Professional Documents

Culture Documents

Nâ°11 Fuels

Nâ°11 Fuels

Uploaded by

ironite0 ratings0% found this document useful (0 votes)

21 views14 pagesOriginal Title

n°11_Fuels

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views14 pagesNâ°11 Fuels

Nâ°11 Fuels

Uploaded by

ironiteCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 14

DES MACHINES A COMBUSTION })

\ INTERNATIONAL COUNCIL

/ ON COMBUSTION ENGINES

CONSEIL INTERNATIONAL /

RECOMMENDATIONS REGARDING

FUEL REQUIREMENTS

FOR DIESEL ENGINES

Al

Vv

Poss

RECOMMANDATIONS CONCERNANT LES EXIGENCES

DES COMBUSTIBLES LIQUIDES POUR MOTEURS DIESEL

CIMAC

Number 11 1990

INTERNATIONAL COUNCIL

ON COMBUSTION ENGINES

CONSEIL INTERNATIONAL

DES MACHINES A COMBUSTION

CIMAC is an international organisation, founded in

1950 by @ Franch initiative, promoting technical and

scientific knowledge in the field of internal

combustion engines (piston engines and gas

turbines). This is achieved by organising congresses

and working groups,

‘tis supported by engine manufacturers, engine

users, technical universities, research institutes,

component suppliers, fuel and lubricating olf

suppliers and several other interested parties.

The national member associations are listed in the

‘back of this publication, as are previous CIMAC Re-

commendations.

Secretary General Mr. P. Davies, The Institution of Mechanical Engineers, 1 Birdcage Walk, Westminster,

London SW1H WJ, United Kingdom, Tel, 44-71-222.7899 Teletax 4d-71-222.4857

\ INTERNATIONAL COUNCIL

ON COMBUSTION ENGINES

CONSE!IL INTERNATIONAL /.

DES MACHINES A COMBUSTION

RECOMMENDATIONS REGARDING

FUEL REQUIREMENTS

FOR DIESEL ENGINES

THIRD EDITION‘)

RECOMMANDATIONS CONCERNANT LES EXIGENCES

DES COMBUSTIBLES LIQUIDES POUR MOTEURS DIESEL

TROISIEME EDITION’)

*| The tirst edition was published in professional magazines in January 1982, the second as CIMA

Recommendations nr. 8, 1986.

*} La promiére édition a é%é publiée dans la presse spécialisée en Janvier 1982, la deuxleme comme

Recommandations CIMAG nr, 8, 1986,

This cocument has been elaborated by the Working Group Heavy Fuel and approved by the Permanent

Commitiee on 15 May 1990.

Le present documenta été élabore par le Groupe de Travail Combustibles Lourds ot approuve par le Comité

Permanent le Mai 15 1990,

SIMAC assumes no legal responsibility for any consequence of the application of these Recommendations.

Le CIMAG n'accepte aucune responsabilité légaie pour toutes conséquences concemant |'application de ces

Recommandations.

CONSEIL INTERNATIONAL

DES MACHINES A COMBUSTION

PARTICIPANTS of the Working Group “Heavy Fuels”

Members

Mr J.H. Wesselo chairman)

Dr U. Agnelli

Mr G, Athenstaaa!

Dr Baer

Mr D, Bastenhot

Mr €rikeson

Prof. G Fiskae

Or H. Fujita

Mr. Grone

Dr. Havenith

Mr F.P. Holbrook

ir. Konrad

Me ¥. Miki

McH, Niven

Mir. Mt

Mr 2. Pokiewsky-Koziell

Me R.A, Rudsrud

MrH. Siéberg

Price

Pormanent Guests (experts)

Mr B.A. Carpenter

Mr. Fledier

Mr P.J. Newbery

MrAP. Orme

Mr K. Wilbraham

Acknowledgements

Useful contributions were given by:

Or. Davenport

Mr A.A. Wright

Stork-Wartsilé Diesel BV.

Diesel Ricerche Sp.

AVL

Technical University Delft

SEMT PieistickiG E M.T

Alfa-Laval

Norw. inst. of Technology

Japan Internal Gombustion Engine Federation

MAN-B&W

Klockner Humboldt Deutz A.G.

FOBAS, Lloyds Register of Sripping

MBS Diesel (Suizer)

Kawasaki Heavy Industries, Europe

Ricardo

Midlands Electricity Board

Z.P.M.H. Cegielski

Bergesen Group

Wartsiba Diesel

Mobil Oil Company Lto

F.M.C. Kiel

Veritas Petroleum Sorvice (DnV}

British Petroleum

Shell Int. Petroleum

predecessor of Mr J. Wilbraham

colleague of Mr R.P. Holbrock

INTERNATIONAL COUNCIL

ON COMBUSTION ENGINES

Netherlani

aly

Austria

Netherlancs

France

Sweden

Norway

Japan

Denmark

W. Germany

United Kingdom

Switzerland

Japan

United Kingdom

United Kingdom

Poland

Norway

Finland

United Kingdom

W. Germany

Norway

United Kingdom

United Kingdom

CONSEIL INTERNATIONAL

DES MACHINES A COMBUSTION

INTERNATIONAL COUNCIL

ON COMBUSTION ENGINES

SUMMARY

‘These Recommendations are a further development of earlier CIMAG publications In respect of fuel

requirements and although stilf based on the International Standards Organisation ~ Specification of Marine

Fuels - ISO 8217; 1987, are in some respocts more restrictive and include a number of additional

characteristics,

Adgitionat in‘ormation is also given regarcing fuel grade selection criteria and the backgrounc to some of the

less clearly defined characteristics which govern ual quality

SOMMAIRE

Les recommandations complétent les précédentes publications CIMAG détinissant des limites pour les

caractéristiques des fiouls. Bien que basées sur les spécifications |.S.0. paur las flouls marins ~ SO 8217.

1987 ~ces recommandetions, parfois plus restrictives, introduisent de nouvelles caractéristiques.

Aussi, les critéres sélectifs pour les classes de fiouls sont précisés. En arriére plan, on donne des informations

Sur certaines des caraciéristiques les moins blen définies ayant une importance sur la qualité du fioul

CONTENTS

Page

Historical Background

Scope

Relation between CIMAC Requirements and ISO Standard

General requirements

Sampling

Test methods

Precision and interpretation of test results

8. Selection of fuel grades

Table: Requirements ‘or distillate fuols

Requirements for residual fuels

Appendix: addtional information cegarding some properties

Total sediment after ageing

2 Aluminium’ Siison

3. Ignition properties

HISTORICAL BACKGROUND

The decreasing quality of residual fuels,

experienced worldwide in the past two

decades, andthe economic incentive to

operate larger diesel engines virtually

exclusively with low grade fuels, have resulted

in an increasing demand for an internationally

accopted fuel specification

The first action to obtain such a marine fuel

specification was taken by the British

‘Standards Institution (BSI) and resulted in the

BS-MA 100: 1982 standard. Simultaneously,

the CIMAC working group on “Future Fuels

began to prepare requirements for resicual

fuels, spectiically for diesel engines, These

requirements were published in the

professional magazines in January 1982

IMAC continued its work to develop,

requirements for heavy fuels, published as

GIMAG Recommendations Volume 8 in 1886. Io

‘the meantime BS! introduced a proposal for 2

new international standard to be approved by 4.

the international Organisation for

Standardization, This has led to ISO 8217:

1987, the first and until now only international

standard on heavy fuel, also reptacing the

original BS-MA 100: 1982 standard

Further efforts by all concerned with fuel

specifications have led to these new

Recommendations (nr 11) for Fuel

Requirements by CIMAC which now

supercede Recommendations Volume &.

SCOPE

‘The scope of the CIMAG recommendations is 5,

intended to cover all fuels for marine and

stationary diesel engines. The requirements

apply to the fuel as delivered. The

recommendations are intended primarily for

use by the engine manufacturers in their

manuals. This allows engine users to specity

fuels suitable for engine type and fuel

treatment plant. They are published by the

central CIMAC secrotariat from which al

interested parties can obtain copies.

‘The recommendations will be periodically

reviawed and revised when necessary

RELATION BETWEEN CIMAC

REQUIREMENTS AND ISO

SPECIFICATIONS

The scope of the two requirements differs

because ISO covers marine fuels for steam

boilers as well as for diesel engines. The

difference can be shown as follows:

Iso cimac

Marine

installations Diesel engines:

= Diese! engin' ~ Marine

~ Steam boilers, installations

= Land based

installations

Whereas ISO. as an olticial standards

‘organisation. can only specity characteristics

for which official test procedures exist, CIMAC.

can and may Sometimes rely on proposed or

proprietary test methods

However, CIMAG ensures that there are no

conflicting requirements, and thus there is @

common basis between CIMAC and |SO

specifications. All grades and the system of

designation are comparable and every CiIMAG

grade is an ISO grade with some additional or

more stringent requirements

GENERAL REQUIREMENTS

‘The fuels shali be homogeneous mixtures of

hydrocerbors derived from petroleum. This

shall nct preciude the incorporation of small

‘amounts of additives intended to improve

‘some aspects of performance:

The tue| shalt not contain contaminants from

non-petroleum sources (such as inorganic

acids and alkalines) other than those

particularly mentioned in the specification

The proporties of the fuels shall not exceed the

meximum values nor be less than the

minimum values set out in the tables.

SAMPLING

‘Sampling of fuels for analysis should be

carried outin accordance with the procedures

given in I$03170. Acditional information on

‘sampling procedures are given in IMAC.

Recommendations nr. 9 for Heavy Fue!

Treatment.

TEST METHODS

The following test methods should be used to

determine compliance with the requirements

Density:

180 3675—Crude petroleum and liquid

petroleum products — Laboratory

determination of density or relative density

Hydrometer method. This method is to be used

ata temperature between 50°C and 60°C and

the hydrometer readings converted to 15°C

Using ASTM table 538 referred to in ISO 91/1

Kinematic viscosity:

1S0 8104 ~Petroleum products —Transparent

63.

64.

65.

68.

ey.

68.

63.

6.10.

eat

612

613.

6.14,

6.16.

and opaque liquids ~ Determination of

kinematic viscosity and calculation of dynamic

viscosity.

Flash point

180 2719. Petroleum products ~

Determination of lash point. Pensky-Martens

closed cup method.

Pour point:

150 3016 ~ Petroleum oils ~ Determination of

pour point.

Cloud point:

150.3015, Petroleum oils~ Determination of

cloud point.

Carbon Residue:

Grades OX and DA:

1S0 4262, Petroleum products — Determination

of carbon residue ~ Ramsbottom method

Allother grades:

ASTM D 4530: Determination of Microcarbon

residue. ISO 10370 (provisional)

Ash:

180 6245~ Petroleum products ~

Determination of ash

Sediment by extraction

180 8735, Crude petroleum and fuel oils ~

Determination of sediment— Extraction

method.

Total sediment after ageing (potential):

IP 375/86’. Total sediment in residual fuel oils.

‘The method IP 390 (proposed ISO 10307) gives

two procedures for ageing fuel samples which,

when used in combination with IP 375,

determine the increase in sediment aiter

heating (see appendix, section 1).

water

180 3733 ~ Petroleum products and bituminous

materials — Determination of water ~

Distillation method.

Cetane index:

180 4262 and IP 380/86" Calculated Cetane

Index by four variable equation.

Cotane number

ISO 5165, Diesel fuels — Determination of

Ignition quality —Cetane Method.

Visual inspection (qual tative)

ASTM D 4176, "Free water and particulate

contamination”

Sulphur:

180 8754, Petroleum products ~ Determination

of sulphur contant~ Non-dispersive X-ray

fluorescence method,

Vanadium:

DIN 51790 (July 1978), part. 1 and 2, Proposed

IS 8691

6.18, Aluminium + Silicon

IP 377/88", proposed ISO 10478, Determination

of Aluminium + Silicon (see also appendix,

section 2)

Note: Ignition properties

No generally accepted test method is

currently available for residual fuels (see

appendix, section)

7. PRECISION AND THE INTERPRETA-

TION OF TEST RESULTS

‘The majority of methods, specitied in section

8, contain a statement of precision

(repeatability and reproducibility for each

test. Attention is drawn ta ISO 4258 ~

Petroleum Products: “Determination and

Application of Precision Data in Relation to

Methods of Test”. This procecure shall be

used in all cases of d'spute

Itis accepted thatin same cases the

reproduceability can load to daviations which

are larger than the value of tne actual limit.

8. SELECTION OF FUEL GRADES

a) Distillate grades:

DX isa fuel which is suitable for use at

ambient temperatures dawn to-15°C

without heating the fuel. In merchant

marine applications, its use is

restricted to lifeboat engines and

certain emergency equipment due to

reduced flash point

DA isahigh quality distillate, generally

designated MGO (Marine Gas Gil) in

the marine field,

DB ie. goneral purpose fuel which may

contain trace amounts of residual fue!

and Is intended for engines not

specifically designed to burn residual

4uels. Itis generally cesignated MDO

(Marine Diesel Oil) in the marine field,

DC ‘sa fuel which can contain a significant

proportion of residual fuel

Consequently itis unsuitable for

installations where engine or fuel

treatment plant are not designed for the

use of residual fuels,

b) Residual grades:

A10and 8 10

are available tor operation atiow

ambient temperatures in installations

without storage tank heating, where a

our point lower than 24 or 30°C is

necessary

Of these two grades A 10 has a lower

density and a minimum viscosity to

Increase the probability of good

Ignition properties

Tho range of © 10 up to H 55

are fuels, intended for treatmentby a

conventionat purifier-clarifier

centrifuge system.

Generally the highest viscosity,

allowed by the heating capacity of the

installation and the maximum

temperature, allowed by the engine

design, should be used, except when

other parameters take precedence

over viscosity in selecting tne fuet

grade, Of hese grades, E 25nasa

inimurn viscosity limitto increase the

probability of reasonable ignition

properties.

K 35, K 48 and K 55

‘are only for use in installations with

centrifuges specially designed for

higher density fuels.

GS

( oe } Requirements 190 or ast fuels for diesel engines (as delivered)

£8 a

Designation: CIMAG-| OX OA 03 00%)

Related to 150 8217 Mx DMA, OMB DMC

Characteristic Dim limit 7

some

Residual inclusion none none trace allowed

Density at 1550 kgm? max ~ 690 ‘900 20

Kinematic est) | max 585 6 1 14

| viscosity at 40°C min 1a 18 25

[Flash point

SS Sy SE Ge GL OL 9 900k 18

eu | = 60h (fquo uojeuzoju 4}) sey so08in yuoyeainba oyeunxosddy (,

¢ Uoqoes ‘xipuedde aas s0;v0do1d uoKUBy

0 oe oe we 0 wow | OyOw | dooms +uimuiryy

08 009 ove | os | ove | ose | ooe 8 ew | yb nipouen

[os 8 “os os ov oe ew way) %|——anyding

OF oF oF ob 080 050 we AIA) % ae

ns Bujabe seye

ovo avo ove ovo ovo ove xew {uu} yuouuipes eo

sho ee so | oo | oo ovo xew fara) % sy

a wz wz a | o ls fw | a “) xeu usu) %) ——anpysy uoqueg

L -

oe o oe oe oc | ve 3 xew | 96 10d nog

08 08 09 08 we 09 uu | O wed yseia

zi = : ee (91001 8 Ausoosia

ci oy ce ae ob ou xe (aso oneweuly

aor | roo | oro | te | oir 180 169 086 316 036 xew |

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Case Study - Fuel OilDocument34 pagesCase Study - Fuel OilironiteNo ratings yet

- Ose 5-91 2066-9001-200-Im PDFDocument210 pagesOse 5-91 2066-9001-200-Im PDFironite100% (1)

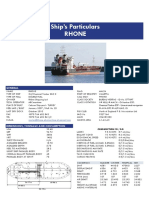

- Rhone 9327164 Oil Chemical - Tanker 71386Document2 pagesRhone 9327164 Oil Chemical - Tanker 71386ironiteNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Azolla Zs 68 PDFDocument1 pageAzolla Zs 68 PDFironiteNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- PowerPlant BrochureDocument4 pagesPowerPlant BrochureironiteNo ratings yet

- Ushio ReinetsuDocument1 pageUshio Reinetsuironite100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Oil List - Compressor HSC - 20142Document1 pageOil List - Compressor HSC - 20142ironiteNo ratings yet

- MAN Diesel & Turbo: Surveyor's Day Gard/Norwegian Hull ClubDocument29 pagesMAN Diesel & Turbo: Surveyor's Day Gard/Norwegian Hull ClubironiteNo ratings yet

- URS R404aDocument1 pageURS R404aironiteNo ratings yet

- Condensate Treatment 9-150 25 LTRDocument18 pagesCondensate Treatment 9-150 25 LTRironiteNo ratings yet

- Equivis Zs 68Document1 pageEquivis Zs 68ironiteNo ratings yet

- Shell Tellus s2 VX 68Document3 pagesShell Tellus s2 VX 68ironiteNo ratings yet

- Liner MaterialDocument1 pageLiner MaterialironiteNo ratings yet

- Diagomar Plus GuideDocument8 pagesDiagomar Plus GuideironiteNo ratings yet