Professional Documents

Culture Documents

IVT Network - Facilities, Utilities, and Equipment - GMP-Critical vs. Business-Critical - 2014-03-14

IVT Network - Facilities, Utilities, and Equipment - GMP-Critical vs. Business-Critical - 2014-03-14

Uploaded by

Omar FaruqOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IVT Network - Facilities, Utilities, and Equipment - GMP-Critical vs. Business-Critical - 2014-03-14

IVT Network - Facilities, Utilities, and Equipment - GMP-Critical vs. Business-Critical - 2014-03-14

Uploaded by

Omar FaruqCopyright:

Available Formats

Published on IVT Network (http://www.ivtnetwork.

com)

Facilities, Utilities, and Equipment: GMP-Critical vs. Business-Critical

Jan 6, 2014 11:57 am EST

Courtesy of Getty Images

Within the complex facilities, utilities, and equipment (F/E/U) in a manufacturing plant, a line in the sand needs to be drawn

between GMP-critical and business-critical. While the process for identification has been discussed before, the following

are the differences between a GMP-critical and business-critical F/E/U, including the respective change management, taken

from a Jorge Cordero presentation given at IVT’s Validation Week Canada.

GMP-Critical

GMP-critical F/E/U have a direct impact on the safety, identify, potency-strength, quality, or purity of the product. This can, in

part, be determined by following the questions outlined at the beginning phase of identifying a GMP-project. Furthermore,

GMP-critical F/E/U will directly impact regulatory aspects of the manufacturing process; this includes activities such as

labeling, and evaluation, generation, archiving, and reporting data that is used for product release. GMP-critical F/E/U

maintain, control, and monitor environmental conditions to preserve product quality. They are also used to clean, sanitize, or

sterilize to preserve product quality. Some examples of GMP-critical F/E/U include bottle/cap molding machines, filtered

compressed air, ISO 5 cleanrooms, and inspection systems.

Business-Critical

Business-critical F/E/U are those elements that affect the ability to manufacture and operate efficiently; such as boilers, plant

steam, compressed air; or elements that affect customer satisfaction; such as cosmetic defects, failures in deliver on time, and

missing promotional material. They can also include systems that evaluate and monitor operation efficiencies as well as

equipment that helps improve operation efficiencies.

Business-critical F/E/U must comply with good engineering practices (GEPs). This requires:

Fitness to purpose, reliability, cost effectiveness.

A design following industry guidance and statutory requirements.

Consideration GMP, Environmental Safety & Health, ergonomic, operational, and maintenance requirements.

Proof of professional and competent design, construction, installation testing, and commissioning.

Appropriate documentation such as design concepts, as build drawings, manuals, certifications, maintenance

instructions, and test records.

Change Management

Regarding change management, any change to a GMP-critical F/E/U should be managed under the quality change control

system and should be evaluated by a multidisciplinary team. A change description, justification, risk evaluation, change plan,

and pre/post-approval should be included. It should follow the applicable project lifecycle, and qualification shall be performed

based on criticality of the F/E/U.

For business-critical change management, new F/E/U shall be evaluated and approved by engineering, operations, process

excellence, quality, and finance, as applicable. Any change will have to comply with GEP.

Source URL: http://www.ivtnetwork.com/article/facilities-utilities-and-equipment-gmp-critical-vs-business-

critical

You might also like

- 2007 - Isuzu - NPR - W3500, NPR HD - W4500, NQR - W5500 Diesel Electric - 46 PDFDocument24 pages2007 - Isuzu - NPR - W3500, NPR HD - W4500, NQR - W5500 Diesel Electric - 46 PDFPhil B.100% (2)

- SOP On Handling of DeviationsDocument10 pagesSOP On Handling of Deviationschemist_tma100% (1)

- Configuration Management for Senior Managers: Essential Product Configuration and Lifecycle Management for ManufacturingFrom EverandConfiguration Management for Senior Managers: Essential Product Configuration and Lifecycle Management for ManufacturingNo ratings yet

- Role of QC & QA in OperationsDocument6 pagesRole of QC & QA in OperationsmaheshNo ratings yet

- Engineering Documentation Control Handbook: Configuration Management and Product Lifecycle ManagementFrom EverandEngineering Documentation Control Handbook: Configuration Management and Product Lifecycle ManagementRating: 5 out of 5 stars5/5 (2)

- Adopting The Product Lifecycle ApproachDocument4 pagesAdopting The Product Lifecycle Approach刘朝阳No ratings yet

- MOC GuidanceDocument5 pagesMOC GuidanceSergiu Lung100% (1)

- Facility Validation: A New Approach: Process InvolvementDocument4 pagesFacility Validation: A New Approach: Process InvolvementsukmaNo ratings yet

- Change Control For Functionally Equivalent Like-For-Like ChangesDocument5 pagesChange Control For Functionally Equivalent Like-For-Like Changesdm_alvesNo ratings yet

- Medical Device Validation RadhaDocument27 pagesMedical Device Validation Radhas1a2d3f40% (1)

- VP Quality Operations Executive in Kansas City MO Resume Saul PachecoDocument3 pagesVP Quality Operations Executive in Kansas City MO Resume Saul PachecoSaulPacheco100% (2)

- Court of Appeal Handout On Writs Mandate Etc 9 Pages 8-13-13Document9 pagesCourt of Appeal Handout On Writs Mandate Etc 9 Pages 8-13-13traderash1020No ratings yet

- FDA 483 and Warning LetterDocument38 pagesFDA 483 and Warning LetterOmar FaruqNo ratings yet

- Fda-Process-Validation UpdateDocument5 pagesFda-Process-Validation UpdateLeyvert De JesusNo ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- 2.10 Risk-Based Qualification For The 21st CenturyDocument7 pages2.10 Risk-Based Qualification For The 21st CenturyJorge Humberto HerreraNo ratings yet

- Qualification Existing Equipment FinalDocument16 pagesQualification Existing Equipment FinalAjay Kumar100% (1)

- Change ControlDocument7 pagesChange ControlPrince MoniNo ratings yet

- SaivDocument5 pagesSaivRohith korrapatiNo ratings yet

- Validation Master PlanDocument29 pagesValidation Master Planspark80988100% (6)

- Inspection Readiness ExecSeriesDocument33 pagesInspection Readiness ExecSeriesOmar Faruq100% (3)

- Resume SnehaDocument2 pagesResume SnehaHardik ModiNo ratings yet

- A Case Study: A Process FMEA Tool To Enhance Quality and Efficiency of Manufacturing IndustryDocument8 pagesA Case Study: A Process FMEA Tool To Enhance Quality and Efficiency of Manufacturing IndustryBONFRINGNo ratings yet

- Development of Quality System For Engine AssemblyDocument55 pagesDevelopment of Quality System For Engine AssemblysvrbchaudhariNo ratings yet

- GMP Checklist For VeterinaryDocument89 pagesGMP Checklist For VeterinaryDoan Chi Thien100% (1)

- Lecture 3 - Change ManagementDocument66 pagesLecture 3 - Change ManagementZakir HussainNo ratings yet

- NMMU Validation Notes PRDocument14 pagesNMMU Validation Notes PRPhillip RautenbachNo ratings yet

- An Audit Approach To Address Microbial C PDFDocument39 pagesAn Audit Approach To Address Microbial C PDFOmar Faruq100% (1)

- Chilled Water PipingDocument34 pagesChilled Water Pipingapi-2599951798% (50)

- Commissioning Fundamentals 2 - Pharmaceutical Commissioning and QualificationDocument13 pagesCommissioning Fundamentals 2 - Pharmaceutical Commissioning and QualificationJoão Cavalcanti100% (2)

- HR SummitDocument7 pagesHR SummitAndreeaMare1984No ratings yet

- Preparing For Successful Design TransferDocument7 pagesPreparing For Successful Design TransferRahul Dhingra100% (1)

- Qualification of Equipment - A Risk-Based ApproachDocument6 pagesQualification of Equipment - A Risk-Based ApproachJorge Humberto Herrera100% (9)

- Error Detection and CorrectionDocument31 pagesError Detection and Correctionmarxx100% (2)

- Director Manufacturing in Greater Denver CO Resume Erik Van HornDocument2 pagesDirector Manufacturing in Greater Denver CO Resume Erik Van HornErik Van HornNo ratings yet

- ISPE ArticleDocument12 pagesISPE Articledrs_mdu48No ratings yet

- Willie Jolley - Turn Setbacks Into Greenbacks PDFDocument223 pagesWillie Jolley - Turn Setbacks Into Greenbacks PDFrama krishna100% (1)

- Preventing of Cross ContaminationDocument27 pagesPreventing of Cross ContaminationOmar FaruqNo ratings yet

- What Is Retrospective ValidationDocument2 pagesWhat Is Retrospective ValidationMarvel tumainiNo ratings yet

- Internship DiaryDocument9 pagesInternship DiaryS VasanthNo ratings yet

- Process Validation From An FDA Perspective - Part 2Document4 pagesProcess Validation From An FDA Perspective - Part 2Darren Tan100% (1)

- Strenght of Material ExplanationDocument7 pagesStrenght of Material ExplanationMohamed MostafaNo ratings yet

- SOP On Handling of DeviationsDocument9 pagesSOP On Handling of DeviationsBlueSaga100% (1)

- 10 GOLDEN RULES OF PICS, PHARMACEUTICAL, PHARMA, CGMP, PROJECTDocument19 pages10 GOLDEN RULES OF PICS, PHARMACEUTICAL, PHARMA, CGMP, PROJECTAmina SharimNo ratings yet

- DeCaris2007 RiskBasedEquipQualDocument12 pagesDeCaris2007 RiskBasedEquipQualTim WongNo ratings yet

- Router 6000 R17 Operation and Maintenance: Solution To ExercisesDocument84 pagesRouter 6000 R17 Operation and Maintenance: Solution To ExercisesAhsanSaleemNo ratings yet

- Dirty-Hold Time Effect On The CleaningDocument6 pagesDirty-Hold Time Effect On The CleaningOmar FaruqNo ratings yet

- (HTTPS://WWW - Lifetime-: How To Get Optimal Enterprise Physical Asset Utilization and Asset PerformanceDocument8 pages(HTTPS://WWW - Lifetime-: How To Get Optimal Enterprise Physical Asset Utilization and Asset PerformancekarimmebsNo ratings yet

- Siawan v. Judge InopiquezDocument5 pagesSiawan v. Judge InopiquezChimney sweepNo ratings yet

- Dev HanDocument9 pagesDev HanTuriyo AnthonyNo ratings yet

- Clause Wise Tutorials-7.1.4 Change Control ExplanationDocument2 pagesClause Wise Tutorials-7.1.4 Change Control ExplanationBharathNo ratings yet

- GMP Standard Operating ProceduresDocument13 pagesGMP Standard Operating Proceduresfagbemi.maNo ratings yet

- X02QSDocument7 pagesX02QStrungthanhnguyen_83No ratings yet

- Terotechnology SummaryDocument9 pagesTerotechnology SummaryWichard BendixNo ratings yet

- Pharmabeginers Com Investigation Tools GuidelineDocument31 pagesPharmabeginers Com Investigation Tools GuidelineSrinivasaRaoNo ratings yet

- Is RBT The New TQMDocument3 pagesIs RBT The New TQMroshan.gajeenkarNo ratings yet

- Cairosem09 Part 6Document9 pagesCairosem09 Part 6mohamed eissaNo ratings yet

- 326 Validation and Qualification Approach Outlined in New Annex 1 RevisionDocument8 pages326 Validation and Qualification Approach Outlined in New Annex 1 RevisionSandro SotomayorNo ratings yet

- Clean RoomsDocument4 pagesClean RoomsAtul SharmaNo ratings yet

- Validation SDFDocument4 pagesValidation SDFPatel VinayNo ratings yet

- Moorthy Murugan: CQV EingineerDocument4 pagesMoorthy Murugan: CQV EingineerVijay LS SolutionsNo ratings yet

- From Single To A Multiproduct Facility, Key ConsiderationsDocument8 pagesFrom Single To A Multiproduct Facility, Key ConsiderationsCathal DoranNo ratings yet

- Integrated Commissioning and Qualification: Saving Time and Money With TC II Q Lit Without Compromising QualityDocument42 pagesIntegrated Commissioning and Qualification: Saving Time and Money With TC II Q Lit Without Compromising QualityGirish KasatNo ratings yet

- Six Steps To Implement A Revised Standard Successfully - Compliance Navigator BlogDocument4 pagesSix Steps To Implement A Revised Standard Successfully - Compliance Navigator BlogDoaa KhalilNo ratings yet

- Pharmaceutical Validation: Why Is Validation Required?Document26 pagesPharmaceutical Validation: Why Is Validation Required?raju niraulaNo ratings yet

- Pharmaceutical Process Validation ThesisDocument8 pagesPharmaceutical Process Validation Thesisafkogftet100% (1)

- Las June 1Document4 pagesLas June 1Vengie MejosNo ratings yet

- Auditando Un Sistema ValidacionDocument8 pagesAuditando Un Sistema ValidacionIglesias LauraNo ratings yet

- Industrial Pharmacy-2 UNIT-1Document16 pagesIndustrial Pharmacy-2 UNIT-1dwivedishrishti18No ratings yet

- M4 - Lesson 1 - Introduction To Process ValidationDocument4 pagesM4 - Lesson 1 - Introduction To Process ValidationWilliam DC RiveraNo ratings yet

- Maximizing Efficiency and Compliance: Essential Tips For Conducting An Effective Annual Product Quality Review (APQR)Document10 pagesMaximizing Efficiency and Compliance: Essential Tips For Conducting An Effective Annual Product Quality Review (APQR)aniaaa220No ratings yet

- Mohammed HaseebDocument5 pagesMohammed HaseebAbdul samiNo ratings yet

- What Is The Difference Between Qualification and ValidationDocument7 pagesWhat Is The Difference Between Qualification and ValidationAnil Chowadary Anil ChowadaryNo ratings yet

- Cipla Limited - Warning LetterDocument7 pagesCipla Limited - Warning LetterOmar FaruqNo ratings yet

- Cleaning ValidationDocument40 pagesCleaning ValidationOmar FaruqNo ratings yet

- Risk Assessment ChecklistDocument1 pageRisk Assessment ChecklistOmar FaruqNo ratings yet

- Three Times and Were Alright ReplicatesDocument5 pagesThree Times and Were Alright ReplicatesOmar FaruqNo ratings yet

- Operation of Sterility Testing Isolators and Validation IssuesDocument44 pagesOperation of Sterility Testing Isolators and Validation IssuesOmar FaruqNo ratings yet

- NGVF 2016 D1.T1.3.1 Trevor Schoerie EU GMPS Impact On Australian GMPDocument34 pagesNGVF 2016 D1.T1.3.1 Trevor Schoerie EU GMPS Impact On Australian GMPOmar FaruqNo ratings yet

- Incident Management System Checklist - SafetyCultureDocument17 pagesIncident Management System Checklist - SafetyCultureOmar FaruqNo ratings yet

- Human Resources Division, Renata Limited: Standard Operating Procedure (SOP)Document3 pagesHuman Resources Division, Renata Limited: Standard Operating Procedure (SOP)Omar FaruqNo ratings yet

- Usp 1116 Pres Mar 2016Document40 pagesUsp 1116 Pres Mar 2016Omar FaruqNo ratings yet

- ECA How To Pass Auditor 2011Document6 pagesECA How To Pass Auditor 2011Omar FaruqNo ratings yet

- Activity Plan (11 11 2019)Document1 pageActivity Plan (11 11 2019)Omar FaruqNo ratings yet

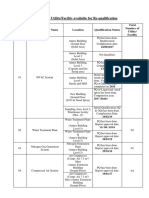

- Number of Utility For RequalificationDocument2 pagesNumber of Utility For RequalificationOmar FaruqNo ratings yet

- Daily Activities Plan of Microbiology Personnel (Cephalosporin Facility) Dated On 11.11.2019Document1 pageDaily Activities Plan of Microbiology Personnel (Cephalosporin Facility) Dated On 11.11.2019Omar FaruqNo ratings yet

- SL No. Name of Activity Details of Activity Start Time End Time SignDocument1 pageSL No. Name of Activity Details of Activity Start Time End Time SignOmar FaruqNo ratings yet

- Blended Learning ElcDocument8 pagesBlended Learning ElcZack DanialNo ratings yet

- Glass - Philip - Music in FifthsDocument8 pagesGlass - Philip - Music in FifthsH RavelNo ratings yet

- Labor CasesDocument8 pagesLabor CasesMhelanie WilliamNo ratings yet

- Marketing Plan On HTC OneDocument20 pagesMarketing Plan On HTC Oneharsh_desai2429No ratings yet

- Epson Aculaser Cx16nfDocument26 pagesEpson Aculaser Cx16nffefotroncitoNo ratings yet

- CD Breckenridge Military Bio 2013Document1 pageCD Breckenridge Military Bio 2013api-224028536No ratings yet

- Laptop AsdDocument2 pagesLaptop AsdJoão KaraśNo ratings yet

- The History of PencilDocument6 pagesThe History of Pencilquỳnh hảiNo ratings yet

- Bondgraph To Transfer FunctionsDocument19 pagesBondgraph To Transfer FunctionskkkprotNo ratings yet

- d2 ChillerDocument3 pagesd2 ChillerPranay SawantNo ratings yet

- 8612 - 1 Spring 2019-1Document15 pages8612 - 1 Spring 2019-1Engr GM SialNo ratings yet

- Shuddhikaumudi Lesson19 07102017Document6 pagesShuddhikaumudi Lesson19 07102017AdiNav PabKasNo ratings yet

- Catalogo-Bistos Ingles PDFDocument5 pagesCatalogo-Bistos Ingles PDFAlexander Guzmán HerreraNo ratings yet

- 3-Year SoW End of Term 1 Foundation Test AnswersDocument5 pages3-Year SoW End of Term 1 Foundation Test Answerslucas0% (1)

- Los Angeles Elementary SchoolDocument2 pagesLos Angeles Elementary SchoolFe VelezNo ratings yet

- Nationality Act of 1940-Ch4 S401-410Document4 pagesNationality Act of 1940-Ch4 S401-4100x2f551e6371No ratings yet

- Unilever Sustainable Living Plan India 2011 Progress Report Tcm114 241468Document16 pagesUnilever Sustainable Living Plan India 2011 Progress Report Tcm114 241468Jagwant SinghNo ratings yet

- 2537 VD4G-50 Vacuum Circuit-Breaker GBDocument4 pages2537 VD4G-50 Vacuum Circuit-Breaker GBburvanov0% (1)

- National Day Supplement 10 Gems MarketDocument9 pagesNational Day Supplement 10 Gems Marketjanitha_dNo ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)