Professional Documents

Culture Documents

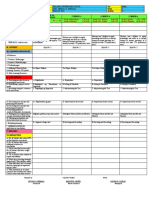

Individual Background Information Tensile Test

Uploaded by

Kelvin YapOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Individual Background Information Tensile Test

Uploaded by

Kelvin YapCopyright:

Available Formats

YAP KHAI WEN 19WVR05859

My name is Yap Khai Wen and I am from RQS Semester 1 Group 2. My teammates and

I had carried out the cube test on 7 th of August 2019, Wednesday, in TARUC laboratory. I have

gained a lot of valuable knowledge and information throughout the experiment. I got to know all

the procedures to carry out the universal tensile machine test as well the apparatus needed in the

experiment. Firstly, we have to calculate the weight, length and density of the rebar and then key

in all the information into the tensile test software. To obtain an accurate graph and result, the

steel bar must be secured in the top and bottom grip of the testing machine and make sure that it

is gripped exactly at the marked distance of the steel. We have to keep a distance away from the

machine while the test is in progress as it is dangerous and may even cause injuries when the

steel is about to break into two or fractured. After that, the broken bar can be removed after the

stress strain curve and the results are formed. The tensile test is operated in 3 stages before the

fracture. First is elastic limit, second is yield stress, third is ultimate stress and eventually it is the

breaking stress point, which is also known as the point of fracture. I have learnt how to calculate

every equation for stress strain curve of steel such as young’s modulus, percent reduction of area,

percent elongation and also modulus of resilience. I also have a better understanding on each

characteristics of the curve.

The purpose of conducting this experiment is to determine the fundamental mechanical

properties of structural members for use in design to ensure that the structure is safe against

failure. By measuring the force required to elongate a specimen to breaking point, material

properties can be determined that will allow designers and quality managers to predict how

materials and products will behave in application. The tensile strength of the materials should

also meet the strength requirements of the structural applications for safe design of structural

components in bridges, buildings and so on. Many engineering applications that require high

tensile strength normally use mild steel. This is because of the structure of mild steel allows it to

withstand high axial loads before fracture can occur. This is the reason why steel is commonly

used as structural members of bridges, buildings and also as reinforcements in reinforced

concrete structure. In conclusion, tensile test is very important as it helps to determine properties

of material to be used to ensure that the project or building constructed by those materials are in

high tensile strength and would not collapse or fracture easily.

You might also like

- Implementation of Occupational Safety and Health in Construction IndustryDocument6 pagesImplementation of Occupational Safety and Health in Construction IndustryKelvin YapNo ratings yet

- PD - Competitive Supply Analysis LatestDocument15 pagesPD - Competitive Supply Analysis LatestKelvin YapNo ratings yet

- Malaysia Real Estate Highlights 1h 2022 9222Document28 pagesMalaysia Real Estate Highlights 1h 2022 9222Kelvin YapNo ratings yet

- Suspension BridgeDocument4 pagesSuspension BridgeKelvin YapNo ratings yet

- Day No Exercise Weight Reps SetsDocument19 pagesDay No Exercise Weight Reps SetsKelvin YapNo ratings yet

- Basic Earnings Per Share vs. Diluted Earnings: 3. Preferred Vs Common StockDocument1 pageBasic Earnings Per Share vs. Diluted Earnings: 3. Preferred Vs Common StockKelvin YapNo ratings yet

- Site Survey Transverse ProcedureDocument8 pagesSite Survey Transverse ProcedureKelvin YapNo ratings yet

- Second Case Law, Yap Eng Thong & Anor V Faber Union LTDDocument4 pagesSecond Case Law, Yap Eng Thong & Anor V Faber Union LTDKelvin YapNo ratings yet

- Illuminance Readings Against The Square of Distance (E Vs D 2)Document1 pageIlluminance Readings Against The Square of Distance (E Vs D 2)Kelvin YapNo ratings yet

- Law Case SummaryDocument3 pagesLaw Case SummaryKelvin YapNo ratings yet

- Balfour V Balfour: (1919) 2 KB 571, (1918-19) All ER860 (Court of Appeal)Document5 pagesBalfour V Balfour: (1919) 2 KB 571, (1918-19) All ER860 (Court of Appeal)Kelvin YapNo ratings yet

- Malaysian Legal SystemDocument7 pagesMalaysian Legal SystemKelvin YapNo ratings yet

- The Second Case Is Jones V Padavatton (1969) - It Is An Agreement Between Parents and Children WhereDocument3 pagesThe Second Case Is Jones V Padavatton (1969) - It Is An Agreement Between Parents and Children WhereKelvin YapNo ratings yet

- BCT Chapter 7 (Print)Document4 pagesBCT Chapter 7 (Print)Kelvin YapNo ratings yet

- Departmentalization POM RevisionDocument3 pagesDepartmentalization POM RevisionKelvin YapNo ratings yet

- (S) Topic 3 - Market Theory - Elasticities of Demand and SupplyDocument14 pages(S) Topic 3 - Market Theory - Elasticities of Demand and SupplyKelvin YapNo ratings yet

- (S) Topic 4 - Cost of Production and Corporate Organisation BehaviourDocument15 pages(S) Topic 4 - Cost of Production and Corporate Organisation BehaviourKelvin YapNo ratings yet

- (S) Topic 1 - IntroductionDocument11 pages(S) Topic 1 - IntroductionKelvin YapNo ratings yet

- Site Survey Traverse ProcedureDocument8 pagesSite Survey Traverse ProcedureKelvin YapNo ratings yet

- Four Major Functions of CommunicationDocument1 pageFour Major Functions of CommunicationKelvin YapNo ratings yet

- Invert LevelDocument27 pagesInvert LevelKelvin YapNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Selected Objective Question On Introduction To Computers With Answer Set 5Document27 pagesSelected Objective Question On Introduction To Computers With Answer Set 5Ankit JainNo ratings yet

- How Could Auto Manufacturer Use Transportation To Increase The Efficiency of Supply Chain?Document25 pagesHow Could Auto Manufacturer Use Transportation To Increase The Efficiency of Supply Chain?guddianushaNo ratings yet

- Cirrus HD-OCT RNFL and ONH Analysis ReportDocument4 pagesCirrus HD-OCT RNFL and ONH Analysis ReportSoma AlshokriNo ratings yet

- Useful Relations in Quantum Field TheoryDocument30 pagesUseful Relations in Quantum Field TheoryDanielGutierrez100% (1)

- Chapter 1 Intro To QualityDocument34 pagesChapter 1 Intro To QualityRonah Abigail BejocNo ratings yet

- Sergey Kojoian Graph Theory NotesDocument11 pagesSergey Kojoian Graph Theory NotesSergey KojoianNo ratings yet

- Topic 054 Linear Operators: Operator: in The Case of Vector Spaces and in Particular NormedDocument28 pagesTopic 054 Linear Operators: Operator: in The Case of Vector Spaces and in Particular NormedAsmara ChNo ratings yet

- 100 Golden Rules of English Grammar For Error Detection and Sentence ImprovementDocument8 pages100 Golden Rules of English Grammar For Error Detection and Sentence ImprovementHajra bibiNo ratings yet

- The PotometerDocument6 pagesThe PotometerRonald Deck Yami100% (1)

- Measure and IntegralDocument5 pagesMeasure and Integralkbains7No ratings yet

- Ef3e Upper-Inter WL PDFDocument32 pagesEf3e Upper-Inter WL PDFDubravka Kovacevic100% (2)

- Differential AnalysisDocument26 pagesDifferential AnalysisEdma Glory MacadaagNo ratings yet

- PayPal Verification Guide - AllienwareDocument14 pagesPayPal Verification Guide - Allienware1.o2asNo ratings yet

- Nabin Bhusal Oracle Developer (1)Document6 pagesNabin Bhusal Oracle Developer (1)HARSHANo ratings yet

- DLL Q3 Week 4 Day5 WWDocument3 pagesDLL Q3 Week 4 Day5 WWCecilia Guevarra DumlaoNo ratings yet

- Ar. Laurie BakerDocument21 pagesAr. Laurie BakerHardutt Purohit100% (1)

- Migrant Nurses Ausi Integrative ReviewDocument7 pagesMigrant Nurses Ausi Integrative ReviewBony Yunaria TanuNo ratings yet

- Alexander Galloway Laruelle Against The DigitalDocument321 pagesAlexander Galloway Laruelle Against The DigitaljacquesfatalistNo ratings yet

- Indo Africa Indianparticipants-09Document870 pagesIndo Africa Indianparticipants-09Guruprasad T JathanNo ratings yet

- Demo Teaching Lesson Plan in MTB Mle 1Document5 pagesDemo Teaching Lesson Plan in MTB Mle 1Aubrey Angel Wisemoron Redoña95% (42)

- Vdocuments - MX Atlas Copco Pneumatic Rock Drilling RigsDocument8 pagesVdocuments - MX Atlas Copco Pneumatic Rock Drilling RigsMohamed SadekNo ratings yet

- VungleDocument14 pagesVunglegaurdevNo ratings yet

- Quantitative Aptitude Shortcuts & TricksDocument14 pagesQuantitative Aptitude Shortcuts & Tricksrock_on_rupz99No ratings yet

- Saltwater Aquarium Guide: What's The Difference Between Saltwater and Freshwater? WhereasDocument10 pagesSaltwater Aquarium Guide: What's The Difference Between Saltwater and Freshwater? WhereasTimmy HendoNo ratings yet

- Schizophrenia - Risperidine 2Document1 pageSchizophrenia - Risperidine 2Bukola OgunnaikeNo ratings yet

- SCIDDocument9 pagesSCIDgarimaupadhyay20002No ratings yet

- Presidents Accomplishments With Science and TechnologyDocument19 pagesPresidents Accomplishments With Science and TechnologyClarisse Sollano59% (29)

- 2015 Nissan Service Maintenance GuideDocument70 pages2015 Nissan Service Maintenance GuideAhmed Almaghrby100% (2)

- Word As "BUNDLES" of MeaningDocument19 pagesWord As "BUNDLES" of MeaningDzakiaNo ratings yet

- History of ComputerDocument19 pagesHistory of ComputerGarcia Mary Ann T.No ratings yet