Professional Documents

Culture Documents

5 - Governor Mechanisms

Uploaded by

Nitpreet RandhawaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5 - Governor Mechanisms

Uploaded by

Nitpreet RandhawaCopyright:

Available Formats

Solution of UPSC Papers

Of

Theory of Mechanism and Machines

Governor Mechanisms

Prepared By

Brij Bhooshan

Asst. Professor

B. S. A. College of Engg. And Technology

Mathura, Uttar Pradesh, (India)

Supported By:

Purvi Bhooshan

Please welcome for any correction or misprint in the entire manuscript and your

valuable suggestions kindly mail us brijrbedu@gmail.com.

1987

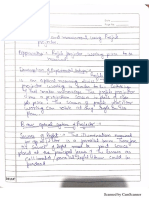

Problem: A centrifugal governor shown in Fig. 4 has two masses each of weight w

connected by a helical spring. The arms carrying the weights are parallel to the axis of

rotation at the speed of 900 r.p.m. If the speed is increased by 1%, it requires a force of 3

kgf to maintain the sleeve at the same position. Determine—

(i) the weight w of masses;

(ii) the stiffness of spring and its initial extension if the sleeve moves by 1 cm for a

change of speed of 250 r.p.m.

FC1 FC m

mg 7 cm

7.5 cm

5 cm

O

W/2

[Engg. Services – 1987]

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 1

2 Solution of UPSC Papers of Governor Mechanisms

Solution: Given that: Speed (N) = 900 rpm, ω = 2N/60 = 2 900/60 = 94.24 rad/s,

Speed increased 1%, W = 3 9.81 = 29.43 N, r = 7 cm = 0.07 m, x = 7.5 cm = 0.75 m, y = 5

cm = 0.05 m.

Weight of masses:

Centrifugal force at equilibrium position

FC = mω2r = m (94.24)2 0.07 = 621.68m N

Speed is increased by 1%, then

ω1 = ω + 0.01ω = 1.01ω.

Centrifugal force at increased speed

FC1 = m r = m (95.18)2 0.07 = 634.17m N

Taking moment about point O,

After solving we get m = 0.78 kg.

Then weight W = mg

= 0.78 9.81 = 7.65 N.

Stiffness of spring:

Suppose k is the stiffness of spring.

Centrifugal force at equilibrium speed

FC = 621.68 m = 621.68 × 0.87 = 484.91 N.

Since speed change 250 rpm.

Total speed = 900 + 250 = 1150 rpm.

= 2N/60 = 2 1150/60 = 120.42 rad/s,

The sleeve movement is 1 cm at 250 rpm speed.

h = 1 cm = 0.01 m.

Let r radius of rotation at 900 rpm = 0.07 m,

r2 = radius of rotation at 1150 rpm

r2 = 0.085 m.

Centrifugal speed at increased speed (2)

= 961.41 N.

Then,

After solving, we get k = 15883.49 N/m.

Initial extension in spring

= Fc/k = 484.91/15883.49

Then, = 0.030 m.

1988

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 2

Solution of UPSC Papers of Theory of Mechanism and Machines By Brij Bhooshan 3

Problem: A loaded porter governor has 4 link each 25 cm long, 2 revolving masses each

weighing, to N and a central dead weight weighing 200 N. All the links are attached to

respective sleeves at radial distances of 4cm from the axis of rotation. The masses

revolve at a radius of 15 cm at minimum speed and at a radius of 20 cm at maximum

speed. Determine the range of speed.

[Engg. Services – 1988]

0.25 m 0.25 m

h1 h2

0.15 m 0.20 m

W W

0.25 m 0.25 m

W1 W1

Solution: Given that: l = 25 cm = 0.25 m, W1 = 200 N, r = 4 cm = 0.04 m, rmin = 15 cm =

0.15 m, rmax = 20 cm = 0.20 m, W = 10 N.

Now, from geometry

h1 = [0.252 0.152]1/2 = 0.2 m.

h2 = [0.252 0.202]1/2 = 0.15 m.

Now, we know that

Then

Then, N1 = 306.55 rpm.

Then, N2 = 353.97 rpm.

1990

Problem: A watt governor has an arm of uniform section of length L and mass m and a

ball of mass M. Show that when revolving with angular velocity ω, it makes an angle θ

to the vertical, where

m

g M

2

cos

m

2 L M

3

Also determine the angle θ for the case when bar is not of uniform cross-section, its

radius of gyration about the point of attachment being k and distance of CG to the point

of attachment being d.

[Engg. Services – 1990]

O

l

FC B

A

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 3

4 Solution of UPSC Papers of Governor Mechanisms

Solution: Taking moment about point O

FC l cos Mgl sin mg(l/2) sin = 0

Using Eqns. (i) and (ii)

Also given bar is non-uniform radius of gyration is k, d is the distance from C.G.

1992

Problem: Discuss the requirements for satisfactory performance of a centrifugal

governor. Define controlling force, stability, sensitiveness and hunting with reference to

governors.

[IAS – 1992]

Solution: A centrifugal governor should have the following qualities for satisfactory

performance:

1. When its sleeve reaches its lowest position, the engine should develop maximum

power.

2. Its sleeve should at once reach the topmost position when the load on the engine

is suddenly removed.

3. Its sleeve should float at some intermediate position under normal operating

conditions.

4. Its response to a change in speed should be fast.

5. It should have sufficient power so that it can exert the required force at the

sleeve to operate the control mechanism.

The definitions of some terms used for describing these qualities of a governor follow.

Controlling Force

In a centrifugal governor, the resultant of all the external forces which control the

movement of the ball can be regarded as a single inward radial force acting at the centre

of the ball. The variation of this force F with the radius of rotation of the ball can be

studied under static conditions by measuring the outward radial force on the ball which

is necessary to keep the ball in equilibrium at various configurations (i.e., for different

values of r). The force F is known as the controlling force and is a function of a single

variable r. Thus,

F = F(r) [5.1]

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 4

Solution of UPSC Papers of Theory of Mechanism and Machines By Brij Bhooshan 5

F B

C

F

D E G

r

A

r

Diagram 5.4

Diagram 5.4 shows a typical plot of the controlling-force characteristic (curve AB). The

controlling force is derived from purely statical considerations without reference to the

speed of rotation.

Now, let us suppose that the governor ball rotates at a speed ω. The centripetal force

needed for maintaining the radius of rotation r is given by mω2r, where m is the mass of

each ball. The plot of this force against r for a given speed ω will obviously be a straight

line passing through the origin as shown by the line OC in Diagram 5.4. So, the

equilibrium radius for this speed ω will be determined by the intersection of the curve

AB with the line AC (at the point D). For this value of r, controlling force will be equal to

the centripetal force. Mathematically, we can express this equilibrium condition as

F(r) = mω2r [5.2]

Stability

If the governor ball is displaced from its equilibrium position for a particular speed

without any change in the speed of rotation, and thereafter if it tends to return to its

original equilibrium position, then the governor is said to be stable.

A governor is said to be stable when for each speed within the working range there is

only one radius of rotation of the fly balls at which the governor is in equilibrium. For a

stable governor, if the equilibrium speed increases, the radius of governor balls must

also increase. A governor is said to be unstable, if the radius of rotation decreases as the

speed increases.

To determine the condition necessary for stability, suppose the speed of the governor be

ω at the equilibrium position given by the point D (Diagram 5.4). If the speed remains

the same, and if the radius changes to r + δr, the increment in the controlling force EF

will be (dF/dr) δr, and the corresponding increment in the centripetal force EG will be

EG = mω2δr. The restoring force FG on the ball is

FG = EF EG = (dF/dr mω2)δr

This should be greater than zero for the equilibrium position to be regained. Thus, for

stable operation, we get dF/dr > mω2. Using (5.2), we get

In other words, the condition for the stability of a governor is that the slope of the curve

for the controlling force should be more than that of the line representing the centripetal

force at the speed considered.

Sensitiveness

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 5

6 Solution of UPSC Papers of Governor Mechanisms

If a governor operates between the speed limits ω1 and ω2, then sensitiveness is defined

as the ratio of the mean speed to the difference between the maximum and minimum

speeds. Thus,

Hunting

If the frequency of fluctuations in engine speed happens to coincide with the natural

frequency of oscillations of the governor, then, due to resonance, the amplitude of

oscillations becomes very high, with the result that the governor tends to intensify the

speed variation instead of controlling it. Such a situation is known as hunting. The

problem of hunting becomes more acute when the sensitiveness of a governor is high,

i.e., when a change in speed causes a large sleeve movement. For example, an

isochronous governor (i.e., one that is infinitely sensitive) will oscillate between the

highest and the lowest positions if the speed deviates from the isochronous speed.

1994

Problem: Explain the phenomenon of hunting in centrifugal governors. Calculate the

natural period of oscillation of the governor balls considering Hartnell governor.

[IAS – 1994]

Solution: The free-body diagram of the bell-crank lever are shown in Diagram 5.16,

when the radius of rotation of the ball is r. Let

k = stiffness of the spring,

F1 = total force at the sleeve due to the weight of the sleeve and the spring,

m = mass of the ball,

F = controlling force of the ball,

p = distance of the pivot O from the axis of rotation,

b = length of the arm to which the ball is connected,

a = length of the arm connected to the sleeve, and

= inclination of the arms as indicated in Diagram 5.16.

For the present, we shall neglect the friction at the sleeve.

Taking moments about the pivot O, we have

Further, we see that F1 = F0 + ka sin , where F0 is the value of F1 with = 0, and

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 6

Solution of UPSC Papers of Theory of Mechanism and Machines By Brij Bhooshan 7

Using this value of F1 in (5.26), we get,

The equilibrium speed ω at any radius r is given by

where is found from (5.27) and F0 depends on the initial compression of the spring (by

initial compression, we do not necessarily mean the compression for = 0; it is the

compression of the spring at the lowest position of the sleeve).

To start with, let us neglect the moment of the weight of the ball, i.e., the last term in

(5.28), so that

For a Hartnell governor, to find meq, we use the fact that the kinetic energy of the ball

remains the same. If V is the actual velocity of the ball, then ẋ = V cos (see Diagram

5.16). Now,

From (5.27), we get

From (5.28), we get

Using (5.43), we find this equation becomes

Substituting the values obtained from (5.42) and (5.44) in (5.41), for a Hartnell governor,

we get

Problem: In the Proel governor shown in Fig. 2 each ball weighs 3 kg and the central

sleeve weight is 25 kg. The arms are of 20 cm length and pivoted about axes displaced

from the central axis of rotation by 37.5 mm, y = 238 mm, x = 303.5 mm, CE = 85 mm,

MD = 142.5 mm. Determine the equilibrium speed.

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 7

8 Solution of UPSC Papers of Governor Mechanisms

FC B

w

E

r

y

W/2

I M D L

x

3.75

[Engg. Services – 1994]

Solution: Given that: m = 3 kg, M = 25 kg, BE = ED = 20 cm = 0.2 m, y = 238 mm =

0.238 m, x = 303.5 mm = 0.3035 m, MD = 142.5 mm = 0.1425 m, CE = 85 mm = 0.085 m,

Radius of rotation

r = ML = MD + DL = 0.1425 + 0.0375 = 0.18 m.

Centrifugal force FC = mr2

FC = 5.92 × 103 N2

Taking moment about point I

FCy = mg × IM + Mg/2 × ID

5.92 × 103 N2 × 0.238 = 3 × 9.81 × (0.3035 0.18) + 25 × (9.81/2) × (0.3035 0.0375)

Then, we get N = 160.98 rpm.

1995

Problem: Explain the use of controlling force curves in the determination of stability of

a centrifugal governor.

[IAS – 1995]

Solution: In a centrifugal governor, the resultant of all the external forces which

control the movement of the ball can be regarded as a single inward radial force acting

at the centre of the ball. The variation of this force F with the radius of rotation of the

ball can be studied under static conditions by measuring the outward radial force on the

ball which is necessary to keep the ball in equilibrium at various configurations (i.e., for

different values of r). The force F is known as the controlling force and is a function of a

single variable r. Thus,

F = F(r) [5.1]

F B

C

F

D E G

r

A

r

Diagram 5.4

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 8

Solution of UPSC Papers of Theory of Mechanism and Machines By Brij Bhooshan 9

Diagram 5.4 shows a typical plot of the controlling-force characteristic (curve AB). The

controlling force is derived from purely statical considerations without reference to the

speed of rotation.

Now, let us suppose that the governor ball rotates at a speed ω. The centripetal force

needed for maintaining the radius of rotation r is given by mω2r, where m is the mass of

each ball. The plot of this force against r for a given speed ω will obviously be a straight

line passing through the origin as shown by the line OC in Diagram 5.4. So, the

equilibrium radius for this speed ω will be determined by the intersection of the curve

AB with the line AC (at the point D). For this value of r, controlling force will be equal to

the centripetal force. Mathematically, we can express this equilibrium condition as

F(r) = mω2r [5.2]

To determine the condition necessary for stability, suppose the speed of the governor be

ω at the equilibrium position given by the point D (Diagram 5.4). If the speed remains

the same, and if the radius changes to r + δr, the increment in the controlling force EF

will be (dF/dr) δr, and the corresponding increment in the centripetal force EG will be

EG = mω2δr. The restoring force FG on the ball is

FG = EF EG = (dF/dr mω2)δr

This should be greater than zero for the equilibrium position to be regained. Thus, for

stable operation, we get dF/dr > mω2. Using (5.2), we get

In other words, the condition for the stability of a governor is that the slope of the curve

for the controlling force should be more than that of the line representing the centripetal

force at the speed considered.

Problem: The arms of a Porter governor are pivoted on the governor axis and are each

250 mm long. Mass of each ball is 0.5kg and mass of sleeve is 2 kg. The arms are

inclined at an angle of 30° to the governor axis in the lowermost position, of the sleeve.

Lift is equal to 50 mm. Determine the force of friction if the speed at the moment the

sleeve starts lifting from the lowermost position is the same as the speed at the moment

it falls from the uppermost position.

[Engg. Services – 1995]

C C1

0.25 0.25

h1 h2

A r1 A1 r2

D D1

mg mg

B B1

Mg/2 Mg/2

Solution: Referring to Diagram 5.8, we have h1 = 0.25 cos 30 = 0.216 m, r1 = 0.25 sin

30 = 0.125 m.

If speed is same, then

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 9

10 Solution of UPSC Papers of Governor Mechanisms

Put e = 0, then

Similarly,

Put e = 0.05, then

Now, according to problem = , then we get

After solving, we get fr = 7.19 N.

1996

Problem: Define Effort and Power in relation to governors. Obtain the expressions for

these in the case of a Porter Governor.

[IAS – 1996]

Solution: Effort

A governor can exert force at the sleeve of the mechanism which controls the supply of

energy to the engine. This force is referring to effort of governor. When the speed of

rotation is constant then effort is zero as the sleeve does not move at all but if a sudden

variation of speed takes place then sleeve tends to move toils new equilibrium position

and a force is exerted on the sleeve mechanism. This force gradually diminishes to zero

as the sleeve moves to the equilibrium position corresponding to the new speed. The

mean force exerted during the given change of speed is termed the effort. For

convenience to compare different governor is defined as the effort or force that can be

exerted by a 1% change of speed.

Power

The power of a governor is defined as the work done at the sleeve for a given percentage

change of speed. It is the product of the governor effort and the displacement of the

sleeve. The power required depends on the controlling mechanism which the governor

operates. Where large power is required usually compressed air or hydraulic pressure is

used in order to change the position of the valve that controls the supply of energy to the

engine.

Analysis

Evaluation of governor effort and power is illustrated with the help of Porter governor.

The principle can be applied to any other governor in a similar manner.

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 10

Solution of UPSC Papers of Theory of Mechanism and Machines By Brij Bhooshan 11

Diagram 5.23 Governor Effort and Power

Suppose N = Equilibrium speed corresponding to the configuration as shown in Diagram

5.23, and k = Percentage increase in speed.

Increase in speed = kN

and increased speed = N + kN = N (1 + k)

The magnitude of this force may be determined by finding what increase is requited in

the gravitational force on the sleeve in order to cause the governor to revolve in

equilibrium in the full line position at the increased speed.

Let the angles θ and β be equal so that k = 1 and speed be N rpm. Then the height h is

given by Eq. 5.19

If the speed increases to (1 + k) N r.p.m. and the height of the governor remains the

same, the load on the sleeve increases to M1g. Therefore

using equations (i) and (ii), we have

Now mean force Fm,

Then effort is

Suppose x = Lift of the sleeve.

Then governor power (Pg) = Fm × x

If the height of the governor at speed N is h and at an increased speed (1 + k) N is h1,

then

Now we know that

then we have

Then x will be

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 11

12 Solution of UPSC Papers of Governor Mechanisms

Then power will be

1997

Problem: Deduce the condition under which a centrifugal governor becomes unstable.

[IAS – 1997]

Solution: In case of spring controlled governors, the controlling force curve will be

straight line, as shown in Diagram 5.6. i.e. they are isochronous. Then

r D2

C2D2 Unstable F = Ar + B

D CD Isochronous F = Ar

C2 D1 C1D1 Stable F = Ar B

C F

C1

Diagram 5.6

There are following points, for the stability of spring-controlled governors, may be noted:

For the governor to be stable, the controlling force (F) must increase as the radius of

rotation (r) increases, i.e. F/r must increase as r increases. Hence the controlling force

line C1D1 when produced must intersect the –ve rotation axis, as shown in Diagram 5.6.

The relation between the controlling force and the radius of rotation for the stability

of spring controlled governors is given by

F = Ar B [a]

where A and B are constants.

The value of B in equation (a) may be made either zero or positive by increasing the

initial tension of the spring. If B is zero, the controlling force line CD passes through the

origin and the governor becomes isochronous because F/r will remain constant for all

radii of rotation.

The relation between the controlling force and the radius of rotation, for an isochronous

governor is, therefore,

F = Ar [b]

If B is greater than zero or positive (CC2 – B) > 0, then F/r decreases as r increases, so

that the equilibrium speed of the governor decreases with an increase of the radius of

rotation of balls, which is not possible. So for governor is unstable, then

F = Ar + B [c]

Problem: In a spring controlled governor of the Hartung type, the lengths of the

horizontal and vertical arms of the bell crank levers are 100 mm, and 80 mm

respectively. The fulcrum of the bell-crank lever is at a distance of 120 mm from the axis

of the governor. Each revolving mass is 8 kg. The stiffness of the spring is 20 kN/m. If

the length of each spring is 120 mm, when the radius of rotation is 70 mm and the

equilibrium speed is 380 rpm, find the free length of the spring. If the radius of rotation

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 12

Solution of UPSC Papers of Theory of Mechanism and Machines By Brij Bhooshan 13

increases to 120 mm, what will be the corresponding percentage increase in speed?

Ignore sleeve mass.

[Engg. Services – 1997]

m = 8 kg

FC FS

A

0.012 m

0.1 m

Mg

0.08 m

O B

Solution: Given that: r = 0.07 m, N = 380 rpm, l = 0.120 m.

Taking moment about point O

(Mg/2) × 0.08 FS × 0.1 + FC × 0.1 = 0.

Neglect sleeve mass then, FS = FC

mr2 = kx

Then, we get x = 0.044 m.

The free length of spring is

lf = l + x = 0.12 + 0.44 = 0.164 m.

Final position r = 0.12.

Total compression of spring at final position is

x = x + (r r) = 0.04 + (0.12 0.07)

After solving we get r = 0.094 m.

Now, FC = FS, then

mr = kx

8 × 0.12 × =20 × 103 × 0.094

Then, 1 = 44.25 rad/s.

% increased in speed

Then, % increased in speed is 10.07%.

1998

Problem: The controlling force curve of a spring-controlled governor is a straight line.

The weight of each governor ball is 40 N and the extreme radii of rotation are 10 cm and

17.5 cm. If the values of the controlling force at the above radii are respectively 205 N

and 400 N and the friction of the mechanism is equivalent to 2.5 N at each ball, find:

(i) The extreme equilibrium speeds of the governor; and

(ii) The equilibrium speed and the coefficient of insensitiveness at a radius of 15

cm.

[IAS – 1998]

Solution: Since given controlling force curve of a spring controlled governor is a

straight line, then

FC = Ar + B [1]

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 13

14 Solution of UPSC Papers of Governor Mechanisms

Now, weight of ball mg = 40 N, m = 4.08 kg.

At r = 10 cm = 0.1 m, FC = 205 N.

At r = 0.175 m, FC = 400 N.

From Eqn. (1), then

205 = A × 0.1 + B

400 = A × 0.175 + B

After solving, we get A = 2600 N/m, and B = 55 N.

Extreme equilibrium speeds:

At r = 0.1 m, FC = 205 N

FC = mr

205 = 4.08 × × 0.1

Then, we get = 22.412 rad/s.

Now,

Then, we get Nl = 214 rpm.

For highest position

At r = 0.175 m, FC = 400 N

FC = mr

400 = 4.08 × × 0.175

Then, we get = 23.664 rad/s.

Now,

Then, we get Nu = 226 rpm.

Equilibrium speed with k = 0.15 m:

We have

This means that FC N2, then FC = kN

FC = Ar + B = 2600 × 0.15 55

FC = 335 N.

Suppose N be the equilibrium speed at r = 0.15 m, N, and, N be the speeds when the

sleeve tends to move upwards and downwards respectively.

FC = kN2 [2]

FC + kb = kN 2 [3]

FC kb = kN 2 [4]

kb is the equivalent force at the ball due to friction at sleeve = 2.5 N.

From Eqns. (3) and (4), we have

2 kb = k(N2 N2) [5]

From Eqns. (5) and (2)

Then we get insensitiveness

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 14

Solution of UPSC Papers of Theory of Mechanism and Machines By Brij Bhooshan 15

Insensitiveness is 0.0075.

1999

Problem: In a Hartnell governor where a central spring under initial compression is

used for control, under what conditions does the governor become unstable? Also explain

the effect of friction between the sleeve and spindle on the performance of the governor.

[IAS – 1999]

Solution: See the solution of IAS 1997.

Effect of friction between the sleeve and spindle on the performance of the governor:

For the analysis with friction, the force at the sleeve should be replaced by (P f), where

f is the friction force. Positive taken for rising speed, and, negative for falling speed.

Controlling force

2000

Problem: A watt governor has an arm of uniform section of length L and mass m and a

ball of mass M. Show that when revolving with angular velocity ω, it makes an angle θ

to the vertical, where

m

g M

2

cos

m

2 L M

3

[IFoS – 2000]

Solution: See the solution of Engg. Services 1990.

Problem: A governor of Proell type has each arm 250 mm. The upper and lower ends of

the arms are pivoted on the axis of the governor sleeve. Each ball has a mass of 15 kg

and attached to the extension of the lower arms which are 100 mm long. The minimum

and maximum radii of the governor are 125 and 175 mm. The central sleeve is of mass

75 kg. Determine the range of equilibrium speeds, assuming that the extensions of the

lower arms are parallel to the governor axis, at the minimum radius.

[Engg. Services – 2000]

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 15

16 Solution of UPSC Papers of Governor Mechanisms

P P

250

B h B h

FC FC

mg mg

100 100

F 125 G F 175 G

250

D D

I M I M

Mg/2 Mg/2

Solution: Given that: l = 250 mm = 0.25 m, m = 15 kg, r1 = 125 mm = 0.125 m, r2 = 175

mm = 0.175 m, M = 75 kg.

Now, from geometry

h = PG = [PF2 FG2]1/2 = 0.216 m.

FM = GD = PG = 0.216 m

BM = BF + FM = 0.1 + 0.216 = 0.316 m.

Now, we know that

Then, we get N = 130.35 rpm.

Again from geometry

h = PG = [PF2 FG2]1/2 = 0.178 m.

FM = GD = PG = 0.178 m

BM = BF + FM = 0.1 + 0.178 = 0.278 m.

Now, we know that

Then, we get N = 138.98 rpm.

Now, range is

= N N = 138.98 130.35

Then range is 8.63 rpm.

2001

Problem: In a spring controlled governor, mass of each governor ball is 7 kg and moves

radially under the action of a controlling force F If the speed range is 420 RPM to 440

RPM with range of ball path radius r equal to 12.4 cm to 13.2 cm, determine the linear

relationship between ball path radius and controlling force. Sketch the graph between F

and r. What is the equilibrium speed at r = 12.8 cm?

[IAS – 2001]

Solution: Given that: m = 7 kg, N1 = 420 rpm, 1 = 2N1/60 = 2 × 420/60 = 43.98

rad/s, N2 = 440 rpm, 2 = 2N2/60 = 2 × 440/60 = 46.07 rad/s, r1 = 12.4 cm = 0.124 m,

r2 = 13.2 cm = 0.132 m.

Now,

F1 = mr1 = 7 × 0.124 × 43.982 = 1678.92 N.

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 16

Solution of UPSC Papers of Theory of Mechanism and Machines By Brij Bhooshan 17

F2 = mr2 = 7 × 0.132 × 46.072 = 1961.13 N.

Given F = A + Br

F1 = A + Br1

1678.92 = A + 0.124B [1]

F2 = A + Br2

1961.13 = A + 0.132B [2]

After solving Eqns. (1) and (2), we get

A = 2695.33, B = 35276.25.

At r = 0.128, then

mr2 = A + Br

7 × 0.128 × 2 = 2695.33 + 35276.25 × 0.128

Then, we get = 45.06 rad/s.

Now, N = 60 × /2 = [60 × 45.06]/2

Then, we get N = 430.29 rpm.

2002

Problem: What is meant by haunting of governor? Explain briefly the causes of as

occurrence. Justify with reasons, whether it is more severe in ease of unstable governor

or isochronous governor

[IFoS – 2002]

Solution: See the solution of IAS 1992.

The problem of hunting is more accurate when the sensitiveness of a governor is high

this is when a change in speed causes a large sleeve movement. As isochronous governor

(infinitely sensitive) will oscillate between the highest and the lowest positions, if the

speed deviates from isochronous speed.

Problem: The total sleeve movement in a Hartnell governor is 3 cm. The mass of the

rotating balls is 1.5 kg each. At the mid-position of the sleeve, the sleeve arm, which is

6.5 cm long, is horizontal. The ball arm has a length of 7.5 cm. At the mid-position of the

sleeve, the balls rotate at a radius of 10.5 cm. Due to maladjustment of the spring, the

equilibrium governor speed at the topmost position of the sleeve is 415 r.p.m. and that

corresponding to the lowest position is 430 r.p.m.

Determine (i) the stiffness and initial compression of the spring and (ii) the required

initial compression of the spring to give an equilibrium speed at the topmost position

which is 10 r.p.m. more than that at the lowest position. Neglect the moment due to the

weight of the balls.

[Engg. Services – 2002]

r r2 = r1

FC r

r r2

y

y 3/2 cm

K/2

3/2 cm

x x

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 17

18 Solution of UPSC Papers of Governor Mechanisms

Solution: Given that: m = 1.5 kg, N1 = 415 rpm, 1 = 2N1/60 = 2 × 415/60 = 43.45

rad/s, N2 = 430 rpm, 2 = 2N2/60 = 2 × 430/60 = 45.02 rad/s, r = 10.5 cm = 0.105 m, x

= 6.5 cm = 0.065 m, y = 7.5 cm = 0.075 m, N = 10 rpm.

Stiffness and initial compression:

Now, from geometry

Then r1 = 0.122 m.

FC1 = mr1 = 1.5 × 0.122 × 43.452 = 345.48 N.

Taken moment about point O

FC1 y = K1x/2

K1 = [345.48 × 2 × 0.075]/0.065 = 797.26 N

Similarly again from geometry

Then r2 = 0.088 m.

FC2 = mr2 = 1.5 × 0.088 × 45.022 = 267.53 N.

Taken moment about point O

FC2 y = K2x/2

K2 = [267.53 × 2 × 0.075]/0.065 = 617.37 N

Then, stiffness of spring is

Stiffness of spring is 5996.33 N/m.

Now initial compression

= K2/K = 617.37/5996.33 = 0.102 m.

According to problem

N1 = N2 + N

1 = 2 + 1.04 [1]

Taken moment about point O

FC2 y = K2x/2

K2 = [2mr2 y]/x = [2 × 1.5 × × 0.088 × 0.075]/0.065

K2 = 0.304

Similarly

FC1 y = K1x/2

K1 = [2mr1 y]/x = [2 × 1.5 × × 0.122 × 0.075]/0.065

K1 = 0.295

Now, we know that

Total sleeve movement = [K1 K2]/K

K1 = K2 + 0.03K

K1 = K2 + 0.03 × 5996.33 = K2 + 179.88

0.295 = 0.304 + 179.88 [2]

Now, from Eqns. (1) and (2)

2 = 32.77 rad/s.

Then, K2 = 0.304 × 32.772

Then, initial compression

= K2/K = 326.45/5996.33 = 0.0544 m.

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 18

Solution of UPSC Papers of Theory of Mechanism and Machines By Brij Bhooshan 19

2005

Problem: An automobile fitted with a spring loaded Hartnell governor, the flyballs of it

rotate at 500 r.p.m. having radius of rotation of 7 cm with sleeve in mid-position and

balls arms vertical. The length of ball and sleeve arms is same. The maximum sleeve

movement is 2 cm with ± 5% variation in speed. The mass of the sleeve is 5 kg and the

friction may be assumed to be equivalent of an additional load of 30 N at the sleeve. The

effort of governor is sufficient to overcome the friction of the sleeve caused by 1% change

of speed at mid-position. Calculate -

(i) the mass of flyballs;

(ii) the spring rate;

(iii) the initial compression of the spring;

(iv) the governor effort for 1 % change of speed;

(v) the power of governor.

[IAS – 2005]

Solution: Given that: M = 5 kg, Fr = 30 N, x = y, h = 2 cm = 0.02 m, r = 7 cm = 0.07 m, N

= 500 rpm, = 2N/60 = 2 × 500/60 = 52.35 rad/s.

Mass of flyball: Min speed with friction

1 = 5/100 = 0.95

1 = 0.95 × 52.35 = 49.73 rad/s.

Max speed with friction

2 = + 5/100 = 1.05

2 = 1.05 × 52.35 = 54.96 rad/s.

The governor effect is to overcome the friction at the sleeve by 1 % change of speed at

mid position.

Min speed at mid position

= /100 = 0.99

= 0.99 × 52.35 = 51.84 rad/s.

Max speed with friction

= + /100 = 1.01

= 1.01 × 52.35 = 52.88 rad/s.

Centrifugal force at min speed

= m r = m × (51.84)2 × 0.07 = 188.11m N.

Centrifugal force at min speed

= m r = m × (52.88)2 × 0.07 = 195.74m N.

We know that

Maximum speed at mid position:

Fs = 391.48m 70.05 [1]

Maximum speed at mid position:

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 19

20 Solution of UPSC Papers of Governor Mechanisms

Fs = 379.22 m 19.05 [2]

From Eqns. (1) and (2)

379.22 m 19.05 = 391.48m 70.05

Then, we get m = 3.34 kg.

Spring Rate (K):

Min radius of rotation considering friction

Max radius of rotation considering friction

Centrifugal force at min speed with considering friction

FC1 = m r1 = 3.34 × (49.74)2 × 0.06 = 495.803 N.

Centrifugal force at max speed with considering friction

FC2 = m r2 = 3.34 × (54.96)2 × 0.08 = 807.10 N.

For maximum speed

For minimum speed

From Eqns. (3) and (4)

FS2 FS1 = 2(FC2 FC1 Fr)

FS2 FS1 = 2 × (807.10 495.80 30) = 562.6 N.

Now, we know that

K = (FS2 FS1)/h = 562.6/0.02 = 28130 N/m.

Now,

FS1 = 2FC1 W + Fr = 2 × 495.80 5 × 9.81 + 30 = 972.55 N.

Now, we have FS2 FS1 = 562.6 N.

FS2 = 972.55 + 562.6 = 1535.15 N.

Initial compression of the spring (x1):

x1 = FS1/K = 972.55/28130 = 0.034 m.

Governor effort for 1 % change of speed:

Now, we know that effort of governor is

Fm = 13.02 N.

The power of governor:

We know that P = Fm × h

P = 13.02 × 0.02 = 0.260 N-m.

2007

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 20

Solution of UPSC Papers of Theory of Mechanism and Machines By Brij Bhooshan 21

Problem: Explain the concept of controlling force in connection with a centrifugal

governor and state its importance in determining the stability of a centrifugal type

governor.

In a spring loaded governor of Hartnell type, the mass of each ball is 1 kg. The length of

the vertical arm of the bell crank lever is 100 mm and that of horizontal arm is 50 mm.

The distance of the fulcrum of each bell crank lever is 80 mm from the axis of rotation of

the governor. The extreme radii of rotation of the balls are 75 mm and 112.5 mm. The

maximum equilibrium speed is 5 per cent greater than the minimum which is 360 rpm.

Find initial compression of the spring and mass of the sleeve neglecting obliquity of the

arms. Also find the equilibrium speed corresponding to the radius of rotation equal to

100 mm.

[IAS – 2007]

Solution: See the Solution of IAS 1992, and 1995.

Given that: m = 1 kg, y = 100 mm = 0.1 m, x = 50 mm = 0.05 m, r = 80 mm = 0.08 m, r1 =

112.5 mm = 0.1125 m, r2 = 75 mm = 0.075 m, N2 = 360 rpm, 2 = 2N2/60 = 2 × 360/60

= 37.69 rad/s.

Maximum equilibrium speed is 5% greater than the minimum equilibrium speed, so

max speed is

1 = 1.052 = 1.05 × 37.69 = 39.57 rad/s.

Centrifugal force at max speed

FC1 = m r1 = 1 × (39.57)2 × 0.1125 = 176.15 N.

Centrifugal force at min speed

FC2 = m r2 = 1 × (37.69)2 × 0.075 = 106.54 N.

For maximum equilibrium position (M = 0)

Then, FS1 = 704.6 N.

For minimum equilibrium position (M = 0)

Then, FS2 = 426.16 N.

Lift of sleeve h is

Then, h = 0.01875 m

Now, we know that stiffness of spring

K = (FS1 FS2)/h = (704.6 426.16)/0.02 = 14850.13 N/m.

Initial compression of the spring (x1):

x1 = FS2/K = 426.16/14850.13 = 0.028 m.

Equilibrium speed at r = 0.10 m

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 21

22 Solution of UPSC Papers of Governor Mechanisms

Then FC = 152.94 N.

Now, we know that

FC = mr2 = mr × (2N/60)2

152.94 = 1 × 0.1 × (2N/60)2

After solving, we get N = 373.44 rpm.

2008

Problem: Classify types of governors. State what are methods used to increase

controlling force. Explain stability of Hartnell governor.

[IFoS – 2008]

Solution: Governors may be classified on the basis of their operating principles. The

types most commonly used are (i) centrifugal governors, and (ii) inertia and flywheel

governors.

Pendulum Watt governor

type governor

Centrifugal Dead weight Porter governor

governor governor Porell governor

Loaded type

Governor

governor Hartnell governor

Inertia Spring control Hartung governor

governor governor Wilson governor

Pickering governor

In the centrifugal governor, the change in the centrifugal forces of the rotating masses

due to a change in the speed of the engine is utilized for the movement of the governor

sleeve.

Problem: Differentiate between the functions of the flywheel and the governor.

[IFoS – 2008]

Solution: The function of a governor is to automatically regulate the power input to the

engine as demanded by the variation of load so that the engine speed is maintained at or

near the optimum value.

In otherworld’s, the function of a governor is to regulate the mean speed of an engine,

when there are variations in the load. This means that, when the load on an engine

increases, its speed decreases, therefore it becomes necessary to increase the supply of

working fluid. On the other hand, when the load on the engine decreases, its speed

increases and thus less working fluid is required. The governor automatically controls

the supply of working fluid to the engine with the varying load conditions and keeps the

mean speed within certain limits.

If the efficiency of an engine is plotted against the speed of the engine, a curve similar to

that shown in Diagram 6.1 is obtained. As can be observed, there exists an optimum

speed Nopt for which the efficiency of the engine is maximum. So, for an efficient

operation, it is desirable that, irrespective of the load, the speed of the engine should

remain close to Nopt. To achieve this, engines are provided with a regulatory control or

governor.

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 22

Solution of UPSC Papers of Theory of Mechanism and Machines By Brij Bhooshan 23

N Cyclic speed variation

controlled by flywheel

Governor control

Load Time

Variation

Diagram 5.1 Diagram 5.2 Function of Governor Vs flywheel

We know that, the function of governor is to maintain the speed of an engine with in

prescribed limits for the various altering load conditions. It maintains speed within set

limits right from no load on the engine to full rated load on the engine. The function of

governor is distinct from that of a flywheel. As we have seen in Diagram 5.2, a flywheel

smoothens the cyclic fluctuations of speed which are inevitable because of variations in

the turning moment on the crank shaft. Flywheel does not controlled speed variations

caused by a varying load.

2010

Problem: What is the difference between centrifugal and inertia type of governors?

Which one is more sensitive? Why is the former preferred to the latter?

[IAS – 2010]

Solution: See the Solution of IFoS 2008.

Problem: Show the controlling force vs. radius of rotation graphs for (i) Porter governor

and (ii) Spring-controlled governors, and discuss the stability considerations.

[IFoS – 2010]

Solution: See the Solution of IAS 1997, and 1995.

2011

Problem: The total sleeve movement in a Hartnell type of governor is 3 cm. At mid

position of sleeve, the sleeve arm which is 6 cm long, is horizontal. The length of ball

arm is also 6 cm. The speed at the lowest position is 430 rpm. If the spring stiffness is 50

N/cm, find the speed in rpm at the top position of the sleeve. At mid-span the ball

rotates at 10 cm radius. The mass of the ball is 1.3 kg.

[IFoS – 2011]

Solution: Given that: Sleeve movement = 3 cm =0.03 m, K = 50 N/cm, r = 10 cm = 0.1

m, m = 1.3 kg, a = b = 6 cm = 0.06 m, Nl = 430 rpm, l = 2Nl/60 = 2 × 430/60 = 45.02

rad/s.

Now, we know that

Then, = 8.8 cm = 0.088 m.

Then, = 11.2 cm = 0.112 m.

Centrifugal force at lowest position

Fl = m rl = Pla/2b

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 23

24 Solution of UPSC Papers of Governor Mechanisms

Then, we get Pl = 463.73 N.

Centrifugal force at upper position

Fu = m ru = Pua/2b

Then, we get Pu = 0.2912 .

Now, we know that stiffness is

K = (Pu Pl)/Sleeve movement

Pu Pl = K × Sleeve movement = 50 × 0.03

Now,

0.2912 463.73 = 1.5

Then, we get u = 39.97 rad/s.

Now, we know that

Nu = (u × 60)/2 = (39.97 × 60)/2

Speed at the top position Nu = 381.68 rpm.

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 24

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Solution Manual For Engineering Mechanics Statics and Dynamics 2nd Edition by PleshaDocument376 pagesSolution Manual For Engineering Mechanics Statics and Dynamics 2nd Edition by PleshaVenkat Dalai0% (5)

- Deflection of Curved BeamsDocument14 pagesDeflection of Curved BeamsStephen Mirdo82% (28)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Training Manual For Engineers On Solar PV SystemDocument258 pagesTraining Manual For Engineers On Solar PV Systemadmercano95% (22)

- The HY6801M Electric Leakage Relay Using Introduction: Edition v1.0Document10 pagesThe HY6801M Electric Leakage Relay Using Introduction: Edition v1.0Jon Chen0% (2)

- Eia Assignment NITPREETDocument39 pagesEia Assignment NITPREETNitpreet RandhawaNo ratings yet

- Assignment No 1: Metal Cutting and FormingDocument10 pagesAssignment No 1: Metal Cutting and FormingNitpreet RandhawaNo ratings yet

- Design Analysis and Performance of Low Cost Refrigeration System Using LPGDocument4 pagesDesign Analysis and Performance of Low Cost Refrigeration System Using LPGNitpreet RandhawaNo ratings yet

- Design Analysis and Performance of Low Cost Refrigeration System Using LPGDocument4 pagesDesign Analysis and Performance of Low Cost Refrigeration System Using LPGNitpreet RandhawaNo ratings yet

- Design Analysis and Performance of Low Cost Refrigeration System Using LPGDocument4 pagesDesign Analysis and Performance of Low Cost Refrigeration System Using LPGNitpreet RandhawaNo ratings yet

- Eia Assignment 2 NITPREETDocument22 pagesEia Assignment 2 NITPREETNitpreet RandhawaNo ratings yet

- GME1830551 NITPREET RANDHAWA Exp 4Document5 pagesGME1830551 NITPREET RANDHAWA Exp 4Nitpreet RandhawaNo ratings yet

- Assignment No 1: Metal Cutting and FormingDocument10 pagesAssignment No 1: Metal Cutting and FormingNitpreet RandhawaNo ratings yet

- Scribd 11Document1 pageScribd 11Nitpreet RandhawaNo ratings yet

- Scribd 5Document1 pageScribd 5Nitpreet RandhawaNo ratings yet

- Design Analysis and Performance of Low Cost Refrigeration System Using LPGDocument4 pagesDesign Analysis and Performance of Low Cost Refrigeration System Using LPGNitpreet RandhawaNo ratings yet

- Unit 7: A/D and D/A Converter: Lesson 1: Interfacing With The Analog WorldDocument20 pagesUnit 7: A/D and D/A Converter: Lesson 1: Interfacing With The Analog WorldAnonymous Ia9LPz100% (1)

- Scribd 6Document1 pageScribd 6Nitpreet RandhawaNo ratings yet

- Scribd 2Document1 pageScribd 2Nitpreet RandhawaNo ratings yet

- Scribd3 PDFDocument1 pageScribd3 PDFNitpreet RandhawaNo ratings yet

- Scribd 1Document1 pageScribd 1Nitpreet RandhawaNo ratings yet

- Castigliano S TheoremDocument19 pagesCastigliano S TheoremAhver ChaudharyNo ratings yet

- Nptel: Design of Machine Elements I - Video CourseDocument3 pagesNptel: Design of Machine Elements I - Video CourseNitpreet RandhawaNo ratings yet

- 3 - Dynamics Force and Motion Analysis of Plane MechanismDocument21 pages3 - Dynamics Force and Motion Analysis of Plane MechanismdoomraNo ratings yet

- Admission Notice (Academic Session 2019-2020) : Panjab University, ChandigarhDocument3 pagesAdmission Notice (Academic Session 2019-2020) : Panjab University, ChandigarhNitin BhardwajNo ratings yet

- mm2 PDFDocument10 pagesmm2 PDFNaresh YadavNo ratings yet

- Simulation Methods: DX X F PDocument7 pagesSimulation Methods: DX X F Papi-256504985No ratings yet

- 2019 20 Academic Calender UG PG ProgramDocument2 pages2019 20 Academic Calender UG PG ProgramNitpreet RandhawaNo ratings yet

- Result of AP MEDocument6 pagesResult of AP MENitpreet RandhawaNo ratings yet

- Chapter 5. System Reliability and Reliability Prediction.: Problems & SolutionsDocument29 pagesChapter 5. System Reliability and Reliability Prediction.: Problems & Solutionsdialauchenna100% (1)

- Academic Calander 2017 18Document1 pageAcademic Calander 2017 18Nitpreet RandhawaNo ratings yet

- Intrinsic Point Defects: VacanciesDocument23 pagesIntrinsic Point Defects: VacanciesNitpreet RandhawaNo ratings yet

- 5 2Document13 pages5 2vivekzzNo ratings yet

- Syllabus Gme-16 (Sem-5)Document6 pagesSyllabus Gme-16 (Sem-5)Nitpreet RandhawaNo ratings yet

- Department of Chemical Engineering Heat Transfer Lab (CHD-228)Document8 pagesDepartment of Chemical Engineering Heat Transfer Lab (CHD-228)prasoonNo ratings yet

- Composition and Resolution of Forces and Condition of Equilibrium of ForcesDocument13 pagesComposition and Resolution of Forces and Condition of Equilibrium of Forcesdevli falduNo ratings yet

- Fluid Mechanics Answer KeyDocument2 pagesFluid Mechanics Answer KeySeedy B Fofana100% (1)

- Electric Motor ModellemeDocument18 pagesElectric Motor ModellemeCanan DönmezNo ratings yet

- AVL HandoutDocument3 pagesAVL HandoutAkash ByjuNo ratings yet

- LHC at CernDocument96 pagesLHC at CernshehabthegreatNo ratings yet

- Thermal Properties of MatterDocument2 pagesThermal Properties of MatterRiya BhardwajNo ratings yet

- Pro/Ii Excel - Engine Unitid XXX: NcalDocument32 pagesPro/Ii Excel - Engine Unitid XXX: NcalYves-donald MakoumbouNo ratings yet

- Vladimir N. Yershov - Fermions As Topological ObjectsDocument8 pagesVladimir N. Yershov - Fermions As Topological ObjectsMopadDeluxeNo ratings yet

- RFET Calibration Tube Standerds & Signal AnalysisDocument33 pagesRFET Calibration Tube Standerds & Signal AnalysisJeganJjNo ratings yet

- Eepw 2150 Module 1Document51 pagesEepw 2150 Module 13nathNo ratings yet

- Lecture 22 Small Signal StabilityDocument24 pagesLecture 22 Small Signal StabilityManuelNo ratings yet

- TN 11th Chemistry Model Question Paper 2018 WWW - Governmentexams.co - inDocument9 pagesTN 11th Chemistry Model Question Paper 2018 WWW - Governmentexams.co - inJohn alexanderNo ratings yet

- Nema-C12.1 2008Document120 pagesNema-C12.1 2008Diego Ernesto Mariño SilvaNo ratings yet

- Descriptive Physical Oceanography An IntroductionDocument3 pagesDescriptive Physical Oceanography An IntroductionAnonymous xdDh30QONo ratings yet

- Exp. 2. Photo Electric EffectDocument6 pagesExp. 2. Photo Electric EffectMounika SaiNo ratings yet

- Microsensors and MicroactuatorsDocument46 pagesMicrosensors and MicroactuatorsShalan KosékarNo ratings yet

- GE 6163 - Physics Lab Manual PDFDocument21 pagesGE 6163 - Physics Lab Manual PDFsatya_vanapalli3422No ratings yet

- (Template) Physics Cls 12Document9 pages(Template) Physics Cls 12sreelakshmiNo ratings yet

- Flow VisualizationDocument6 pagesFlow VisualizationMuralikrishnan GMNo ratings yet

- SSP Ii CH 13aDocument12 pagesSSP Ii CH 13aAkil SundarNo ratings yet

- VTU Question Papers 18EE36Document7 pagesVTU Question Papers 18EE36VISHWANATH GNo ratings yet

- Jack Westin MCAT Content PhysicsDocument6 pagesJack Westin MCAT Content PhysicsLoraNo ratings yet

- ADAMS Getting StartedDocument24 pagesADAMS Getting Startedordenador90No ratings yet

- The Heat Transfer Across A 5" Wall of Firebrick Is...Document3 pagesThe Heat Transfer Across A 5" Wall of Firebrick Is...MelindaNo ratings yet