Professional Documents

Culture Documents

Abstract Azreen

Abstract Azreen

Uploaded by

Zaza SarizaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abstract Azreen

Abstract Azreen

Uploaded by

Zaza SarizaCopyright:

Available Formats

Abstract

For any production firm to be successful, it must be able to produce quality products and

also ensure the products get to the consumer in time, in good condition and at the

minimum cost possible. For this to be achieved there is need for an efficient and effective

distribution logistics structure in place. Despite much effort by manufacturing firms to

ensure that their distribution systems are efficient, many customers still experience delays

for deliveries, which show that distribution logistics performance performs short of

customer expectations in most companies.

The main objective of this research is to examine the factors influencing logistics

performance on product distribution from manufacturer to distribution centers. The

research investigates on two factors that affect the distribution performance start from

order receiving, order processing and delivery of goods. Data were collected from staffs at

Camps and Apparels Corporation Sdn Bhd through questionnaire by using purposive

sampling technique.

The result suggests that speed and quality is the most important factors influencing logistics

performance for the industry. The data from the study constituted employees and

customers of 22 people and was analysed through a descriptive statistics. The study reveals

that the mode of transportation does not always achieve smooth delivery and satisfaction

desired but adds value to the mode of transport. It also shows that delivery times to

customers are not always meet.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

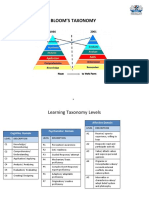

- BloomsTaxonomy SamplesDocument6 pagesBloomsTaxonomy SamplesZaza SarizaNo ratings yet

- BLSCM Singapore Prog StructureDocument8 pagesBLSCM Singapore Prog StructureZaza SarizaNo ratings yet

- Good Practices For Conducting Live Proctored Online Exams Using ZoomDocument10 pagesGood Practices For Conducting Live Proctored Online Exams Using ZoomZaza SarizaNo ratings yet

- Chapter 1 - Revised2Document12 pagesChapter 1 - Revised2Zaza SarizaNo ratings yet

- Abstract SampleDocument2 pagesAbstract SampleZaza SarizaNo ratings yet

- Fyp SlidesDocument31 pagesFyp SlidesZaza SarizaNo ratings yet

- How Will E-Commerce Growth Impact Our Transportation Network?Document38 pagesHow Will E-Commerce Growth Impact Our Transportation Network?Zaza SarizaNo ratings yet