Professional Documents

Culture Documents

CTLSC1xT314-w2l1vs1 Intro V1-En

CTLSC1xT314-w2l1vs1 Intro V1-En

Uploaded by

Farid Tangarife0 ratings0% found this document useful (0 votes)

10 views4 pagesTexto del ctl

Original Title

CTLSC1xT314-w2l1vs1_intro_v1-en

Copyright

© © All Rights Reserved

Available Formats

TXT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTexto del ctl

Copyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views4 pagesCTLSC1xT314-w2l1vs1 Intro V1-En

CTLSC1xT314-w2l1vs1 Intro V1-En

Uploaded by

Farid TangarifeTexto del ctl

Copyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

You are on page 1of 4

OK, recall that we said that supply chain management is

all about making supply match demand.

So understanding and being able to forecast that demand

is a critical and usually a first step

in designing a supply chain.

But before we get into the math of forecasting,

let's step back and talk about demand planning

to understand what we're really trying to do.

It's important to always remember

when we're in the middle of forecasting

and all the different models what our objective is,

and that forecasting isn't the end game.

We don't forecast just for forecast sake.

We always forecast for a reason, whether it's

the planned capacity, to manage our inventory,

or to set up our transportation plan,

or anything in between that.

But there's always a reason for doing a forecast.

And forecasting is actually part of a larger process.

And then you can think about the demand process.

And there are three main big questions

that we try to answer in this demand process.

The first one is, what should we do to shape and create

demand for our product?

And this is sometimes known as demand planning.

And you can think of what falls in this category as the five

p's.

You want to think about the product that you're making

and the packaging.

What does the size and the final form look like?

Because this will shape demand.

It'll change whether people really want it or are not

as interested in it.

Think about promotions.

And so the interesting thing about promotions,

if you're talking to the consumer

packaged good industry, the companies that make things

that you buy in the grocery store or department store,

40% of all products in supermarkets sold by CPG

are sold under a promotion.

Promotions drive huge swings in the business.

So that will definitely change demand.

You want to think about the pricing.

What's your list price versus what discounts do you offer?

Because that changes the way the demand will be shaped.

And then finally, place.

And what we mean here is what kind of channels are you using?

Is it all internet?

Is it small mom and pop stores?

Is it large grocery stores?

Anything in between.

So how you set up your product, your packaging,

the way you run promotions, your pricing plan,

and where you place, where you sell your products,

that will help shape demand.

So now we can think about the next question.

And that's given this plan, what do we expect the demand to be?

And so this is where forecasting comes in.

So we've got this plan in place.

We know what the promotions are going to be

and all these different things.

And now we're going to forecast.

And as we'll see in a second, there

are different levels of forecasting.

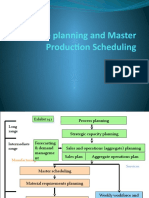

You can think of strategic, tactical, and operational.

And they all vary with the time horizon

you're trying to plan over.

And we'll talk more about that in a second.

But the second thing is you want to consider

both internal and external factors.

And the key word here is factors.

So you want to understand that demand plan-- that's

the internal factors that you're shaping,

how you're setting up your promotions and everything--

but also your external factors, the competitive landscape.

What you don't want to include in here is your capabilities.

You don't want to set a forecast based

on what you want to happen or what

you think you would like to see.

It's really all about what your unbiased, the baseline

or unconstrained forecast is.

So you try not to have other things influence

the forecast that don't fit in.

You look at those factors that are

beyond your control-- the competitive landscape.

But you really don't want to bias your forecast.

And we'll talk much more about that in later lectures.

And then the third question is, OK,

given that we have this demand, how do we prepare and act

for this when it starts materializing?

And this is known as demand management.

And this is kind of at the end of the process.

But it's an ongoing process.

And this is where we try to balance the demand

and supply across the organization.

So you can think about this demand planning up here.

A lot of this is happening at the marketing or sales side.

Product development, they're trying to figure out policies.

Forecasting is done in different places within a company.

A lot of times it's done in the marketing side,

sometimes on the supply chain side.

But demand management is the process

that involves all of the company,

because you're balancing the demand and the supply.

So the key tool or process used here

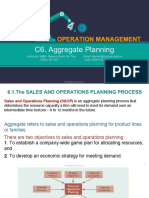

is the S&OP processor, Sales and Operations Planning,

which we'll talk about a little bit later.

But essentially what this is, it's

a meeting or series of meetings or a mechanism

that ties the operations or the supply side

with the demand side.

So the supply side is focused on minimizing cost and inventory.

This is the guys in the supply chain trying

to make things as efficient as possible.

And they balance this with the demand side.

These are the marketing and sales side.

And their objective is to maximize revenues and margins.

And so what this S&OP does, it creates a bridge

across the firm to try to balance

between what we want to sell and what we're able to make.

So these are the three key questions

within the demand process.

And the last thing I want to say before we

get into some of the details is the different types

of forecasts.

And again, they all differ based on the time horizon.

So you can think of a strategic plan or strategic forecast

as being multiple years.

This is one year, multiple years.

In the pharmaceuticals industry, you

might be planning five, 10 plus years out,

because you have to base it on the life of the drug

that you're creating.

For large infrastructure investments,

such as for the government for a department of transportation,

they've got to look 20 to 30 years out,

because the life of the product itself, the investment,

the highway, the bridge, whatever has a long lifespan.

So they have to look much further.

So you see these strategic level forecasts, mainly

for investment strategies.

And the big questions-- capacity planning, building a new plant,

large business changes.

Then you get down to the tactical level.

You can think of quarterly tactical plans as well as

months or weeks plans.

And they're really all about those things

that we can change within a quarter

or within a month or a week.

So here on the month or week, we can

think about short term capacity planning,

master planning, inventory planning.

This is where we'll spend a lot of time.

But quarterly, that's pretty much

how you can adjust your labor, your manpower, some

of your sales planning.

A lot of these things run on quarterly cycles.

Whether that's a good thing or a bad thing is another question.

But a lot of times, you have these things tied to a quarter.

And then finally, you have these operation or shortform term

plans.

And I'm forecasting over days or hours.

A lot of times you'll see this for transportation

on the current operations, production planning, inventory

deployment, those kinds of things.

So essentially, you forecast to the level

that which your process can change.

So if an investment up here, like

we're talking about for a factory or a large plant,

if it's going to last for 50 years

and takes five to 10 years to build,

then you're going to need a longer term

vision than if you're trying to plan how many trucks I need

next Tuesday.

So the type of the forecast depends

along the length of the horizon you're trying to plan for.

So what are we going to talk about for the rest

of this lecture?

Four things.

First, we're going to go into some truisms about forecasting.

We always have to address these when we first

talk about demand forecasting.

We're going to talk about different approaches

and classify them as subjective versus objective.

And then we're going to go into quality of forecast,

how do you tell if it's good or bad,

and then getting into metrics.

So let's get started.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CH 13 - Aggregate Planning PDFDocument15 pagesCH 13 - Aggregate Planning PDFMERINANo ratings yet

- Sales and Operations PlanningDocument17 pagesSales and Operations PlanningcharlesNo ratings yet

- Kinaxis Rapid Response EditedDocument25 pagesKinaxis Rapid Response EditedVinod Venkatesan100% (1)

- Abcd Checklist For Manufacturing ExcellenceDocument33 pagesAbcd Checklist For Manufacturing Excellencefrancisco_zacariasNo ratings yet

- Demantra SOP EBS Integration Process v1.0Document20 pagesDemantra SOP EBS Integration Process v1.0kmurali321100% (1)

- Sales Operational PlanningDocument4 pagesSales Operational PlanningJose LaraNo ratings yet

- Aggregate Planning and Master Production SchedulingDocument17 pagesAggregate Planning and Master Production SchedulingAshwani Singh100% (1)

- Aggregate PlanningDocument47 pagesAggregate Planningmarah nimerNo ratings yet

- Executive Sales and Operations PlanningDocument56 pagesExecutive Sales and Operations PlanningJuan José G.80% (5)

- Chapter 15 - Operations Planning and Scheduling PDFDocument11 pagesChapter 15 - Operations Planning and Scheduling PDFfazlin100% (2)

- Final Assignement S&OP IBP by EL KORCHI 14 01 2024Document3 pagesFinal Assignement S&OP IBP by EL KORCHI 14 01 2024elkorchihananeNo ratings yet

- W5 - Master Production Schedule (Pendek 2022 2023)Document29 pagesW5 - Master Production Schedule (Pendek 2022 2023)HENRIKUS HARRY UTOMONo ratings yet

- Aberdeen Group - Sales-Operations-PlanningDocument9 pagesAberdeen Group - Sales-Operations-PlanningDavid SantoNo ratings yet

- PPC Project MockDocument20 pagesPPC Project MockbxoaoaNo ratings yet

- C6 - Aggregate PlanningDocument72 pagesC6 - Aggregate PlanningVõ Nguyên HạnhNo ratings yet

- Aggregate PlanningDocument27 pagesAggregate PlanningRajat AgrawalNo ratings yet

- Aggregate Planning in Supply ChainDocument43 pagesAggregate Planning in Supply ChainAyush KumarNo ratings yet

- Ebm2024 1946Document43 pagesEbm2024 1946karen.oldham702No ratings yet

- Using Sales and Operations PlanningDocument192 pagesUsing Sales and Operations PlanningGaurav MeenaNo ratings yet

- Test Bank For Introduction To Materials Management 8th EditionDocument7 pagesTest Bank For Introduction To Materials Management 8th EditionJoseph Williams100% (36)

- UntitledDocument20 pagesUntitledmohita malhotra100% (1)

- Ramneekjain - Opscm Ind. Assignment-1Document6 pagesRamneekjain - Opscm Ind. Assignment-1Ramneek JainNo ratings yet

- Session 16A Chapter 9 Chopra 5thedDocument15 pagesSession 16A Chapter 9 Chopra 5thedNIkhilNo ratings yet

- Master Production SchedulingDocument19 pagesMaster Production Schedulingnatrix029No ratings yet

- SCM 302 RatcliffeDocument34 pagesSCM 302 RatcliffeRashidi KhanNo ratings yet

- Sales and Operations Planning - APICS Exam WarehouseDocument6 pagesSales and Operations Planning - APICS Exam Warehousevishalyerawar100% (1)

- Chapter 14 Latihan Soal & SolusiDocument25 pagesChapter 14 Latihan Soal & Solusiandre suryantoNo ratings yet

- Full Download Ebook Ebook PDF Logistics Management and Strategy Competing Through The Supply Chain 6th Edition PDFDocument42 pagesFull Download Ebook Ebook PDF Logistics Management and Strategy Competing Through The Supply Chain 6th Edition PDFsarah.steir690100% (46)

- Operations and Supply Chain Management: Prof. Svenja Sommer Sommers@Document22 pagesOperations and Supply Chain Management: Prof. Svenja Sommer Sommers@michmich1245No ratings yet

- Sap Production Planning (Old)Document100 pagesSap Production Planning (Old)Nina PagkatipunanNo ratings yet