Professional Documents

Culture Documents

Artificial Lift Management Recommendations and Suggestions of Best Practices

Uploaded by

Rosy Mar Chura SilesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Artificial Lift Management Recommendations and Suggestions of Best Practices

Uploaded by

Rosy Mar Chura SilesCopyright:

Available Formats

CT&F - Ciencia, Tecnología ARTIFICIAL LIFT4 MANAGEMENT

y Futuro - Vol. Num. 3 RECOMMENDATIONS AND SUGGESTIONS OF BEST PRACTICES

Jun. 2011

ARTIFICIAL LIFT MANAGEMENT

RECOMMENDATIONS AND

SUGGESTIONS OF BEST

PRACTICES

Clemente-Marcelo Hirschfeldt*

Oil Production Consulting & Training, Comodoro Rivadavia, Argentina

Universidad Nacional de la Patagonia San Juan Bosco, Comodoro Rivadavia, Argentina

e-mail: marcelo@oilproduction.net

(Received Apr. 04, 2011; Accepted Jun. 07, 2011)

ABSTRACT

A

rtificial lift systems (ALS) play an important role during the oil field production process. The selec-

tion, acquisition, installation, evaluation, monitoring and subsequent inspection of these systems

involves different stakeholders, including the companies and different sectors therein. When you

add factors such as field location, local culture and the experience of the companies in the area, understan-

ding and analyzing each of the factors is critical not only to maximize the life of a specific ALS, but also to

maximize and optimize field production in an efficient, effective manner. Another important factor to con-

sider is the dynamic of developing new oil fields or those affected by different EOR technologies, such as

secondary recovery by water injection, where field requirements and conditions change on a continuous basis.

This paper presents concepts and recommendations regarding the management of ALS during the productive life

of an oil field, contemplating the criteria of selection, acquisition, installation, evaluation and monitoring, as well as

the subsequent inspection thereof. The issues analyzed herein also involve concepts related to operating as well as

service companies and sectors involved in acquisition, evaluation and monitoring, among others. It also mentions

definitions of the roles, functions and competencies required to live up to the challenges posed by these systems.

Keywords: Artificial lift systems, Production engineering, Mature fields.

Citation: Hirschfeldt, C. M. (2011). Artificial lift managemente recommendations and suggestions of best practices. CT&F -

Ciencia, Tecnología y Futuro, 4 (3), 7-20.

*To whom correspondence may be addressed

CT&F - Ciencia, Tecnología y Futuro - Vol. 4 Num. 3 Jun. 2011 7

CLEMENTE-MARCELO HIRSCHFELDT

RESUMEN

L

os sistemas de levantamiento artificial (SLA) juegan un rol importante durante el proceso de produ-

cción de un campo hidrocarburífero. Su selección, adquisición, instalación, evaluación, monitoreo

y su posterior inspección, involucra a diferentes actores, así también como compañías y diferentes

sectores dentro de ellas. Si además le agregamos factores como la ubicación de los campos, la cultura local

y la experiencia de las empresas en esas locaciones, el conocimiento y análisis de cada uno de todos estos

factores es crítico no solo a la hora de maximizar la vida útil de un SLA específico, sino también a la hora

de maximizar y optimizar la producción de un campo de forma efectiva y eficiente. Otro factor importante a

ser considerado es la dinámica que presenta el desarrollo de nuevos campos hidrocarburíferos o aquellos

que estén afectados a distintas tecnologías de EOR como los de recuperación secundaria por inyección de

agua, donde los requerimientos y las condiciones de los campos cambian en forma continua. El siguiente

trabajo presentará algunos de los conceptos y recomendaciones relacionadas a la gestión de los sistemas de

levantamiento artificial durante la vida productiva de un campo hidrocarburífero, contemplando los criterios

de selección, adquisición, instalación, evaluación y monitoreo, así como su posterior inspección. Estos puntos

analizados también involucrarán conceptos que estarán relacionados tanto a las empresas operadoras, como

las empresas de servicio, y a sectores relacionados a la adquisición, evaluación y monitoreo, entre otros

puntos. Así mismo se mencionarán algunas definiciones de roles, funciones y competencias a ser requeridas,

para poder hacerle frente a los desafíos que estos sistemas presentan.

Palabras claves: Sistemas de levantamiento artificial, Ingeniería de producción, Campos maduros.

RESUMO

O

s sistemas de levantamento artificial (SLA) cumprem um papel importante durante o processo de

produção de um campo Hidrocarbonífero. Sua seleção, aquisição, instalação, avaliação, monito-

ramento e sua posterior inspeção envolvem diferentes atores, assim como companhias e diferentes

setores dentro delas. Se, além disso, acrescentamos fatores como a localização dos campos, a cultura local

e a experiência das empresas nesses lugares, o conhecimento e a análise de cada um de todos estes fatores

é crítica não apenas no momento de maximizar a vida útil de um SLA específico, mas também no momento

de maximizar e otimizar a produção de um campo de forma efetiva e eficiente. Outro fator importante que

deve ser considerado é a dinâmica que apresenta o desenvolvimento de novos campos hidrocarboníferos

ou daqueles que estiverem afetados a distintas tecnologias de EOR como os de recuperação secundária

por injeção de água, onde as necessidades e as condições dos campos mudarem de forma contínua. O

seguinte trabalho apresentará alguns dos conceitos e das recomendações relacionadas à gestão dos siste-

mas de levantamento artificial durante a vida produtiva de um campo hidrocarbonífero, contemplando os

critérios de seleção, aquisição, instalação, avaliação e monitoramento, assim como sua posterior inspeção.

Estes pontos analisados também envolverão conceitos que estarão relacionados tanto com as empresas

operadoras, como com as empresas de serviço, e com setores relacionados com a aquisição, avaliação e

monitoramento, entre outros pontos. Também serão mencionadas algumas definições de papéis, funções e

competências necessárias, para poder fazer frente aos desafios que estes sistemas apresentam.

Palavras chaves: Sistemas de evantamento artificial, Engenharia de produção, Campos maduros.

8 CT&F - Ciencia, Tecnología y Futuro - Vol. 4 Num. 3 Jun. 2011

ARTIFICIAL LIFT MANAGEMENT RECOMMENDATIONS AND SUGGESTIONS OF BEST PRACTICES

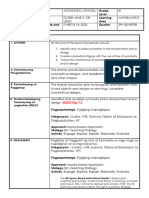

During this management cycle, interdisciplinary

1. INTRODUCTION

work and the participation of the different companies

involved is a common factor in these processes. These

ALS Management Cycle

factors have been listed and classified in Table 1 below.

Developing an oil field using Artificial Lift Systems

(ALS) involves different stakeholders and activities that

are part of the comprehensive management cycle of said 2. ALS ANALYSIS, SELECTION AND DESIGN

systems. Identifying each of the stages and the people

who take part in the processes is fundamental to be able

Selection Criteria

to optimize existing procedures or implement a compre-

Although there has been discussion regarding ALS

hensive medium and long-term management strategy.

selection criteria over the last 40 years as the industry

has involved, it is important to review some of the most

The system illustrated in Figure 1 can be considered important criteria and considerations when it comes

a management cycle during the implementation and to selecting an ALS (Clegg, Bucaram & Hein, 1993).

operation of ALS, and can serve as a guide to be able The selection criteria include but are not limited to the

to analyze the different aspects involved in the process. following:

The cycle can start out with the selection of one or ● Based on the mechanical limit.

more ALS alternatives based on the analysis of infor- ● Based on advantages and disadvantages.

mation on the reservoirs to be produced, well data in

terms of the construction, and other aspects that will be ● Selection through expert programs.

discussed throughout this paper. Based on this analysis ● Selection by comparison of Net Present Value (NPV).

and once the best method(s) have been selected, we

go on to the stage of well acquisition, installation and

Based on the experience of companies using the

operation, which closes one of the first sub-cycles in a

different ALS, the conjunction of these methodologies

comprehensive management system (Hirschfeldt, 2010).

is common practice, so more than one methodology is

usually used. Table 2 provides a summary of the consi-

Once the well has been started up, the monitoring derations that encompass the criteria listed above.

and control of its operating variables is essential not

only to guarantee the optimum operation of the ALS

Processes and Participants Involved in ALS Selection

within the established parameters, but also to maximize

and Design

reservoir production. Continuous analysis may gene-

rate the need to work on the system in operation, either The selection process should include a vision of the

based on surface action (changes in systems or other present as well as the future development of the field,

operating condition) as well as downhole action, either without disregarding past experiences. It should also

by replacing elements or the ALS for another in order consider multidisciplinary efforts, mainly in the fields

to meet development objectives. that are subjected to sustained, continuous development.

This process definitely begins with the planning of dri-

Another situation that may arise is the failure of one lling and termination, and the development strategy of

of the components of the installed system, which, based the wells in question (Clegg et al., 1993).

on the analysis and evaluation thereof, should provide

information for decision-making when it comes to the For instance, when a well is designed (diameter and

design of future facilities. In other cases, when the me- route), many aspects should be shared beforehand with

chanical limit of the ALS has been exceeded, you may those who will play a direct role in selecting an artificial

have to redefine the development strategy of an oil field lift system, because it can limit the type of systems that

as regards the implementation of secondary recovery can be used or the maximum extraction capacity there

projects, geometry and well depth, etc. of, and therefore affect the development of the reservoir.

CT&F - Ciencia, Tecnología y Futuro - Vol. 4 Num. 3 Jun. 2011 9

CLEMENTE-MARCELO HIRSCHFELDT

Development

strategy review

Reservoir data Well data Others

Caudal, % W, Pwf

Monitoring Analysis

Operation Data

Optimization Design and Failures

Selection

Acquisition

Wells Intervention

Inspection / Testing

Installation / Pulling

Operation

Figure 1. ALS Management Cycle

In addition, the reservoir department should provide ● Principle of operation and limits of the different ALS.

information on the production forecast based on the

implementation of a secondary recovery project or other

development plan. Mechanical Limit as an ALS Selection Criterion

During the selection and design process, one of the

The minimum technical competencies required by most important factors to be taken into consideration

those who will participate directly in selection, design is a system's capacity to transfer power from the unit

and analysis include: itself to the pump. Therefore, casing diameter becomes

one of the most important border conditions because it

● Performance analysis of the reservoir and surroun- restricts not only tubing diameter, but also other ele-

ding areas (PI - Productivity Index and formation ments such as sucker rods or centrifugal pump shafts.

damage are parameters that affect flow performance Figure 2 illustrates power transfer in classic artificial

in reservoirs). lift systems (Hirschfeldt & Ruiz, 2009).

● Physical chemical properties of the fluids produced.

Dealing with the unpredictability of the failure of the

● Concepts of fluid dynamics, mechanics and elec- elements of ALS that exceed said mechanical limit is an

tricity. everyday task for Production Engineering Departments.

10 CT&F - Ciencia, Tecnología y Futuro - Vol. 4 Num. 3 Jun. 2011

ARTIFICIAL LIFT MANAGEMENT RECOMMENDATIONS AND SUGGESTIONS OF BEST PRACTICES

Table 1. Processes and Participants Involved in ALS Management

PARTICIPANTS

PROCESSES OPERATOR SERVICES

Analysis Production engineer Commercialization

Selection Production operations Application engineering

Acquisition Reservoirs Engineering/field operations

Installation/pulling Drilling Sales

Inspection Supplies

Operation Contracts

Monitoring

Table 2. Summary of considerations contemplated in ALS selection criteria

RESERVOIR WELL OTHERS ECONOMIC

Productivity (Static Pressure Caudal vs Pwf) Location (on-shore - off-shore) Flexibility Initial investment

Reservations involved Geometry Energy Operating cost

Fluid type (% of phases, viscosity, solid

content, fluid aggressiveness) Diameter Products and services Services cost

GOR Availability Re-sale

Bottom temperature Completion Previous experience

Depth Surface disturbance

Temperature Visual impact

Although some of the recommended procedures in duction decline (normal situation in Sec. Rec.

this area are mentioned throughout this paper, it can projects).

be said that failure analysis and subsurface equipment

testing following extraction are fundamental when it

comes to making decisions regarding new designs or ● The increase in water injection triggers an increase

repairs. In addition, if the analysis of the root cause in total fluid per well and, therefore, in the power

of said failures concludes that the mechanical limit transmitted from the motor to the pump, which can

of the ALS has been reached, a change in production cause the sucker rods (mechanical or progressive

strategy is required. cavity pumping) or the centrifugal pump shafts to

exceed maximum capacity.

The following is an example of how the mechani-

cal limit of an ALS can condition the development of

an oil field, where oil production is the result of water ● This situation can lead to the reconsideration of a

injection as a secondary recovery method: restriction in the water injection volume or other

distribution, because the optimum development of

● The project considers a gradual increase in water these projects is associated with the right balance

injection volumes in accordance with oil pro- between Injection and Production.

CT&F - Ciencia, Tecnología y Futuro - Vol. 4 Num. 3 Jun. 2011 11

CLEMENTE-MARCELO HIRSCHFELDT

Power Bottom

Motor Converter

Transmission Pump

FLOWRATE AND

ENERGY Sucker Rods PRESSURE

Sucker Rods

PCP Drive head

motor and

Pumping Unit protector shaft

BEC Protector

Figure 2. Power transfer in artificial lift systems

3. ALS PERFORMANCE EVALUATION tial (volume vs. dynamic pressure), production control

and level measurements should be in line with similar

The analysis requires the proper logging of operating development conditions for the best approximation to

variables, in which their quality is fundamental in order determine the extractive potential of production wells.

to make the right decisions. Regardless of whether the

variables are taken manually or automatically (sensors Operating Parameters

/ recorders), their analysis and integration is important

● Electric current (fundamental in Electric Submersible).

in order to be able to conduct a performance analysis

for decision-making purposes. These variables include:

● Loads in surface units (PCP and Sucker Rod Pumping).

Production Controls ● Loads in rods (PCP and Sucker Rod Pumping).

The measurement of the volume produced by the di-

fferent phases (oil, water and gas) is fundamental when ● Pumping Speed: RPM (Revolutions per minute), SPM

it comes to evaluating not only well potential but also (Strokes per minute), Hz, working stroke, etc.

the performance of the production system itself. The first

question we have to ask ourselves is “What do we need?… ● Downhole vibrations (ESP).

¿a large number of production controls each month to

meet the quantitative objectives ..or few quality controls ● Wellhead pressure.

that will enable us to make decisions that will add value

and help optimize the fields? ● Downhole temperatures (Motor temperature, down-

hole equipment temperature).

Fluid Levels (Dynamic Pressures) The following are examples of variable monitoring

Monitoring dynamic fluid level (associated with the in different artificial lift systems: Figure 3, 4 and 5.

reservoir's dynamic pressure) should be a part of essential

monitoring routines.

They can be acquired by down hole sensors (mea- 4. INSPECTION, FAILURE ANALYSIS AND

suring suction pressure) or at the surface using manual REUSE OF SUBSURFACE ELEMENTS

echo-sounders.

After extracting Subsurface elements used in ALS

Due to the importance of these measurements, along from the well, inspection should be a part of the work

with production volume to determine reservoir poten- routines at the companies using the different systems.

12 CT&F - Ciencia, Tecnología y Futuro - Vol. 4 Num. 3 Jun. 2011

ARTIFICIAL LIFT MANAGEMENT RECOMMENDATIONS AND SUGGESTIONS OF BEST PRACTICES

Operating Speed vs. Suction Pressure

Pump setting depth 2,925 ft Down Hole Pressure (psi) Speed (RPM) Well # Las Flores

450 450

With control loop Without control loop

400 400

350 350

Down Holo Prossure (psi)

300 300

Speed (RPM)

250 250

200 200

150 150 psi - Down hole Pressure set point 150

100 100

50 Shut down Shut down 50

0 0

24-mar

24-mar

24-mar

25-mar

25-mar

25-mar

25-mar

25-mar

25-mar

26-mar

26-mar

26-mar

26-mar

26-mar

27-mar

27-mar

27-mar

27-mar

27-mar

27-mar

28-mar

28-mar

28-mar

28-mar

28-mar

29-mar

29-mar

29-mar

29-mar

29-mar

29-mar

30-mar

30-mar

30-mar

30-mar

Date

Figure 3. On line revolution speed log (RPM) and suction pressure in BCP based on a control loop governed by a frequency inverter (Hirschfeldt, 2005)

Figure 4. Dynamometric log in wells with mechanical pumping based on telemonitoring systems

CT&F - Ciencia, Tecnología y Futuro - Vol. 4 Num. 3 Jun. 2011 13

CLEMENTE-MARCELO HIRSCHFELDT

2500

2400 350

Pressure

2300 Temperature

Motor Temperature

330

2200

2100

Temperature (°F)

310

Pressure (PSI)

2000

1900

290

1800

1700

270

1600

1500 250

19/0514:24

19/0519:12

20/0500:00

20/0504:48

20/0509:36

20/0514:24

20/0519:12

20/0500:00

18/0514:24

18/0519:12

19/0500:00

19/0504:48

19/0509:36

Days

Figure 5. Log of motor temperature, downhole temperature and suction pressure in a ESP system

These processes not only allow you to evaluate the of subsoil equipment extracted from the well of the

performance of the equipment extracted, but also enable main ALS:

more in-depth failure analysis and the reuse of subsoil

elements if they are within certain parameters.

Progressive Cavity Pumping (PCP)

As regards the reuse of materials, this does not mean ● Visual and dimensional rotor inspection. Chrome pla-

elements deficient in quality are going to be installed in ting of those that lose only the external cover.

the well, because you have to bear in mind that one of ● Visual and dimensional stator inspection.

our objectives is to maximize the life cycle of produc-

● Performance testing in test bench, logging of the

tion wells. Proper classification of materials based on

volume, power and torque required for different

the traceability of their history will help us save a great

deal on production costs. pressures and RPM.

● Identification of deformation cycles accumulated by

"In mature fields where the production cost increases stator elastomer before testing as criteria for acceptance

significantly, inspection and the reuse of subsoil ele- and disposal (Hirschfeldt, 2001) (Figure 6 and 7).

ments is fundamental in order to maintain the profita-

bility of many fields, but in order to do so, the operating

Electric Submercible Pump (ESP)

company and the professionals in charge have to become

directly involved in the process." ● Pump testing in test bench (measurement of flow and

power consumed).

Inspection of Subsurface Equipment ● Disassembly of pumps for dimensional control, elimi-

The following is a description of examples asso- nate scaling or plugging due to heavy crude during the

ciated with inspection and the performance analysis different stages and subsequent reuse of the elements.

14 CT&F - Ciencia, Tecnología y Futuro - Vol. 4 Num. 3 Jun. 2011

ARTIFICIAL LIFT MANAGEMENT RECOMMENDATIONS AND SUGGESTIONS OF BEST PRACTICES

● Motor testing and repair: Drying of winding, condi- making circuit. It is a well-known fact that a recurring

tion of bearings, dielectric state of winding, etc. failure in a key ALS element not only causes production

losses, but also gives rise to costs associated with pu-

● Testing of protective seals: dynamic testing, logging lling services to replace elements of the installed system.

power consumed based on axial charges.

In turn, depending on the type of location/environ-

● Dielectric testing for power cable (API 11S) (Figu-

ment where the system is installed (jungle, sea, remote

re 8).

fields, etc.), not only will the associated costs be higher,

but at times, it cannot be accessed with service to extract

Sucker Rod Pumping the damaged element from the well in time and form.

● Disassembly of pumps inspecting each of the ele-

ments: valves (seat and ball), barrel, anchor. All the above translates into the reliability of the

equipment that many times is not only associated with

● Hydraulic testing (API 11AR). installing expensive equipment, but also knowing about

previous experiences based on the historic log of failures

Failure Analysis and Evaluation and their respective root cause analyses.

Subsurface Failures and Their Impact on ALS Imple-

mentation Key Performance Indicators (KPI)

The use of performance indicators is important when

As regards ALS management, both failure analysis

it comes to making decisions or monitoring the evolution

and statistical monitoring and logging are important

of a field as regards failures in ALS elements. Classic

when it comes to providing feedback for the decision- indicators include:

Figure 6. "In-House" inspection and Recovery procedures for PCP. Diadema Field (CAPSA). Patagonia Argentina (Year 2001) (Hirschfeldt,

2001; Hirschfeldt, 2006; Hirschfeldt, 2003)

Figure 7. “In-House” testing of PCP. Diadema Field (CAPSA). Patagonia Argentina (Year 2001) (Hirschfeldt, 2001; Hirschfeldt, 2006;

Hirschfeldt, 2003)

CT&F - Ciencia, Tecnología y Futuro - Vol. 4 Num. 3 Jun. 2011 15

CLEMENTE-MARCELO HIRSCHFELDT

Figure 8. Testing of centrifugal pumps and inspection of ESP equipment stages in service company workshops

(WoodGroup ESP. Colombia)

API (Annual Pulling Index) with high productivity / high gas: liquid ratio and avai-

This indicator can be logged month by month and it lability as regards injection gas pressure and volume.

allows you to forecast the number of failures wells will

have on average in one year. It is expressed in Interven- ● As well productivity begins to decline (power loss),

tions / well / year. For instance, if we have a population more external power has to be supplied.

of 100 production wells and, in one month, we have 5

interventions with pulling equipment due to failures in

● As this demand increases, the system is inefficient

the wells, we have:

at times from the energy standpoint as well as due

to the lack of gas compression capacity (high costs,

IPA= (Nº of interventions)/(Running Productive wells)× maintenance, gas shortage, etc.).

12 months=5/100×12=0,6interventions/well/year

● Due to the decrease in the gas: liquid ratio (increase

This means each well would fail 0,6 times per year, in liquid column density), depending on the liquid

or that the life cycle of a well is approximately 1,6 years. volume to be extracted, it may be possible to migrate

to an intermittent BN system, plunger lift, mechanical

This simple indicator can be applied to monitor pumping, or perhaps an electric centrifugal pumping

failures per well, per field, per type of ALS, per system system (ESP) depending on production potential.

element (rods, pump, tubing, etc.) or per causes origi-

nating the failures. Oversaturated Fields in the Process of Decline

Where depending on reservoir pressure and petro

physical parameters, the decline can take place over

several years’ time (between 5 and 10 years), or even

5. APPLICATION OF ALS BASED ON THE less, such as the case of reservoirs with very low per-

PRODUCTION HISTORY OF WELLS meability with sudden declines over the first 6 months

of development:

Variation in production potential

During the life of an oil well, its production potential ● The ESP installation is the first choice due to the

will vary depending on the type of drain system and/or mechanical pumping limitations for the assumed

external power input such as secondary recovery pro- conditions of depth and volume.

jects. This is an everyday situation in most oil fields in the

world and the following are several possible scenarios:

● As well production begins to decline (decrease in

the potential fluid volume), the mechanical pumping

Fields with naturally flowing wells system may be the alternative to cover a wide range

Kickoff with continuous Gas Lift in flowing wells of volumes during the remaining productive life.

16 CT&F - Ciencia, Tecnología y Futuro - Vol. 4 Num. 3 Jun. 2011

ARTIFICIAL LIFT MANAGEMENT RECOMMENDATIONS AND SUGGESTIONS OF BEST PRACTICES

IPA-Fishing Rod Interventions IPA - Average 6 months

12 0,300

10 0,250

8 0,200

N° Interventions

6 0,150

4 0,100

2 0,050

0 0,000

may. - 04

jul. - 04

sep. - 04

nov. - 04

mar. - 05

jul. - 05

sep. - 05

nov. - 05

Jan. - 04

Jan. - 05

mar. - 04

may - 05

Months

Figure 9. Example of monitoring the well intervention index as a performance indicator in the life cycle of wells with ALS

Mature fields affected by a secondary recovery project References - Figure 10

Are another common scenario during the revitaliza-

tion of mature fields. 1. Mechanical Pumping: At a low extraction rate

as total fluid production declines.

● During its history of decline (previous case), a well

can end its productive life cycle with a mechanical 2. Progressive Cavity Pumping (PCP): The fle-

pumping system with a low production rate and small- xibility of this system makes changes in extrac-

diameter pumps. tion rate fast and simple, as the output of fluid

from the reservoir increases.

● When water injection starts in an adjacent secondary

3. Electric Centrifugal Pumping (ECP): The high

recovery project, productivity (associated with the

RPM of ECP generates problems of wear in

increase in reservoir pressure) will rise, so depending

production tubing and rods, and the elastomer

on the mechanical limit and flexibility of the current

becomes brittle. Since new perforations are

system, changing over to other systems such as pro-

opened at a deeper level to expand the secon-

gressive cavity (PCP) or electric centrifugal pumping

dary recovery project, the ECP system allows

(ECP) is a step to be taken into consideration.

the extraction of these volumes at said depths,

perhaps exceeding the mechanical limit of the

Evolution of the Application of ALS sucker rods of a PCP system.

Based on the productive history of the oil fields, and

as its power is modified, different ALS can be used to

adapt to their requirements. Figure 10 illustrates the pro- “A production well may require more than one

ductive history of a well and the possible ALS changes type of Artificial Lift System during its productive life

throughout the life thereof. (Hirschfeldt, Distel & Martínez, 2007)."

CT&F - Ciencia, Tecnología y Futuro - Vol. 4 Num. 3 Jun. 2011 17

CLEMENTE-MARCELO HIRSCHFELDT

bpd

jul.-98 apr.-01 jan.-04 oct.-06 jul.-09 apr.-12 dec.-14

Years

Figure 10. Evolution of the application of an ALS throughout the productive life of a well

6. INTEGRAL MANAGEMENT OF ALS work agreements between operators and product/

service suppliers, but they are generally the result of

As we have gone over throughout this article, compre- the knowledge of the needs of the operator, supported

hensive ALS management in an oil field is associated by the experience of a specific service company.

with different stages that involve stakeholders, including

people, sectors and companies. Case B -Operators with out experience in ALS ma-

nagement

The different management models depend on the Design, selection and installation are almost entirely

ALS experience of operating companies and their pro- delegated in the companies that supply these products,

fessionals. The following are two possible scenarios that with practically minimal participation of the oil field

represent cases existing in the Latin American region. operators in this stage (Figure 12).

As regards the acquisition of the equipment related to

Case A -Oil Field Operators with Experience in the

each ALS, it is often based on framework agreements or

application and widespread use of ALS

alliances where the service companies design, provide

They can be in condition to evaluate and select the and operate the ALS in which the equipment for each

products offered on the market as well as the service well is leased in many cases.

companies associated with said products (Figure 11).

This method would be a good start during the lear-

Depending on the size of these companies, many time ning curve of operators, because it is important to depend

acquisition takes place by alliance (between operators on the experience of service companies in this regard.

and services), which also include maintenance, inspec- But in many cases, the practically full delegation of ALS

tion, monitoring and engineering services, among others. management disregards the responsibilities of those who

The Production Engineers of the operating companies should be carrying out the process, such as the areas of

also play an active role in testing equipment, evaluating Production Engineering or Development, because not

performance and analyzing failures, at either their own only is optimum reservoir development at stake, but also

laboratories or those of the service companies. This the costs associated with the development of the fields

model is usually associated with alliances or frame- (costs of materials, services, power, etc.).

18 CT&F - Ciencia, Tecnología y Futuro - Vol. 4 Num. 3 Jun. 2011

ARTIFICIAL LIFT MANAGEMENT RECOMMENDATIONS AND SUGGESTIONS OF BEST PRACTICES

Performance Design and

Production engineering (Operator) selection

analysis and

operational decision

making

Technical-economical

proposals

Performance

Production operations evaluation

(OP) Application engineering

(service)

Operation, Installation and

control, putting into

monitoring

Figura 11. Management system of companies operating oil fields with experience in ALS application

Exploitation management Contracting

(Operator) (Operator)

Commercial

management (Service)

Alliance or general contract

Well information

Production delivery

engineering/productivity Application engineering

(Operator) Design and selection (Service)

Installation, operation,

monitoring, optimization

Figure 12. Operators with Scarce Experience in the management and widespread use of ALS

Another possible disadvantage of these models is that not choose candidate wells once the ALS have been

they are usually static and Production Engineers find acquired in a widespread manner."

that the only options to choose an ALS are delimited

by a framework agreement. This situation may prevent In order to increase the involvement of operators

people from choosing alternatives that actually match in this management process (Case A), you should start

the needs of the well or field to be developed. out with comprehensive training for the professionals

related to the activity to get to know the types of ALS,

"It is important to select and acquire ALS equipment their principles of operation, mechanical limits and

based on the present and future needs of my wells and maintenance requirements, among other important

CT&F - Ciencia, Tecnología y Futuro - Vol. 4 Num. 3 Jun. 2011 19

CLEMENTE-MARCELO HIRSCHFELDT

aspects. In addition, benchmarking with operators Clegg, J.D., Bucaram, S.M. & Hein, N.W. (1993). Reco-

that have more experience is another valid alternative, mmendations and Comparisons for Selecting Artificial Lift

because you can learn from those who have already Methods. J. Petrol. Tech. 45 (12), 1128-1131, 1163-1167.

gone down the same path on the matter.

Hirschfeldt, C. M. (2001). PC Pump in Diadema Oilfield. San

Jorge Basin. Argentina. SPE Progressing Cavity Pumps

Workshop, Puerto la Cruz, Venezuela.

7. CONCLUSIONS Hirschfeldt, C. M. (2003). Manifestación del Fenómeno de

Histeresis En Pcpump En Yac. Diadema. II Congreso de

Although the strategies to develop oil fields may vary Hidrocarburos IAPG. Buenos Aires, Argentina.

a great deal based on their maturity or the corporate phi-

losophy regarding the development of a field, ALS mana- Hirschfeldt, C. M. (2005). Pcpump Automation in Cerro

Dragon Oilfield. SPE Progressing Cavity Pumps ATW,

gement should be taken on with a strategic, integrated

Bariloche, Argentina.

vision in accordance with the development of a field.

Hirschfeldt, C. M. (2006). Artificial Lift Experience in Mature

It is obvious that the increasing number of production Fields - Case Study Golfo San Jorge Basin. Artificial Lift

Conferences, Jakarta, Indonesia.

wells that require an ALS in a field make it fundamental

to implement management systems or work methodolo- Hirschfeldt, C. M. (2010). Artificial Lift Management. SPE

gies as regards analysis, selection, design, operation and Applied Technology Workshop- Artificial Lift System,

optimization, not only due to the need to maximum oil Cancún. Mexico.

production, but also due to the high economic impact

that the products and services associated with the ALS Hirschfeldt, C. M., Distel, F. & Martínez, P. (2007). Artificial-

Lift Systems Overview and Evolution in a Mature Basin:

have on production costs.

Case Study of Golfo San Jorge . SPE Latin American and

Caribbean Petroleum Engineering Conference held in

Regardless of the working methodology implemen- Buenos Aires, Argentina. SPE 108054.

ted, the starting point is an understanding of the theoretic

and practical/operative concepts related to the principles Hirschfeldt, C. M. & Ruiz, R. (2009). Selection Criteria for

of operation and limits of the ALS. Artificial Lift System Based on the Mechanical Limits:

Case Study of Golfo San Jorge Basin SPE Annual Tech-

nical Conference and Exhibition held in New Orleans,

In addition, the firm commitment of those who have

Louisiana, USA. SPE 124737.

to deal with these issues will be required, from deve-

lopment management units to operating sectors, mainly

in the fields where there is no culture associated with

the use of ALS and where classic systems can turn into

new technologies for these areas due to their scarce use.

REFERENCES

API 11S. Recommended Practice for the Operation, Main-

tenance and Troubleshooting of Electric Submersible

Pump Installations.

API 11AR. Recommended Practice for Care and Use of

Subsurface Pumps.

20 CT&F - Ciencia, Tecnología y Futuro - Vol. 4 Num. 3 Jun. 2011

You might also like

- Gas and Oil Reliability Engineering: Modeling and AnalysisFrom EverandGas and Oil Reliability Engineering: Modeling and AnalysisRating: 4.5 out of 5 stars4.5/5 (6)

- Artificial Lift Management Recommendations and Suggestions of Best PracticesDocument15 pagesArtificial Lift Management Recommendations and Suggestions of Best PracticesALBERTO MADRIGAL MAGAÑANo ratings yet

- Managerial Judgement and Strategic Investment DecisionsFrom EverandManagerial Judgement and Strategic Investment DecisionsRating: 4 out of 5 stars4/5 (2)

- Asset Condition Assessment & Life Extension ManagementDocument7 pagesAsset Condition Assessment & Life Extension ManagementHugoCabanillas100% (1)

- Benchmarking Best Practices for Maintenance, Reliability and Asset ManagementFrom EverandBenchmarking Best Practices for Maintenance, Reliability and Asset ManagementNo ratings yet

- Lean MiningDocument9 pagesLean MiningmichelleNo ratings yet

- Implementing Lean Principle Into Mining Industry Issues and ChallengesDocument9 pagesImplementing Lean Principle Into Mining Industry Issues and ChallengesDavid Omar Torres GutierrezNo ratings yet

- TQM in Sri Lankan Service OrganizationsDocument14 pagesTQM in Sri Lankan Service Organizationsamit kumawatNo ratings yet

- Evolution of Management System Certification: An Overview: March 2021Document12 pagesEvolution of Management System Certification: An Overview: March 2021Huy Hoàng Lê ĐứcNo ratings yet

- Flotation Circuit Optimization Using Modelling and SimulationDocument14 pagesFlotation Circuit Optimization Using Modelling and SimulationOnesime MutebaNo ratings yet

- Hif 15001Document10 pagesHif 15001Khan MARCEL NjiNo ratings yet

- LCA Background Lecture NotesDocument15 pagesLCA Background Lecture Notessalman hussainNo ratings yet

- Notes BPSM 12 Feb 2020Document2 pagesNotes BPSM 12 Feb 2020varun rajNo ratings yet

- Life Cycle CostingDocument82 pagesLife Cycle CostingronfrendNo ratings yet

- Manuscript v.4Document36 pagesManuscript v.4Kim PVNo ratings yet

- Auditing of Explorative ProcessesDocument16 pagesAuditing of Explorative ProcessesLeeNo ratings yet

- Chevron TexacoDocument9 pagesChevron TexacoSzideritNo ratings yet

- Management Ofc: Examples From PracticeDocument10 pagesManagement Ofc: Examples From PracticeKaterina HadzijevskaNo ratings yet

- Term Paper Synopsis 2009-2011 MGT-519: Lovely Professional UniversityDocument9 pagesTerm Paper Synopsis 2009-2011 MGT-519: Lovely Professional UniversityChandan Kumar SinghNo ratings yet

- Auditing of Explorative ProcessesDocument16 pagesAuditing of Explorative ProcessesSoufiane LabraziNo ratings yet

- Catalyst Scale UpDocument5 pagesCatalyst Scale UpJayakumar PararasuramanNo ratings yet

- Developing A Maintenance StrategyDocument8 pagesDeveloping A Maintenance StrategyPaulo RobertoNo ratings yet

- Applications of Maintenance OptimizationDocument12 pagesApplications of Maintenance OptimizationmelatorNo ratings yet

- Marsh Risk Engineering Position Paper 05 Management of ChangeDocument24 pagesMarsh Risk Engineering Position Paper 05 Management of ChangeMathew MammenNo ratings yet

- OA BestPracDocument60 pagesOA BestPracUpik BulkisNo ratings yet

- Lean SaurinDocument11 pagesLean SaurinRodrigoGoyannesNo ratings yet

- Assessment Emerging Approaches, Challenges and Opportunities in Life CycleDocument6 pagesAssessment Emerging Approaches, Challenges and Opportunities in Life CycleKenan SaatciogluNo ratings yet

- Pareto Analysis of Total Quality Management Factors Critical To Success For Service IndustriesDocument15 pagesPareto Analysis of Total Quality Management Factors Critical To Success For Service Industriesvishaalnannaware28No ratings yet

- Management of Change - 2013 - Rev 3Document24 pagesManagement of Change - 2013 - Rev 3Ivan Guerrero100% (1)

- Lean Six Sigma Applications in Oil and Gas Industry: Case StudiesDocument5 pagesLean Six Sigma Applications in Oil and Gas Industry: Case StudiesJASH MATHEW100% (1)

- Reliability Centered Maintenance RCM Implementation and BenefitsDocument4 pagesReliability Centered Maintenance RCM Implementation and BenefitsNguyễn Duy KhangNo ratings yet

- Identification and Prioritization Lean Six Sigma Barriers in MsmesDocument9 pagesIdentification and Prioritization Lean Six Sigma Barriers in MsmesShad AlertNo ratings yet

- Chapter One Feasibilities Study of Maintenance Activities of Foldfields Plant. 1.0 Background of StudyDocument4 pagesChapter One Feasibilities Study of Maintenance Activities of Foldfields Plant. 1.0 Background of Studyanon_304962925No ratings yet

- Holistic Route SelectionDocument10 pagesHolistic Route SelectionrayzaNo ratings yet

- Managing Obsolete Technologies - Strategies and PracticesDocument30 pagesManaging Obsolete Technologies - Strategies and PracticescarakooloNo ratings yet

- Application of Reliability Centred Maintenance To Dynamic PlantDocument13 pagesApplication of Reliability Centred Maintenance To Dynamic Plantgvc1No ratings yet

- HSE Ageing Plant - Site Operator Self-Assessment Question SetDocument15 pagesHSE Ageing Plant - Site Operator Self-Assessment Question SetkzlpNo ratings yet

- A Review On Lubricant Condition Monitoring Information Analysis For Maintenance Decision SupportDocument35 pagesA Review On Lubricant Condition Monitoring Information Analysis For Maintenance Decision SupportHector JNo ratings yet

- A Review of Production Planning and ControlDocument32 pagesA Review of Production Planning and ControlengshimaaNo ratings yet

- Lean Management Tools and Techniques A LDocument7 pagesLean Management Tools and Techniques A LHammamiSalahNo ratings yet

- 2014 - Sustainable OM - Design, Modelling and AnalysisDocument6 pages2014 - Sustainable OM - Design, Modelling and AnalysisSrishti PandeyNo ratings yet

- Best Practices in Systems Development Lifecycle: An Analyses Based On The Waterfall ModelDocument8 pagesBest Practices in Systems Development Lifecycle: An Analyses Based On The Waterfall ModelLelisa SdNo ratings yet

- Project TurnaroundsDocument10 pagesProject TurnaroundsjorgedwinNo ratings yet

- COM2014 PAPERID-8565Thwaites ProtectedDocument44 pagesCOM2014 PAPERID-8565Thwaites ProtectedmineralmadnessNo ratings yet

- National Seminar On Value Stream Mapping For Process Improvement FinalDocument9 pagesNational Seminar On Value Stream Mapping For Process Improvement FinalsreerpilNo ratings yet

- Strategic Dimensions of Maintenance Management: Albert H.C. TsangDocument33 pagesStrategic Dimensions of Maintenance Management: Albert H.C. Tsangsuna06m6403No ratings yet

- 2012 PsychogiosDocument18 pages2012 PsychogiosGuilherme CietoNo ratings yet

- The Value of Remote Operating Centers VfinalDocument9 pagesThe Value of Remote Operating Centers VfinalCseixas100% (1)

- CAT Performance Metrics For Mobile Mining Equipment Version 1.1 PDFDocument64 pagesCAT Performance Metrics For Mobile Mining Equipment Version 1.1 PDFPamella Julian100% (9)

- Research Proposal, Oil and Gas FrameworkDocument11 pagesResearch Proposal, Oil and Gas FrameworkMuhammad Ahmed100% (1)

- Kuliah 03 Audit Dan Tata Kelola TIDocument101 pagesKuliah 03 Audit Dan Tata Kelola TIAdam RiskyNo ratings yet

- Amie PDFDocument21 pagesAmie PDFJunaid PalangadNo ratings yet

- Emerging Approaches, Challenges and Opportunities in Life Cycle AssessmentDocument6 pagesEmerging Approaches, Challenges and Opportunities in Life Cycle AssessmentJoãoPauloAzevedoNo ratings yet

- MGT410 Operations ManagementDocument7 pagesMGT410 Operations Managementprashant jainNo ratings yet

- 0510 Performance Metrics For Mining EquipmentDocument64 pages0510 Performance Metrics For Mining EquipmentLorenzoNoePerezRodriguez75% (4)

- Systems Development Life CycleDocument17 pagesSystems Development Life CycleanaeemkhanNo ratings yet

- The ISO 13381-1 Standard's Failure Prognostics Process Through An Example-2010-12pDocument12 pagesThe ISO 13381-1 Standard's Failure Prognostics Process Through An Example-2010-12pwylfredy100% (1)

- An Approach To Reservoir ManagementDocument7 pagesAn Approach To Reservoir ManagementRicci FGNo ratings yet

- A Survey On Lean Manufacturing Implementation in Malaysian Automotive IndustryDocument9 pagesA Survey On Lean Manufacturing Implementation in Malaysian Automotive IndustryMaria Jose Guevara CabreraNo ratings yet

- Applsci 13 07022Document18 pagesApplsci 13 07022Nur AzlinaNo ratings yet

- Project Presentation On Rocker Bogie Suspension System: Babu Banarasi Das Northern India Institute of Technology, LucknowDocument21 pagesProject Presentation On Rocker Bogie Suspension System: Babu Banarasi Das Northern India Institute of Technology, LucknowAnoop SinghNo ratings yet

- Discussion EssayDocument25 pagesDiscussion EssayAnkur SharmaNo ratings yet

- Grundig Cuc4511Document68 pagesGrundig Cuc4511Saulius KalasauskasNo ratings yet

- Bank and Shore Protection in California Highway Practice., - Full - ViewDocument442 pagesBank and Shore Protection in California Highway Practice., - Full - Viewnicole moralesNo ratings yet

- Optimum Theory of Population: An Assignment OnDocument10 pagesOptimum Theory of Population: An Assignment OnHarsh SenNo ratings yet

- Tantasqua Regional High School Staff Directory: AdministrationDocument4 pagesTantasqua Regional High School Staff Directory: AdministrationLauren RockNo ratings yet

- IB Questionbank - SL Logs WsDocument10 pagesIB Questionbank - SL Logs WsEmNo ratings yet

- REELY Chapter 7 Flashcards - QuizletDocument2 pagesREELY Chapter 7 Flashcards - QuizletCERTIFIED TROLLNo ratings yet

- Sant Gadge Baba Amravati University: Examination Application Form SUMMER 2021Document3 pagesSant Gadge Baba Amravati University: Examination Application Form SUMMER 2021Bramhanand pawarNo ratings yet

- Activity 9 Measuring Mass Calculating DensityDocument5 pagesActivity 9 Measuring Mass Calculating Densityapi-285524270No ratings yet

- Notes On Intertemporal Optimization: Econ 204A - Henning BohnDocument11 pagesNotes On Intertemporal Optimization: Econ 204A - Henning BohnHector RubiniNo ratings yet

- Art in Our Life.Document2 pagesArt in Our Life.hhNo ratings yet

- 10) Assessment On Performance and Challenges of EthiopianDocument11 pages10) Assessment On Performance and Challenges of EthiopianyaregalNo ratings yet

- DESIGN AND ANALYSIS OF HYDRAULIC POWERPACK AND PUMcalculationsDocument10 pagesDESIGN AND ANALYSIS OF HYDRAULIC POWERPACK AND PUMcalculationssubhasNo ratings yet

- Math 1st CODocument6 pagesMath 1st COfloriejanedNo ratings yet

- DRU#1 Engineering Meeting Minutes 12-04-14 - 004Document3 pagesDRU#1 Engineering Meeting Minutes 12-04-14 - 004vsnaiduqcNo ratings yet

- Non Heat Treatable Commercial-Purity Aluminium 1050 A: Chemical Composition Limits (In %) Aluminium 99,5% MinimumDocument1 pageNon Heat Treatable Commercial-Purity Aluminium 1050 A: Chemical Composition Limits (In %) Aluminium 99,5% Minimumprivate 2No ratings yet

- Training Evaluation Form: Seven Seas HotelDocument2 pagesTraining Evaluation Form: Seven Seas HotelPiyush SevenseasNo ratings yet

- SOP For Preparation and Standardization of Volumetric SolutionsDocument3 pagesSOP For Preparation and Standardization of Volumetric SolutionsSolomonNo ratings yet

- Ravi Shankar's Birth Chart / Kundali: Astrological Services For Accurate Answers and Better FeatureDocument1 pageRavi Shankar's Birth Chart / Kundali: Astrological Services For Accurate Answers and Better FeatureEd ReesNo ratings yet

- AJ BIGs Serpentine Pavilion Organic in Form But Not in ConstructionDocument3 pagesAJ BIGs Serpentine Pavilion Organic in Form But Not in ConstructionItamarJuniorNo ratings yet

- A Level Physics Units & SymbolDocument3 pagesA Level Physics Units & SymbolXian Cong KoayNo ratings yet

- Department of Education: Republic of The PhilippinesDocument36 pagesDepartment of Education: Republic of The PhilippinesKristine Rose CADUTDUTNo ratings yet

- Leonardo Da Vinci I&S Essay Riccardo Cellentani M8ADocument3 pagesLeonardo Da Vinci I&S Essay Riccardo Cellentani M8AVictorNo ratings yet

- Tam2601 Tutorial LetterDocument18 pagesTam2601 Tutorial LetterAnastasia DMNo ratings yet

- Appendix A 2Document7 pagesAppendix A 2MUNKIN QUINTERONo ratings yet

- MSDS - SpaDocument6 pagesMSDS - SpaChing ching FongNo ratings yet

- Maths Statistics & LR MockDocument11 pagesMaths Statistics & LR MockInnovation SkylineNo ratings yet

- Promass 63 ManualDocument48 pagesPromass 63 Manualleopoldo alejandro antio gonzalezNo ratings yet

- How Fast and Which Way?: Friday 13 October MR PatelDocument20 pagesHow Fast and Which Way?: Friday 13 October MR PatelBenjamin WatsonNo ratings yet