Professional Documents

Culture Documents

ShopNotes 052 Derevyannoe Kruzhevo

Uploaded by

chrix100%(1)100% found this document useful (1 vote)

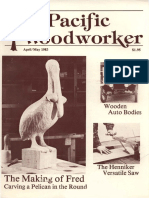

20 views32 pagesOriginal Title

ShopNotes_052_Derevyannoe_Kruzhevo

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

20 views32 pagesShopNotes 052 Derevyannoe Kruzhevo

Uploaded by

chrixCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 32

eee eee es

shopNc

f Build this knock

; down workbench”

in a weekend

Learn the basics |

Df.chip carving 7

7 simple steps

to tune Up your

radial arm Saw

Easy-to-build jig

for cutting perfect

miter joints ona

radial arm saw

www.shopnotes.com

Issue 52 July 2000

puousuer Donald B. Peschke

‘prroR Tim Robertson

associate emirer "Tor Bagal

assisuereorron Zrvan Nelzon

‘anrinccron Cary Christensen

‘snonariepesienen Kurt Sele

‘stmonmiustesrons Roger Relland

‘Marc Higdon

te pe et ae

comrn aia ire te:

Sees Soe

Serene iments

optic otal

spin rab ote

Sper Sra te separ

Ema Sea

een

seated tear

ee ed

sega ote

acetal!

ate ane

see ema

Tete lohan ear

femunes Sram te Naet

Pag corer

Sri

Roiterlon ie ana

Seer mayen

poorer race

cee eran:

Sa Se

erations Diner Ba Dar» Costner Serine

‘fag deme os» Warts Sep Na

Dove pdt te we ee ee

‘Am Cex Tuer Debuah Ric A

‘Rava cnt Verne gina, Da

Se Shere

Manager Dara Soe Sif WexdlSteneJ

‘am ey Si Cany Moen, Te

{in ai Bn fr Mo

Speen ig er

‘Raking, 2800 Smt er Mac, LAGS

eee eee

ee ee

ee

pee ea arog

eee eee

fees teeta oce

Postmaster’ url chang of recto Sheps, BO.

as

aps, FAX 6IG2-T a

ee

aes

PRINTEDINUS.A.

ETT

Cutoffs

Fen you think of a work-

bench, what often comes to

mind is a classic, European-style

bench, Chanees are it has a sturdy

base with lots of storage, a thick,

hardwood slab for a top, and heavy-

duty vises to clamp work in place,

There's no doubt about it, This

type of bench is a great addition to a

woodworking shop. But let's face it.

{t's big and heavy, s0 it sits in one

place most of the time, (My work

‘bench has been a

permanent fixture A bench in a box .

new twist to a traditional

hand tool. Two simple

Thats okey a8 solutions from our shop.

in my shop for

‘moro years than I

can remember)

Jongas Inever have

to move it around. But sometimes Pa

like to be able to use 2 workhench

outside the shop. Of course, dragging

a massive bench out to the garage or

‘back yard isn't very practical. So T

usually set up a couple of sawhorses

touse asa makeshift worksurface.

The only problem is there never

seems to be a good way to clamp

things in place, So T often end up bal-

aneing a workpiece precariously on

the sawhorses, holding it with one

hand, and making a less than perfect

ceut-with the other.

‘What I needed was asmal, portable

workbench — one that had a lot of

the same clamping features I'd come

‘to appreciate on my full-size beneh,

Besides being portable, there were

a number of other requirements for

‘tho bench, It had to be inexpensive

and easy to build. Plus T wanted 2

strong, stable bench that wouldn’ tip

over. Then T added one last item to

amy list. It had to “knoek down” for

storage to make iteasy to carry around,

Well, it was starting to sound like

ShopNotes

an awfully long “wish list,” and atone

point [began to wonder fit was even

feasible. But when T mentioned the

‘dea to our designers, they had lots of

good suggestions to make it work.

Knock-Down Workbeneh - If you

look at the front cover, you'll see how

cour knock-down workbench turned

out, Its made from a single sheet of

4" plywood which reduces the cost

considerably. And the holes and slots

peppered across the benehtop pro-

vide @ number of

different damping

options, Finally, it

canbe “Knocked

down” and stored

in a box that you

carry like a suit-

case. (Think of tas a bench in a box.)

Is it Sturdy? That sounds great

But is a knoek-down bench sturdy

‘enough? To find out, we conducted a

highly scientific test — two of the

_guys climbed on top and stood on it.

Fortunately, the bench was as solid

and sure-footed as @ mountain goat.

Saw Handle - Another project in

thisissue that provided an interesting

challenge is making a replacement

handle for a carpenter's hand sav 1

bought the saw at a second-hand

store, and since the handle wasin rough

shape, I decided to make a new one.

wanted it tolook like a traditional

saw handle with a graceful, eurved

shape. That sounded simple enough.

Yd just eat a ehunk of wood to shape

and stick in the saw blade,

But there was a eateh. The blade

fit into a very thin slot in the old

handle that must have been eut by &

specialized tool (one I certainly didn't

have). So as it. turns out, T took a

rather unorthodox approach to make

a traditional looking handle.

- anda

e Contents

Features

Adjustable Miter Jig____._______6

This shop-made jig makes it easy to cut perfect 45° miters

(on a raakal arm sav It features @ short and a long pair of

fences for different length workpieces, an aojustable stop

{or consistent results, and a hold-down to make cuts safely.

Radial Arm Saw Tune-Up____ 12

A\l takes to improve the performance of your radial asm

ssavr is @ simple tune-up. We show you seven quick steps

to producing smooth, accurate cuts.

Knock-Down Workbench______ 16 &

Whether you use this plywood bench to build a woodworking: ‘Reco oa: Wor wbencis 7gae

projector deck inthe back yar, is tree different clamping xs

‘options are sure to came in handy. Once you complete ab,

e ‘tonly takes @ minute to “knock down’ the bench for storage.

Cherry Saw Handle ____24

The graceful curves and the carved wheat patter of this

cherry saw handle resemble a traditional design. But to

simpilly the construction, we've iaken @ unique approach

to fitting the saw blade into the handle.

ChipiCarving..._____- 28

You can add an old fashioned accent to your saw handle 2

by using a chip caring kifetomake sions of wheal. Wah «Saw Handle fe page 24

a lite bit of practice and a few help hints, you'l be chip

carving ike apron no tine

Departments

Readers ipa ee. sd

(Our readers offer thelr own shop-tested tips dealing with

some of the most cammon woodworking problems.

rr couices® se

Mail-order sources and supplies to help you build the projects

featured in his sve Chip Carving page 28

No. 52 ‘ShopNotes 3

TIPS & TECHNIQUES

Readers’ Tips °

Knock-Down Sawhorses.

ap suet

WA set of sahorses always comes

in handy — until you put them away.

Then they're a nuisance. The legs

splay out, they're hard to stack, and

they take up valuable space. oH,

So recently, I built a pair of

sawhorses that “knock down" for SHORT

storage. Besides saving space, these ION

sawhorses can be assembled. (or

taken aper) in just afew seconds

‘A The interlocking Ifyou look at the drawing atright,

parts ofthis itseasy to see how this works. Each pa sir

sawhorse prevent it sawhorse consists of along stretcher

trom racking, Plus that fits down into a notch in two A-

they provide a way shaped supports. used Ixt pine)

foknock down the To prevent the sawhorse from

sawhorse for racking, there are four small cleats

pact storage. near each end of the stretcher (00

on each side). These cleats are

spaced far enough apart to form a

channel that fits down over the sup-

ports and “Iocks” the stretcher in

place. (You can see tis interlocking,

connection inthe photo above) Both ends of the legs and braces to seta square on the angled end of

Once the cleats are glued and are mitered at a 15° angle. Also, to thee and mark alin that's equal in

screwed in place, it's justamatter of form the notch that accepts the length to the width of the stretcher.

‘making the two Supports. Bach sup- stretcher, youll need to trim the fp After trimming off the waste, just

port consists of two angled lags that inside corner ofeach leg at an angle, — glie and serew the supports together.

are held together with four braces (a as shown inthe deal above WER. Richardson

Jong and short brace on each side). An easy way to lay out this angle i Great Falls, Montana

LONG Brace

ener)

Quick Tips

‘A Horo’ a simple pencil tay for your & At a glance, its dificult to tall if ak Tomake a “holster” fora cordless ctl,

‘shop. Adolph Peschke of Des Moines, caster is locked or not. So P. A. Jones Terrence MoGinty of Sutions Bay, Mi

1A cuts @ scrap PVC pipe cown its of Seattle, WA paints the “lock lever removes the bottom from a plastic botle

fongth and glues the halves together. red and the “release” lever green. and serews the cantainer to his bench.

4 ‘ShopNotes No. 52

Installing Hinges

ve nit

pes Ga eat oad

attach one leaf of the hinge to the

box easily enough. But locating the

ee ane,

eee

One solution is to use hot glue to

ine

lid. The only problem is the glue often

dries before you can align the lid on

the box. So I use a simple trick to

‘quickly and accurately position the lid

eee

Start by screwing one leaf of the

hinge to the box. Then use hot giue

to attach small scrap blocks to the

front and sides of the lid, as shown in

the drawing. Note: These scrap blocks

should stick down past the lid so

they fit snugly around the box.

After shimming the leaf of the

hinge with a piece of cardboard, apply

Plastic Runner.

Finishing Fix

TIPS & TECHNIQUES

FREE

Online Tips

you'd like even

more woodworking

tips, the solution

is simple. Just

vist us al our

website and sign

up to receive &

free tip via oma

every week

\wirwShoplotes.com

a dab of hot glue (detail a’). Then

‘quickly ft the blocks on the lid down.

over the box. When you open the lid,

the leaf of the hinge is stuck in its

proper location, so it's easy to mark

the mounting holes (detail ¥). Note:

After removing the scrap blocks,

sand any excess glue off the id.

Joe B. Drane

Yigo, Guam

1 Many of the jigs used on a table

‘saw have a runner

‘that slides in the miter

szauge slot. Typically, these runners are mad of

hardwood, But recently I started using another type

‘of material like even better — plastic.

One nice thing about a plastic runner (lke the one

shown at lef) is it wont swell or shrink with changes in

‘humidity. Sit sides smoothly without binding. Pius plastic

is readily available. As you can see inthe photo atight, I

just cuta narrow strip from a plastic eutting board.

Its easy to repair a small nick or

a scratch in a piece of furniture

that’s already had a finish applied.

Al it takes is a brown (or black)

permanent marker.

After choosing a marker that most

‘closely matches the color ofthe wood,

scribble the marker across the nick

and wipe off the excess, Note: There's

no need to touch up the finish.

George Reid

Dayton, Ohio

ShopNotes

Jerry Long

Silver Lake, Wisconsin

Send in Your Shop Tips

you have a unique shop ti, we'd like

‘toconsider featuring itin one or more of

‘our print or electronic publications.

We'll pay up to $200 for a tip we pub-

lish. Just write down the tip and mail it

to ShopNotes, Attn.: Readers’ Tips, 2200

Grand Ave, Des Moines, IA 50812. Or |

FAX it to 5152826741, or send us an

email at shopnotes@shopnotes.com.

Please include your name, address

and daytime phone number in case we

have any questions. |

ee

bouste THis

De RaNEE TS peTeRMINE

TRON OF BREE

1g to cut a miter joint on a radial arm saw can be

ab afrustrating experience. Asyou swing the arm first

toone side and then the other to cuteach miter, it may not

always return to a perfect 45° setting. Unfortunately, you

‘may not even notice that the cut is “off” unt it’s too ate

So to make it easy to cut tight-fitting miter joints

‘quickly and accurately, I made a simple jig that clamps to

the table ofthe radial arm saw. (See photo above.)

Fences ~ This jig has two fences that are used to post

tion a workpiece at 45° to the saw blade. So instead of

swinging the arm to the side, the idea isto leave it set at

90°, This way, as you pull the head of the saw across the

‘workpiece, the blade trims the end ata perfect 45° angle.

The fences are designed to slide back and forth. The

{ence that’s in use is moved all the way forward to support

the workpiece close to the blade. The other fence is slid

back to provide clearance for the end of the workpiece.

Perr 7

AUXILIARY ©

efron

Seay

6 ShopNotes:

Rae eT.

roar

Accessories ~ In adiion tothe fences, there are two

accessories that help simplify cutting a miter joint. A stop

Dock that attaches to ether fence ensures that each pair

‘of pieces is mitered to the same length. And a haldédowon

‘keeps your hands safely away from te blade during cat.

Auniliary Fence ~ Before you bild the ig, there's one

thing to take care of fist. To prevent small cutoff pieces

from getting jammed against the fence and thrown back

by the saw blade, ifs important to install an auxiliary

fence in your radial arm saw: As you can see in Figure 1,

the auiiary fence [used isa piece of "thick pine with

along notch that provides clearance forthe culo pieoes.

BASE

‘The base of the miter jg acts as a mounting platform for

the two fences, Plus it has a couple of T'shaped slots that

provide a way to attach the holddown.

‘Two Layers - To make it easy to form the T'slots, the

base is made up of two layers of material: a bottom piece

made of #" MDP and a 34" hardboard top (Figure 1)

One part of the T'slot will be cut in each piece.

‘Size ~ But first, you'll need to determine the size ofthe

base. I wanted itto be flush with the Jf end and front edge

ofthe sawtable, (It's easierto clamp itto the table that way)

So [made the base twice as long as the distance from the

blade to the end of the table (Figure 1). As for width, it

‘equal the distance from the fence tothe front edge.

‘Bottom ~ At this point, you can cut the bottom (A) of

the base to size. Then, to form the lower part of the T:

slot, you'l need to cut two stopped dadoes. These dadoes

accept the head ofa toilet boltused to attach the hold-dawn.

‘So what's the purpose in cutting stopped dadoes? Why

not extend them all the way across? Because the hold

dovm only needs to be adjustable toward the outer part of

the base, Asa result, the slots run about halfway across.

Assimple way to cut these dadoes is to use a hand-held

No. 52

PERT

router and a "straight bit. Start by

clamping a scrap fence to the work-

piece to guide the base of the router

(Figures 2 and 2a). Its also a good

idea to clamp a stop block to the

‘workpiece to establish the end of the

dado. Now adjust the depth of cut,

‘urn on the router, and make a pass

from left to right until the router

‘base contacts the stop block.

Since the dado is Ys" wide, youll

need to reposition the fence and

‘make a second pass to remove the

resto the waste material, Then repeat

the process io cutthe second dado.

‘Top — With the dadoes complete,

you can add the hardboard top (B).

Is best to start with an oversize

piece (about ¥" all the way around).

“Then after giuing it on with contact

ccement, trim the edges flush with a

hand-held router and flush trim bit.

‘Now it’s time to complete the T-

slot by routing @ narrow, stopped

dado in the top Figure 2). Here

again, used the same basic routing

procedlure. Only this time, the slotis

senreh esl

ay HARROD)

©

Sha! wide, so T used a 34" straight bit

‘and mace a couple of passes to

center the dado over the one below.

Guides ~ The next step is to add

‘two angled guides (C) to the base

(Figure 3). These are narrow strips of

hardwood that position the fences at a

45° angle to the blade, In use, the

fences fit over the guides which allows

you to slide them back and forth.

‘To ensure accurate results, the

guides must be at a 45° angle to the

bback edge ofthe base. So what's the

ShopNotes,

best way to lay out the angled lines

cused to position the guides? A little

bit of geometry is just the ticket.

‘The idea is to lay out a right

fsosecles triangle. If you need a

refresher, that's a triangle that has

one 90° angle and two equal sides.

‘This means that the other two angles

of the triangle must be 45°.

‘So to lay out the angied lines,

mark a point centered on the length

of the base and measure the distance

to one end. Thisis one side of the t=

angle. (It's shown as dimension ‘A’ in.

Figure 3,) Nowlay outthe second side

and mark another point. Connecting

the two points creates the third side

of the triangle and the two 45° angles.

Attach Guides - At this point,

you can glue and screw the runners

along the layout lines. Just be sure

they don't slip out of alignment as

‘you tighten the screws.

‘T-Nuts - There's one last thing to

do to complete the base. That's to

install a pair of Tats in the bottom

of the base. Later, these Tuts

accept a threaded knob that's used

to clamp the fences to the guides.

‘The T-nuts are centered on the

length and width of the guides. But

since they're installed in the bottom

of the base, the trick is locating the

centerpoints of the counterbored

shank holes forthe Fnuts.

“To do this startby diling a small

pilot hole in each guide (Figures 4

and 4a). Then flip the base over and

use the point where the bit cut through

as the centerpoint ofthe counterbore

(Figure 4b). Now simply drill the shank

hole (Figure 4c) and install a T-nut.

i

Fence System __

eH

erarinon

CRE SSB

wither

——~sror

BLOCK

ae,

- ara thos,

4 ora NSEe)

itt

)

wie

BETATEND OF FENCE,

‘The heart of this miter jig is a thereis one thing tokeepin mind, _‘Two Layers — Regatilless oftheir

| Hardware | stwletence system ttconsists ofa To cut pairs of mitered pieces to length, exch fence is made up of 00

pair of adjustable fences that are identical length, there's a stop block — differentlayers of material (Figure 6).

(fant Fa used to position a workpiece at a that slides along a Telot in the A %'thick hardwood body fits over

ES perfect 45° angle to the saw blade. fence. Setting the stop block all the the guides on the base. (used

Rea Fence Length -There’s nothing way at the end of the T'slot allows maple.) And there's a top face made

+()5%e"Washere | citical about the length ofthe fences. you to miter pieces up to 22" long. If of ¥4" hardboard. As with the base,

*(2)%e'steckrobs | The two fences shown in Figure are you plan to work with longer pieces, this double layer type of construc.

tr bad) 24 long, so they provide plenty of its a good idea to make a pair of tion will make it easy to form the

+2)" tar srobe | support for most work. But when extrelong fences as shown in the ‘T-shaped sltsin the fence.

“fee determining the length ofthe fences, photo on page 9. Body ~ I began by making the

ge sees body of each fence. It’s worth taking

rung Jb

a ttle extra time and being a bit

picky when selecting wood for the

ody. ‘To prevent the fence from

‘warping or twisting, be sure to use a

piece of straight grained stock that's

free of knots or other defects.

Once you've selected the lumber,

the frst step isto rip enough stock to

‘width to make the desired number of

pieces. Then simply crosscut the

pieces to final length to make the

body (D) of each fence.

‘TSlot - Now you can turn your

attention to the T'slot. The first part

of this slot is formed by cutting a

wide, shallow groove in the body of

the fence (Figure 6a). This groove

accepts the head of a toilet bolt that

uides the stop blockin the slot.

Before cutting the second part of

ShopNotes

No. 52

the Tslot, you'l need to add the

hardboard top face (B). Eventually, it

ends up the same size as the body.

But is best to start with a piece

that’ slightly oversize (about 4" all

the way around). Then, after gluing

it onto the body ofthe fence, you can

trim the overhanging edges flush.

Here again, it only takes a minute

to remove the waste, Just mount a

‘lush trim bitin the router table, and

adjust the height of the bit so the

bearing rides against the body of the

fence (Figure Gb). Then rout all four & Long Fenoes. As an option, you may want to build a pair of 48long

sides to produce a clean, crisp edge fences o use when mitering extra-long workpieces. With the stop block

athe way around. set at the end of the fence, you can cut pieces up to 46" ong,

‘To complete the Tot, it’s just a

matter of cutting a narrow groove in the photo above, the left fence is table sawand make several passes to

the top face that’s centered over the moved all the way forward to pro- “sneak up” on the perfect fi. Just be

wide groove underneath (Figure vide support for the workpiece up sure to check the ft frequently as

0). This groove provides clearance close tothe saw blade. But to allow you work

for the shank of the toilet bot. the end of the workpiece to extend Adjustment Slot ~ Once you're

‘Wide Groove -In dition to the _pastthe fence onthe right, thatfence satisfied withthe fi, the next step is

‘Telotin the top ofeach fence, there's _isli all the way back to cut along adjustment slot in each

also awide groove in the bottom. As Even though the fences move fence. As you can see in Figure 5,

you can see in Figure 9, the groove back and forth, you don't want any this slot provides clearance for a

fits over the hardwood guides that extra sideto-side “play.” (That could plastic knob with a threaded shank

‘were installed earlier in the base. change the 45° angle of the fence) that’s used to lock the fence

‘These guides are lke a “key” that So when cutting the groove, the goal Ifyou look at Figure 5a, you can

automatically positions the fence at isa snug fit that stllalows the fence see thatthe knobs thread into the T

45° to the saw blade. toslide smoothly onthe guides, nuts that were installed cartier in the

‘Another purpose of the groove is An easy way to accomplish that is base. As you recall, these T-nuts are

toallow the fence to sideforward or shown in Figures 7 and 7a. The idea centered on the width ofthe guides,

back on the guide. For example, in is to mount a ¥" dado blade in the This means the adjustment slot also

needs to be centered on

onAIRTESSEEARAY | the groove that fits over

the guides

Aquickway odo this

isto clamp a serap piece

to the drill press table

and use it to position the

fence (Figures 8 and

$2). Then place a scrap

block under the fence to

prevent chipout and drill

a series of overlapping

holes to form the slots.

Al it takes to clean up

the slots to pare of the

remaining, waste with a

chisel and then file the

edges smooth.

Install Fences - Now

Just install the fences

and thread in the knobs

tohold them in place.

No. 52 ShopNotes 9

mre

A Stop Block.

An adjustable stop

biock provides

a quick, accurate

way to miter pieces

to identical lengths.

A Hola-Down.

For safety, this

simple hold-down

‘clamps work

securely against the

base of the jig.

PET

Accessories

To ensure safe, accurate cuts when

using the miter fig, T added nwo

simple accessories: a stop block and a

hholddown, (See photos in margin.)

‘STOP BLOCK

‘There's more to cutting perfect miter

Joints than establishing the correct

angle. To end up with a ightsitting

joint, opposite pieces (the sides and

top/bottom of a picture frame for

instance) must be identical in length.

‘Thats where the sop block comes

in, To produce consistent results,

‘you simply lock the stop block atthe

desired distance fom the blade, butt

the end of the workpiece against it,

‘and make the cut. Note: only made

‘one stop block and then used it on

both of the fences.

LShaped Block - As you can

see in Figures, the stop block is just

an Lshaped block thats made up of

two pieces of "thick hardwood. A

sliding block (F) vith a hole drilled

near the edge accepts the shank of

the toilet bolt. And the sip (G) isthe

part that the end of the workpiece

actually butts up against.

Aller gluing up the top block, just

slip the end ofthe toilet bolt through

the hole and slide the head into the

‘slot. Tightening a knob on the end

SECON acres

10

s supe

vba XD Salad

waste Block

waite Bai

NE Fea

BIDE ee woe Stoo BOLT

of the bolt pinches the stop block To accommodate workpieces of

against the fence and locksitin place. different lengths, the holddown

slides along the TEslots in the base.

PeEnoM ere again, I only mate one hold-

‘The second accessory for the miter _ down and used itin both slots)

jig is a holddown that’s used to The unusual thing about this hold-

clamp work securely in place. This down sits angied shape. Ifyou look

‘way, there's no need to worry about at the lower photo in the mangin,

getting your hands too close to the youll see that the long, straight end

saw blade, especially when mitering of the holddown rests against the

short pieces, base ofthe jig, and the short, angled

end applies pressure against the

workpiece. This clamping pressure

is produced by tightening a knob on

the end of a toilet bott that slides in

the Tslot (Figures 10 and 102).

Giue Up Blank - As you can see

in Figure 11, the holédown (ED starts

off as a 14'square blank. ( glued

up two pieces of "hick maple)

‘There are two ways to go about

transferring the basic shape of the

eS On FouRTHs| holddiown to the blank. You can

either enlarge the pattern in Figure

11 by 150% and use a spray-mount

adhesive to stick it to the blank. Or

justlay out the shape on the blank.

‘To accept the toilet bolt, youl

need to drilla series ofholes to make e

a Slot in the blank. Then just use a

band sew to cut the holddown to

shape and sand it smooth,

ShopNotes: No. 52

Setup

It only takes a minute to set up the

‘iter jig on the radial arm saw.

Dowels - That's because there

are two dowels in the base of the jig

that automatically position it on the

‘saw table. As you can see in Figures,

12 and 12a, these dowels fit down

into holes in the saw table.

‘To determine the location of the

dowels, set the jig on the table so it

Dutis against the auxiliary fence. Also,

be sure to check its location from

side to side. The goal is to have the

‘saw blade centered on the length of

the jig. This way, the blade won't

accidentally cut into the fences when

they're slid all the way forward.

Once the jig is positioned prop-

Using the Jig

Once the jig is clamped in place,

‘you're ready to miter the frame pieces.

Rough Length ~ I start by eross-

ting all the pieces to rough

length. I'they'e less than 434" wide,

‘you can cut ther with the jin place

Just instal the original radial arm saw

Fence (the one without the notch),

slide bath fences onthe ig back, and

cette pieces. Note: For wider pieces,

you'll need to remove the jis.

Label Pieces ~ Next, to avoid

confusion, [label the sides ‘A? and

the top/bottom pieces ‘Bas in the

drawing at right. But even with the

pieves clearly marked, its still pos

sible to get them mixed up So theips

DERE

op Bese

(

\

erly, it’s just a matter of driling a

‘couple of holes through the base

‘and the saw table, Before installing

the dowels, its a good idea to chamfer

the rim of the hole in the base. This

to follow a specific cutting sequence.

Cutting Sequence ~ The first

step is to miter one end of ail the

pieces, (These are the ends marked

with an % in the drawing at right)

All of these cuts are made with the

‘workpieces held against the right

fence. So slide this fence forward

and the left fence back (Figure 13).

‘Then set the first’ piece against

the fence, tighten the holtdown,

and make the cut. Note: Locking the

stop block against the end of the

‘workpiece provides a quick way to

position the other ‘A’ piece. Then

repeat this process for the ‘pieces.

After cutting the miters on one

‘will make it easy to fit the dowels in

the holes when setting up the jig.

‘After sanding a slight chamfer on the

end of each dowel, i’s simply glued

into the hole in the base,

ae,

end of each A Labeling the

piece, the next trame pieces

step is to miter the ‘makes it easy 0

opposite ends, These culs are made keep track of things

with the workpiece against the let when cutting the

fence, as shown in Figure M4. miter joints

Start by setting the sop block the

desired distance from the blade.

‘Then butt the end of the piece

against the stop block, tighten the

hholdiown, and make the cut. Note:

Unless you're working with a square

frame, reposition the stop block to

ccut the second pair of pieces.

SBE RTT

renee Atte

WA ESSA

gro

Se

Pc atid

WAPFSRWAES Houo. pow

\

No. 52

ShopNotes

= Step lay

How it Works ~ Before you get

i iota twinge os how

Jal ATM saw

the parts ofthe saw work together. A

long arm supports the head (blade

une - an motor of the sa, The head is

held in an adjustable yoke that allows

you to pivot the blade 90° (or rip-

ping lumber) or tt it at an angle (o

Hnere's no question that aradial blade may “grab" and race through make beveled cuts).

arm saw is aversaile tool. You the workpiece under its ovm power. To crosscut a board, the yoke is

All it takes to keep canuse'itfor everything from cross Thats downright scary ‘mounted on sliding carriage. When

a radial arm saw cutting or ripping a bosrd to cutting Tune-Up ~Fortunately,allittakes you pull the head ofthe saw forward,

running in top. ‘iters and bevels, toproducea smooth, accurate cuton _ the cariage is guided by a set of four

condition is q _ Butthere’sa tradeoff for this wer aradial arm sawisa simple tuneup. roller bearings that ride on a track

1S a salty. Ifthe saw isn't adjusted prop- This doesn't require any specialized housed inside the arm,

little periodic ery, the result isa less than perfect tools. And all the adjustments can be To provide rigid support for the

maintenance and cut. Perhaps the end of a board isnt boiled down to seven basic steps, so arm, i's attached to a. cylindrical

a simple tune-up. square, or the saw blade leaves athe entire process usually only takes coluren that an be raised or lowered

rough, burned edge. Worse yet, the about a half hour. to adjust the depth of cut, By

releasing a lock mechanism and

re ae swinging the arm to one side or the

rr Steper fe Gay athe, it allows you to make angled

ws haere cuts. Or return the arm to a 91F set

trade arm camp Sinz to square up the end ofa board

_-mechaniem Clean Saw ~ Needless to say,

‘orarm "cach of these parts needs to operate

smoothly to ensure good results,

One of the easiest (andl most effec-

tive) things you can do to accom

plisi this is to clean up the saw by

siving ita good “once-ove.”

Start by using an air compressor

(or shop vacuum) to remove the

loose dust. Then wipe off any caked

on dust with 2 rag damp-

ened with mineral

spirits. Pay special

attention to the column,

roller bearings, and the track.

(i they're covered with dirt and

grime, its much more difficult to

make accurate adjustments,

Lubrication ~ Ater cleaning off

the gunk, I make it a point to Iubri-

cate the moving parts of the saw,

Note: The lubrication points are

shown inthe drawing atleft.

Since a radial arm saw produces

quite a bit of dust, its best to avoid

RADIAL using an oily lubricant. Dust sticks to

ARMSAW like glue and makes a gooey mess.

ANATOMY So Tuse a “dry” spray lubricant that

doesn't attract dust. (Por more infor

‘mation about the type of dry lubri-

cant [use, refer to page 31.)

2 ShopNotes No. 52

1. Adjust Column

‘The first step is to remove any “play”

in the column. Ideally, it should fit

‘snug (not tight) in two places: the

column support and the arm.

‘Tocheck the amount of movement

in the column support, grasp the end

of the arm and liftit up and down, as

shown at right. Ifthe column moves

front to back, tighten the column

‘support (detail ‘a’.

Ifthere’s any slop when you apply

sideways pressure against the arm,

just “sug” the adjustment screws

against the colurnn (detail b).

2. Check Bearings

‘The next step is to check the roller

bearings that guide the carriage.

‘When you pull the head of the saw

forward, the bearings should glide

‘smoothly without any side-to-side play.

If the movement feels sloppy (or

there's alot of resistance), the bear

‘ngs can be adjusted closer to (or far-

ther from) the track inside the arm.

‘There are two bearings on each

side, but only one pair is adjustable.

‘These bearingsare mounted offcenter

(etal). So when you loosen a lock.

‘mut and rotate an adjustment nut, it

‘moves the bearing or out detail b).

3. Flatten Table

‘To get consistent results, its impor

tant thatthe table is flat.

Acquick way to test the flatness of

the table is to lay a straightedge

across the table and check for light

underneath, as shown at right.

If the table is Tow, raise it by

turning a set screw (detail ‘a). If

there's a hump in the middle, tighten

amachine screw to dattenit (detail b)

‘Note: With use, the saw table will

_get chewed up which can cause it to

sag in the middle. So you may need

to replace the table from time to

time. To protect the surface of the

new table, its a good iddea to carpet

tape a piece of hardboard to the top.

No. 52

‘ShopNotes.

RSLEPOERENGE

‘AQUSTABLE

ne

NT

ayer,

Heer

Nie

13,

eT

4. Align Table

Getting the table flat is one thing.

But the surface of the table also

needs to be parallel to the arm.

Otherwise, when you crosscuta board

(or cut a dado), the depth of cut will

vary from one edge to the other.

Usually, there's no adjustment for

the arm. So you'l need to align the

table tothe arm instead. Thisis done

by raising or lowering a pair of metal

brackets that connect the table tothe

saw (detail 2).

To determine the amount of this

adjustment, start by removing the

blade guard and saw blade, Then

release the bevel lock and rotate the

‘head of the saw so the arbor points

straight down, as shown at right.

After securing the bevel lock, release

the clamp mechanism for the arm so

‘you can swing i from side to side.

‘The idea here is to slide the head

of the saw along the arm so you can

position the arbor at all four corners

ofthe table. At each corner, the arbor

should just barely touch a scrap

block that’s used as a fecler gauge.

‘When that happens, the table is par-

allel to the arm,

I start with the back, righthand

FIRST: kore

EAS EE

Ponto Bonn Hi

SECOND: ene

Fens Bbe INE

STiBe HEAD OVER coRNER

PRS Bee

‘corner ofthe table. Begin by backing

off the nut used to secure the

bracket so it’s just snug. Then lower

‘the arm uni the arbor just touches

the block. When you can slide the

5. Square Blade to Table

It-goes without saying — to get a

‘square cut, the blade has to be square

tothe table. But actually there's more

toitthan that (more about that late).

For now, le’s just say that squaring

the saw blade to the table is the fni-

fal step in ensuring square cuts.

Start by checking that the clamp

‘mechanisms for the arm, yoke, and

‘carriage are locked. Then mnlack the

ni

Sh

block back and forthwith only slight @

resistance, tighten the nut that holds

the bracket in place. Then, without

changing the height ofthe arm, repeat

the processatthe other three corners.

bevel lock, grasp the motor, and

-wigale it up and dovm to make sure

the index pin is engaged at 90°.

‘After retghtening the bevel lock,

set a framing square against the

blade. To get a “true” reading, be

sure to place the square against the

dndy ofthe bade, not the teth.

If the blade is lat against the

square, there's no need to make an

adjustment. IFts tited away from it

(es in detail ‘a, it only takes a few

‘minutes to square up the blade

As you can see in the drawing at

Jef this is just a matter of removing

the bevel scale to provide access to

the adjustment bolts, After slightly

loosening the bolts tt the motor to

square up the blade. Then alternately

refighten the bolts, replace the scale,

and set the bevel indicator to zero,

No. 52

6. Square Up Arm

‘As I mentioned, squaring the saw

blade to the table is just one part of

the “squaring-up" process. The next

stepis to square the arm tothe fence.

‘This way, the saw blade will travel in

a line that’s square to the fence.

Before you get started, check that

the clamp mechanism for the arm is

locked. Also, grasp the end of the

arm and move itback and forth. This

ensures that the index pin that holds

the arm at 90° is properly engaged.

‘The first step is to find out if you

even need to make an adjustment. To 3

o this, Imake a simple test using a

framing square tha'srestng on scrap

blocks, (Plexplain the blocks late.)

Start by placing the short “leg” of

the square against the fence, as

shown at right. Then mark a single

tooth on the blade to use as a refer

cence and slide the square againstthat

tooth. Note: You may have to adjust

the height ofthe bladetodo this. If it veers to one side or the other welded to the back of the column

Now slowly pull the blade all the (detail ‘b) the arm needs an adjust. (Getail‘a). On my saw, this requires

‘way forward, checking to see ifthe ment. (f the blade moves toward the loosening some lock nuts and tight

reference tooth stays in contact with square, the scrap blocks prevent it ening set screws against the bar to

the square. If the tooth scrapes from “climbing” up on the square.) nudge the arm one way or the other.

against the square forthe entire dis- To adjust the arm, the idea is to Note: Check the owner's manual to

tance, the armis square tothe fence, apply pressure against a metal bar find the adjustment on your saw.

7. Check for Heel

Atthis point, the blade travelis square

to the fence, But that doesn't mean

the blade itsefs square tothe fence.

Sometimes the yoke (and there:

fore the blade) is slightly twisted on

the carriage. This is called heeting.

‘The problem with heeling is the

blade “plows” a wide kerf, creating

rough, burned edges.

It’s best to check for heel near the

center of the blade where there's

‘more surface area. So I seta framing

square on tall blocks, as shown in

the drawing at right and detail ‘b!

Note: You may needa tall fence to hold

the short leg of the square against.

Ifthe blade needs to be aligned,

unlock the yoke and loosen the bolts

used to secureitto the saw (detail'a),

Then swivel the yoke to square up

the blade and retighten the bolts #&

a

taal ula LA lata

SRE [eal

TTTTEs

No. 52 ShopNotes 15

Turn a single sheet of plywood

and a few pieces of hardware into

@ portable workbench that “knocks

down’ for compact storage.

Wa

AX bench in a box. No, it’s not a new magic act. It's what

£ Aone of the guys cals my new knock-down workbench.

‘When you think about it isa fiting description,

‘That's because the bench provides a solid, stable worksur-

face like you'd expect from a bench. (There's even a tool tray

underneath.) Then, once ajob is completed, the bench can be

“knocked down’ and stored in a

compact box that you carry Hke

asuitase. (See photo aright)

‘The best thing about this

knockdown design is it makes

it easy to take the bench out to

the driveway or back yard, or to

auiend’s house to heip on apro-

ject. No matter where you're

‘working, setting up the bench

only takes a minute.

Setup ~To do this, start by

unlatching the lid on the box

and setting it aside. (The lid

doubles as the top of the work-

bench) Then simply remove

the two stretchers and flip up

the sides ofthe bench, as shown in photo A below.

‘The sides are hinged to the base, so you'l need to “spring”

them apart a bitto fit the stretchers between them (Photo B).

‘These stretchers hook securely into the sides with an ordi-

nary set of bed rail fasteners, Then just set the top down over

the sides and pull it toward you to lock itn place Photo C).

‘Clamping Options ~ Once the bench is setup, there are

three different ways to clamp a workpiece to the benchtop.

‘That explains the holes and slots in the top as well as the

notches in the top ofthe stretchers, Note: Fora closer look at

the different clamping options, turn to page 23.

Plywood ~ Just one more note. You won't need a lot of

‘material to bul this bench. The entire project is made from

a single sheet of 4" plywood. (used pine plywood.)

{nd fli up the sides, as shown in photo ‘A.’ To provide rigic

“support forthe tp of the bench, the stretchers hook into the

Unlatching the top and sattng it aside, remove the stretchers sides (Photo B). Then just ft the top down over the sides of

the bench and pullitoward you to “lock” itn place (Photo C).

‘ShopNotes No. 52

FEATURE PROJECT

‘TOP PANEL EXPLODED VIEW

srg OVERALL DIMENSIONS

Co ‘rn Sasa 2arD x BOR

———@

each fh sonleeme ie

meas wu

ss

tbe

eee

orton (agen

+ (20) #8 x 1h" Fh

ae

Cs

nae

© (4) 0 xt" Fh

women

eames

ps aces

/ phonon

© Fasteners

ce BEE

8

Nog

(1900) "ez" Latch

Hinge

+ @)isra19" Plano

Hinges w/Serews

+ @)Draw Latches

w/Sereus

+ (4) %4" Rubber Bumpers

48 xorg

+ (4) %e"16 FNute

TALL SIDE

Cutting Diagram | | Materials

“or 00° = POOP Sheri sas Babe

A. Front/Back (2) &x32-% Py |

© © B Ends (2) 6x 21% -% Ply. |

| TALL SIDE “SHORT 2108 € Bottom (1) 2th x ts - 54 Ply.

© Comer ects (4) Thx 3th

Soe ( Sy

e conve F talltde tox20h-%

Quowrierenns| Sse@ 0 steer F ShortSue(), tna

sienna eee maeD G Spacer Block (1) hx 20% -% Ply.

HH Stretchers (2) 10x29 -% Ply

ee Top

I Top Panel (1) 22x 32 -% Ph

@ ©zerem 4 oops a) S30 Pe

K End iter Seopo(S) Sax tthe-%er

ee | U Ineld itr Stipe (2) Shox 10-%4 PN.

No. 52 ShopNotes Ww

Base

Tegan work by making the dase of

the bench. As you can see in Figure

1Lit’sa shallow box with alarge “foot-

print” that helps the bench resist tip-

ping. The base provides @ handy

compartment for tools while you're

working. And when you “knock

down” the bench for storage, the

base holds the sides and stretchers.

Frame - The base starts out as a

plywood frame that’s made up of a

Sront/back (A) and two ends (B). To

pose oe

WeoDSEEN

sone tn

strengthen the base (and help align wots

the pieces during assembly), the front re

and back are rabbeted at each end.

An easy way to cut these rabbets

isto use adado blade mounted in the

table saw. As you can see in Figures

2and 2a, part of the blade is “buried” wipe he”

in an auxiliary fence that's attached My z]

{othe rip fence with carpet tape. NOE wave

‘The fence is positioned so the =

blade will cut the shoulder of the

rabbet. The only problem is the front

and back pieces are fairly narrow, of the storage compartment in the — the fence will produce a groove thats

too narrow to ride against the fence base. Lwanted to make sure the com- 2%" down from the top edge. This

‘without twisting. To prevent that, I partment was deep enough to hold provides enough room for the sides

attached a long fence to the miter the sides and stretchers (and still be and stretchers plus litle extra,

‘gauge and used itto guide the work- able to fasten the top on the base). Notehes ~ After completing the

Piece through the biade, So after adjusting the width of the grooves, I cut a long notch in the

Cut Grooves ~ In addition to the dado blade to match the thickness of bottom edge of each piece (Figures

rabbets, there’s a groove in the the plywood bottom, I set the rip 4a and 4b). These notches provide

inside face of each piece that holds fence 394" away from the outside of some “toe room” soT ean work a the

the botfom ofthe base. The location the blade (Figures 3anda).Running bench without kicking the base. A

of this groove determines the depth the botlom edge of each piece against sabre saw (or band sav) is all that's

Sr:

Zetia

i

weer

MARRS oy e

No. 52

TauA Le

needed to cut the notches to rough

shape. And a drum sander chucked

in the drill press makes quick work

‘ofremoving theres of the material.

But a drum sander can create a

scalloped edge if you're not careful

‘Topreventthat, [used along straight

scrap piece as a fence (Figure 4)

With the “Yeet” of the

the fence, its easy to

sand a straightedge.

‘To sand the entire thickness of

the edge, youll need to attach an

auxiliary table to the drill press and

cet a hole init to accept the drum

sander. Then, alter notching the

fence to fit around the drum sander,

positon it to sand to the desired

depth and clamp the fence in place.

Now turn on the dill press, and

push the workpiece into the drum

sander until it contacts the fence.

The idea sto start atthe rig end of

the noich, then slowly feed the work

piece from left to right to sand the

‘edges smooth.

Bottom ~ Before assembling the

base, there's one more thing to do.

‘That's to cut the plywood bottom (C)

to ft. Then just glue and screw the

base together. [ also “eased” all of

the edges with a sanding block to

kkeep them from splintering when

they get bumped or knocked around,

Corner Blocks Allthat'seftto

complete the base is to add four

thick comer blocks (D). These

blocks “beef up” the corners ofthe

base to hold a set ofrubber bumpers

that ae added later (Figure 1).

ach corner block is made up of

two pieces of 4" plywood. To avoid

working with small pieces, glued

up two long strips of plywood first

Figure 5). Then i just a matter of

cutting each corner block to length.

Here again fence attached tothe

iter gauge provides support fr the

blank. But this time, to cut each

blocko the same length, [clamped a

scrap piece of wood to the rip fence

and used it as a stop. The idea is to

set the fence so that when you butt

the end of the blank against the stop,

itwill producea ong corner block.

Rubber Bumpers After cutting

all the corner blocks, the next step is

to add a set of four rubber bumpers,

(We've shown two in the margin.)

‘These bumpers thread into T-nuts that

fit into a hole drilled in each corner

block (Figures 6 and 6a). After giving

the blocks in place, simply tap in the

‘Tuts and install the bumpers.

aero

eee

Hee

A Hard rubber

bumpers thread into

the base of the

bench to keep it

from siding around

and to prevent

damage to a

finished floor (See

‘page 31 for sources.)

TEU

Supports

‘This workbench is designed with a

simple system of interlocking parts

that provide solid support for the

top. As you can see in Figure 7, it

consists of two hinged sides com

nected by a pair of stretchers.

To prevent the bench from

racking, the connection between the

sides and stretchers must be rigid

and strong. At the same time, I

‘wanted a quick and easy way to take

them apart.

Bed Rail Fasteners ~ The solt-

tion is a mechanical fastener like the

‘ype used to hold the parts of a bed

together. (See photo at eft) One part

of the fastener (attached to the end

: ofthe stretcher) has two hooks that

fit into slots in the other part

(mounted to the sides). This “locks”

the parts together, yet still allows

them to be quickty disassembled,

Sides — I started by making the

‘two sides of the bench. Both sides

ate the same width (18°). And they

‘appear to be the same length. But

that's not the case. To allow both

sides to fold flat inside the base, the

tall side (E) is" longer than the

short side (F), as shown in Figure 8.

‘Aside from the difference in

length, the sides are identical. To

reduce the weigt ofthe bench, Teut

a large opening in each side. Also,

-

‘Gat

a

s

A A two-piece bed

rail fastener creates

a strong, rigid

connection that's

quick and easy

take apart. (See

page 31 for sources.)

oxen

wbebdeht

aes

altho

ar tence,

SHORT

SIDE,

02)

©

TALL SIDE

Coresan5

fa

oS ,

"Ras

‘SPACER BLOCK

eee

Howe

BOE

RSE

# B=

if ~

cp [i woxtnton

)) | otretcHer

TALL SIDE

SHORT SE.

PASE

there's a short, metal bar on the

‘upper back corner of each side that’s

used to secure the top to the bench,

Bars — The two metal bars are

easy to make. I bought a ¥4-thick

aluminum bar at a home center and

used a hack saw to cut each one to

length. Then I drilled a couple of

countersunk shank holes in each

piece for mounting screws.

Before attaching the bars, youl

a.

need io cut a“tairstep” notch in the

corner of each side. The upper par

of this notch is sized to fit the bar

(gure 8). When you screw the bar

in place, itforms lip over the lower

part of the notch. This lip captures a

pin that's installed later inthe top.

Cut Mortises — The next step is

to cut the mortises that hold the

loted part ofthe bed ral fasteners.

‘As you can seein Figure &, the idea

is tocut.atwotiered mortise. A wide,

shallow mortise is sized to accept

the fastener, and two narrow, deep

mortises provide clearance for the

hhooks on the other part ofthe fastenes.

‘An easy way to make the shallow

mortises isto use a drill press and a

Forsiner bit (Figure 9). A. careful

layout will ensure that the upper

ends ofthe mortises align, As for the

distance of the mortises in from the

edge, I clamped a fence to the dri

press table and used itto position each

workpiece. Now it's just a matter of

dsiling a series of overlapping holes

and paring avay the remaining waste

with a chisel Figure a)

‘Once the fastener fis neatly in the

‘mortise, you can use ito lay ou the

location of the two deep mortises

No. 52

Zea

(Figure). "The thing tobe aware of

isthese mortises are 9/3" longer than

the slots in the fastener. The reason

has to do with the hooks on the mating

fastener. To lock the two parts of the

fastener together, the hooks have to

fit straight into the slots and then

slide downward. Increasing the length

‘of the mortise provides the clear-

ance that’s needed for the hooks,

‘Alter laying, out the deep mor.

ties, chuck a smaller bit inthe dill

pressand use the same procedure as

before to cut two pockets (Figure

9c). Then screw the fasteners in place,

Install Sides - Now you're ready

to install the sides. The tall side (E)

ishinged directly to the base (Figure

7b). But as you can seein Figure 7a,

the short side (F) is hinged to a

spacer Wock (G).Thisisa3i" square

strip of plywood that’s glued to the

base. The spacer block raises the

short side so it can fold down flat

across the tal side.

Stretchers — The next step is to

add the stretchers (H). As you can

‘see in Figure 10, these are long, I-

shaped pieces of plywood that are

cut to length to fit between the sides.

Bach stretcher has a long notch

‘cut in the top and bottom edge. The

upper notch lets you slip @ pipe

clamp underneath the benchiop £0

you can clamp a workpiece against

the edge of the bench. The lower

notch is simply cut to match,

After sanding the edges smooth,

all that’s left is to add the hooked fas-

teners (Figures 10 and 102). Each of,

these fasteners fits in a shallow

notch in the end ofthe stretcher.

‘The location of these notches

determines the up and down posi-

tion of the stretchers. I wanted the

stretchers to sit fush with the top of

the sides, so the notch is 2" down

from the top edge (Figure 112).

“eae

Ancasy way to cut the notchesisto

mount a dado blade in the table saw

and to attach a tll fence to the miter

gauge (Figure 11). Then stand the

stretcher on end, holditfrmly against

the fence, and nibble away the waste

Belore attaching the fasteners,

take a look atthe back of each one.

You!l notice there's a large “nib”

behind each hook. To make the fs-

tener sit fat in the notch, you'll need

to dri a pocket for each nib. Then

just screw the fasteners in place

®

STRETCHER

Way

Nome aa

SOS

- tA

Bee :)

ShopNotes

Top.

“The top of the workbench thats

shown in Figure 12 has two

rain jobs, It creates a solid

wworksurface, Plsit serves as 2

lid for the base winen you knock

down the bench for storage

But the andiest thing about

this benchtop is it provides

three different ways to clamp a

workpiece to the bench. (Refer

to the photos on page 23)

Built-Up Top ~ To increase

the thickness of the top, it's

“uit up" from two layers of

Ye plywood. The upper layer

is formed by a top panel

that’s sized to fit fish with the

base Figure 13). And the

lower layer is made up of sev

eral smaller filler strips.

Filler Strips ~ These strips create

along, narrow recess underneath the

top which ts down over the sides of

the bench. Plus they provide the

thickness that’s needed to hold a set

of bench dogs. (For more about the

Dench dogs used, turn to page 3.)

The front and back filer sirips

are simply cut to match the length of

the top panel. To fitover the sides of

A A simple two-part

system is used to

fasten the top to the

bench. Metal pins in

ne top fit under the

iinum bars on

the sides (upper

photo). And spring-

loaded latches lock

the top in place

(lower photo).

TET

then glued in place.

Slots for Clamps - With the filler

strips in place, the next step is to cut

{our slots in the top. Bach slot forms

‘an opening fora bar clamp that lets

you clamp work near the middle of

the benchtop. A quick way to cut

cach slot is to drill a small starter

hole and then remove the rest ofthe

‘waste with asabre saw Figure 1).

Bench Dog Holes - In addition

to the slots, T drilled a number of

hholes in the top to hold the bench

dogs. Since the top is quite larwe, I

clamped an auxiliary table tomy dil

press to support it Figure 15). It's

the bench, youl need to cuta notch

near each end of these strips. Then

jst gue them in place.

Next, I added two narrow end

filler strips (10. Theyre ripped to

‘width so when they're flush with the

outside edge of the top, they align

with the notch in the front/back

strips. As for length, is usta matter

of ctting them tot the opening.

‘ter gluing on the end strips, I

added two inside fle strips (L). To

provide clearance forthe stretchers,

these strips are shorter than the end

sips. Here again, the strips are

aligned flush with the notch and

INSIDE FILLER

aon

NOTE: au rapes age

MADE FRM PEED

BACK FILLER

‘STRIP.

Bees

d

He,

exouer

rt

en

eee

Ss] Z

"a =a a, Ze

eo| [oars of |oeme su NOTE:

22 ShopNotes No. 52

also a good idea to clamp a fence to

the table to make sure the holes are

located the same distance in from the

edge. Then lay out and drill the holes

Locking System ~ At this point,

the top is almost complete. But

before seting it on the bench, 1

added a simple, two-part system that

"locks" it secure in place.

Ifyou look at the photos on page

22, you can see how this works. In

back, the top isheldin place with two

‘metal pins that fit under the alu

‘minum bars installed earlier: In

front, its secured with a couple of

springloaded latch hinges.

Install Pins ~ Asyou can seein

Figure 16, each pins a short piece of

1{-dia, metal rod. The pin fits into 2

hole drilled in the end of the dack

filler strip (Figure 162), After

applying a small amount of epoxy in

the hole, tap inthe pin and clean up

any excess that squeezes out

Latch Hinges ~ The second part

of the locking system Is a pair of

Jatch hinges, Bach ltch hinge has a

springloaded pin that fits into a hole

in the side of the bench (Figure 12)

(Fora source aflateh hinges, refer to

page 51.) An easy way to locate the

holes forthe spring-loaded pins isto

screw the latch hinge tothe top, as

shown in Figure Y7a. Note:The etch

hinges I purchased didn't have

mounting holes, so I had to drill a

couple of holes in each one.

‘Now lower the top down over the

sides and pull it toward you so the

metal pins in back slip under the

aluminum bars. iter centering the

top from front to back, tap each of

the springloaded pins to make a

No. 52

dimple in the side. Then simply

remove the top and drill the holes

for the latch pins,

Draw Latches ~ In addition to

the latch hinges, I also installed two

draw latches on each end of the

bench. (Refer to Exploded View on

‘ShopNotes

‘page 17) These latches hold the top

and base together when you knock

the bench down for storage.

Handle ~ All that's lefts o add a

handle to make it easy to carry the

bench, Its centered on the front of

the base and screwed in place.

~< Pipe Clamps. To hald a

workpiece against the edge

of the bench, stio pioe

clamps through the notches

at the top of the stretchers.

< Bar Clamps. Fit the

head of a bar clamp down

through one of the siots in

the top to clamp work near

the midalle of the benchtop.

~< Bench Dogs. Using one

(or more) pais of bench dogs

lets you hold work tightly

against the top without

clamps getting in the way.

23

Cherry

Saw

Handle

ecenty, Iwas poking around

secondhand store, and T

came across an old hand sav. The

weathered handle of the saw was

‘broken in one place and missing a

chunk of wood in another. ifs the

hhandle inthe before photo at left) A

Jong bolt held the handle together,

Dut twas a clumsy “ix” at best. And

years of use had almost worn the

carving offthe handle,

In spite of that, something, about

the saw intrigued me. So Ipicked it

upto examine it more closely.

‘The blade was rusty and dull,

but cleaning and sharpening it would

take care of that. More important,

none of the brass hardware pieces

that held the saw blade in the handle

‘were missing. (ts difficult to find

replacement hardware.)

In short, the saw looked like it

£3) had the potential to be a quality

tool. Notonly that, theprice ta was

right. (At$1.50, how could Igo wrong?)

So I bought the saw and decided to

restore itto a usable condition,

Sneak Peek — Ifyou'd ike to take

a peek at how it turned out, take a

Jook at the ar photo above. IP's the

same saw, only Tve cleaned it up had

the blade sharpened (which cost

$7.50), and made anew handle.

lot - Making the saw handle

provided an interesting challenge. It

has to do with the slot in the handle

that holds the saw blade. This slot is.

quite thin (about the thickness of

four playing cards) Pius, it’s curved

PREIS ee, tomatch the profile onthe end ofthe

oat blade. No doubt the manufacturer

spol sone heeft

CROSS ee cue sat (tel dds awe).

SECTION Poceknwaceusaer, EXPLODED So how do you cut a thin slot in

ee VIEW. a handle? The answer is simple —

ote NN you don't. Let me explain

ea ShopNotes No. 52

Veneer - The slot is made by

using a double thickness of veneer

fas a spacer. As you can see in the

Exploded View on page 24, the

veneer is cut to match the shape of

the blade and then giued between

‘wo hardwood blocks. This creates a

thin slo that matches the shape ofthe

blade exactiy.

‘There'salsoa side benefit to using

veneer. By orienting the grain of the

veneer across the grain of the wood

blanks, it strengthens the handle, so

its less likely to break.

Traditional Shape ~ Okay Iknow,

this method for making a saw handle

isabitunorthodox. But I still wanted

a traditional looking handle — one

witha graceful, curved shape. Perhaps

Td even try my handat carving apat-

tern in the handle like Pd seen on

other old hand saws.

‘Before making the “real” handle, I

‘experimented by making several ver-

sions out of softwood. This gave me a

chance to modify the shape of the

handle to get a comfortable grip.

Qe shope ed pestis shovminthe

‘pattern. above, Note: This is @ half

size pattern, so you'll need to enlarge

ity 200% on a photocopy machine,

Carving ~ Aiter working out the

basic shape, I drew several different

carving patterns. As you can see, the

fone [ended up witha simple wheat

pattern, Of course, the handle would

Jook great even without the carving.

But if you decide to give it a ty,

we've included an article on page 28

that provides some useful tips.

‘Three Layers - To make the

handle, I started by preparing the

three layers of material (Figure 1).

‘Theideahereistomake the combined

thickness of these layers equal to the

thickness of the off handle, (Mine

‘was ust a hair more than ‘4 thick.)

‘The two outer layers are 7iq"thick

blanks ofhardwood. (used cherry)

And the middle layer is made up of

two oversized pieces of veneer that

are glued up and then trimmed to

the same size as the two blanks.

‘Transfer Pattern ~The next step

{s to transfer the pattern Gncluding

the wheat) to the upper blank and

the veneer. Drawing the pattern on

both pieces makes it easy to locate

the holes forthe hardware later on.

‘Also, to help simplify things when

working with the handle pieces, I

WZ4

a

Xt

Tess 4

De

Sp08

‘made ita point to align the top edge

of the pattern with the top edge of

each pieoe before drawing the pat-

tern. (For a tip on transferring a pat-

tern, refer to page 28)

‘Trim Veneer ~ Now its just a

matter of trimming the veneer to

‘match the shape of the saw blade. As

‘you can see in Figure 2, the end of

the blade serves as a handy guide

‘when cutting the veneer.

‘Start by positioning the blade on

top of the veneer. There area couple

of things to keep in mind here, First,

the blade should align with the top

edge of the veneer. Also, be sure the

hioles in the blade don't cover up the

pattern for the carving. Now hold

the blade firmly in place and make

several scoring cuts with a knife to

cutthe veneer to shape.

Touse this

pattern to make a

saw handle, enlarge

it 200% on a photo-

copy machine.

UPFER BLANK

ubeeearane

BRD Veneer

(enven 1B PREE ES)

"or eooe

Peet

ShopNotes

25

oe

Fag

=

4 105 easy to ait

centered counter-

bores for the brass

hardware on the

existing holes. Use a

smal bit to position

"e blank on the di

ress table (top)

hen clamp the

blank in place (top)

Now chuck in a

iange bit and oti

ths hols (bottom)

Gluing up the three pieces of the

hhandle sounds simple enough. The

challenge is keeping the pieces from

slipping out of alignment.

‘Veneer — Take the veneer for

instance. As you can see in

Figure 3, its glued to the lower

blank, flush on three sides,

Now it’s one thing to position

© the veneer while its “dry” The

trickisto make itstay putafter

the glue is applied,

~~ What I found worked well

here isto attach the saw blade

to the lower blank with carpet

tape. Then brush a hin film of

glue on the veneer, butt it

against the blade, and staple it

to the blank. Clamping a scrap

block aver the veneer willhelp

distribute the pressure, and

‘wax paper prevents the block

from sticking,

Drill Holes — Once the

glue dries, you can remove the

serap block, but leave the

blade in place. It provides a

handy template for drilling the

holes in the blanks that accept

the blade hardware (Figure 4),

To ensure that these holes

ine up, [ attached the upper

nk to the bottom of the

lower blank with carpet tape,

Note: The blanks are flush on all

es, Then chuck a bit in the drill

press that matches the diameter of

NORA fie as Te

ete AR Shoe << —

War Tbiiek SLANE

PRrERN SIDE UP

the holes in the blade and carefully

drill the holes through both blanks,

‘Upper Blank - The next step is

toglue on the upper blank. I's impor

tant that this blank doesn't shit.

Otherwise, the holes you just drilled

‘won't align, The solution is to insert

a couple of drill bts inthe holes and

use them as alignment pins when

giving and clamping the blanks

together (Figure 6). Note: Be sure to

use the same size bits as the holes.

Blade Hardware ~ Now you can

‘urn your attention to the hardware

that holds the blade in place. On my

‘saw, there were three brass machine

screws that thread intoPnuts. Note:

‘Depending on your savy, the number

of pieces of hardware (or size) is

likely to vary.

‘Whatever the case, you'll need to

drill counterbores in the handle to

acceptthe machine serewsand Tuts.

This requires drilling several coun-

terbores, as shown in the detail on

page 24 and the photosiin the margin

Carve Handle ~ If you're going to

carve the handle, this is good ti

to do it. The gluedup blank provid

Detter support for your hand than

alter the handle is cut to shape.

No. 52

Shaping the Handle - At this

point, you're ready to start cutting

the handle to shape. To create the

tight curves of the handle, driled a

number of holes (Figure 6). Note:

Slipping a scrap of veneer into the

slot will prevent chipout which could

‘make it hard to insert the blade.

‘Next, form the hand opening,

removed the waste between the

hholes with a sabre save. A band saw

made quick work of cutting the

handle to rough shape (Figure 7)

“Most of the remaining waste can

be removed using a drum sander

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Singer 518 538Document58 pagesSinger 518 538chrixNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DIY Contoured Maternity Pillow - Homemade ToastDocument9 pagesDIY Contoured Maternity Pillow - Homemade Toastchrix100% (1)

- Contoured Maternity Pillow Pattern PDFDocument3 pagesContoured Maternity Pillow Pattern PDFchrixNo ratings yet

- Popular Woodworking 216 (February 2015)Document68 pagesPopular Woodworking 216 (February 2015)chrix100% (1)

- Phase Linear 200 Power Amplifier Schematic PDFDocument1 pagePhase Linear 200 Power Amplifier Schematic PDFchrixNo ratings yet

- Popular Woodworking 219 August-2015Document68 pagesPopular Woodworking 219 August-2015chrix80% (5)

- Cat Coaster Templates PDFDocument4 pagesCat Coaster Templates PDFchrix100% (1)

- Popular Woodworking - 012 - 1983 PDFDocument44 pagesPopular Woodworking - 012 - 1983 PDFchrix50% (2)

- Phase Linear 200 Power Amplifier SchematicDocument1 pagePhase Linear 200 Power Amplifier SchematicchrixNo ratings yet

- Hfe Kenwood kr-8010 8110 Service en PDFDocument20 pagesHfe Kenwood kr-8010 8110 Service en PDFchrixNo ratings yet

- Wavetek 132 Function and Noise Generator PDFDocument51 pagesWavetek 132 Function and Noise Generator PDFchrix100% (1)

- Maquina de Cocer KenmoreDocument65 pagesMaquina de Cocer KenmorechrixNo ratings yet