesCasting ProceduresSneha SinghNo ratings yet

- Taper Lok Offshore and SubseaDocument8 pagesTaper Lok Offshore and Subseaazm81No ratings yet

- Fishing Operations and ToolsDocument24 pagesFishing Operations and ToolsMohamedElAbbasyNo ratings yet

- Conveying Wet, Sticky Bulk MaterialsDocument1 pageConveying Wet, Sticky Bulk MaterialsJoao Henrique ZanettiNo ratings yet

- Runners and GatesDocument35 pagesRunners and Gatesbjdavies2010100% (2)

- Tubular Drag Conveyor Brochure WWDocument8 pagesTubular Drag Conveyor Brochure WWsamvendanNo ratings yet

- FB Screw Conveyor Trough LinersDocument2 pagesFB Screw Conveyor Trough LinersAlbertoNo ratings yet

- Attachments: Volvo Wheel LoadersDocument12 pagesAttachments: Volvo Wheel LoadersAchmad PrayogaNo ratings yet

- Manual Bego de Diseño y Colado de EstructurasDocument40 pagesManual Bego de Diseño y Colado de EstructurasHugoMoralesTecnicoDentalNo ratings yet

- The Ultimate Shaft-To-Hub Connection (Polygon Shapes - Multi-Faceted Problem Solvers)Document6 pagesThe Ultimate Shaft-To-Hub Connection (Polygon Shapes - Multi-Faceted Problem Solvers)kristoffer_mosshedenNo ratings yet

- Tubular Drag ConveyorDocument8 pagesTubular Drag ConveyorYavuz SolmazNo ratings yet

- Chapt 4 Type of Wood Adhesive JointsDocument26 pagesChapt 4 Type of Wood Adhesive JointsHarith ZikryNo ratings yet

- Applying Appropriate SealantDocument64 pagesApplying Appropriate SealantShina AbieraNo ratings yet

- WaboElastoFlex Park 0408Document4 pagesWaboElastoFlex Park 0408Cristhian Alfonso Mandujano PérezNo ratings yet

- Permaban Wave FAQs Issue 6 131119Document4 pagesPermaban Wave FAQs Issue 6 131119Inteligencia MercadoNo ratings yet

- Tubular Drag ConveyorsDocument8 pagesTubular Drag ConveyorsLuiz CostaNo ratings yet

- Presentation On Transfer Chute (IKC) PDFDocument53 pagesPresentation On Transfer Chute (IKC) PDFidey100% (2)

- Sedes de ValvulasDocument3 pagesSedes de ValvulasLuizGustavoVicenteNo ratings yet

- BMHE Lecture Notes 3 0Document18 pagesBMHE Lecture Notes 3 022je0398No ratings yet

- Roll FormingDocument5 pagesRoll FormingvundavilliravindraNo ratings yet

- Screw Conveyors: IntroductionDocument52 pagesScrew Conveyors: IntroductionrajksharmaNo ratings yet

- Buffing Tech TipsDocument9 pagesBuffing Tech TipsYash BelaniNo ratings yet

- Moxon Vise Instructions-BC0317Document12 pagesMoxon Vise Instructions-BC0317Cameron RiosNo ratings yet

- 091 Choosing Metal Drawer Slides PDFDocument4 pages091 Choosing Metal Drawer Slides PDFHomerSimsonnakisNo ratings yet

- Mechanical HandbookDocument48 pagesMechanical HandbookbenlandisNo ratings yet

- Brochure Housings - SKF Taconite Seals - EN 201502Document6 pagesBrochure Housings - SKF Taconite Seals - EN 201502Jose ChambiNo ratings yet

- What Characterizes A Good High Production MoldDocument3 pagesWhat Characterizes A Good High Production MoldVijay PalNo ratings yet

- Resin Infusion of A Carbon FibreDocument14 pagesResin Infusion of A Carbon FibreMAXIMODRAGON100% (1)

- W E L L H E A D T U T O R I A L: Technical Services Unit Abolfazl AnsariDocument14 pagesW E L L H E A D T U T O R I A L: Technical Services Unit Abolfazl AnsariMehdi NorouziNo ratings yet

- Ball Transfer Units PDFDocument40 pagesBall Transfer Units PDFHyundianto AgNo ratings yet

- LIFTING BEAMS OX 2024 EnglishDocument17 pagesLIFTING BEAMS OX 2024 EnglishThanos KazakosNo ratings yet

- MOMENT Grout CouplersDocument15 pagesMOMENT Grout CouplersDio DikaNo ratings yet

- Solids Conveying Edu Ctors Data SheetDocument11 pagesSolids Conveying Edu Ctors Data SheetBenny GomezNo ratings yet

- Packing of Control Valves PresentationDocument58 pagesPacking of Control Valves PresentationMuhammadAsim100% (1)

- Vag Ekn Butterfly Valve: Double Eccentric Bearing and Soft SealingDocument4 pagesVag Ekn Butterfly Valve: Double Eccentric Bearing and Soft SealingAhmedRamadanNo ratings yet

- Cooper - Hanger BearingsDocument4 pagesCooper - Hanger BearingsJose ChambiNo ratings yet

- PolymorphDocument9 pagesPolymorphzaccaro_86No ratings yet

- Working On WaterDocument13 pagesWorking On WaterPontoon & Dock Ltd.No ratings yet

- Unilift de DGDDocument36 pagesUnilift de DGDLove SemsemNo ratings yet

- Rocla Alfabloc BrochureDocument12 pagesRocla Alfabloc BrochureJakesNo ratings yet

- Laboratory Procedures, Casting of Different Materials and Fitting The Framework1Document24 pagesLaboratory Procedures, Casting of Different Materials and Fitting The Framework1Lubna QanberNo ratings yet

- Industrial Products BrochureDocument16 pagesIndustrial Products BrochureJames EllisNo ratings yet

- TT OpVEE V-Notch Ball-Valve-BrochureDocument16 pagesTT OpVEE V-Notch Ball-Valve-BrochureSergio Gana GonzalezNo ratings yet

- Groove 1 2006 General enDocument32 pagesGroove 1 2006 General enAlan ScarparoNo ratings yet

- FOSROC Submittal PVC Waterstop - ASIADocument85 pagesFOSROC Submittal PVC Waterstop - ASIAlensa jijiNo ratings yet

- Cable Railing Project GuideDocument14 pagesCable Railing Project GuideArumoy DasguptaNo ratings yet

- 20IN027 - Arslan AhmedDocument12 pages20IN027 - Arslan AhmedArsalan SidikiNo ratings yet

- EP-Flex Brochure (LR)Document8 pagesEP-Flex Brochure (LR)Ahmad FawazyNo ratings yet

- 13 y 14. Schletter-SingleFix-V-Data-SheetDocument3 pages13 y 14. Schletter-SingleFix-V-Data-SheetDiego Arana PuelloNo ratings yet

- Grooved Drum ArticleDocument2 pagesGrooved Drum ArticleLizardladNo ratings yet

- How and Why Are Butterfly Valves UsedDocument2 pagesHow and Why Are Butterfly Valves UsedMOHAMMAD ASIFNo ratings yet

- 4Th Lec. Preparing Master Casts For Duplication: July 2015Document8 pages4Th Lec. Preparing Master Casts For Duplication: July 2015Satya AsatyaNo ratings yet

- Indirect Tooling OptionsDocument11 pagesIndirect Tooling OptionsDiscord YtNo ratings yet

- Highh Mast LightingDocument6 pagesHighh Mast LightingAsghar KhanNo ratings yet

- BFValveDocument3 pagesBFValveThamotharanNo ratings yet

- Brochure Alfa 2019Document15 pagesBrochure Alfa 2019ClarkFedele27No ratings yet

- Tower Manual en PDFDocument73 pagesTower Manual en PDFJoao Henrique ZanettiNo ratings yet

- ContratoDocument18 pagesContratoJoao Henrique ZanettiNo ratings yet

- DS SugarProcessing CX 1214 ENGDocument2 pagesDS SugarProcessing CX 1214 ENGJoao Henrique ZanettiNo ratings yet

- SteamPipe Exit PDFDocument1 pageSteamPipe Exit PDFJoao Henrique ZanettiNo ratings yet

- Steam Chest PDFDocument1 pageSteam Chest PDFJoao Henrique ZanettiNo ratings yet

- Slide Valve PDFDocument1 pageSlide Valve PDFJoao Henrique ZanettiNo ratings yet

- Rockshaft Short Rod PDFDocument1 pageRockshaft Short Rod PDFJoao Henrique ZanettiNo ratings yet

- Steam Chest Cover PDFDocument1 pageSteam Chest Cover PDFJoao Henrique ZanettiNo ratings yet

- Rocker Shaft Assembly PDFDocument1 pageRocker Shaft Assembly PDFJoao Henrique ZanettiNo ratings yet

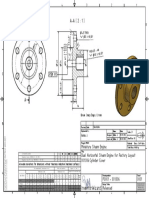

- Inventorwizard: Miniature Steam Engine Dual Horizontal Steam Engine For Factory Layout 000.007 FlywheelDocument1 pageInventorwizard: Miniature Steam Engine Dual Horizontal Steam Engine For Factory Layout 000.007 FlywheelJoao Henrique ZanettiNo ratings yet

- Cylinder Cover PDFDocument1 pageCylinder Cover PDFJoao Henrique ZanettiNo ratings yet

- Inventorwizard: Miniature Steam Engine Dual Horizontal Steam Engine For Factory Layout 000.008 EccentricDocument1 pageInventorwizard: Miniature Steam Engine Dual Horizontal Steam Engine For Factory Layout 000.008 EccentricJoao Henrique ZanettiNo ratings yet

- Inventorwizard: Miniature Steam Engine Dual Horizontal Steam Engine For Factory Layout 002.002 Crosshead Guide PlateDocument1 pageInventorwizard: Miniature Steam Engine Dual Horizontal Steam Engine For Factory Layout 002.002 Crosshead Guide PlateJoao Henrique ZanettiNo ratings yet