Professional Documents

Culture Documents

Exploring The Earth With Geophysics

Uploaded by

Johann DarnleyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exploring The Earth With Geophysics

Uploaded by

Johann DarnleyCopyright:

Available Formats

Exploring the Earth with Geophysics We can even record seismic data in the ocean

The tools we use… - For offshore surveys the seismic sensors are

installed in long streamers behind a boat.

- Gravity

Airguns serve as the energy source.

- Magnetics

- Sound waves *Seismic data looks like an "Xray" image of the

- Electricity Earth

Gravity Survey (The "Gravity" of the Situation) *Signals from the geophones go into the

"Doghouse" where they are recorded on

- In gravity prospecting, we measure very small

magnetic tape

variations in the force of gravity from rocks

within the earth. Different types of rocks have *An "Interpreter" studies the seismic data to

different densities, and the dense rocks have the learn about the shape and kind of rocks and

greater gravitational attraction. where to drill an oil well

- a gravitometer or referred to as “gravimeter”

measures the force of gravity in the earth The Well

- In oil exploration, we measure changes in Well

gravity that may be only one-millionth or even

one-ten millionth of the earth's total gravity field - The hole made by the drilling bit, which can be

open, cased, or both. Also called borehole, hole,

Magnetic Survey (Magnetic Rocks) or wellbore.

- In Magnetic prospecting we look for variations Types of wells

in the magnetic field of the earth. The magnetic

field of sedimentary rocks is usually much 1. Wildcat well - a well drilled where no

smaller than igneous or metamorphic rocks. This Hydrocarbons exist

lets us measure the thickness of the sedimentary 2. Exploration well - a wells drilled either in

section of the earth’s crust. search of an as-yet- undiscovered pool of oil or

- a “magnetometer” lets us measure the magnetic gas or to extend greatly limits of a known pool.

field of the earth 3. Confirmation well - a well drilled to verify

whether a wildcat well tapped a rock layer w/

Electricity and Rocks enough hydrocarbons for the company to

- All rocks conduct electricity to varying degrees. develop.

The resistance to electrical current flow is called 4. Development well - a well drilled in proven

“resistivity”. Resistance is measured using territory in an oilfield to complete a

electrodes that are implanted in the earth. pattern of production

Resistivity surveys are commonly used for 5. Infilling wells - wells drilled in between known

groundwater studies producing wells to exploit the reservoir better

- Fresh water is resistive, brackish water is 6. Step-out wells - a well drilled adjacent to or near

conductive a proven well to ascertain the limits of the

- Pyrite has little resistance. It conducts electricity reservoir; also called outpost well

easily. *What do we do after we find a reservoir?

- Sandstone is very resistive. It does not conduct - We Drill Into It

electricity very easily. *What do we drill with?

Seismic Survey (Using Sound Waves to Find Oil) - A Drilling Rig

- Vibroseis shake the earth

- We "listen" to sound waves using a geophone

(records SEISMIC energy like a microphone Drilling Rig

records music) - They are used to drill the hole, lower and cement

- A “Jughustler” plants the geophones on the casing in the well, and provide a means to

ground perform various auxiliary functions such as

logging and well testing. Today’s rig require It floats on the surface of the water when being moved

highly experienced, trained personnel for from one site to another, but may or may not float once

efficient operations. If improperly selected, the drilling begins. They are portable and classified based on

rig can cause for different problems and high the bottom support of the rig on the sea floor either:

well costs.

Bottom-Supported Units

They fall on two broad categories: - They rest on seafloor or pads built on

the seafloor. They are classified either:

1. Cable tool rigs - A drilling rig that uses wire

1. Platform rig

rope (cable) to suspend a weighted, chisel point

2. Submersibles

bit in the hole. Machinery on the rig repeatedly

3. Jackups

lifts and drops the cable and bit. Each time the

Platform rig - It is a kind of rig that is once

bit strikes the bottom of the hole, it drills deeper.

built, it will never be mobilized nor moved from

Rotary drilling rigs have virtually replaced them.

the drill site. It drills several wells on the area

2. Rotary rigs - Rigs that uses drilling fluid, Fluid

where it is built. 2 kinds are:

circulation, weight on bit, rotating bit to drill a

1. Tender Assisted Platform

hole. They fall under:

2. Steel jacket platform

Onshore rigs 3. Complaint platform rigs

Offshore rigs 4. Concrete Gravity Type Platform

Onshore rigs - Rigs that drill on land. Example of o Concrete offshore structures are

onshore rigs are: mostly used in the petroleum

industry as drilling, extraction

Land rigs or storage units for crude oil or

- The most common land rigs use either a natural gas.

standard derrick or a truck mounted o Those large structures house

derrick, or a component rig. machinery and equipment

- They are classified according to the needed to drill and/or extract oil

maximum drilling depth they could and gas. But concrete structures

reach are not only limited to

Maximum Drilling applications within the oil and

Rig size gas industry.

Depth, Feet (Meters)

3,000 – 5,000 5. Caisson Type platform

Light duty o A rigid offshore drilling

(1,000 – 1,500)

4,000 – 10,000 platform that stands on steel

Medium duty

(1,200 – 3,000) caissons and is used to drill

12,000 – 16,000 development wells.

Heavy duty

(3,500 – 5,000) o The caissons are firmly affixed

18,000 – 25,000+ to the seafloor, and the drilling

Very heavy duty

(5,500 – 7,500) and production decks are laid on

top of them.

Portable rigs o The platform is used in certain

- It is usually considered to be a truck- arctic waters, where the caissons

mounted unit. The truck bed contains a are needed to protect equipment

derrick, drawworks, and mud pumps. A from moving ice.

principal advantage of the portable rig is

the low rig-up and rig-down time as well Submersibles - They float on water’s surface

as lower truck requirements. Portable when moved from one drilling site to another.

units are generally restricted to light When it reaches the site, crew members flood

duty work. compartments that submerge the lower part of

the rig to the seafloor. With the base on the

Offshore rigs - known as Mobile Offshore Drilling seafloor, winds, waves, and current have little

Unit, or MODU; are the widely used drilling rig that is effect on it. Examples are:

used to drill offshore exploration and development wells.

1. . Posted Barge Submersibles - It floats on a barge hull when towed to

o It drilled its initial well in 1949 the drilling location. A jackup’s leg can

off the Gulf Coast of Louisiana be cylindrical columns, or they can be

in 18 ft of water. It has a barge open-truss structures, which resemble a

hull and steel posts supported mast or a derrick.

deck and drilling equipment. - The largest jackups can drill water

Posted barges are now virtually depths up to about 400 ft, and are

obsolete, however, because capable of drilling holes up to 30,000 ft

newer and better designs have deep.

replaced them.

2. Bottle-Type Submersibles Floating units

o About 1954, drilling moved into - A type of MODU that floats and is not

water depths beyond the posted in contact with the seafloor (except

barge capabilities, which was anchors) when it is in the drilling mode.

about 30 ft. So, naval architects Floating Units includes:

designed bottle-type 1. Semisubmersibles

submersibles. It has four tall 2. Drill ships

steel cylinders at each corner of 3. SPAR

the structure that when flooded, Semisubmersibles

the bottles cause the rig to - A floating drilling offshore drilling unit

submerge to the seafloor. that has pontoons and columns that

3. Arctic Type Submersibles when flooded, cause the unit to

o It is a special type of submerge to a predetermined depth.

submersible rig. Arctic type - Semisubmersibles are more stable than

submersibles have reinforced drill ships and are extensively to drill in

hull, a caisson. One type of wildcat wells in the rough waters

caisson has a concrete base on - They are capable of drilling in water

which the drilling rig is thousands of feet deep. Semis can work

installed. When the sea is ice- in water depths ranging from 1000 to

free in the arctic summer, boats 3500 ft, and can drill holes up to 30000

tow the submersible to the ft deep.

drilling site. There, workers

submerge the caisson hull

deflects the floes, enabling

operations to continue.

4. Inland Barges

o It has a barge hull- a flat-

bottomed, flat-sided, rectangular

steel box. Inland barge rigs

normally drill in marshes, bays,

swamps, or other shallow inland

waters. Boats tow them to

drilling location and when

positioned at the drilling site,

the barge is flooded so that it

rests on the bottom ooze. They

often drill in swampy shallow

waters that’s why they are also

called swamp barges.

Jackup rig Drill ships

- It is the most widely used MODU.

- A self-propelled floating offshore

drilling unit that is a ship constructed to

permit a well to be drilled from it.

- Although not stable as

semisubmersibles, drill ships are capable

of drilling exploratory wells in deep,

remote waters.

- Anchors keep some of these drill ships

on station while drilling, but those

drilling in deep water require dynamic

positioning system.

SPAR

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Acoustic Consultant Resume Sample, Example & Format - FREE Sample Resume For Acoustic ConsultantDocument2 pagesAcoustic Consultant Resume Sample, Example & Format - FREE Sample Resume For Acoustic ConsultantFuji GohNo ratings yet

- Fuzzy Identification of Systems and Its Applications To Modeling and ControlDocument17 pagesFuzzy Identification of Systems and Its Applications To Modeling and Controlladjevci82No ratings yet

- Herd MentalityDocument7 pagesHerd MentalityPNo ratings yet

- Doble Fase AcuosaDocument18 pagesDoble Fase AcuosaEdgar Ortiz AhumadaNo ratings yet

- PKM - Quiz 3 - VlanDocument6 pagesPKM - Quiz 3 - VlanGodFather23No ratings yet

- StarWind Virtual SAN FREE Vs PAID PDFDocument6 pagesStarWind Virtual SAN FREE Vs PAID PDFwenptNo ratings yet

- Case Study 21 Polymers UKDocument3 pagesCase Study 21 Polymers UKWylmer Ann Dionisio86% (7)

- Margolin GR 11 NegDocument22 pagesMargolin GR 11 NegbhupatinNo ratings yet

- 18 Business StudiesDocument33 pages18 Business StudiesKabir SinghNo ratings yet

- Windows ProgmmmingDocument2 pagesWindows ProgmmmingAsha KavediaNo ratings yet

- Sverchok Plugin For BlenderDocument167 pagesSverchok Plugin For BlenderartisanicviewNo ratings yet

- Industrial Policy 10-15Document36 pagesIndustrial Policy 10-15Rameswara ReddyNo ratings yet

- ACC Enhances Logistics and Supply Chain ManagementDocument9 pagesACC Enhances Logistics and Supply Chain ManagementAmritMohanty0% (1)

- Earthquake Grade 8Document34 pagesEarthquake Grade 8Norigen ItangNo ratings yet

- Debates and Theories in International RelationsDocument29 pagesDebates and Theories in International RelationsMohd Zulhairi Mohd NoorNo ratings yet

- Spec For Piping Painting CoatingDocument82 pagesSpec For Piping Painting CoatingMd faizan AlamNo ratings yet

- C07772 MD-008 Coating SpecificationsDocument29 pagesC07772 MD-008 Coating SpecificationsGiuditta OhNo ratings yet

- How To Use WSET Level 2 Systematic Approach To Tasting WineDocument1 pageHow To Use WSET Level 2 Systematic Approach To Tasting Winezeus izzy yeeNo ratings yet

- Codigos MOMDocument138 pagesCodigos MOMlucho0314No ratings yet

- Patient Specific Functional Scale PDFDocument1 pagePatient Specific Functional Scale PDFabhimanyu thakurNo ratings yet

- Rhumaa Pitch Deck Daniel 1st Draft - Pptx-CompressedDocument19 pagesRhumaa Pitch Deck Daniel 1st Draft - Pptx-CompressedNikolay BerdyaevNo ratings yet

- Quiz Key 8611 AIOU B.ed Help GroupDocument7 pagesQuiz Key 8611 AIOU B.ed Help GroupRana Hamza Muhammad YousafNo ratings yet

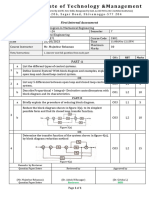

- 7th 1st IA Question Paper 2023-24Document1 page7th 1st IA Question Paper 2023-24Mujeeb ur RehmanNo ratings yet

- Upperstructure E265 Tier3 7 enDocument166 pagesUpperstructure E265 Tier3 7 enAram YetumyanNo ratings yet

- 39 Interesting Facts That I Learned About RomaniaDocument10 pages39 Interesting Facts That I Learned About RomaniaBuşatovici LucicaNo ratings yet

- 2011-2012 Annual Report Department of Pediatrics Saint Louis University School of MedicineDocument131 pages2011-2012 Annual Report Department of Pediatrics Saint Louis University School of Medicineslusompeds0% (1)

- Creativity in Organizations: A Case Study of Hilti AbDocument26 pagesCreativity in Organizations: A Case Study of Hilti AbANKITNo ratings yet

- Report On Survey Camp Civil EnggDocument3 pagesReport On Survey Camp Civil EnggJodha SinghNo ratings yet

- Heat Capacity of GasesDocument9 pagesHeat Capacity of Gasesismail100% (1)

- Were The Spaniards That CruelDocument4 pagesWere The Spaniards That CruelKathryn Craven100% (1)