Professional Documents

Culture Documents

Denim Group PDF

Denim Group PDF

Uploaded by

karan patel0 ratings0% found this document useful (0 votes)

27 views4 pagesOriginal Title

Denim Group.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views4 pagesDenim Group PDF

Denim Group PDF

Uploaded by

karan patelCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

. 6

delerpcioiam ES

JOB DESCRIPTION: JD-20 (MES/MCR/MCP)

Category of Personnel: PLANNING TECHNICIAN

Base Location: QP REFINERY

Reports to: PLANNING ENGINEER

Primary Purpose of Job:

Provides Work Order for planning and schedules and reports for QP refinery routine

maintenance using various project planning software and CMMS (SAP) in order to

maximize the asset reliability.

Principle | Key Responsibilities:

1. Receiving. logging and processing of all maintenance requests (Notifications).

ensuring conformance with the latest revision of the maintenance work order.

2. Review and analyse maintenance Work Request and ensures that all the information

are correct and complete. Plans and check the required resources. materials. etc. in

liaison with respective engineers before a Work Order is planned and executed.

3. Ensure correct job priority as per equipment criticality & system condition in co-

ordination with operations and liaise with respective maintenance engineers.

4. Prepare draft maintenance work specification and task list including discipline man-

hour; duration and special resources requirement for plan scope of work. Entails visits

to sites. liaising with maintenance. operation. and facilities personnel.

5. Responsible to verify notification completion. work order completion with details of

accounting information (man-hours/materials utilized) and technical information (work

carried out. fault diagnosed. failure code and failure mode).

6. Utilizes extensive knowledge of craft skills and knowledge of the equipment involved

and places job steps in the proper sequence to ensure efficient completion of work to

meet operational requirement.

7. Check and provide required sub work orders for support services like Rigging.

scaffolding. Insulation etc.. to coincide with the work order scheduling,

8. Co-ordinate all day-to-day maintenance work carried out by Mechanical. Electrica.

Instruments & Facilities disciplines for effective and timely execution of the work in

order to maximum usage of resources.

9. Operate proprietary planning software (Primavera. MS Project) to develop schedule.

10, Maintain various hard copy and electronic files covering all planning related works in

professional manner.

11. Develop Eight weeks One week look ahead plans.

12.Participates along with the area Planning Engineer in the RBWS /Weekly/Schedule

Coordination Meeting and presents the Weekly Schedule of workable maintenance

Page 31 of 50, Job Description - OM(R)

Contract No. GC161048C0 y Page No. 157 of 385

keke

2, |

Letras 2 | ve

Joplin py

Qatar Petroleum maa

JOB DESCRIPTION: JD-08 (MES/MCR-MCM)

Category of Personnel: GENERAL TECHNICIAN (FABRICATION)

Base Location: OPERATIONS (REFINING)

Reports to: SR. MECH. ENGINEER (FABRICATION)

Primary Purpose of Job:

To perform & supervise all types of fabrication works by referring to engineering drawings.

specifications. sketches and field data at Refinery site and within workshop including

consumables. equipment. tools. permits and preparations for the job.

Principle / Key Responsibilities:

1. Main Areas of work are Refinery 1/2. RFCC. Condensate Refinery. Utilities. and

Offsite including Berth 6. WOQOD. SEEF and QATEX.

2, Receives work orders from Sr. Mechanical Engineer (Fabrication) check work at

site including taking the measurements. prepare bill of quantities and establishing

work requirements. Should be able to work from drawings. sketches and

engineering specs. Issue relevant Work permits in RIS as per job requirements at

site

3, Identify and check the availability of materials in SAP as required for IAT

(inspection Advise Tickets) and coordinates work execution with Operations and

other sections.

4. Read. understand and prepare the material list. as per the engineering

constructional isometric drawings of steel structure. for piping and pressure

vessels

5. Prepare sketch with dimension for the works as per the visit of the concerned area

and to read the isometric drawings.

6. Carry out piping. pressure vessel fabrication tubes bending, sheets rolling and to

use flame cutting and beveling. grinding machine. The individual should know how

to use drills. hand grinders and hot taping machines.

7. To carry out fabrication work on all types of materials including aluminum. bronze.

brass. carbon steels. stainless steels. alloy steels. etc. He should be aware and

capable of special measures & procedures for each category of work.

8. Should be able to do repairs on equipment and machinery including heaters.

boilers. pressure vessels. turbo machinery. pumps. etc. Supervise the Contractual

Welding Manpower and make all necessary preparations for performing works

during Normal Routine and unplanned Shutdowns.

9. Ensure safe working condition for the workers and the work. He shall ensure fire-

blanketing, masks. fire extinguishers and protective clothing to ensure safety.

Ensures that the company environmental. health and safety procedures are

Page 13 of 59 Job Description - OM(R)

Contract No. GC161048C0 Page No. 139 of 385

eh 2

JOB DESCRIPTION: JD-05 (OEM-MES)

Category of Personnel: EQUIPMENT OPERATOR

Base Location: MESAIEED- NGL FACILITY - TRANSPORT BUILDING NO. 14

Reports to: WORKSHOP SUPERVISOR (AUTOMOBILE)

Primary Purpose of Job:

Drives and operates various types of QP vehicles and equipment's such as Mobile Telescopic

Cranes. Self Loading Knuckle Boom Trucks. Fork Lift Trucks and when required Heavy Vehicle

& Trailers,

Principle / Key Responsibilities:

1. Perform pre-start inspection of vehicle/associated equipment for effects and ensure

proper condition. Also. shall perform before use and periodically check of associated

‘equipment such as fittings. ropes. hooks and slings. and shall report defects if any.

2. Inspects and checks equipment for safe operation at commencement of each jobitip.

includes checking of oil. water. fuel. battery. tyres. brakes, cable. horn. lights. signaling

equipment. hooks. ropes. sling and their fittings: and ensures their safe condition.

3. Reports directly to QP Automobile Representatives

4. Operates mobile cranes. boom trucks. and other various type of heavy equipment.

5. Follow manufacturer's operating instructions and observe load limitations.

6. Use electrical. hydraulic and pneumatic devices. Shall ensure adherence to safety

procedures.

7. Use lifting equipment to load/unload machinery and equipment including in confined

quarters.

8. Reports on all serious and minor malfunctions and shalll complete inspection reports on

daily basis regarding documents worn or damaged items. and shall check for the correct

operations of various switches and controls.

9. Ensure validity of vehicle documentation (including lifting certification).

10.Be alert to faults/equipment failure indicated by sight. sound. and loss of performance

or observation of instruments/indicators. Shall immediately report defects and

malfunctions.

11. Maintain daily log sheet of all activities assigned

12.Perform other related duties as directed by QP

13.Shall insure that his third party certifying authority certificates are kept valid at all

times.

Page 9 of 51

Contract No. GC161048C0

[eeetickena &

‘

a t

Bir hroam BS

JOB DESCRIPTION: JD-15 (OEM-MES)

Category of Personnel: TECHNICIAN 1 (MECHANICAL / WELDER)

Base Location: MESAIEED, CENTRAL WORKSHOP BUILDING NO. 15

Reports to: WORKSHOP SUPERVISOR

Primary Purpose of Jol

To carry out ail welding and fabrication work assigned to him ensuring high standards of

workshop practice and safety procedures usually in the form of Engineering Work Orders or

verbal requests. supported by detailed drawings welding specification.

Principle / Key Responsibilities:

To have thorough knowledge of the workshop equipment and machinery.

2, Ensures that all the work activities carried out are as per the implemented QMS

procedures.

3. Carries out fabrication and installation of pipe work and structural steel

4. Works with other welders with regard to various acceptance standards associated with

the welding of gas transmission pipelines

5. Reports to Senior Technician to ensure appropriate procedures and standards are

maintained and on work completion that the work area is left safe and tidy and that

equipment and the balance of consumables are returned to the store,

6. Resolves problems encountered during execution of preparation and welding of various

assignments relating to clearances etc. required by the welding procedures being

performed,

7. Responsible for ensuring that all safety rules are applied and adhered to by

subordinates and any one else in the work area and fully understands his

responsibilities regarding hot and cold permit restrictions and procedures

Remains available on stand-by duty for emergency cover.

Qualifications & Exp

ience:

At least 5 years experience within oil and Gas / Petrochemical industries in mechanical and

machine workshops activities. Should have obtained valid coded welders certificate.

‘Completion of Secondary (12 years) education followed by two years full ime mechanical trade

training leading to possession of a registered qualification (OND or equivalent). Sound

knowledge of English.

Qatar Traffic Department — Holder of a Light Vehicle Driving License.

Page 30 of 51

Contract No. GC161048C0

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Employers List - Surat Rozgar Mela For AllDocument3 pagesEmployers List - Surat Rozgar Mela For Allkaran patelNo ratings yet

- Amazon Pay KYC - Training PPT For VendorsDocument19 pagesAmazon Pay KYC - Training PPT For Vendorskaran patelNo ratings yet

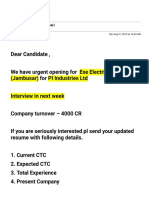

- Gmail - Job - Exe Electrical (Jambusar) PDFDocument2 pagesGmail - Job - Exe Electrical (Jambusar) PDFkaran patelNo ratings yet

- Career Opportunity With Spie Oil & Gas Services PDFDocument1 pageCareer Opportunity With Spie Oil & Gas Services PDFkaran patelNo ratings yet

- Travel Information To QatarDocument2 pagesTravel Information To Qatarkaran patelNo ratings yet

- Adgas Abu DhabiDocument7 pagesAdgas Abu Dhabikaran patelNo ratings yet

- Ahmedabad Janmarg Limited: Advertisement No:-07 DT: 15-11-2018Document3 pagesAhmedabad Janmarg Limited: Advertisement No:-07 DT: 15-11-2018karan patelNo ratings yet

- Apprenticeship - Vacancy - Session 2019-2020Document1 pageApprenticeship - Vacancy - Session 2019-2020karan patelNo ratings yet

- Installation of Large Rotating Equipment Systems - A Contractor'S Comments by John R. MasseyDocument8 pagesInstallation of Large Rotating Equipment Systems - A Contractor'S Comments by John R. Masseykaran patelNo ratings yet