Professional Documents

Culture Documents

Böhler Fox Dcms KB: Classifi Cations

Uploaded by

Branko Ferenčak0 ratings0% found this document useful (0 votes)

58 views1 pageFOX

Original Title

FOX DCMS-Kb

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFOX

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

58 views1 pageBöhler Fox Dcms KB: Classifi Cations

Uploaded by

Branko FerenčakFOX

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

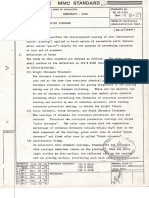

Welding consumables for creep resistant steels

BÖHLER FOX DCMS Kb

SMAW

Stick electrode, low-alloyed, creep resistant

Classifications

EN ISO 3580-A AWS A5.5 / SFA-5.5

E CrMo1 B 4 2 H5 E8018-B2 H4

Characteristics and typical fields of application

Basic coated, core wire alloyed low hydrogen electrode for 1% Cr 0.5% Mo alloyed boiler, plate, and tube steels. Approved in long-term

condition up to +570°C service temperature. Fully alloyed core wire which will provide reliable creep rupture properties for the whole

service life of a boiler plant. High ductility and crack resistance. The weld metal deposit is heat treatable. Very low hydrogen content (acc.

AWS condition HD < 4 ml/100 g). Metal recovery approximately 115%. Suitable for step-cooling application. Bruscato ≤ 15ppm. post-

weld tempering at 660 – 700°C for at least ½ h followed by cooling in furnace down to 300°C and still air.

Base materials

Creep resistant steels and similar alloyed cast steels, case hardening and nitrite able steels of similar chemical composition, similar

alloyed heat treatable steels with tensile strength up to 780 MPa, steels resistant to caustic cracking

1.7335 13CrMo4-5, 1.7262 15CrMo5, 1.7728 16CrMoV4, 1.7218 25CrMo4, 1.7225 42CrMo4, 1.7258 24CrMo5, 1.7354 G22CrMo5-4,

1.7357 G17CrMo5-5

ASTM A 182 Gr. F12; A 193 Gr. B7; A 213 Gr. T12; A 217 Gr. WC6; A 234 Gr. WP11; A335 Gr. P11, P12; A 336 Gr. F11, F12; A 426 Gr. CP12

Typical analysis of all-weld metal

C Si Mn Cr Mo P Sb Sn As

wt.-% 0.08 0.25 0.8 1.1 0.5 ≤ 0.010 ≤ 0.005 ≤ 0.005 ≤ 0.005

Mechanical properties of all-weld metal - typical values (min. values)

Condition Yield strength Rp0.2 Tensile strength Rm Elongation A (L0=5d0) Impact values ISO-V KV J

MPa MPa % 20°C

a 480 (≥ 460) 580 (≥ 550) 23 (≥ 20) 160 (≥ 47)

v 380 520 28 190

a annealed 680 °C/2h / furnace down to 300 °C / air

v quenched/tempered 930 °C/0.5 h / air 680 °C/10 h / furnace down to 300 °C / air

Operating data

Polarity DC+ Dimension mm Current A

Electrode 2.5 × 250 80 – 110

FOX DCMS Kb 8018-B2 E CrMo1 B 2.5 × 350 80 – 110

identification

3.2 × 350 100 – 140

Redrying 300-350°C/2h 4.0 × 350 130 – 180

4.0 × 450 130 – 180

5.0 × 450 180 – 220

Preheat and interpass temperature acc. to the requirements of the base material (for 13CrMo4-5 at 200 - 250ºC, annealing after welding

at 660 - 700ºC, min 1/2 h / oven to 300ºC / air cooling).

Approvals

TÜV (00728.), DB (10.014.42), ABS, DNV GL, NAKS (Ø 3.2 mm; Ø 4.0 mm), CE

144

You might also like

- BS 970 Chemical Composition TableDocument18 pagesBS 970 Chemical Composition Tablepm Starkeon100% (1)

- Welding of AluminiumDocument68 pagesWelding of Aluminiums_m_taheriNo ratings yet

- TurnbuckleDocument6 pagesTurnbuckleAbi Latiful HakimNo ratings yet

- Astm A434Document3 pagesAstm A434Evandro Luis Gomes100% (1)

- Material GradesDocument32 pagesMaterial GradesMarius PopaNo ratings yet

- Octobre/October 2009: ASTM A691/A691MDocument7 pagesOctobre/October 2009: ASTM A691/A691MPrashant AgrawalNo ratings yet

- Basic Principles of Heat TreatmentDocument26 pagesBasic Principles of Heat TreatmentYaser Mohamed AbasNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- 1 - Classification of CasingDocument68 pages1 - Classification of CasingnabiNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Ruukki Hot Rolled Steels Processing of Material WeldingDocument11 pagesRuukki Hot Rolled Steels Processing of Material Weldingprince5621No ratings yet

- Iso 3506 1 2020Document46 pagesIso 3506 1 2020Anna BubblegumNo ratings yet

- Aisi 4140 Alloy Steel (Uns g41400)Document4 pagesAisi 4140 Alloy Steel (Uns g41400)UmerNo ratings yet

- ASTM A276 - Stainless Steel Bars and Shapes (2017.3)Document8 pagesASTM A276 - Stainless Steel Bars and Shapes (2017.3)정영우100% (1)

- No.29 MMC Standard-Zinc Electroplating Standard. MS82-3701Document7 pagesNo.29 MMC Standard-Zinc Electroplating Standard. MS82-3701Alejandro Tique100% (1)

- Astm B209Document26 pagesAstm B209Elias Cruz100% (2)

- Ductile Iron Casting Specfications and Details All StandardsDocument15 pagesDuctile Iron Casting Specfications and Details All StandardsN.Palaniappan100% (1)

- Hot Rolling ProcessesDocument175 pagesHot Rolling Processesidownloadbooksforstu100% (2)

- The TEMPCORE ProcessDocument15 pagesThe TEMPCORE ProcessShanna Lee100% (1)

- Böhler Fox CM 2 KB: Classifi CationsDocument1 pageBöhler Fox CM 2 KB: Classifi CationsBranko FerenčakNo ratings yet

- Acfrogb5xupx1uiu51q4qpegob11kinx4cpthkjuzsxe Qrny8qp19zkiaaqlrzp5mtx7fqalib7js6hirn5qet1v1 Jzc9t4e1g1 Ywrk Xx3fgo44x6qxwaembbcmDocument1 pageAcfrogb5xupx1uiu51q4qpegob11kinx4cpthkjuzsxe Qrny8qp19zkiaaqlrzp5mtx7fqalib7js6hirn5qet1v1 Jzc9t4e1g1 Ywrk Xx3fgo44x6qxwaembbcmdodoNo ratings yet

- Böhler Fox CM 5 KB: Classifi CationsDocument1 pageBöhler Fox CM 5 KB: Classifi CationsBranko FerenčakNo ratings yet

- Böhler Fox CN 13/4 Supra: Classifi CationsDocument1 pageBöhler Fox CN 13/4 Supra: Classifi CationsBranko FerenčakNo ratings yet

- Böhler Fox CM 5 Kb electrode for creep resistant steelsDocument1 pageBöhler Fox CM 5 Kb electrode for creep resistant steelsjaroNo ratings yet

- FPO22001 ASME Filer Metal Data SheetDocument5 pagesFPO22001 ASME Filer Metal Data Sheetyousab creator2No ratings yet

- L1 7723 en BOEHLER FOX FF 2SF7A05E 3383108 ENDocument1 pageL1 7723 en BOEHLER FOX FF 2SF7A05E 3383108 ENkamals55No ratings yet

- Thermanit P24Document1 pageThermanit P24Branko FerenčakNo ratings yet

- WELDING SPREADER Electrode KALMAR PDFDocument1 pageWELDING SPREADER Electrode KALMAR PDFArtin HykoNo ratings yet

- Welding consumables for ferritic stainless steelsDocument1 pageWelding consumables for ferritic stainless steelsBranko FerenčakNo ratings yet

- High-alloy creep resistant stick electrode for 9% Cr steelsDocument1 pageHigh-alloy creep resistant stick electrode for 9% Cr steelsmisthahNo ratings yet

- 02112015000000B - Boehler FOX DCMS Ti - CeDocument1 page02112015000000B - Boehler FOX DCMS Ti - CeparbinaNo ratings yet

- Bohler Fox DMV 83 KB - SmawDocument1 pageBohler Fox DMV 83 KB - Smawsoft4gsmNo ratings yet

- Boehler CM2-UPDocument1 pageBoehler CM2-UPdiahNo ratings yet

- L1 34264 en T Thermanit MTS 3 Se en v2Document1 pageL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaNo ratings yet

- Citorail OerlikonDocument1 pageCitorail OerlikonGiancarlo BlandinoNo ratings yet

- UTP 641 KBDocument1 pageUTP 641 KBVIRPOPNo ratings yet

- Bohler Fox S 308L-16Document1 pageBohler Fox S 308L-16HAKANNo ratings yet

- TOOLCORD MMA Electrodes for HardfacingDocument1 pageTOOLCORD MMA Electrodes for HardfacingbrunizzaNo ratings yet

- Carbo 4370 Mpr-E307Document1 pageCarbo 4370 Mpr-E307ali torabiNo ratings yet

- SMAW Bohler Fox S EV 50 1 E7018 1H4RDocument1 pageSMAW Bohler Fox S EV 50 1 E7018 1H4RYoga ArdiansyahNo ratings yet

- L1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Document1 pageL1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Dimitris NikouNo ratings yet

- Basic Coated Electrode For Creep Resisting Steels: 1501 GR 622 To 1504 GR 622, BS 359 GR 622/640 1503 GR 660, 1504Gr 660Document1 pageBasic Coated Electrode For Creep Resisting Steels: 1501 GR 622 To 1504 GR 622, BS 359 GR 622/640 1503 GR 660, 1504Gr 660mohamed AdelNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- Tencord KB (E 42 4 Z B 42 h5)Document1 pageTencord KB (E 42 4 Z B 42 h5)brunizzaNo ratings yet

- Thermanit P23Document1 pageThermanit P23Branko FerenčakNo ratings yet

- 1564 Fox Ev 85 ElettrodoDocument1 page1564 Fox Ev 85 ElettrodoAminNo ratings yet

- Basinox 318: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageBasinox 318: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- Boehler 2507 P100 Rutile E2594 16 Covered ElectrodeDocument1 pageBoehler 2507 P100 Rutile E2594 16 Covered ElectrodekapsarcNo ratings yet

- L1 34410 en Avesta 309 AC DC 2SE6A22E 3383012 ENDocument1 pageL1 34410 en Avesta 309 AC DC 2SE6A22E 3383012 ENkamals55No ratings yet

- Bohler Fox N CM 2 KBDocument1 pageBohler Fox N CM 2 KBkamals55No ratings yet

- Böhler Fox EV 65 electrode for high-strength steelsDocument1 pageBöhler Fox EV 65 electrode for high-strength steelsMohamed AdelNo ratings yet

- Böhler CM 5-Ig: TIG Rod, High-Alloyed, Creep ResistantDocument1 pageBöhler CM 5-Ig: TIG Rod, High-Alloyed, Creep Resistantwesley59No ratings yet

- Supranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageSupranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- Böhler CM 5-IG solid wire for high-temperature steel weldingDocument1 pageBöhler CM 5-IG solid wire for high-temperature steel weldingPT. CATUR MATRA NusantaraNo ratings yet

- BOHLER FOX S EV 50-1 Stick ElectrodeDocument1 pageBOHLER FOX S EV 50-1 Stick ElectrodeKrishna Vacha100% (1)

- 02112015000000B - Boehler FOX EV 70 - CeDocument1 page02112015000000B - Boehler FOX EV 70 - CeOPAZOSCNo ratings yet

- Join & Repair High-Carbon Steels with NiCr HLSDocument1 pageJoin & Repair High-Carbon Steels with NiCr HLSwalter091011No ratings yet

- Datasheet BOHLER AWS E7018-1 Stick ElectrodeDocument1 pageDatasheet BOHLER AWS E7018-1 Stick ElectrodeArhamNo ratings yet

- Phoenix SH Ni 2 K 80 PDFDocument1 pagePhoenix SH Ni 2 K 80 PDFPrakash RajNo ratings yet

- Bohler Fox S Ev 50: Stick Electrode, Unalloyed BasicDocument1 pageBohler Fox S Ev 50: Stick Electrode, Unalloyed Basickiki270977No ratings yet

- T Thermanit GEW 316L-17 Se en 5Document1 pageT Thermanit GEW 316L-17 Se en 5PubcrawlNo ratings yet

- E 8018 B2Document1 pageE 8018 B2ElMacheteDelHuesoNo ratings yet

- Overcord R12: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageOvercord R12: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Carbo 4842 Ac-E310Document1 pageCarbo 4842 Ac-E310ali torabiNo ratings yet

- sl502 EngDocument2 pagessl502 EngArsalan QutbiNo ratings yet

- Fox - FFDocument1 pageFox - FFGustavo NietoNo ratings yet

- T - Thermanit MTS 4 - Se - en - 5Document1 pageT - Thermanit MTS 4 - Se - en - 5bhanu.kiranNo ratings yet

- 02112015000000B_Boehler FOX EASN 25 M_ceDocument1 page02112015000000B_Boehler FOX EASN 25 M_ceABNo ratings yet

- E 7016 Product-SheetDocument1 pageE 7016 Product-SheetAlireza TakrimiNo ratings yet

- 02.CARBO - RC 3 Blau eDocument1 page02.CARBO - RC 3 Blau eMario CastilloNo ratings yet

- Böhler Fox Skwam: Classifi CationsDocument1 pageBöhler Fox Skwam: Classifi CationsBranko FerenčakNo ratings yet

- Groupe Automobile Jeandot - Wrangler-448Document1 pageGroupe Automobile Jeandot - Wrangler-448DarkedgeNo ratings yet

- Electrode Booklet F Web 100Document1 pageElectrode Booklet F Web 100satnamNo ratings yet

- Supercito E: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageSupercito E: MMA Electrodes C-MN and Low-Alloy Steelsantonio111aNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- SUPERCITO MMA Electrodes for Structural and Heavy WorkDocument1 pageSUPERCITO MMA Electrodes for Structural and Heavy Workantonio111aNo ratings yet

- Böhler Cat 409 Cb-Ig: Classifi CationsDocument1 pageBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNo ratings yet

- Böhler Fox Skwam: Classifi CationsDocument1 pageBöhler Fox Skwam: Classifi CationsBranko FerenčakNo ratings yet

- Binz 1Document1 pageBinz 1Branko FerenčakNo ratings yet

- MB Evo/Evo Torches: Air & Liquid CooledDocument1 pageMB Evo/Evo Torches: Air & Liquid CooledBranko FerenčakNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- Uv 420 TTRDocument1 pageUv 420 TTRBranko FerenčakNo ratings yet

- Marathon 543: Classifi CationsDocument1 pageMarathon 543: Classifi CationsBranko FerenčakNo ratings yet

- Böhler KW 10-Ig: Classifi CationsDocument1 pageBöhler KW 10-Ig: Classifi CationsBranko FerenčakNo ratings yet

- Welding consumables for ferritic stainless steelsDocument1 pageWelding consumables for ferritic stainless steelsBranko FerenčakNo ratings yet

- Uv 420 TT-LH: Classifi CationsDocument1 pageUv 420 TT-LH: Classifi CationsBranko FerenčakNo ratings yet

- Uv 419 TT-W: Classifi CationsDocument1 pageUv 419 TT-W: Classifi CationsBranko FerenčakNo ratings yet

- Thermanit P23Document1 pageThermanit P23Branko FerenčakNo ratings yet

- AFROX Stainless Steel 98Document1 pageAFROX Stainless Steel 98Branko FerenčakNo ratings yet

- Afrox Subarc 347: Back To Section 12Document2 pagesAfrox Subarc 347: Back To Section 12Branko FerenčakNo ratings yet

- Thermanit P24Document1 pageThermanit P24Branko FerenčakNo ratings yet

- Coremax 71Document2 pagesCoremax 71Branko FerenčakNo ratings yet

- Classifications of Solid Stainless Steel WiresDocument3 pagesClassifications of Solid Stainless Steel WiresBranko FerenčakNo ratings yet

- 5614-1 Offizielle InterpretationenDocument1 page5614-1 Offizielle InterpretationenBranko FerenčakNo ratings yet

- Alloy 310Document2 pagesAlloy 310Branko FerenčakNo ratings yet

- Stainless Steel Wires For Flux Cored Welding: Afrox Coremax 308LPDocument3 pagesStainless Steel Wires For Flux Cored Welding: Afrox Coremax 308LPBranko FerenčakNo ratings yet

- Metrode Supercore 2205P: Welding Consumables Stainless SteelDocument2 pagesMetrode Supercore 2205P: Welding Consumables Stainless SteelBranko FerenčakNo ratings yet

- Alloy 318Document2 pagesAlloy 318Branko FerenčakNo ratings yet

- Alloy 309lDocument2 pagesAlloy 309lBranko FerenčakNo ratings yet

- Cored Wires For CMN & Low Alloy Steels: Oerlikon Fluxofil 14 HDDocument3 pagesCored Wires For CMN & Low Alloy Steels: Oerlikon Fluxofil 14 HDBranko FerenčakNo ratings yet

- Alloy 2209Document2 pagesAlloy 2209Branko FerenčakNo ratings yet

- E16 8 2Document4 pagesE16 8 2Branko FerenčakNo ratings yet

- A 983 - A 983M - 01 - Qtk4my9botgzts1sruqDocument7 pagesA 983 - A 983M - 01 - Qtk4my9botgzts1sruqhoangNo ratings yet

- BS Iso 4991Document27 pagesBS Iso 4991Thomas ValoNo ratings yet

- (Asce) 1076 0431 (2001) 7:3Document7 pages(Asce) 1076 0431 (2001) 7:3maheshNo ratings yet

- 5083 Material FatigueDocument142 pages5083 Material Fatiguecen1510353No ratings yet

- ASTM A350/A350M-07 Standard Specification For Carbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing For Piping ComponentsDocument9 pagesASTM A350/A350M-07 Standard Specification For Carbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing For Piping ComponentsAtul Anand SrivastavaNo ratings yet

- 6 Materials: ISO 898-1:2009 (E)Document4 pages6 Materials: ISO 898-1:2009 (E)Dasith SithiraNo ratings yet

- Progress Energy's Experiences with Quality Issues on Cast C12A Valve BodiesDocument28 pagesProgress Energy's Experiences with Quality Issues on Cast C12A Valve BodiesinorwoodNo ratings yet

- 026 TS Hardox 600 The Ultimate Wear Plate UKDocument4 pages026 TS Hardox 600 The Ultimate Wear Plate UKNguyen Duc DungNo ratings yet

- Akrylon XT - : Technical ManualDocument21 pagesAkrylon XT - : Technical ManualMaria TamasanNo ratings yet

- Dievar D20140715Document4 pagesDievar D20140715Rizal IephoNo ratings yet

- Nickel in Ferritic & Martensitic Stainless Steel PDFDocument23 pagesNickel in Ferritic & Martensitic Stainless Steel PDFhimanshu17121990No ratings yet

- CrankDocument9 pagesCrankKresna BayuNo ratings yet

- 005 Plate PDFDocument22 pages005 Plate PDFnice guyNo ratings yet