Professional Documents

Culture Documents

Gratings

Gratings

Uploaded by

Akber Hassan0 ratings0% found this document useful (0 votes)

20 views9 pagesOriginal Title

05530 - GRATINGS

Copyright

© © All Rights Reserved

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentYou are on page 1of 9

RAYADAH HOUSING COMPLEX (RHC)

PACKAGE 3- BUILDINGS

PROJECT STANDARD SPECIFICATION, May 2013,

SECTION 05530 - GRATINGS

PART | - GENERAL,

RELATED DOCUMENTS.

Drawings and general provisions of the Contract, including Conditions of Contract and

Division | Specification Sections, apply to this Section,

Related Sections include the following

1. __ Division 5 Section, "Structural Steet” for structural steel framing system components.

2. Division 6 Section "Cast Plastic Fabrications” for GRP gratings.

12 SUMMARY

‘A. This Section includes the following:

1. Metal bar gratings.

2. Heavy-duty metal bar gratings.

3. Expanded metal gratings.

4. Ductile east iron grating.

5. Extruded-aluminum plank gratings.

6. Metal frames and supports for gratings.

13 PERFORMANCE REQUIREMENTS

A. Structural Performance: Provide gratings capable of withstanding the following structural

loads without exceeding the allowable design working stress of the materials involved,

including anchors and connections:

1. Floors: Capable of withstanding a uniform load of 11.97 kNisq. m or a concentrated

load of 13.40 KN, whichever produces the greater stress.

2. Walkways and Elevated Platforms Used as Exits: Capable of withstanding a uniform

load of 4.79 kNisq. m or a concentrated load of 1.33 kN on an area of 25.8 sq. cm,

whichever produces the greater stress. Limit deflection to L/360 or 6.4 mm,

whichever is less.

3. Sidewalks and Vehicular Driveways: Capable of withstanding a uniform load of

11.97 kNisq, m or a concentrated load of 35.60 KN, whichever produces the greater

stress

4, Heavy Vehicular Driveways: Capable of withstanding a uniform load of 20 kN/sq. m

‘ora truck wheel load of 130 kN, whichever produces the greater stress.

14 SUBMITTALS

A. Product Data: For the following:

1, Formed-metal plank gratings.

2, Extruded-aluminum plank gratings.

GRATINGS neuen 05530 - Page 1/9

ISSUED FOR TENDER

RAYADAH HOUSING COMPLEX (RHC)

PACKAGE 3- BUILDINGS

PROJECT STANDARD SPECIFICATION May 2013,

3. Clips and anchorage devices for gratings.

4. Paint products.

Shop Drawings: Show fabrication and installation details for gratings. Include plans,

elevations, sections, and details of connections. Show anchorage and accessory items.

Provide templates for anchors and bolts specified for installation under other Sections.

1. For installed products indicated to comply with design loads, include structural

analysis data signed and sealed by the qualified professional engineer responsible for

their preparation.

Mill Certificates: Signed by manufacturers of stainless-steel sheet certifying that products

furnished comply with requirements.

Welding Certificates: Copies of certificates for welding procedures and personnel, under

the “Quality Assurance” article

Qualification Data: For firms and persons specified in the "Quality Assurance" Article to

demonstrate their capabilities and experience. Include lists of completed projects. with

project names and addresses, names and addresses of architects/engineers and owners, and

other information specified.

As-Built Drawings: At project close out, submit Record/As-Built Drawings of completed

‘work products, in accordance with requirements of the Specification as indicated in Divi

iq

QUALITY ASSURANCE

Quality System: Comply with ISO 9001/9002 Quality System as a minimum. Incorporate all

the standard procedures supplied by the Engineer and the Employer.

Professional Engineer Qualifications: A professional engineer who is legally qualified to

practice in jurisdiction where Project is located and who is experienced in providing

engineering services of the kind indicated. Engineering services are defined as those

performed for installations of gratings that are similar to those indicated for this Project in

‘material, design, and extent.

Fabricator Qualifications: A firm experienced in producing gratings similar to those

indicated for this Project and with a record of successfil in-service performance, as well as

sufficient production capacity to produce required units.

Metal Bar Grating Standards: Comply with applicable requirements of the following:

1. Non-Heavy-Duty Metal Bar Gratings: Comply with NAAMM MBG 531, "Metal Bar

Grating Manual for Steel, Stainless Steel, and Aluminum Gratings and Stair Treads."

2. Heavy-Duty Metal Bar Gratings: Comply with NAAMM MBG 532, "Heavy-Duty

Metai Bar Grating Manual."

Welding: Qualify procedures and personnel according to relevant codes of Authorities

having jurisdiction.

ISSUED FOR TENDER

105530- Page 29

RAYADAH HOUSING COMPLEX (RHO)

PACKAGE 3 - BUILDINGS,

PROJECT STANDARD SPECIFICATION, May 2013,

16

17

1. Certify that each welder has satisfactorily passed qualification tests by Authorities

having jurisdiction for welding processes involved and, if pertinent, has undergone

recertification

PROJECT CONDITIONS

Field Measurements: Where gratings are indicated to fit to other construction, verify

dimensions of other construction by field measurements before fabrication and indicate

‘measurements on Shop Drawings. Coordinate fabrication schedule with construction

progress to avoid delaying the Work.

COORDINATION

Coordinate installation of anchorages for gratings, grating frames, and supports. Fumish

setting drawings, templates, and directions for installing anchorages, including sleeves,

conerete inserts, anchor bolts, and items with integral anchors, that are to be embedded in

‘concrete or masonry. Deliver such items to Project site in time for installation.

PART 2 - PRODUCTS

po FP >

22

9 92 p>

GRATINGS

FERROUS METALS

Steel Plates, Shapes, and Bars: ASTM A 36/A 36M.

Wire Rod for Grating Crossbars: ASTM A 510M.

Uncoated Steel Sheet: ASTM A 1011/A 1011M, Grade 33.

Galvanized Steel Sheet: ASTM A 653/A 653M, structural quality, Grade 230, with 2275

coating.

Expanded Metal, Carbon Steel: ASTM F 1267, Class |

Expanded Metal, Galvanized: ASTM F 1267, Class 2, Grade A.

Welding Rods and Bare Electrodes: Select according to AWS specifications for metal alloy

to be welded.

Steel Bars for Gratings: ASTM A 569M or ASTM A 36M.

STAINLESS STEEL,

Sheet, Strip, Plate, and Flat Bars: ASTM A 666, Type 304.

Bars and Shapes: ASTM A 276, Type 304 or 316.

Sheet, Strip, Plate, and Flat Bars: ASTM A 666, Type 316.

Expanded Metal: ASTM F 1267, Class 3,

05530- Page 3

ISSUED FOR TENDER

RAYADAH HOUSING COMPLEX (RHC)

PACKAGE 3 - BUILDINGS

PROJECT STANDARD SPECIFICATION May 2013

23. ALUMINUM

‘A. Extruded Bars and Shapes: ASTM B 221M, alloys as follows:

24

25

GRATINGS:

L. 6061-T6 or 6063-16, for bearing bars of gratings and shapes.

2. 6061-T1, for grating crossbars.

Aluminum Sheet: ASTM B 209M, alloy 5052-H32.

PAINT

Shop Primers: Provide epoxy zine rich primers with minimum dry film coating of 40

microns.

Shop Primer for Ferrous Metal: Fast-curing, lead- and chromate-tree, universal modified-

alkyd primer complying with performance requirements in FS TT-P-664; selected for good

resistance to normal atmospheric corrosion, compatibility with finish paint systems

indicated, and capability to provide a sound foundation for field-applied topcoats despite

prolonged exposure.

Galvanizing Repair Paint: High-zine-dust-content paint for regalvanizing welds in steel,

complying with SSPC-Paint 20.

Bituminous Paint: Cold-applied asphalt mastic complying with SSPC-Paint 12, except

containing no asbestos fibers, or cold-applied asphalt emulsion complying with

ASTM D 1187.

Painting to Steel Surfaces:

1. Two coats of epoxy zinc rich primer shop applied.

2. One coat of high build epoxy enamel.

3. One finishing coat of high build polyurethane enamel.

FASTENERS,

General: Provide Type 304 or 316 stainless-steel fasteners for exterior use and zinc-plated

fasteners with coating complying with ASTM B 633, Class Fe/Zn 5, where built into

exterior walls, Select fasteners for type, grade, and class required.

Fasteners for Aluminum Gratings: Provide fasteners of aluminum, nonmagnetic stainless

steel, zine-plated steel, or other material warranted by the manufacturer to be compatible

with aluminum gratings and other components.

Bolts and Nuts: Regular hexagon-head bolts, ASTM F 568M, Property Class 4.6; with hex.

nuts, ASTM A 563M; and, where indicated, flat washers.

Plain Washers: Round, carbon steel, ASME B18.22M.

Lock Washers: Helical, spring type, carbon steel, ASME B18.21.2M.

Expansion Anchors: Anchor bolt and sleeve assembly of material indicated below with

capability to sustain, without fai

RAYADAH HOUSING COMPLEX (RHC)

PACKAGE 3- BUILDINGS

PROJECT STANDARD SPECIFICATION May 2013

installed in unit masonry and equal to four times the load imposed when installed in

concrete, as determined by testing per ASTM E 488, conducted by a qualified independent

testing agency.

1, Material: Carbon-steel_ components zine-plated to comply with ASTM B 633,

Class FeiZn 5.

2. Material: Alloy Group I or 2 stainless-steel bolts complying with ASTM F 738M

and nuts complying with ASTM F 836M.

FABRICATION

Shop Assembly: Fabricate grating sections in shop to greatest extent possible to minimize

field splicing and assembly. Disassemble units only as necessary for shipping and handling

limitations. Use connections that maintain structural value of joined pieces. Clearly mark

units for reassembly and coordinated installation.

B. Form from materials of size, thickness, and shapes indicated, but not less than that needed to

support indicated loads,

C. Shear and punch metals cleanly and accurately. Remove burrs.

D. Ease exposed edges to a radius of approximately I mm, unless otherwise indicated.

E, Fit exposed connections accurately together to form hairline joint.

F. Welding: Comply with AWS recommendations and the following:

1. Use materials and methods that minimize distortion and develop strength and

corrosion resistance of base metals.

2. Obtain fusion without undercut or overlap.

3. Remove welding flux immediately.

G. Provide for anchorage of type indicated; coordinate with supporting structure. Fabricate and

space anchoring devices to secure gratings, frames, and supports rigidly in place and to

suppor indicated loads.

1. Fabricate toeplates to fit grating units and weld to units in shop, unless otherwise

indicated.

2. Fabricate toeplates for attaching in the field.

3. Toeplate Height: 100 mm, unless otherwise indicated.

2.7 METAL BAR GRATINGS

‘A. Medium and heavy-duty gratings manufactured from Hot-dip galvanized steel, stainless

steel grade 304, of stainless steel grade 316, Bearing bars and cross bars are to be of

rectangular section with size and spacing as per manufacturer's written recommendation for

the span and type of loading indicated on the Drawings. Cross bars are to be locked at right,

angles to and in the same plane as, the top surface of bearing bars. Properties shall be as

follows:

1. Grating Mark: As indicated, but with bearing bar size not less than that required

complying with structural performance requirements.

GRATINGS 05530 Page 59

ISSUED FOR TENDER

RAYADAH HOUSING COMPLEX (RHC)

PACKAGE 3- BUILDINGS

PROJECT STANDARD SPECIFICATION May 2013

2. Type: Welded.

3. Traffic Surface for Aluminum Bar Gratings: Plain,

4. Traffic Surface for Steel Bar Gratings: Plain

5. Aluminum Finish: As indicated

6. Steel Finish: Hot-dip galvanized with a coating weight of not less than 550 g/sq. m of

28

coated surface. Shop paint with epoxy primer and epoxy high build coating,

7. Cut outs: Fabricate cutouts in grating sections for penetrations indicated. Arrange

cutouts to permit grating removal without disturbing items penetrating gratings.

4. Edge band openings in grating that interrupt 4 or more bearing bars with bars

‘of same size and material as bearing bars.

'b. Do not notch bearing bars at supports to maintain elevation

8. Fabricate removable grating sections with banding bars attached by welding to entire

perimeter of each section. Include anchors and fasteners of type indicated or, if not

indicated, as recommended by manufacturer for attaching to supports.

a. Provide not less than four weld lugs for each heavy-duty grating section, with

each lug shop welded to two bearing bars.

. Furnish threaded bolts with nuts and washers for securing grating to supports

©. Provide not less than 4 saddle clips for each grating section composed of

rectangular bearing bars 4.8 mm or less in thickness and spaced not less than

24 mm on centers, with each clip designed and fabricated to fit over 2 bearing

bars,

Ductile Cast Iron Grating: Medium and heavy-duty gratings non-rock type, manufactured

from ductile cast iron to ASTM A 536, grade 65-45-12 for mediuin duty and grade 80-55-06

for heavy duty. All castings shall be free from blow holes, shrinkage defects, swells, cracks

and other defects. Heavy-duty gratings are to be capable of supporting 13 tons axle loads.

EXPANDED METAL GRATINGS

Provide expanded metal gratings in material, finish, style, size thickness, weight, and type

indicated or, if not indicated, as recommended by manufacturer for indicated applications

and as needed to support indicated loads.

1. Material: Stainless Steel.

2. Stainless-Steel Finish: Mill, as fabricated,

3. Type: Il, expanded and flattened.

Fabricate cutouts in grating sections for penetrations of sizes and at locations indicated. Cut

openings neatly and accurately to size. Edge-band openings with bars having a thickness

not less than overall grating thickness at contact points,

Where gratings are pierced by pipes, ducts, and structural members, cut openings neatly and

accurately to size and weld a strap collar not less than 3 mn thick to the cut ends. Divide

panels into sections only to the extent required for installation where grating platforms and.

runways are to be placed around previously installed pipe, ducts, and structural members.

29 EXTRUDED-ALUMINUM PIpAM

cose (Gl

RATINGS Tina ew

ISSUED FOR TENDER

RAYADAH HOUSING COMPLEX (RHC)

PACKAGE 3 - BUILDINGS,

PROJECT STANDARD SPECI

A

210

“GRATINGS

‘ATION. May 2013,

Provide extruded-aluminum plank gratings in type, size, and finish indicated or, if not

indicated, as recommended by manufacturer for indicated applications and as needed to

support indicated loads.

1. Type: Extruded-aluminum planks approximately 152 mm wide with multiple flanges

approximately 30 mm 0.c., acting as beating bars connected by a web that serves as a

walking surface. Top surface has raised ribs to increase slip resistance.

2. Depth: As needed to support indicated loads.

Perforations: As fabricated.

4. Finish: Mill, as fabricated,

GRATING FRAMES AND SUPPORTS

General: Provide steel frames and supports, where indicated.

Steel Frames and Supports: Fabricate from structural-steel shapes, plates, and bars of

welded construction to sizes, shapes, and profiles indicated and as necessary to receive

‘gratings. Miter and weld connections for perimeter angle frames. Cut, drill, and tap units to

receive hardware and similar items.

Aluminum Frames: Fabricate frames for aluminum gratings from extruded-aluminum

shapes to sizes, shapes, and profiles indicated and as necessary to receive gratings. Miter

and weld connections. Cut, drill, and tap units to receive hardware and similar items.

Equip units with integrally welded anchors for casting into concrete or building into

masonry.

1. Unless otherwise indicated, space anchors 600 mm o.c. and provide minimum anchor

units in the form of steel straps 32 mm wide by 6 mm thick by 200 mm long.

Galvanize frames and supports in the following locations:

1 Exterior.

2. Interior, where indicated,

FINISHES,

‘Comply with NAAMM's "Metal Finishes Manual for Architectural and Metal Products" for

recommendations for applying and designating finishes.

Finish gratings, frames, and supports after assembly.

Galvanizing: For those items indicated for galvanizing, apply zine coating by the hot-dip

process complying with ASTM A 123.

Preparation for Shop Priming: Prepare uncoated ferrous-metal surfaces to comply with

minimum requirements indicated below for SSPC surface-preparation specifications and

environmental exposure conditions of installed items;

1, Exteriors (SSPC Zone 1B): SSPC-SP 6/NACE No. 3, "Commercial Blast Cleaning,"

2. Interiors (SSPC Zone 1A): SSPC-SP 3, "Power Too! Cleaning."

ee (05530- Page 75)

ISSUED FOR TENDER

RAYADAH HOUSING COMPLEX (RHC)

PACKAGE 3 - BUILDINGS

PROJECT STANDARD SPECIFICATION May 2013

Apply shop primer to uncoated surfaces of gratings, frames, and supports, except those with

galvanized finishes and those to be embedded in concrete or masonry, unless otherwise

indicated. Comply with SSPC-PA 1, "Paint Application Specification No. 1," for shop

painting,

PART 3 - EXECUTION

Ba

32

33

A

GRATINGS

PREPARATION

Coordinate and furnish anchorages, setting drawings, diagrams, templates, instructions, and

directions for installation of anchorages, including sleeves, anchor bolts. and miscellaneous

items having integral anchors that are to be embedded in concrete or masonry construction.

Coordinate delivery of such items to Project site.

INSTALLATION, GENERAL

Fastening to In-Place Construction: Provide anchorage devices and fasteners where

necessary for securing gratings to in-place construction. Include threaded fasteners for

concrete and masonry inserts, through-bolts, lag bolts, and other connectors.

Cutting, Fitting, and Placement: Perform cutting, drilling, and fitting required for installing

gratings. Set units accurately in location, alignment, and elevation; measured from

established lines and levels and free from rack.

Provide temporary bracing or anchors in formwork for items that are to be built into

concrete or masonry.

Fit exposed connections accurately together to form hairline joints. Weld connections that

are not to be left as exposed joints but cannot be shop welded because of shipping size

limitations. Do not weld, cut, or abrade the surfaces of exterior units that have been hot-dip

galvanized after fabrication and are for bolted or serewed field connections.

Attach toeplates to gratings by welding at locations indicated.

Field Welding: Comply with the following requirements:

1. Use materials and methods that minimize distortion and develop strength and

corrosion resistance of base metals.

2. Obtain fusion without undercut or overlap.

3. Remove welding flux immediately.

Corrosion Protection: Coat concealed surfaces of aluminum that will come into contact with

grout, conerete, masonry, wood, or dissimilar metals with a heavy coat of bituminous paint.

INSTALLING METAL BAR GRATINGS

General: Install gratings to comply with recommendations of referenced metal bar grating

standards that apply to grating types and bar sizes indicated, including installation

clearances and standard anchoring details.

05530- Page 89

ISSUED FOR TENDER

RAYADAH HOUSING COMPLEX (RHC)

PACKAGE 3- BUILDINGS

PROJECT STANDARD SPECIFICATION, May 2013,

B.

34

35

Attach removable units to supporting members with type and size of clips and fasteners

indicated or, if not indicated, as recommended by grating manufacturer for type of

installation conditions shown.

Attach non-removable units to supporting members by welding where both materials are the

same; otherwise, fasten by bolting as indicated above.

Attach toe plates to gratings by welding at locations indicated.

INSTALLING METAL PLANK GRATINGS.

General: Comply with manufacturer's written instructions for installing gratings, Use

‘manufacturer's standard anchor clips and hold-down devices for bolted connections.

Attach removable units to supporting members by bolting at every point of contact.

‘Attach nonremovable units to supporting members by welding, unless otherwise indicated,

Comply with manufacturer's writen instructions for size and spacing of welds.

Attach aluminum units to steel supporting members by bolting at side channels at every

point of contact and by bolting intermediate planks at each end on altemate sides. Bolt

adjacent planks together at midspan,

ADJUSTING AND CLEANING

Touchup Painting: Immediately after erection, clean field welds, bolted connections, and

abraded areas of shiop paint, and paint exposed areas with the same material as used for shop

painting to comply with SSPC-PA 1 requirements for touching up shop-painted surfaces.

1. Apply by brush or spray to provide a minimum 0.05 mi dry film thickness.

Touchup Painting: Cleaning and touchup painting of field welds, bolted connections, and

abraded areas of shop paint are specified in Division 9 Section "Painting,"

Galvanized Surfaces: Clean field welds, bolted connections, and abraded areas and repair

galvanizing to comply with ASTM A 780.

END OF SECTION 05530

GRATINGS

05530- Page 99

ISSUED FOR TENDER

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

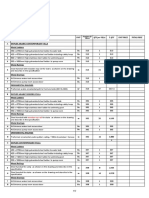

- Div. 12 - BOQ - (Floor Grating)Document1 pageDiv. 12 - BOQ - (Floor Grating)Akber HassanNo ratings yet

- Div. 05 - BOQ - (Metal Works)Document2 pagesDiv. 05 - BOQ - (Metal Works)Akber HassanNo ratings yet

- 14mm Diameter: Project: Rayadah Investment Company Subjet Rayadah Housing Complex, Jeddah Estimated Qty: 56,109 TonDocument1 page14mm Diameter: Project: Rayadah Investment Company Subjet Rayadah Housing Complex, Jeddah Estimated Qty: 56,109 TonAkber HassanNo ratings yet

- Project: Rayadah Investment Company Subjet Rayadah Housing Complex, Jeddah Div. 8: Wooden DoorsDocument3 pagesProject: Rayadah Investment Company Subjet Rayadah Housing Complex, Jeddah Div. 8: Wooden DoorsAkber HassanNo ratings yet

- Plain Concrete Grade 200kg/cm As Described in SpecificationDocument1 pagePlain Concrete Grade 200kg/cm As Described in SpecificationAkber HassanNo ratings yet

- 2019 Course List 1Document2 pages2019 Course List 1Akber HassanNo ratings yet

- Project: Rayadah Investment Company Subjet Rayadah Housing Complex, JeddahDocument2 pagesProject: Rayadah Investment Company Subjet Rayadah Housing Complex, JeddahAkber HassanNo ratings yet

- Ucem PDFDocument7 pagesUcem PDFAkber HassanNo ratings yet

- வீரகேசரி 26072020 PDFDocument48 pagesவீரகேசரி 26072020 PDFAkber HassanNo ratings yet

- Types of Information SystemsDocument8 pagesTypes of Information SystemsAkber HassanNo ratings yet

- Information Technology Features: Centralized SystemsDocument8 pagesInformation Technology Features: Centralized SystemsAkber HassanNo ratings yet

- CS-1 Year: Systems Analysis and DesignDocument22 pagesCS-1 Year: Systems Analysis and DesignAkber HassanNo ratings yet

- Price List NawalaDocument1 pagePrice List NawalaAkber HassanNo ratings yet

- IT2403 Systems Analysis and Design: (Compulsory)Document6 pagesIT2403 Systems Analysis and Design: (Compulsory)Akber HassanNo ratings yet

- ஏறாவூர் வரலாறு புத்தகம்Document8 pagesஏறாவூர் வரலாறு புத்தகம்Akber HassanNo ratings yet

- ஏறாவூர் வரலாறு புத்தகம்Document13 pagesஏறாவூர் வரலாறு புத்தகம்Akber Hassan100% (1)

- Lotus Notes BeginnerDocument28 pagesLotus Notes BeginnerAkber HassanNo ratings yet