Professional Documents

Culture Documents

Maximum Bearing Clearances Service Bulletin

Uploaded by

agus0 ratings0% found this document useful (0 votes)

15 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views1 pageMaximum Bearing Clearances Service Bulletin

Uploaded by

agusCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

SERVICE BULLETIN

Practical Procedures to Simplify Your Service Problems

***********************************************************************

Maximum Allowable Bearing Wear 183

6-14-84

Maximum Allowable Bearing Wear

In response to customer Requests for our recommendation on maximum allowable

bearing wear in National Oilwell equipment, we have contacted several bearing

manufacturers for their recommendations. Their information was found to be

vague and quite conservative.

The following are figures found to be practical and acceptable to most customers,

and are frequently used by our service departments. These figures would apply to

all bearings used in our mud pumps and drawworks with the provision that they

passed a visual inspection.

0.008" - 0.010" Okay to run until the next annual inspection

0.011" - 0.013" Replace at next scheduled maintenance

0.014" - 0.016" Replace at first break in drilling (e.g., logging, or

completion of well)

0.017" & above Replace immediately

These are extreme outer limits and in some cases, the bearing may begin to spall,

which will cause damage to other parts.

Therefore, Close Observation is Essential

The best way to detect bearing spalling is through the use of an oil sample analysis

program.

You might also like

- Operator'S Manual: Bop Control System With Air Remote ControlDocument12 pagesOperator'S Manual: Bop Control System With Air Remote ControlagusNo ratings yet

- Drilling Mast and Subtructure CertificatDocument10 pagesDrilling Mast and Subtructure CertificatAhmed Imtiaz Rao0% (1)

- Safety Alert: Block Hanging Line Load PathDocument1 pageSafety Alert: Block Hanging Line Load PathagusNo ratings yet

- Safety Alert: Block Hanging Line Load PathDocument1 pageSafety Alert: Block Hanging Line Load PathagusNo ratings yet

- Accumulator Function TestDocument1 pageAccumulator Function TestamirakhavansafarNo ratings yet

- 1500 HP SCR Mobile Desert Drilling Rig Example SpecifcationsDocument48 pages1500 HP SCR Mobile Desert Drilling Rig Example SpecifcationsMustafa SaidNo ratings yet

- System Requirements For AutoCAD Plant 3D 2019 - AutoCAD Plant 3D 2019Document3 pagesSystem Requirements For AutoCAD Plant 3D 2019 - AutoCAD Plant 3D 2019agusNo ratings yet

- Level III Inspection Vfinal Form Enabled PDFDocument3 pagesLevel III Inspection Vfinal Form Enabled PDFagusNo ratings yet

- Rig-36 Cyclone Drilling Inc.Document2 pagesRig-36 Cyclone Drilling Inc.leoNo ratings yet

- RS9031 PDFDocument7 pagesRS9031 PDFagusNo ratings yet

- Quick Release ValveDocument5 pagesQuick Release ValveagusNo ratings yet

- Hook Derating ChartsDocument6 pagesHook Derating ChartsagusNo ratings yet

- IOM-RH RotorSealDocument6 pagesIOM-RH RotorSealagusNo ratings yet

- Eaton AirflexDocument12 pagesEaton AirflexagusNo ratings yet

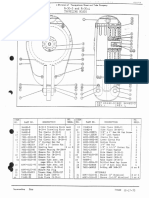

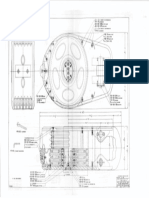

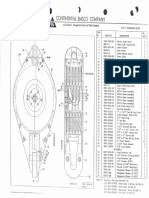

- Mud PumpDocument2 pagesMud PumpagusNo ratings yet

- 2004 Advance Ballast SpecificationsDocument1 page2004 Advance Ballast SpecificationsagusNo ratings yet

- Rotorseal Tech Specs PDFDocument19 pagesRotorseal Tech Specs PDFFAVIONo ratings yet

- National Type G Hook-Block Iadc Check ListDocument2 pagesNational Type G Hook-Block Iadc Check ListagusNo ratings yet

- Emsco L-300 Parts ListDocument1 pageEmsco L-300 Parts ListagusNo ratings yet

- Oilwell 350 HD PartslistDocument4 pagesOilwell 350 HD PartslistagusNo ratings yet

- Block EmscoDocument1 pageBlock EmscoagusNo ratings yet

- Outline Oilwell 480 BlockDocument1 pageOutline Oilwell 480 BlockagusNo ratings yet

- Emsco Nc-36-3 & 36-4 Block PartslistDocument1 pageEmsco Nc-36-3 & 36-4 Block PartslistagusNo ratings yet

- Emsco BlockDocument1 pageEmsco BlockagusNo ratings yet

- Set Up Instructions PWMDocument1 pageSet Up Instructions PWMagusNo ratings yet

- National Type H Block Iadc Check ListDocument2 pagesNational Type H Block Iadc Check ListagusNo ratings yet

- Set Up Instructions PWMDocument1 pageSet Up Instructions PWMagusNo ratings yet

- Quick Release ValveDocument5 pagesQuick Release ValveagusNo ratings yet

- SSSSSSSSSSSSSSSS: Tb1 & 2 For All PWM Control SystemsDocument1 pageSSSSSSSSSSSSSSSS: Tb1 & 2 For All PWM Control SystemsagusNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)