Professional Documents

Culture Documents

E-Clip DIN6799

Uploaded by

YapShenghaoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E-Clip DIN6799

Uploaded by

YapShenghaoCopyright:

Available Formats

HUYETT.

COM • 785 - 392 - 301 7

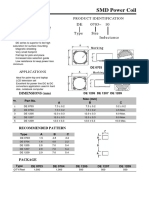

EXTERNAL – E-CLIP METRIC DIN 6799****

Description How to Identify

Perhaps the most popular and widely used 1. Verify E-shape design and appearance.

radial retaining ring is the E-clip (so named 2. Measure the shaft diameter (Ds).

DE because it is shaped like the letter “E”). 3. Measure the ring outside diameter (G).

Three prongs make contact with the bottom 4. Measure the ring thickness (T).

of the groove and provide a shoulder for 5. Find the part in the chart.

effective retention of assemblies.

Dg

W Dg

W Dg

Ds

Ds

d

A T d

G A T L2

G

Ring Dimensions Groove Dimensions Clearance Diameter Installed In Groove

Item Nominal Shaft Diameter Groove Size Ring Size & Weight

# Size

Diameter Width Thickness 2 Gap Weight

Dg Ds Dg Tol. W Tol. T Tol. A Tol. kg/

from to 1,000

DE-008 0.8 1.0 1.4 0.8 -0.040 0.24 0.2 ±0.02 0.58 ±0.040 0.003

+0.04/

DE-012 1.2 1.4 2.0 1.2 -0.060 0.34 0.3 ±0.02 1.01 ±0.040 0.009

-0.00

DE-015 1.5 2.0 2.5 1.5 -0.060 0.44 0.4 ±0.02 1.28 ±0.040 0.021

DE-019 1.9 2.5 3.0 1.9 -0.060 0.54 0.5 ±0.02 1.61 ±0.040 0.040

DE-023 2.3 3.0 4.0 2.3 -0.060 0.64 0.6 ±0.02 1.94 ±0.040 0.069

DE-032 3.2 4.0 5.0 3.2 -0.075 0.64 0.6 ±0.02 2.70 ±0.040 0.088

+0.05/

DE-040 4.0 5.0 7.0 4.0 -0.075 0.74 0.7 ±0.02 3.34 ±0.048 0.158

-0.00

DE-050 5.0 6.0 8.0 5.0 -0.075 0.74 0.7 ±0.02 4.11 ±0.048 0.236

DE-060 6.0 7.0 9.0 6.0 -0.075 0.74 0.7 ±0.02 5.26 ±0.048 0.255

DE-070 7.0 8.0 11.0 7.0 -0.090 0.94 0.9 ±0.02 5.84 ±0.048 0.474

DE-080 8.0 9.0 12.0 8.0 -0.09 1.05 1.00 ±0.03 6.52 ±0.058 0.660

DE-090 9.0 10.0 14.0 9.0 -0.09 1.15 1.10 ±0.03 7.63 ±0.058 1.090

DE-100 10.0 11.0 15.0 10.0 -0.09 1.25 1.20 ±0.03 8.32 ±0.058 1.250

DE-120 12.0 13.0 18.0 12.0 -0.11 1.35 +0.08/ 1.30 ±0.03 10.45 ±0.070 1.630

DE-150 15.0 16.0 24.0 15.0 -0.11 1.55 -0.00 1.50 ±0.03 12.61 ±0.070 3.370

DE-190 19.0 20.0 31.0 19.0 -0.13 1.80 1.75 ±0.03 15.92 ±0.070 6.420

DE-240 24.0 25.0 38.0 24.0 -0.13 2.05 2.00 ±0.03 21.88 ±0.084 8.550

DE-300 30.0 32.0 42.0 30.0 -0.13 2.55 2.50 ±0.03 25.80 ±0.084 13.50

Additional attribute data on adjacent page.

TO ORDER DIFFERENT MATERIAL/FINISHES,

APPEND SUFFIX WITH YOUR CHOICE:

"NONE" • -BC • -SS • -ZD • -Z3

Visit huyett.com to download Material, Compliance, and

RoHS/REACH Certifications* in your Account Order History.

* Some exclusions apply

For de tailed specifications and tole rances, visi t Huye t t.co m.

Prices, materials, dimensions, tolerances, designs, and grades subject to change without notice. © 2017 G.L. Huyett

128

SALES@HUYETT.COM

DIN 6799**** EXTERNAL – E-CLIP METRIC

Suffix Material/Finish

### = CARBON SPRING STEEL, PHOSPHATE

###-BC = BERYLLIUM COPPER, PLAIN

###-SS

###-ZD

=

=

STAINLESS STEEL, PLAIN R Max

CARBON SPRING STEEL, ZINC YELLOW

DE

###-Z3 = CARBON SPRING STEEL, ZINC TRIVALENT

Material/finish combinations may not be available in all sizes.

More finishes available, see page 22 for a complete listing.

Br

R Max

Y

R Max Ch Max

Br*

*The radius “Br” on the load

side must not exceed 0.1T

Br

Y

Ch Max

Y Maximum Corner *The radius

Edge “Br” (Y)

Margin on the

Ch Max Radius (R Max) & Chamfer (Ch Max) load side must not

for Retained Part exceed 0.1T

Item Clearance Supplementary Data Use with

# Applicator

Free Outside Installed Edge Margin Thrust Load Thrust Load Groove Allowable Max. Load RPM Limits

Diameter in Groove Ring 3 (smallest listed Ds) Radii & w/R Max. Standard

Chamfers or Ch Max. Material

G L2 Y Pr Pg Ds' R/Ch P'r

Ref. Max. Min. kN kN Max. kN

DE-008 1.95 2.25 0.4 0.08 0.03 1.2 0.3 0.04 50,000 RRA-708

DE-012 2.90 3.25 0.6 0.12 0.04 1.5 0.4 0.06 47,000 RRA-712

DE-015 3.90 4.25 0.8 0.22 0.07 2.0 0.6 0.11 42,000 RRA-715

DE-019 4.40 4.80 1.0 0.35 0.10 2.5 0.7 0.17 40,000 RRA-719

DE-023 5.90 6.30 1.0 0.50 0.15 3.0 0.9 0.24 38,000 RRA-723

DE-032 6.90 7.30 1.0 0.65 0.22 4.0 0.9 0.32 35,000 RRA-310

DE-040 8.85 9.30 1.2 0.95 0.25 5.0 1.0 0.47 32,000 RRA-340

DE-050 10.85 11.30 1.2 1.15 0.90 7.0 1.0 0.60 28,000 RRA-605

DE-060 11.80 12.30 1.2 1.35 1.10 8.0 1.1 0.70 25,000 RRA-606

DE-070 13.80 14.30 1.5 1.80 1.25 9.0 1.3 1.00 22,000 RRA-607

DE-080 15.75 16.3 1.8 2.50 1.42 10.0 1.5 1.25 20,000 RRA-608

DE-090 18.20 18.8 2.0 3.00 1.60 11.0 1.6 1.50 17,000 RRA-609

DE-100 19.70 20.4 2.0 3.50 1.70 12.0 1.8 1.75 15,000 RRA-610

DE-120 22.70 23.4 2.5 4.70 3.10 15.0 1.9 2.30 13,000 RRA-612

DE-150 28.70 29.4 3.0 7.80 7.00 20.0 2.2 3.30 11,000 RRA-615

DE-190 36.50 37.6 3.5 11 10.00 25.0 2.5 3.60 7,600 RRA-619

DE-240 43.50 44.6 4.0 15 13.00 30.0 3.0 4.00 5,500 –

DE-300 51.30 52.6 4.5 23 16.50 36.0 3.5 5.30 4,200 –

Additional attribute data on adjacent page.

All dimensions in millimeters.

For hardness specifications, see page 131.

**** DIN 6799 only defines rings in carbon steel. Rings in other materials are dimensioned as defined in STA CK ED OPTIO NS

technical prints, contact sales@huyett.com for details.

2

For plated rings add 0.05 mm to the listed maximum thickness. Maximum ring thickness will be a minimum

AVA ILA BLE , SEE

of 0.005 mm less than the listed groove width (W) minimum. HUY ETT.CO M FOR

3

Sharp corner abutment. MO RE DE TAI LS

For de tailed specifications and tole rances, visi t Huye t t.co m.

Prices, materials, dimensions, tolerances, designs, and grades subject to change without notice. © 2017 G.L. Huyett

129

SALES@HUYETT.COM

HARDNESS – E-CLIP METRIC

Hardness Ranges: DE-clips

Hardness

Material Size Range

HV HRC Lower Scale♦ 15N 30N

DE Carbon Steel,

0.8 – 1.5

1.9

460 – 580

460 – 580

46 – 54

46 – 54

83.5 – 87.5 HR15N♦♦

83.5 – 87.5 HR15N

– –

(blank)

(SAE 1060-1090) 2.3 – 9 460 – 580 46 – 54 65 – 72 HR30N

10 – 30 460 – 580 46 – 54 –

0.8 – 1.5 435 – 530 44 – 51 82.5 – 86 HR15N♦♦ – –

Stainless Steel, 1.9 435 – 530 44 – 51 82.5 – 86 HR15N

-SS

(PH 15-7 Mo) 2.3 – 9 435 – 530 44 – 51 63 – 69.5 HR30N

10 – 30 435 – 530 44 – 51 –

Stainless Steel, All 470 – 580 47 – 54 – 84 – 87.5 66 – 72

-SS

(DIN 1.4122 X39CrMo17)

0.8 – 1.5 360 – 415 37 – 43 79 – 82 HR15N♦♦ – –

1.9 360 – 415 37 – 43 79 – 82 HR15N

-BC Beryllium Copper

2.3 – 9 360 – 415 37 – 43 56.5 – 62 HR30N

10 – 30 360 – 415 37 – 43 –

♦

Where Applicable

♦♦

Hardness cannot be checked with any degree of accuracy directly on these rings.

Hardness Ranges: JE-clips

Rockwell

Material Size Range Scale

Hardness

JE (blank)

Carbon Steel,

0.8 – 2.5

3–9

15N

30N

82.5 – 87

63 – 71

(SAE 1060-1090)

10 – 24 C 44 – 53

0.8 – 2.5 15N 82.5 – 86 ♦♦

Stainless Steel,

-SS 3–9 30N 63 – 69.5

(PH 15-7 Mo)

10 – 24 C 44 – 51

0.8 – 2.5 15N 79 – 82 ♦♦ Installation

-BC Beryllium Copper 3–9 30N 56.5 – 62

10 – 24 C 37 – 43 tools available,

♦♦

Hardness cannot be checked with any degree of accuracy directly on these rings. see page 256

Also Available AT

Grease Fittings & Machine Keys & Pins & Wireforms Engineered

Accessories Key Stock Fasteners

DON'T SEE WHAT YOU'RE

LOOKING FOR?

Give our Sales Team a call today.

Blind Threaded Inserts Wave & Spring Washers Hose Clamps

For de tailed specifications and tole rances, visi t Huye t t.co m.

Prices, materials, dimensions, tolerances, designs, and grades subject to change without notice. © 2017 G.L. Huyett

131

You might also like

- ASME B18.2.6 2010 (1) - Fasteners For Use in Structural Applications-18-19Document2 pagesASME B18.2.6 2010 (1) - Fasteners For Use in Structural Applications-18-19Andres SilveyraNo ratings yet

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesFrom EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesRating: 5 out of 5 stars5/5 (3)

- Original Groove System (OGS) Groove Specifications: DimensionsDocument7 pagesOriginal Groove System (OGS) Groove Specifications: DimensionsDalberto RamirezNo ratings yet

- Tacos para TubosDocument21 pagesTacos para TubosPedro SantiagoNo ratings yet

- Drainage Calculations - MaDocument17 pagesDrainage Calculations - MaMarianaNo ratings yet

- Circlips - Washers - Dowel Pin - Sheet Metal ComponentsDocument25 pagesCirclips - Washers - Dowel Pin - Sheet Metal Componentsdebasish chowdhuryNo ratings yet

- General Purpose Metric Screws DimensionsDocument2 pagesGeneral Purpose Metric Screws DimensionsPrabish KumarNo ratings yet

- ASME B18.2.1-2010 Hex Bolt Dimensions and SpecsDocument1 pageASME B18.2.1-2010 Hex Bolt Dimensions and SpecsadrbimNo ratings yet

- Flanges e Parafusos2Document54 pagesFlanges e Parafusos2Edmilson FaustinoNo ratings yet

- Shaft AxialDocument2 pagesShaft AxialAndy YanNo ratings yet

- ASC Groove Specifications v01Document6 pagesASC Groove Specifications v01Pape DiopNo ratings yet

- Shaft AxialDocument2 pagesShaft AxialReyginald MarronNo ratings yet

- Victaulic Firelock Fittings: 1.0 Product DescriptionDocument4 pagesVictaulic Firelock Fittings: 1.0 Product Descriptionmido2112No ratings yet

- Shaft - Axial - Xls Radius Transition or Undercut Between Diameters?Document2 pagesShaft - Axial - Xls Radius Transition or Undercut Between Diameters?Pradeep SarodeNo ratings yet

- ASTM Rebar ChartDocument1 pageASTM Rebar ChartmirfanjpcgmailcomNo ratings yet

- QMS 0003Document10 pagesQMS 0003cucho31No ratings yet

- Kształtki 001 002 003 006 10.03Document4 pagesKształtki 001 002 003 006 10.03Jacek GorgolNo ratings yet

- DIN Pins, Sleeves and Blades - Ejector Sleeves NitridedDocument1 pageDIN Pins, Sleeves and Blades - Ejector Sleeves NitridedDesign STSNo ratings yet

- Victaulic Firelock Fittings: 1.0 Product DescriptionDocument4 pagesVictaulic Firelock Fittings: 1.0 Product Descriptionyeye JNo ratings yet

- Din Pins, Sleeves, BladesDocument1 pageDin Pins, Sleeves, BladesDesign STSNo ratings yet

- Standard External Circlip Specification: IS 3075, DIN 471Document3 pagesStandard External Circlip Specification: IS 3075, DIN 471ThejaswiniNo ratings yet

- Standard External Circlip SpecificationDocument3 pagesStandard External Circlip SpecificationTrushar GhosalkarNo ratings yet

- Calculo de Caida de Presion en Flujo de LiquidosDocument117 pagesCalculo de Caida de Presion en Flujo de LiquidosAlvarez JesusNo ratings yet

- SMD Power Coil: FerrocoreDocument2 pagesSMD Power Coil: FerrocorePuiu BercioiuNo ratings yet

- Lab Analysis Soil ConsolidationDocument17 pagesLab Analysis Soil ConsolidationRandi SetiawanNo ratings yet

- Steel Pipe Dimensions - ANSI Schedule 40Document3 pagesSteel Pipe Dimensions - ANSI Schedule 40StevenAronNo ratings yet

- PVC Schedule 80 Conduit Spec Sheet Allied Tube and ConduitDocument1 pagePVC Schedule 80 Conduit Spec Sheet Allied Tube and ConduitJhaero Esteban PerezNo ratings yet

- Essential furniture fittings and accessoriesDocument12 pagesEssential furniture fittings and accessoriesfuaunNo ratings yet

- ASTM Standards Dimension ComparisonDocument2 pagesASTM Standards Dimension Comparisonvon18No ratings yet

- Timing Belt TheoryDocument18 pagesTiming Belt TheoryCan Kutay TuçNo ratings yet

- ANSI B16.5 Class 150 Socket-Weld FlangesDocument2 pagesANSI B16.5 Class 150 Socket-Weld FlangesshanmuNo ratings yet

- Hari Ke.2 Hari Ke.3 Hari Ke.4 Hari Ke.5 Hari Ke.6: - Lab. AnalysisDocument17 pagesHari Ke.2 Hari Ke.3 Hari Ke.4 Hari Ke.5 Hari Ke.6: - Lab. AnalysisMus TakimNo ratings yet

- Series 18 0.4 Series: SUS304-CSP Spring Steel 1 2 3 SUS304-CSP Spring Steel 1 2 2Document1 pageSeries 18 0.4 Series: SUS304-CSP Spring Steel 1 2 3 SUS304-CSP Spring Steel 1 2 2Luqman Al HakimNo ratings yet

- Basic Dimensions For NPT American National Taper Pipe Threads PDFDocument2 pagesBasic Dimensions For NPT American National Taper Pipe Threads PDFRashedul HasanNo ratings yet

- Herraje Hensley Puntas y PortapuntasDocument10 pagesHerraje Hensley Puntas y PortapuntasPaul ChávezNo ratings yet

- STD Eje PinDocument1 pageSTD Eje PinDesign STSNo ratings yet

- Metric Partially Threaded Hex Bolts PDFDocument1 pageMetric Partially Threaded Hex Bolts PDFRicky ReungNo ratings yet

- Transparante Buizen-1Document6 pagesTransparante Buizen-1testuser01No ratings yet

- Buizen Tuyaux Pipes: Drukbuis Glashelder Tuyau de Pression Transparent Pressure Pipe TransparentDocument6 pagesBuizen Tuyaux Pipes: Drukbuis Glashelder Tuyau de Pression Transparent Pressure Pipe Transparenttestuser01No ratings yet

- Metric Partially Threaded Hex BoltsDocument1 pageMetric Partially Threaded Hex BoltsCarniol DragosNo ratings yet

- Transparante Buizen-1Document6 pagesTransparante Buizen-1testuser01No ratings yet

- Weld Consumable CalculatorDocument7 pagesWeld Consumable CalculatorQuality TeamNo ratings yet

- Fittings For Grooved-End Pipe: FIG. 7050 FIG. 7051 FIG. 7052 7052iDocument1 pageFittings For Grooved-End Pipe: FIG. 7050 FIG. 7051 FIG. 7052 7052iErickNo ratings yet

- 1723208Document44 pages1723208Emmanuel VenturaNo ratings yet

- ISOturninginsertsCodekey 08572170540Document2 pagesISOturninginsertsCodekey 08572170540Mahmoud NasrNo ratings yet

- DS Ipex Pipe SCH40 & SCH80Document3 pagesDS Ipex Pipe SCH40 & SCH80KPHMXNo ratings yet

- ResultsDocument2 pagesResultsGanim ShedNo ratings yet

- Ifi 115Document1 pageIfi 115Vinay PawarNo ratings yet

- De1207 220Document2 pagesDe1207 220Stoica VictorNo ratings yet

- Flange AS4087 AS2129 BS Table DEDocument2 pagesFlange AS4087 AS2129 BS Table DEadamNo ratings yet

- Viswa Consult Pvt. LTD.: Deflection (Loading With Time)Document3 pagesViswa Consult Pvt. LTD.: Deflection (Loading With Time)Pradeep PokhrelNo ratings yet

- Dorman HandbookDocument4 pagesDorman HandbooksharathkammarNo ratings yet

- Duct EstimatesDocument25 pagesDuct EstimatesRhowelle TibayNo ratings yet

- Série HDocument1 pageSérie HwtgarroteNo ratings yet

- Sheet To Calculate ConductivityDocument3 pagesSheet To Calculate ConductivityKishore PagarNo ratings yet

- Cap (Acorn) Nuts: O P H C N, L CDocument1 pageCap (Acorn) Nuts: O P H C N, L CMAI_QualityNo ratings yet

- Nutsert FS38 MMDocument1 pageNutsert FS38 MMAJITHNo ratings yet

- Stainless Steel Flexible Coupling Style 77S: 1.0 Product DescriptionDocument8 pagesStainless Steel Flexible Coupling Style 77S: 1.0 Product DescriptionMahmoudNo ratings yet

- SKF 24032 CCK30 - C3FVE753 Specification PDFDocument2 pagesSKF 24032 CCK30 - C3FVE753 Specification PDFYapShenghaoNo ratings yet

- SKF 24032 CCK30 - C3FVE753 Specification PDFDocument2 pagesSKF 24032 CCK30 - C3FVE753 Specification PDFYapShenghaoNo ratings yet

- Updated To QCDocument1 pageUpdated To QCYapShenghaoNo ratings yet

- Standard Stock Springs Catalogue 13 - English Id1107Document226 pagesStandard Stock Springs Catalogue 13 - English Id1107aleaubrNo ratings yet

- LR Series: Longitudinal Rib For Excellent GripDocument2 pagesLR Series: Longitudinal Rib For Excellent GripYapShenghaoNo ratings yet

- ChecklistDocument1 pageChecklistYapShenghaoNo ratings yet

- Spek UboltDocument2 pagesSpek UboltRafiazis75No ratings yet

- INV IROTCAP CHEAD SCREWCAP NEW REF ModelDocument1 pageINV IROTCAP CHEAD SCREWCAP NEW REF ModelYapShenghaoNo ratings yet

- EM308 Jan 2017 ChapterDocument22 pagesEM308 Jan 2017 ChapterYapShenghaoNo ratings yet

- ChecklistDocument1 pageChecklistYapShenghaoNo ratings yet

- Econ Lecture 1: Interest FormulasDocument18 pagesEcon Lecture 1: Interest FormulasYapShenghaoNo ratings yet

- EM308 Electrical Power & Machines: Welcome !Document12 pagesEM308 Electrical Power & Machines: Welcome !YapShenghaoNo ratings yet

- EM308 Electrical Power & Machines: Welcome !Document12 pagesEM308 Electrical Power & Machines: Welcome !YapShenghaoNo ratings yet

- G3516B Engine Electrical System: Front View (Outside) Right SideDocument2 pagesG3516B Engine Electrical System: Front View (Outside) Right Sidewagner_guimarães_1No ratings yet

- Thermostatic Expansion Valves With Fixed Orifice,: Type TDE / TDEBDocument20 pagesThermostatic Expansion Valves With Fixed Orifice,: Type TDE / TDEBMeher YoussfiNo ratings yet

- D9306 D9308 D9406 D9408 761pages SMDocument761 pagesD9306 D9308 D9406 D9408 761pages SMsxturbo100% (13)

- WM Series Metric 2008Document40 pagesWM Series Metric 2008speed844No ratings yet

- Introduction to HVAC Systems Design and Load CalculationsDocument8 pagesIntroduction to HVAC Systems Design and Load CalculationsbalajivangaruNo ratings yet

- Datasheet A483Document2 pagesDatasheet A483KAKI BELANGNo ratings yet

- Rectangular Linear Voice Coil ActuatorDocument7 pagesRectangular Linear Voice Coil ActuatorjuliangoalNo ratings yet

- Fundamentals of Computer - 100 MCQ Questions MCQ SetsDocument26 pagesFundamentals of Computer - 100 MCQ Questions MCQ SetsSanket ChiksheNo ratings yet

- Instruction-JDC1316 Battery Powered Plastic Strapping Tool - 1Document116 pagesInstruction-JDC1316 Battery Powered Plastic Strapping Tool - 1Eduardo LópezNo ratings yet

- KX-21 Parts List and DiagramsDocument22 pagesKX-21 Parts List and DiagramsThai Phu100% (1)

- Optiplex Small Form Factor Spec SheetDocument9 pagesOptiplex Small Form Factor Spec SheetPablo ChinNo ratings yet

- Fibre Optic Cable For Repeatered Submarine Systems: Oalc4Document2 pagesFibre Optic Cable For Repeatered Submarine Systems: Oalc4Lm BealhyNo ratings yet

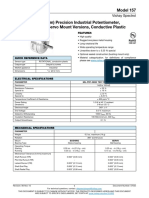

- Model 157: Vishay SpectrolDocument4 pagesModel 157: Vishay SpectrolJulio Vazquez MorenoNo ratings yet

- MF 7700 enDocument44 pagesMF 7700 enriad100% (1)

- Service: Golf 2004 Golf Plus 2005 Passat 2006 Touran 2003Document299 pagesService: Golf 2004 Golf Plus 2005 Passat 2006 Touran 2003George Sas100% (1)

- Audi Self Study ProgramDocument76 pagesAudi Self Study ProgramJorge Gonzalez Perez100% (1)

- Operating Instructions: Vegamet 381Document31 pagesOperating Instructions: Vegamet 381Capacitacion TodocatNo ratings yet

- Escavadora Giratória 130Document36 pagesEscavadora Giratória 130AbilioNo ratings yet

- Klemm KR - 702-2 - 2008Document100 pagesKlemm KR - 702-2 - 2008rf175100% (1)

- WDZ-5211 Line Protection Measurement and Control Device 1 Device Function 2 Protection Function and PrincipleDocument17 pagesWDZ-5211 Line Protection Measurement and Control Device 1 Device Function 2 Protection Function and PrincipleCorey PorterNo ratings yet

- GLPT 5590 en PDFDocument6 pagesGLPT 5590 en PDFmohsen_cumminsNo ratings yet

- Air Circuit Breaker PDFDocument82 pagesAir Circuit Breaker PDFPrabakar P100% (7)

- Panasonic HDC-MDH1 ManualDocument120 pagesPanasonic HDC-MDH1 ManualKuchai BremParkNo ratings yet

- Epson AL M2000 M2010Document228 pagesEpson AL M2000 M2010Catalin PetcuNo ratings yet

- Convenience Store Alfamart Philippines: (As-Built)Document1 pageConvenience Store Alfamart Philippines: (As-Built)arnold san joseNo ratings yet

- Katalog Rexione UpdateDocument34 pagesKatalog Rexione Updatesadid akbarNo ratings yet

- Electric Motor and GeneratorDocument6 pagesElectric Motor and GeneratorJesell JeanNo ratings yet

- Wire Terminal and Fixture Testing ToolsDocument1 pageWire Terminal and Fixture Testing ToolsPASCAL LANDSHEERENo ratings yet

- AL MUTAWWAR Illustrated Parts Manual (JUNE 2007)Document283 pagesAL MUTAWWAR Illustrated Parts Manual (JUNE 2007)Mohammed AhmedNo ratings yet

- Renner RSF OverviewDocument8 pagesRenner RSF OverviewVlad LiviuNo ratings yet