Professional Documents

Culture Documents

Yrv Turbo k3 Vet Engine PDF

Uploaded by

Felipe Ignacio Cortes Fuentes75%(4)75% found this document useful (4 votes)

5K views77 pagesOriginal Title

yrv-turbo-k3-vet-engine.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

75%(4)75% found this document useful (4 votes)

5K views77 pagesYrv Turbo k3 Vet Engine PDF

Uploaded by

Felipe Ignacio Cortes FuentesCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 77

WILLA Turesa

K3-VET-ENGINE

Service and Technical Information

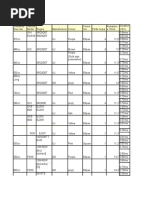

Paga No.

o1

12

13

7

23

34

37

39

56

57

60

64

67

69

70

73

Section

General Information

Maintenance

Engine Tuning

Engine Mechanical

Intake & Exhaust

Lubrication

Cooling

Engine Control System

Emission Control

Ignition System

Automatic Transmission

Front Suspension

Rear Suspension

Drive Shaft

Braking System

Body & Body Electrical Systam

BBE

Part No. 2220000000305 S

GI-1

1-2-2 EUROPEAN SPECIFICATIONS

Model code Sieering position | Grade | Engine | Drive | ‘hansmission Boay type

iors omen

M200LG-GMNEW LHD to ENE out

M201RG-GMNEW LO

neomesoew | © |i

‘201RG-GOGEW HI oo

Tepe! io on

M201LG-GMGEW. LHD HI K3VE_ 5-door

M201LG-GONEW. LO Electronic control

ese cose na

TETAS NEW an

; 0 Econo cou

were Sone a oo nes

meee! | out

heii soheW

eaney | —__ ence con

M201LG-GOSIW_ LHD. Turbo K3-VET 2wO 4AT

eel

onan

1-2-3 AUSTRALIAN SPECIFICATIONS

eT

M200RG-GMNFQ_ EU-DE wT

M201RG-GNNEG RHD Lo K3.VE 2wD 7 5-door

comer ao oa

— oe

sear

a

1-3 EXPLANATION VEHICLE MODEL CODE

cease ates

Drive: Steering NLo None: General

0: 2WD tleft Door GH W: Europe

Be A: i G fe Ss: ll Tce

w2|[o jf 7 |[t je |—[e ][ mu jl |e [fw]

wee ene oe) y90 Tmo fale

OB G: Wagon M:SMT F:4 Valve

ct ne

or Sith cage

Se

G

OE

SPECIFICATIONS

Speciications

MZ0ORGAG M201RGILG M2iTAGILG

lems 2WD 2wo ‘aWO.

EybE | E/VE KSVE, KGET SVE

Mi wr Jat [ar | wa Tap

‘General spac. 1360 1400 7

Gross vericle [australian spec. 1316 1350 =

kg | European spec. 1960 7400 1420 | 1420 [780

Overat iength ‘3765 = =

Overall with 1625 = =

‘Overal Reight 1850, 1880°7 = =

Whee! base 2370 = = _]|

19 inch wheels 1390 = = 1380

ee Front [14 inch wheels 1380 = = 1380

ial 18 inch wheels = = 1380 =

“‘Biinch wheels 1870 = = 1370

Rear [14 inch wheeis 1360 = = 1360

fam, $8 inch wheels = = 1360 =

Max. Front kg 770 ~ =

permissible

axiemass [Rear 'g 760 ~ 785

Without brake i 350 = =

Towra mies ih rae ig 780 a0 =

Permissible root rack load kg 50 = =

Displacement ‘an? 289 1288 =

King of fue Petrol = =

Recommended eclane number Win 80 (RON) = =

Cycle 4 = =

Number of eyinders & Arrangement Sinsing dining =

Firing order 42.8 err =

| ax Stroke im 72x81 Tex7a7 =

Distance of bore center to canter mm] 20 78 =

Compression ratio 1003 = 35E03 iox08

Engine service mass. a | 96 = 9. 94 oe [89

Max. power Fewfrom| 40.5'6200 | 43,096000 [63.0600 | 96/6400 | 63,0/6000

[igeition timing BDC degreeiom| _542"/650:50 6£2°/ 700450 =

Engine valve mechanism OHS = =

Opens pipe Heme 30° --12" BTOG -

— 425° | 2-62"

aunt Closes ase | oroe 10" -52" TDC -

roe Opens Bape faeces 30° BBC ~

Exhaust 7

sere islets :

[Lubricant usea SAE SW3O) = =

"ith rear roof antenna

oecons.08

GI-3

—_—_—_—__—————

Speciications

M200RGLG | M201RGAG M21iRGAG

tterns 20D 20D. AWD

eye | IVE KANE KSVET | _KSVE

MT wr | at | at [on | ar

(Coolant capaci ters 30 44 40 43 [44 40

iat 3.182 = = 3.182

2rd 1.842 = = 1302 [

pane Sid) 1.250 = = 1250 [=

iransmission

gearraio [4th si7 0.865 = oes | —

Sih 0.750 = = ‘o7s0 | =

Fev. 3.143 = = 343 [=

ist = = 2731 =| 27%

‘Automatio (20 = = 1.526 = [1526

transmission [Sed = = 7.000 = 000

gearratio [ath = = 0.696 = [0.696

Rew = = 2.290 =| 2280

Transfer gear ratio = = 1.000

Differential [Front 4.500 4267 |_ 4032 | 3749 [4267 | 4350

gearratio [Rear = = 3.077

ouspension ES Macpherson strut = erece}

sion

‘ype Rear sa ticenencons - 8 Link

ae [Front Cait = =

Rear col = =

Telescope with

Shock eat couble acting - a

absorber jeeinomscans wane

bel | eouble ctning ei it

Type Ball jont = =

FToe-in am ° = =

Frontaie [Camber o = =

(Caster 28" = =

Kingpin angie 1a = 18" tae

Rearave (een mn 3 = °

[Camber =Or1s! = °

‘Type Rack & Pinion = =

‘Steering (Goarratio [Power steering 17.0 72 wa we

(Overall) | tanual 22.0 7 -

TeKoRDate

GI-4

"3 With rear roof antenna

Vehicles mounted with T/C engine

4 VEHICLE IDENTIFICATION

4-1 LOCATION

4-1-1 CHASSIS SERIAL NUMBER

4-1-2 ENGINE TYPE AND ENGINE NUMBER

4-1-3 MANUFACTURER'S PLATE POSITION

GI-5

Vehicle identification number

_{For GCC & EU specifications)

Engine type

Engine number

Mafutacture’s plate

GI-6

ree

5 ABBREVIATION CODES

ABBREVIATION CODE ORIGINAL WORD ABBREVIATION CODE ORIGINAL WORD

210 Fiwo Whee! Drive MP Multipurpose

40 Four Wheel Dive Mir ‘Manual Transmission (ransaxe]

ABS Anivlock Brake System NAL Natural Aspiration

AC. Air Concitionsr NOx Nirogen Odes

API Amierican Petroleum insta ‘OPT Option

AT Automatic Transmission (Transaxie) OS Over Size

AIDC After Top Dead Center PCV Positive Crankcase Ventilation

ATE Automatic Transmission Fiuid PR Ply Rating

Ay Assembly PIO. Power Take Off

BTDC ‘Before Top Dead Center RH Right Hand

ue Data Link Connector HD Fight Hand Drive

DL Distributor Less Igniion FR Rear

Dwr Dynamic Variable Valve Ting SK Sub Assembly

80 Electron Brake force Distiouton SAE Socisly of Automotive Engineers

ECU Electronic Control Unit, SST Special Service Tool

EFI Electronic Fue injection SID Standard

EGR Exhaust Gas Recirculation System SW Switch

EPS Electronic controlled Power Steering it Torque,

ESA Electronic Spark Advance Te Turbocharger

ZZ Xx [Exhaust TOC Top Dead Center

Fi Fusibl Unk us Under Size

Fa Front vav Vacuum Switching Valve

NO Ground vv Vacuum Transmiting Valve

HG Hydro Carbon Wi with

18 Tanition ® Bot

iN Intake © [Screw

186 idle Speed Contot a) Nat

1c integrated Timer Control @ Washer

lED Light Emitting Diode © [clip

tH Left Hand

HO sft Hand Dive

LsPv [Load Sensing Proportoning Valva

TESTES

‘-aBe-co00

6 JACKING POINTS

6-1 JACKING POINTS AND SUPPORTING POINTS OF SAFETY STANDS

6-1-1 JACKING POINTS

CAUTION

+ The jacking-up operation must be carried out only on a level flat place.

+ Never jack up the vehicle at the front and rear sides at the same time.

* Be sure to set the garage jack in such a way that the jack may not interfere with the bumper.

@ vecking points

Font co

Front

Rear suspension

Rear ae

* Never use the rear suspension

‘beam as a jacking point.

(For 26D vehicles)

Sa

F 2 SUPPORTING POINTS OF SAFETY STANDS

CAUTION

+ Never support the vehicle at points other than the specified points.

GI-8

Safety stend suppor

as

GI-9

9-2 DATA LINK CONNECTOR

9-21 DATA LINK CONNECTOR TERMINAL ARRANGEMENT

esmmouescd

No. Terminal code No. Teeminal code

1 4 BAT (05-21), 9 T (TO)

2 = 40 7 S10 (08-21)

3 = 1" 7

4 TiECU) 12 E

5 ea) 13 E

6 W. 4 =

7 = 16 =

8 REV 16 VE

Ta

essomcocone

9-2-2 CONNECTION METHOD OF DATA LINK CONNECTOR

1. Perform it by connecting the engine control system inspection wire (SST) with the data link connector.

Perform the system check of each system by using the terminal for short circuit (SST), the terminal for

detecting engine speed and the terminal for VF output monitoring (SST).

(1) CONNECTION METHOD OF EACH SYSTEM

1. Diagnosis code output of engine control system: Short circuit between T (EFI) - E

Functioning check of 0: sensor for engine control system : Measure between VE - E

Engine speed check of engine control system: Measure between REV - Body earth

Diagnosis code output of ABS system: Short circuit between T (ECU) - E

Diagnosis code output of airbag system: Short circuit between T (ECU) -

Diagnosis code output of automatic transmission system: Short circuit between T (ECU) - E

Functioning check of body integration controller and vehicle speed sensor: T (ITC)-E

Diagnosis code output of immobilizer system: Short circuit between T (ITC) - E

ONDARwN

cinowc-scome

13-1 BODY COLOR CODE

GI-10

—_—_— ee

13 VEHICLE IDENTIFICATION

13-2 CHASSIS SERIAL NUMBER

1. The chassis serial number is stamped on the position as

shown in the illustration.

Bodycare Caras

Serna Sa

Beckmce we

Ughtose mee Tis

Ted 8

Sho nea ma 5

Sunonryetow v0?

a

eearcoprnare | cata | ax2 | ouronr ousumir | BAUD | SAE | cpaoe

Ths wos | Bad | waded —[-DALNGS | ume [teas “| aos

Silver metallic Sov DAHSO7 18842 DAI-SO7_ 81278 97076 S07,

Bick ria wos | paeaos | wssse—| pavnns”[ Cvneie | reg [eee

iiatresemetaia ris oaars | ease —[-partio | wires "| “sesso [ he

Ted wea |" pawco | F700 | pains [aaa] sess | as

Blue metallic mica B50. DAHESO M6981 DAI-BSO WVFSB. 69136 B50

Sule yew soy [ower | sere F pasor | ives] 888 |r

—

comseao

Chassis serial number

Vehicle identification number

-{For GCC & EU specifications)

HT

i3-4-1 CONTENTS OF MANUFACTURER'S PLATE

General, Australian specifications

O-f—DAIHATSU MOTOR CO. LTD. JAPAN

®

ows MCL TTT ET IIIT

@— enone ELT TTT ttt }-+-®

© peoton EEE tAMCEEOE O|

Burt vate CLT TTT }-——J

ENGINE NOCCTITTT+4

SS AA NY LHRRRKSH

European Specification

@-——DAIHATSU_ MOTOR CO..LTD

CEEEPECoon k

© Geen CEED Ks

COOTITTETrea rer 5

CUO ks ea ells

coo He

Croitie OCtikg ttt tt+-8

@-pWECEELLEEEEET EEE |

© enaine“ LTT ITTY) covor([T11+-7-®

GI-11

© Manufacturer's name, Country

® Vehicle model

@ Chassis No.

@ Engine type

engine displacement

© Body colors

Dim coce

@Engine number

@ Manufacturers name in Japanese

Gross vehicle weight

Gross combination weight

@ Maximum permissie front axle weight

(G Maximum permissibie rear exle weight

{ Production month-year (Only for AUS spec.)

@ Authorized number of WTA.

(Only for European spec:)

eT

MA-12

2 MAINTENANCE SCHEDULE

1. For improved maintenance, the maintenance schedule has been simplified.

NOTE

* Perform the periodical maintenance at the specified mileage or the time whichever comes first, un-

less otherwise specified,

2, Continue to perform the periodical maintenance after 90,000 km (54,000 miles) at the same intervals as

before 90,000 km.

If the vehicle should be operated under severe driving conditions, operated occasionally, operated in

dusty areas, repeating short trip, operated under extremely cold climate and/or on salted roads, it is

necessary to perform some maintenance items more frequently than the regular maintenance

schedule.

This maintenance schedule has been prepared based on requirements mentioned in the owner's man-

ual which are to be performed by the Daihatsu owner thoroughly.

(©....Check or inspect _@....Change or teplace

Whattoco ~i0ookm [15 | 30 | «5 | 60 | 7m | 90

Section Item Inspection “x 1000miles,_@ | 1a | 27 | 96 | 45 | 54

interval Years 1 2 3 4 s [6

Seeing

; Ched

Aiccleaner element | CMC eo, eo} e]olole

‘Change

Change (EJ,K3-VE engines) | @ | @ | @ | @ | @ | eo

(Use API SH or higher")

‘Change (K3-VET engine)

(Use API: SH or higher)

Engine oil & ol fiter

Every 10,000 km (6,000 miles) / 1 year

Check

Crack

Fuelline & connections

‘eTightness ° ° 3°

nine | CrebIng fst ses) | = aes

* Damage

Coolant | : |

(Long lite coolant) Change | Every 2 years

Orive bet Check

(Aternator, Tension

water pur. * Crack o}ofloflojol]fo

power steering) $ Damage

[Timng bet Grange Every 100,000 km (601000 miles)

| Crean & check

* Condition

Spark Plug ceo ° ° °

*Damage

Replace every 12,000 km / 1 year, whichever comes first when API SG mult grade ois used.

"2: Only for Type EJ engine.

Macs eos

ET-13

-3 CHANGE ENGINE COOLANT

1-8-1 CLEANING OF ENGINE COOLANT CIRCUIT

1. Drain the engine coolant

2, Fill the water and warm up the engine.

3. Stop the engine and drain the water.

4, Repeat the above steps 1. through 3, two or three times.

ereaunccoie

1-3-2 DRAIN ENGINE COOLANT

1, Remove the radiator cap.

2. Drain the engine coolant by removing the drain plug located at the lower side of the radiator.

3. Install the drain plug to the radiator and tighten it.

ercounoena

4-3-8 FILL ENGINE COOLANT

1. Fill the radiator with the engine coolant in accordance with the instructions of the manutacturer of the

antifreeze solution and warm up the engine.

2. While the engine is warming up, check to see if the leakage is presented.

%. Cool down the engine after the engine has been warmed up.

Fill the engine coolant if the engine coolant ievel is low by checking it

sans

LOW/FULL 0.251098

raver raise

capacity ialcdiced but not the reserve

Poe

Sie” | oxsose

voaly Tota! the heater capacity,

= era

‘Automatic | 4.08 tank capacity.

ro

EJDE Manuel 3.0 | Thisfigure includes

EVE Total oe - the heater capacit

TES

ercoL Rowen

ET-14

————

2 ENGINE OIL

2-1 INSPECTION

2-1-1 CHECK OF ENGINE OIL QUALITY

1. Pullout the oil level gauge.

2, Check the engine cil for deterioration, ingress of water, discoloring or dilution,

IF oll quality is poor, change the engine oil

NOTE

* Use API grade SH or higher multi-grade viscosity, fuel efficient oil,

2-2 CHANGE OF ENGINE OIL

WARNING

* Never touch the cylinder black, exhaust manifold and/or the engine oil. Failure to observe this cautior

will cause you get scalded.

* Operate the engine in a well-ventilated area to avoid the damage of carbon monoxide.

* Protect your eyes by wearing safety goggles.

er es0- con:

Engine type Capacity £

With oil titer: 3.6

Lede idea Without oi iter: 3.3,

Engine oil

With ofl fiter: 2.3

Oe Without oi ter: 2.1

TESORO

rrecon zn,

ET-15

—_—_—_—_—_—_——___——

2 SPARK PLUG

1 INSPECTION

3-1-1 MEASUREMENT OF ELECTRODE GAP

1. Measure the electrode gap, using the plug gap gauge

Hf the electrode gap is not within the specifications, adjust the gap by bending the base of the ground

electrode, being careful not to touch the tip.

K.VET

Manufacturer [_DENSO | NGK

Tyne, PK20PTR-S9_ | BKURGEKPA

Electrode gap (mm) 08-09 -

Width across flats (mm) 16 —

TRTTOTES

CAUTION

* All four plugs should be the same heat range and be once manufactured by the same manufacturer,

ersrcccem

4 COMPRESSION PRESSURE

4-1 INSPECTION

1. Warm up the engine thoroughly.

Stop the engine and remove al ignition coils and spark

plugs.

2, Remove the fuel pump relay.

3. insert a compression gauge into the spark plug hole

Depress the accelerator pedal fully.

While cranking the engine, measure the compression

pressure.

SPECIFIED VALUE: Compression pressure

(330rpm, difference between cylinders: Not to exceed 147 kPa)

Specified Value («pe) Limit (koa)

KS.VET 1196 ‘902

Tes

NOTE

* Be sure to use a fully-charged battery. Also the measurement should be performed in the shortest

Possible length of time,

srourc.zo%m

EM-17

* OUTLINE

1

A

DESCRIPTION

Type K3-VET engine, which has newly been added to those vehicles destined for the EU, is equipped

with @ turbocharger system, based on Type K3-VE engine. This engine is mounted transversely in the

vehicle. As a result of the employment of a turbocharger system with an intercooler, some changes,

such as the compression ratio, have been made from Type K3-VE engine, thus optimizing the specifi-

cations.

encore

EM-18

1-2 ENGINE PERFORMANCE CURVE

100

95kW [6400 rpm]

90 +

eo

7b 41680

170N-m [2800 rpm]

eof 4160

EB sof 4400 E

= z

2 g

“of 4m 2

sof 100

zat 420

woh

7 1 1 1 1. 1

1 2 2 4 5 8 7x10?

Engine revorution speed (rpm)

K3-VET

SP BRS

EM-19

7 ~ ENGINE MAIN SPECIFICATION

Engine type K3-VET

King Gasoline, water-cooled, 4-cycie

(Cylinder number and arrangement Inning, 4-cylinder, transversely mounted

Valve mechanism DOHC chain-criven (intake 2, Exhaust 2)

(Combustion chamber type Pent of type

Intake, exhaust leyout Gross flow type

Total displacement ce) 1208

Bore x stroke riwn| 72 x 79.7

‘Compression ratio 25

‘Maximum output ‘eW/ rpm | 95 / 6400

Maximum torque Nem rpm] 170 / 2800

nko ‘Open sor = 12" BTC

Valve timing Chose 10" §2° ABDC

fue Open 30° BBDC

Close 2° TOC

“ake system Turbo

we! supplying system Electronic fuel injection (EFI)

Igition system Fulltransistorized, OL type, battery ignition

{oling speed 700.

Fuel used Unieaded regular gasoiine

Gilused

SAE 5W-30__ API SH or higher

TERT

eu.oursmte

EM-20

1-4 ENGINE SECTIONAL VIEW

epaite

a

” ENGINE PROPER

« ‘CYLINDER HEAD

1. On Type K3-VET engine, as a result of the change in

blow-by passages, the location of the blow-by tube has

been altered from the side to the top section.

CYLINDER BLOCK

Water outlet port

(tor turbocharger)

‘Turbocharger lubrication oll out.

Oil pressure switch installation portion

On Type K3-VET engine, as a result of the addition of lubrication oil passages and cooling water pas-

sages for the turbocharger, the following parts have been added to the cylinder block to accommodate

the turbocharger oil inlet pipe, turbocharger oi outlet pipe, and turbocharger water hose.

EM-21

Blow-by tube (K3-VET)

Knock sensor

installation portion

Seco

EM-22

2-3 PISTON

1.

On Type K3-VET engine, exclusive pistons have been adopted. In these pistons, the volume of the re

cessed section at the top of the piston has been increased according to the compression ratio. As re

gards the identification mark, an “N" mark is cast at the reverse side of the piston in the case of Typ

K3-VE engine, whereas a “T” mark is cast in the case of Type K3-VET engine.

Identification mat

Hard almite

treatment

‘Assembling condition

2-4 PISTON RING

Leneozoone.

ee,

1. On Type K3-VET engine, exclusive parts for the engine equipped with a turbocharger have been er

ployed.

‘Compression ring No.1 ‘Compression ring No.2 Oil ving

Engine type K3-VET = =

Materials Steel Gastron Steel

Parkerizing Parkerizing

Surface alloying Outer periohery: hard Parkerizing uier periphery: hard

chromium plating chromium plating

Thickness (mm) 23 26. 2.25

With (oom) 12 = 2

Upper surface symbol f R =

a TORE

ev.comon

re

1 “UTLINE

1, On vehicles mounted with Type K3-VET engine, as a result of the addition of a turbocharger system,

parts of the exhaust system have been changed.

e-cureon

2 COMPONENTS

2-1 AIR CLEANER

1. Type K3-VET engine has adopted a resin-made air clean-

er case (3.95 2).

2-2 EXHAUST MANIFOLD AND EXHAUST MANIFOLD GASKET

1... Type K3-VET engine has employed a cast iron exhaust manifold and stainless exhaust manifold gas

ket. The exhaust manifold is provided with a turbocharger with a turbo-to-exhaust manifold gasket ir

terposed. Furthermore, at the outlet port of the exhaust side of the turbocharger, the exhaust manifol

No.2 is provided with an exhaust manifold No,’ case gasket interposed.

Turbocharger to

‘exhaust manifold gasket

Oxygen sensor

Exhaust manifold No.2

Exhaust manifold No.1

case gasket

1E-25

ee

~ 3 TURBOCHARGER SYSTEM

_ 3-1 TURBOCHARGER

1. Type K3-VET engine has employed a small-sized water-cooling type turbocharger that features an en-

hanced response under the low load range of the engine. A floating metal has been adopted at the

bearing section of the turbine shaft of the turbocharger.

no

LS

Intake air temperature sensor

2-3-2 INTERCOOLER

1. On Type K3-VET engine, a drawn-cup type intercooler

has been employed. An intake air temperature sensor is

provided on the pipe at the outlet side of the intercooler in

‘order to correct the air density by the intake air tempera-

ture.

IE-26

2-3-3 BOOST PRESSURE CONTROL SYSTEM

(1) Description

1. On Type K3-VET engine, the EFI ECU is controlling the boost pressure in order to prevent the boost

pressure of the turbocharger from rising excessively. The signal sent from the EF! ECU activates the

boost control VSV, thus controlling the pressure to be applied to the waste gate actuator. Any fluctua-

tion of the pressure to be applied to the waste gate actuator causes the waste gate vaive to be opened

orclosed. In this way, the boost pressure is prevented from rising excessively.

>

Inerccler

=“ t

=

Boost ar

vee it Boost coil VSv EFIECU

wase gate

acualer

Arcleaner

‘Turbocharger ‘intake air

OE

(2) VSV ( Boost pressure control )

1. The boost control VSV has employed a normal closed type VSV. This VSV, controlled by the EFI ECU,

controls air continuity between the air cleaner and the air inlet pipe.

\e-couecoa!

1E-27

OO

>8-4 AIR BYPASS VALVE CONTROL

1) Description

1. On Type K3-VET engine, the air bypass valve (ABV) control is provided in order to prevent the boost

Pressure from rising due to a sudden closing of the accelerator pedal. When the EFI ECU detects a

sudden closing of the accelerator pedal, the VSV for ABV control is tumed ON. When the VSV for ABV

control is turned ON, the negative pressure of the intake manifold acts on the diaphragm chamber of

the ABY, thus releasing the boost pressure at the outlet side of the compressor to the inlet side of the

compressor. In this way, the boost pressure is prevented from ri

FFL

ecu

ABV control VSV

Turbocharger

ee

(2) Air bypass valve

1. The air bypass valve is so constructed that the circuit of the port A (connected to the intercooler) and

port B (connected to the air cleaner hose) is opened and closed by means of the valve, as indicated in

the following figure. When the negative pressure applied to the port C (connected to the VSV for ABV

control) exceeds a certain value, the valve opens, thus opening the passage.

Cport |

spor —e [T ( ) [Jere als

(Airinlt pipe) (Air cleaner hose)

} Aport —> fiero es B port

Cpon

{ABV control VSV) Inner construction

1E-28

(8) VSV ( ABV control )

1. The VSV for ABV control has employed a three-way type. When the power supply is OFF, air continuity

exists between the ABV and the air inlet pipe. Conversely, when the power supply is ON, air continuity

exists between the ABV and the intake manifold,

1 cowoanee

2 INTERCOOLER

2-1 REMOVAL AND INSTALLATION

2-1-1 REMOVAL AND INSTALLATION PROCEDURE

(1) COMPONENTS

TE5EES

* —: Non-reusable parts

T Tightening torque

Unit: Nem

(2) REMOVAL AND INSTALLATION PROCEDURES

1 10 8 GoverS/A engine upper 6 5 F Gasket

2 9b Hose.airiakeNe.t 7 4 9 tercooer ayy

3 Bc Hose S/A, vacuum (VSV for ABV conto -itercoole) © 9h Mose SIA, vacuum (Pressure sensor intake manteld)

47 6 conenactor Ay, intake ae © 2 1 Preseur sensor

5 5 © hiakoairtempertur sensor 10 + Bracket intercooler

recom:

3-1-3 POINTS OF INSTALLATION

1. Install the exhaust manifold gasket.

CAUTION

* Install the exhaust gasket to the cylinder head so that

it's protruded section faces to the cylinder head side.

2. Installation of exhaust manifold

(1) Tighten the bolts and nuts in the sequence as indi-

‘cated in the figure on the right.

4 “6 POINTS OF INSTALLATION

Installation of turbocharger

(1) When the turbo oil outlet pipe S/A is installed, be sure

to instell a new O-ring.

(2) Securely tighten the two attaching bolts of the turbo oil

outlet pipe subassembly with a new turbo cil outlet

gasket interposed.

(3) Temporarily install the turbocharger to the exhaust Turbo pipe Sia

manifold with a new turbo-to-exhaust manifold gasket cil outlet

interposed. At this time, insert the turbo oi! outlet pipe

subassembly into the hole of the cylinder block.

(4) Securely tighten the bolt and nut attaching the turbocharger to the exhaust manifold.

(8) Assemble the turbo oil outlet pipe subassembly to the engine mounting bracket

Assemble the ABV in such a way that the arrow mark provided at the side faces the air cleaner hose

side.

Install the air bypass hose No.1, air bypass hose No.3 and air bypass hose No.2, as indicated in the

following figure given below.

3,

Throttle body

\VSV for purge contrat

SV for ABV control

Boost control VSV

To canister

On CIO

To intercooler

Toair

cleaner hosé

Turbocharger

1E-32

F 3OOST PRESSURE CONTROL SYSTEM

ot ABV

sat INSPECTION

(1) SYSTEM DIAGRAM

Negative pressure

VSV for ABV

control (ON)

Engine control

computer

Turbocharger

@) OPERATION CHECK

Disconnect the ABV at the air cleaner side.

2 During the idling state after starting the engine, there shall be no discharge of the sucked air from the

ABV.

3. Depress the accelerator suddenly from the idling state. When the pointer of the tachometer registers

4000 rpm, release your foot suddenly from the accelerator. There shall be a discharge of the sucked

air from the ABV.

(9) UNIT INSPECTION

Remove the air bypass valve.

2 When's negative pressure is applied progressively to the

sensing port (diaphragm chamber) of the air bypass

valve, ensure that the ABV valve opens. Furthermore,

when the negative pressure is retained under this state,

there shall be no significant drop of the negative pres-

sure

NOTE

* Check negative pressure 53.3 kPa

3, After the check has been made, assemble the air bypass

valve in such a way that the arrow mark provided at the side faces toward the air cleaner hose.

eee

5-2 INSPECTION

5-2-1 ARTICLES TO BE PREPARED

Shape Partnumber par name Use.

sst (09992-00242-000 Measure turbocharger pressure and

a ‘Turbocharger pressure gauge —_| cheok for actuator operation

“Too! | Dial gauge. Torque wrench

Lubiicant_| Engine oll

eacsrcany

5-3 TURBOCHARGER BOOST PRESSURE

5-3-1 INSPECTION

(1) DRIVING TEST

WARNING

* Conduct a driving test in a site where the full open acceleration running can be conducted safely in

the (2) range, with two persons riding.

1. Connect a three-way pipe and a turbocharger pressure gauge between the surge tank (intake man!-

fold) and the pressure sensor. Put the gauge at the vehicle interior.

2, After warming-up the engine, perform a full open acceleration in the (8) range until the engine attains

4400 rom.

3. “Check the pressure at the time’ when the engine attains 4200rpm. If the pressure is not the specified

value, replace the turbocharger Ay.

‘SPECIFIED VALUE: 35-61kpa

CAUTION

* Never perform adjustment or disassembly on the turbocharger Ay.

eal

5-4 WASTE GATE VALVE

5-4-1 OPERATION CHECK

SST: 09992-00242-000

1, Disconnect the waste gate actuator hose at the actuator

side.

2, With a turbocharger pressure gauge connected, apply a

pressure of 67 kPa. Ensure that the rods and links operate

and, when the pressure Is released, they return to the

‘original positions without any binding.

3. Check the hoses for signs of cracks and damage.

CAUTION

* Do not apply a pressure exceeding 78 KPa to the waste gate actuator. Failure to observe this caution

may damage the diaphragm,

epomso00t

LU-34

* OUTLINE

1-1 DESCRIPTION

1, On Type K3-VET engine, a passage for lubricating the turbocharger has been added, based on Type

K3-VE engine. In addition, the discharging amount of the oil pump has been increased

Lao

Se Sa te

ee, aiatat A pe | Co

pn

Vv Vv

v

v

Cranksnak

crannahit pin | Cankenat sin

igual /| Ko} ieuma /| fo

4 oz

er oy

Cif

‘il pen

1-2 TURBOCHARGER LUBRICATION METHOD

1

The oil for lubricating the turbocharger bearing section is sui

LU-35

pplied to the boss leading to the mair

gallery of the cylinder block through the turbo oil inlet pipe, which is connected by means of the union

bolt. Then, the oil is returned from the turbo oil outlet pi

pe to the oil pan.

Oritice

Turbocharger oil inlet pipe

union portion

(Block side)

LU-36

*OMPONENTS

OIL PUMP:

On Type K3-VET engine, the thickness of the rotor section of the oil pump has been changed. Thus,

the discharging amount of the oil pump has been increased.

SPECIFIED VALUE: 36.5 2 /min or more (At time of 5040 rom / 290 kPa)

w-couenoo

1 NUTLINE

1-, DESCRIPTION

CO-37

1. On Type K3-VET engine the passage for cooling the turbocharger has been added, based on the coo

ing system for Type K3-VE engine.

1-2 COOLING SYSTEM LAYOUT

co-curaio19

Water outlet

Throttle body

Turbocharger

Radiator

Turbocharger

Radiator

CO-38

2 COMPONENTS

2-1 RADIATOR

4. On the vehicles mounted with Type K3-VET engine the radiator has different core dimensions and heat

radiating rate, taking into consideration the heat emitting rate of the engine.

co-conenrs

2-1-1 Radiator Specifications:

wT

a

Toa acathg rie wa

Radiator ee mensions erm sSOxS7K 27

[Coolant capacity (g) 1.37

Radiator cap valve-opening pressure (kPa) 108

Oil cooler Heat radiating rate {kW) 1.50

—

co-soncos

iad COOLING FAN AND RADIATOR RESERVER TANK

As a result of the change in the radiator, a fan and a fan motor for the vehicles mounted with Type K3-

VET engine have been set. Furthermore, the mounting location for the radiator reservoir tank is at the

radiator upper support in the same way as with the vehicles mounted with Type K3-VE engine. The

tank capacity remains unchanged.

2-comeoon

2-2-1 Radiator Fan Specifications:

aT

Type Diest current frie

Motor Rated voltage (V) 12

Output (Wi) 120

Fan Outer diameter (mm) $320

Blade number 7

co

o.com

2-3 COOLANT

1. The capacity of the cooling water for the vehicle mounted with Type K3-VET engine has been altered

due to changes in the radiator specifications and the addition of a cooling water passage.

SPECIFIED VALUE: 4.3 £ (W/O Reserve tank capacity )

co coMooot2

EF-39

—————

1 WUTLINE

1-, DESCRIPTION

1. The engine control system for K3-VET engine is a system which totally controls, using an engine control

computer, various control systems, such as the EFI (fuel injection control), ESA (Electronic spark ad-

vance), dynamic variable valve timing control (DVVT), ISC (idle speed control), boost control, air by-

pass control (ABV). The power distribution to spark plugs of each cylinder uses the DL (distributor-less

ignition) method where the distribution is performed directly trom the ignition coil. The vehicles with

European specifications are equipped with an onboard diagnostic system which has complied with the

1999/102/EC directive (generally called EURO-OBD). This system tells the driver that the engine ECU

has detected @ malfunction which will affect the exhaust gas adversely by flashing or illuminating the

malfunction indicator lamp (MIL). Vehicles other than European specifications are also equipped with

an onboard diagnostic system, though this system does not have so diversified functions as the diag-

nostic system for European specifications has. Moreover, the vehicles are equipped with a failsafe

function.

eonene

1-1-1 FUEL INJECTION AMOUNT CONTROL (EFI)

1. For optimum fuel injection, corrections by signals from sensors are added to the basic injection time

salculated according to the engine conditions.

© Use of air-to-fuel ratio feedback control by front and rear oxygen sensors (for improved contro!

accuracy)

@® Use of fuel return-less system (for reduced temperature inside fuel tank)

® Use of constant fuel pressure control (for improved control accuracy)

ee ounce»

41-2 IGNITION TIMING CONTROL (ESA)

1. For appropriate ignition, corrections by signals from sensors are added to the basic ignition timing cal-

culated according to the engine conditions.

© Use of $-DLI (for improved control accuracy of ignition timing)

eros

1-1-3 KNOCK EVALUATION CONTROL (KCS)

4. The knocking correction control is carried out by judging the occurrence of knocking by means of the

signal of the knock sensor, thus retarding the ignition timing,

e-ouromea

4 TORQUE CONTROL AT TIME OF GEAR SHIFTING

1. For reduced gear shifting shooks, the ignition timing is retarded at time of gear shifting of A/T vehicles.

Sours

1. IDLE SPEED CONTROL (ISC)

1. The fast idle speed according to the engine coolant temperature and idle speed after engine warming

up are controlled by means of the ISC valve.

erouranon

1-1-6 DVVT CONTROL

1. The intake valve timing is controlled in accordance with the engine conditions.

es ourenou

1-1-7 BOOST PRESSURE CONTROL

1. The boost control is carried out by operating the boost contro! VSV by means of the EFI ECU in order to.

Prevent the boost pressure from rising excessively.

ours

1-1-8 AIR BY-PASS CONTROL (ABV)

1. The ABY control is carried out by operating the VSV for ABV by means of the EFI ECU in order to re-

lease the boost pressure.

ee-omr-on8t

EF-40

LL

1-2 SUMMARY OF CONTROL SPECIFICATION

O: Applicable _—: Not applicable

Controt

Function

K3-VE K3-VET

For other

than EU

For EU For eu

Front and rear oxygen

‘sensor heater control

‘The oxygen sensor heaters are turned ON or OFF

‘according to the engine coolant temperature and.

‘riving conditions.

° °

Fuel pump contro!

‘The fuel pump is tuned ON or OFF by the IG switch

signal and engine revolution signal

Canister purge control

‘The canister purge flow rate is controled according

to the engine congitions.

Air conditioner cut control

“The air Conditioner magnet clutch Is turned ON or

OFF according to the engine conditions after idle-up

‘control so that the engine can be stabilized (variation

cf the idle speed can be reduced). The magnet

Clutch is turned OFF temporarily during acceleration,

atc.

Electric tan control

‘The radiator fan is tutned ON or OFF according to

the engine coolant temperature and air conditioner

‘operation,

‘The radiator fan is turned ON when the coolant

temperature sensor fats.

a A

(only when air | (only when air

conditioner | ‘conditioner

isworking) | is working)

By using the DS-21 diagnosis tester or OBD I

{generic scan tool, the diagnosis codes specified by

| the [SO standards and ECU data can be read out.

Moreover, the actuator driving function can be used

to drive the actuator by means of the DS-21

Giagnosis tester. This has made it possible to

conduct accurate and efficient trouble shooting,

Diagnosis

Although itis not possible to identify malfunctioning

Sections es precisely as in the case of the EU

specifications, the matfunction code can be read out

from the MIL flashing pattern.

‘When the DS-21 diagnosis tester is used, the

diagnosis codes specified by the ISO standards and

ECU data can be read out.

Moreover, the actuator driving function can be used

to drive the actuator by means of the DS-21

‘Giagnosis tester. This has made it possible to

‘conduct efficient trouble shooting.

Failsafe

When abnormality takes place in signals from

Sensors or actuators, the Control is Continued by

Using the standard values in the engine ECU.

° °

Teraatc00e ops

urea

EF-41

I; ‘-UMMARY OF SENSOR FUNCTIONS

1. ihe following table given below summarizes the roles of each sensor and related control items.

(©: Applicable —: Not applicable

ala 8 KSVE 1GVET

Sensors, signals Function B1e|8 For other

S [Foomer | roreu | roreu

Vacuum sensor “This sensor detects re ntake mantis pressure |O]O]O fo] o o | o

mosphere pressure | ris sensor detocts th atmosphere pressure. | O - | olo

can eguaear This sensor aes we OWTaarercear@® | 5 |S Baas ealaee

Crankangloserer | [RESSHIE dese ng Tovouon olo Sitio uate:

Linear vont sensor | Bsensor denise ratlevabe opening TOTO! [oO] 0 ° °

Coolantiemperature | This sensor detecs the engine coolant olo 7 ode te

ser temperature

Int ar temperature | This sensor detecs theintakeairtemperate. | O| | 0 o | o

Front onygen sensor | This sensor deteos fe oxygen concenvatonin | c a Gaui tHe.

(win eater) the exraust emissions

Rear oxygen sensor ‘This sensor detects the oxygen concentration in | oy | eu ° °

(wth eater} the exhaust emissions

Onygen sensor This sensor detects he oxygen concentration in | c 7 eae

(ont only, without heater) | he exhaust erssions

This ignitor unit detecs ihe on curent during | o | _

combustion to petfown mitre and erock -

Janitor unit

(with fon current detection) ryig ignitor unit detects the ion current during olo °

combustion to perform mise. - =

Knock sensor, This sensor detects the knocking condition. ° °o oe oO

‘Neutral start swtoh | This sensor detects the AT range. ofofe fel _o o | 0

‘Vehicle speed signal__| This sensor detects the vehicle speed. olfolo ° ° °

7

Pe steeringhyeraulia_| This sensor detects the power steering 7 © Seo

Basra mitch nydraule pressure I

Terns ot

EF-42

———— eee

1-4 SUMMARY OF ACTUATOR FUNCTIONS

1. The following table given below summarizes the roles of each actuator and relay, and related control

items.

©: Applicable —: Not appiicable

Bdslela Kove | Kover

Actuator, relay Function B88 2/8/18 | & lroone

2a) > ForEU | ForEU

Se than EU

THis ey suprice re aa power EF

Main lay EeR ee On Serer Oo} oj ofo] o ° °

aapnei Tia pps pve - .

TT nec an optimum avout of

Ful injector fuel at an optimum timing, ° 2 °

ae Tes eaters heal he on/gen sors ©

Erontand car owen | Tne ine feadeuck cool rte oe ° ~|olfo

e r Period.

‘Wis un une ON or OFF re orfon ca iz

lair nit Eurattat an oper ring ° °

Ob conta (oo) | Ts ve conto te nate cam at a of o | o

“Ths ve contol the IS va opering

'SC vane degree according to the engine conditions. e 7 i °

Wav or ovaporaive” |The VE ineeases or cocraases te Bat eae eee

‘emission purging canister purge amount.

Tis VB contls ABV to eloaso ho boost eee eee

VSV for ABV pressure, ° °

WV forboost Ths VV provers he boos pressueom | 3

pressure control rising excessively. a2 om

eae

EF-43

1-5 COMPONENTS LAYOUT

Linear throttie sensor DLC

Valve for ISC

SV for purge

ABV control VSV

bane

TB

.s

TR

és

VAN

ck

Se

EF-44

1-6 SCHEMATIC DIAGRAM

Veticte

speed sensor

Feel pump

tosy

8

ecu)

a

ecuy*—*]

ae

ECU

Atmospheric

prescure

vsvierpuge

ale for 1S

Charcost canister

Povvaive Manifold qbsolut

pressure sensor

ear oxygen

Intercooler

Bee

EF-45

7 “STEM WIRING DIAGRAM

oneny

eee

EF-46

Se

2 BOOST PRESSURE CONTROL

a -1 DESCRIPTION

The boost control is carried out by operating the boost control VSV by means of the EF! ECU in order to

prevent the boost pressure from rising excessively. it can be classified into two kinds of control: Fully-

closed control and feedback control. The boost pressure is controlled by performing the duty opera-

tion of the boost contro! VSV in accordance with signals sent from the pressure sensor and vehicie

speed sensor, which are to be inputted into the EF! ECU, and engine revolution speed, thus controlling

the pressure to be applied to the actuator of the waste gate valve.

Mainrelay EFI

Cam angle sensor

Absolute pressure

sensor

Coolant temperature

sensor

Linear throttle

sensor

Vehicle speed

sensor

2-2 CONTROL MODE

2-2-1 FULLY-CLOSED CONTROL MODE

1, When any one of the following three conditions is satisfied, the EFI ECU will not energize the VSV. As a

result, the VSV will be fully closed. Consequently, the boost pressure will be applied to the waste gate

actuator,

® When the engine is cold, or when the cooling water temperature is high

® During the engine starting period

© When the pressure sensor or the water temperature sensor is malfunctioning

er -esrem

2-2-2 FEEDBACK CONTROL MODE

1. When all of the following three conditions are satisfied, the EF! ECU will perform the feedback contro!

for the energizing duty ratio to the VSV so that the boost pressure may become the target value.

@ After the engine has warmed up.

@® Arter the engine has started

@ When the pressure sensor and the engine coolant temperature sensor are normal

er astoon:

EF-47

3 *8V CONTROL

3-, JESCRIPTION

1. When all of the following three conditions are satisfied, the EFI ECU will turn ON the VSV for ABV in

order to open the ABY, thus releasing the boost pressure.

@ When the rise of the pressure in the intake manifold is the set valué or more, or when the change

in the throttle valve (closing side) is the set value or more.

@ The pressure in the intake manifoid is the set value or more at the time when the condition (1) is

satisfied

@® The throttle valve opening degree is the set value or less at the time when the condition (1) is

satisfied.

[Absolute pressure

Linear throte

sensor

5 COMPONENTS

5-1 BOOST PRESSURE CONTROL VSV

1. The boost control VSV controls the pressure to be applied

to the waste gate valve actuator by means of the duly sig-

nal from the EFI ECU so that the pressure may become

the target pressure.

5-2 ABV CONTROL VSV

1. The VSV for ABV control switches the pressure to be ap-

plied to the diaphragm of the ABV by means of the signal

from the EF! ECU, thus preventing the boost pressure

from rising at a time when the throttle valve is suddenly

closed

EF-49

1 EFI SYSTEM

1 SYSTEM DESCRIPTION

1-1-1 LOCATION OF ELECTRONIC CONTROL PARTS

Linear throttle sensor OLE

Vaive for Isc

VSV for purge

ABV control VSV

‘Boost control VSV

Ignition colt

ee

IAS

i a e

A

soa

Front oxygen sensor

Injector

Engine coolant

EF-50

4 CONNECTORD

Re, ‘Cattants of connection Re, Conteris ofeomecion

“1 BAT] Weiner bacicup supply ‘$3 |ATNE]| Engine soeed signalto WT ECU

[FCT | Fuel pump relay (With iB) ‘34_[ Ve _{ VE monitor tema

‘S_[W[ Malfunciios incieator amp. ‘35 [FEOF | Fuei pump relay OFF

4 ATI Serial data tensmission to ATECU ‘36 | 482 | Fower supp)

[8102 | Serial por ter vB fe2_Tvoo | —

‘6 TAROT — 3 =

7 [481 | Power supph 64 IDLO | —

25. |E21_T AIG Evaporaicrlemp. sensor ground. 8 | co |=

'30_|"FO2| Fuel ume relay (vthout MB) 66 [TPR

‘S1[ REV} Engine speed signal er lact | —

'32 [ATX Serial dala recepion ram AT ECU 66 STA | Starter aigrel

1-2 DIAGNOSIS

1-2-1 ARTICLES TO BE PREPARED

ers

eeioronn

c Sass Faas anber oats i

(09842-97203-000 For inspection of computer

‘Sub-harness, EFI computer check inpuvoutput vottage

sz eer oe

SEZ seo ERSTE | crrapesin utes

2,

= aon

S

lene

= eS) | gessnoroceo alaliteatlad

SS

Pie iit cotati

Vid inj uel at jaeeeess | eed ana tora oop nes

For shorting terminal T

— iia cepa ae For shorting terminal T

09268-87701-000

Gauge, EF! fuel pressure For inspection of fue! pressure

Tiana Ses te, Compson panaae ga TT

—

sional

1-3 FUNCTION CHECK

1-3-1 VOLTAGE CHECK

1. Install the SST between the engine ECU and the vehicle harness and measure the voltages between

the respective terminals of the SST connectors. Check to see if the measured values conform to the

pecification in accordance with the following table.

1-4 TROUBLE SHOOTING ACCORDING TO DTC

1 1 BOOST PRESSURE CONTROL SYSTEM CIRCUIT

EF-51

(1) WIRING DIAGRAM

ECU

Boost control SV Main relay eA

15a

vsvt 2 —_4

STI oN. 0S o-

Lo wie ia sw

fH 104 1G2

aM

60a

| 4

a

Ls]

Et Boost control VSV ‘Main relay

(Hamess side) (Relay box side)

‘Tela alr

23[fsr 32] aloe las

e2faa

ECU-connection vehicle hamess side connector

(2) CIRCUIT DESCRIPTION

(1) Check the hoses of the boost pressure control system for disconnection, breakage, etc.

(2) Check that the waste gate valve operates normally.

(3) Check that the power supply voltage is applied properly to the boost control VSV.

(4) Check that the harness between the boost control VSV and the ECU exhibits no open wire and

short circuit,

(5) Check that the boost control VSV operates normally.

ses seze

F-52

(3) INSPECTION PROCEDURE

(Check to 526 the hoses of the

‘boos! pressure cortrcl eystem are

‘disconnected or damaged.

operation

OK

OK

Check the waster gate valve

NG

Repair or epic

NG

1

<£CU output signa check

1. Connect the SST (sub-herness)

‘SST: 09842 -97208- 009

2 Measure ths vohage betweon SST terminals SV and E1 ouing

ig (cola). (Cooling water temperature 60°C 0: below)

‘Speciied Value: Battery votage

3. Measure the vollage between SST terminals VSV1 and 1 during

faling ater warming).

Specifad value: 0-1

4 Measure me votage between SST temminals VSV1 and EY during

‘running test (2nd, lv-open acceleration = 4400%pm).

‘Specie value: More than the value in step @ above

NO.

Replace tne turbocharger SA

ox

OK

“

1. Disconnect the VSV connecter.

[2 Measure the voltage between the

terminal 2 of VV and the body

‘ground

‘Speci value: Batley votage

Check andior repair te harness

Denween the batery and VSV.

SV connector.

{

Uni inepection &f VEV>.

(CRepais tne hamess and comecior

NG. I

Feplace to V8V.

Ne

‘conction of each con:

ok

Gheck the connecting

2

EF-53

1 2. AIR BYPASS VALVE CONTROL SYSTEM CIRCUIT

(Q, AIRING DIAGRAM

ECU

AaVcontel VV Mainrelay fA

154

vsveo—Lap 2 4 So

S00 J

ae cule = IGSW

0A 12

aM

80a

FL

7 2.0;

2

GE)

OFT ABY control VSV_ Main relay

(Hamess side) (Retay box side)

6

soon fee DPep melo) [er eS erase 2a

Sef saleo[ar[a] [so] selecles[e[es]soL Tso] [eipnTsresa eleTsalsleol]e

ralel [rebrebeinL Cte teat 22

veve

‘eres ay

[sos [s2[oa1 4] 525

ez [es)

Disconnect the VSV connecter.

2, Measure the votage betwoon the

terminal 2 of VSV and the body

‘round,

Speciied valecBattery votage |

Fe ;

——

Seu ana uae Pe) Check andor rai the harness

ECU and VSV'> He dl

Check ‘the harness betwoen | \ belween he bettery ang

teminal VSV2 of ECU connector

_and lerrinal 2 of VSV connector.

ox NG

Repair the harness anc

connecter.

‘Check the connecting

‘conattion ofeach cone

actor,

Replace ine sv.

Inspect the ECU,

2 “NIT INSPECTION

a BOOST PRESSURE CONTROL VSV

Check to see If there is air continuity between the respec-

tive ports of the VSV.

SPECIFIED VALUE: No continuity exists.

2. When the power supply voltage is applied across both

terminals of the VSV connector, check air continuity be-

tween the respective ports.

SPECIFIED VALUE: Continuity exists.

3. Check the resistance between both terminals of the VSV

connector,

SPECIFIED VALUE: Approx. 32.9 (at 20°C )

eeuPoze000

2-2 AIR BYPASS CONTROL VSV

1. Check air continuity between the respective ports of the

vsv.

SPECIFIED VALUE: Air continuity should exist, (Between

AandB)

No air continuity should exist.

(Between A and C; Between B and

c)

2. When the power supply voltage is applied across both

terminals of the VSV connector, check air continuity be-

tween the respective ports.

SPECIFIED VALUE: Air continuity should exist. (Between B and C)

No air continuity should exist. (Between A and B; Between A and C)

3. Measure the resistance between both terminals of the VSV connector.

SPECIFIED VALUE: Approx. 40.2 (at 20°C )

eeupnzo%01

6 BLOW-BY GAS RECIRCULATION DE-

VICE

et DESCRIPTION

‘The blow-by gas in the crank case is flown into the cylin.

der head through the biow-by gas passage of the cylin-

er block. The oylinder head cover is provided with an cit

separator, which separates oil from the blow-by gas. After

oil separation, the blow-by gas is sucked into the com-

bustion chamber to be burnt again. A PCV valve is pro-

vided to get a blow-by gas recirculation amount suited to

the running conditions.

‘Surge

tank

1G-57

* DESCRIPTION

For Type K3-VET engine, platinum plugs, featuring excellent durability, have newly been provided.

1e-ouracoos

1G-58

2 COMPONENTS

2-1 SPARK PLUG

KS-VET

Manufacturer

DENSO

NGK)

Type

PK2OPTR-S9__| BKURGEKPA

Electrode gap (mm)

08-09

With across flats (mm)

16

1G-59

{ IGNITION COIL

1-1 REMOVAL AND INSTALLATION

1-1-1 ARTICLES TO BE PREPARED

Gauge] aoe wnsh Tone

Tan

serecoraae

1-1-2 REMOVAL AND INSTALLATION PROCEDURES

(1) COMPONENTS

we

oy

a

OF,

b t

er?

@® > i

‘ Ts Tigteing wre

f

aoa

N

sasoonnss end

Unit

«2) REMOVAL AND INSTALLATION PROCEDURES,

+ 2 a CoverS/A, engine upper

2 1 b Coll ignition

ieiscorocor

AT-60

—_—_—_—_—_—_—_—_—___ NE

+ OUTLINE

«The automatic transaxle for Type K3-VET engine-mounted vehicles, which has been newly added, em-

Dloys a four-speed automatic transaxle of the A4B-D1 type electronic hydraulic control method, as is

the case with the conventional Type K3-VE engine-mounted vehicles.

However, in the automatic

transaxle for Type K3-VET engine-mounted vehicles, the characterisctis and gear reduction ratios of

the torque converter of the transaxle have been altered in order to cope with the increased torque of

Type K3-VET engine with a turbocharger. Furthermore, changes have been made on the shape of the

shift lever knob and the installation position of the steering shift selection switch, The electronic contro!

specifications of the automatic transaxle have also been partially changed.

s.08ca00

1-1 SPECIFICATIONS

Traneaxie ype BD

Drive method 2D aD

Engine type RENE Raver HAVE

Three-elemem, one-stage, two-phase type

type (with lockup mechanism)

~ sve converter

Sia torque ato / 7267 7.887 1867

Revolution speed (rpm) 1800-2400 2200-2700 1900 - 2400

‘Autoraile gear shit Four foward speeds, One reverse speed

iat 27H

nd 1.526 :

Gear ratio rd 7.000

ath 0.696

Reverse 2.200

pee Flea educlon gear ratio 402 3740 2350

Shit control method Electron hyeraullo pressure control method

Wot ype multiple clutch: Geets

Shit control element Wot type multiple brake: 2sets

One Way clutch : tset

Te DEXAON® Hort)

Lubrication fais [capaaiy ‘About 5.0

Cilesoing system Waler-coolea (radiator bulrin ype)

‘al contd patern P-R-N-Ds3-2

IER

ar oscomea

AT-61

2 AUTOMATIC TRANSAXLE ELECTRONIC CONTROL SYSTEM

2-1 OUTLINE

1. The diagnostic trouble codes (DTC) of No.31/P1706 and No.41/P1711 have been added to the self-di-

agnosis function. Moreover, the fail-safe functions corresponding to these codes have been set

Although the changes above have been made, no sensor or actuator has been added or no contro!

function has been changed.

arenes

AT-62

2x

DIAGNOSIS FUNCTION

2-4-1 CONTENTS OF DIAGNOSIS

(Code No.

Warning inaication | Code Memory Contents of mattunction

2digis | 4digiee

31 P1706 6 x [Abnormal engine toraue

37__| Ports ° ° [No turbine revoiution input

38__| _PoT10 3 ° |Open wie or short of thie temperature sensor Seu

= ae 4 5 Aone sing reacties oi temperate ofa

44 P1711 fe) x [Throttle sensor malfunctioning

42 P0720 [e) ° No output revolution input

55 PO7O5. oO x No neutral start switch input

56 PO70S. oO ° |Multi-input of neutral start switch

57, P1704 ° x |Short of steer shift mode switch circuit

[56 P1705 o x | Short of steer shift up/down switch circut 7

81 PO7SS: ° oO Open wire or short of solenoid No. 1 (81) circuit

62 PO7SS ° °° [Open wire or short of solenoid No. 2 (C2) circult,

63 P0763 2° Q |Open wire or short of solenoid No. 3 (C3/82) circuit

64 P0768 3 ° [Open wire or short of Duty solenoid circuit

65 | po7S ° ° [Open wire or short of LUC solenoid circuit

66 P1780. 2 ° Open wire or short of switch solenoid circuit

72 | P1703 3 ° Lockup revolution speed not matching

ez | Piso ° 2 Faulty communication with EF/-ECU

86 P0725, 3° ° No engine revolution input

* Denotes those output code wien the 5-21 is used.

At 008

*5 FAIL-SAFE FUNCTION

5-1 FAIL-SAFE SPECIFICATIONS

AT-63

Code NO! Contents of mattunction Contents of fail-safe contro! Conditions for releasing

aigtslaciats, failsafe control

+ The engine torque is set toa constant value.

‘+ When the malfunction is detected, a shifting to| After the normal state has been

31 [P1706] Abnormal engine torque | the 3rd gear takes place. Afterward, the 1-3] stored, when the vehicle speed is

shifting takes place, depending upon the| 0 km/h in P or N range, the fall-

vehicle speed and throttle opening, safe function is released.

37. |P0715| Noturbine revolution input

38 [Porto] Open wire or short ofo| | / when the malfunction is detected, a shiting to | After the normal stale has been

lemPerature sensor citcull | ine Src gear takes place. Afterward, the 1-3 | stored, when the vehicle speed is

shitting takes place, depending upon the | 0 kmh in P or N range, the alk

Abnormal rising vehicle speed and throttie opening, safe function is released

characteristics of fhid

88 /POTTH| temperature af ol

temperature sensor

“The throttle opening is set to a constant

valve. ‘After the normal state has been

41 |p1714| Throitie sensor ‘*When the malfunction is detected, a shifting | stored, when the vehicle speed is

maltunctioning to the 3rd gear takes place. Afterward, the 1- | 0 km/h in P ot N range, the fail-

3 shifting takes place, depending upon the | safe function is released.

vehicle speed

Jswhen the sensor system is

‘maitunctioning, alter the normal

state has been restored, when

‘*When the sensor system is mettuntioning | the vehicle speed is 0 km/h in P

and the vehicle stops once, the vehicle | or N range, the fail-safe function

42 |p0720| No output revolution input | Speeds fixed at the 1st gear. is leased, :

‘When the A/T itself is malfunctioning, the |*When the ATT itseli is

vehicle speed is fixed at the 1st gear. ‘maifunctioning, after the normal

state nas been restored, if the IG

is once tured OFF, the fai-safe

function is released

55 lporos| NOneutral start switch | «With the shift position set to the Ds range, | Released when normal state is

input ‘normal gear shitting control takes place. restored,

56 {po705| Muli-input of neutral stat | «with the shift position set to the Da range, | Released when normal state is

switoh normal gear shiting control takes place. restored,

Released when the turning OFF of

57 [P1704] Shertin steer shitt mode | « The stoor shit mode is prohited the steer shit mode switch is

switch circuit detected.

Released when the turning OFF of

58 [P1705] Shor in steer shit +The steer shift mode is prohibited. the steer shift UPIOOWN switch is

UP/DOWN switch circuit isohactee:

ROR

FS-64

———————

*RONT SUSPENSION

1-1 OUTLINE

1. As @ result of the setting of the 15-inch tires, some components have been additionally provided.

2. The wheel alignment remains unchanged.

Fs.r8-c0000

1-2 COMPONENTS

1-2-1 SHOCK ABSORBER

1. Exclusive parts whose damping force has been optimized for the 15-inch tires have been additionally

set,

2. The construction remains unchanged.

15.79.0021

1-2-2 COIL SPRING

1. Exclusive parts whose spring constant has been optimized for the 15-inch tires have been additionally

set.

2. The construction remains unchanged.

Fs.45.002

FS-65

2 TIRE

2-1 OUTLINE

1. 16-inch tires have been adaltionally set.

s-nnoo0oe

2-2 SPECIFICATIONS

M200RG M2018 MaTIRG

-GMINF CEcnE new GMNEW

“GQNEW P

Toueo—f-oMnew = | S0NEEuew = [C050 caNew

-GONEQ | -GOGEW

. °

rasieon1s =| STEEL (200123}) | (2301231) - - = -

a = ° ° .

| STEEL (z2012.2)) | (220(22)) | (220122) | (220(2.2}) i (2201221)

T6SI65R 14S, + + z = x

ALUMINUM | (2202.21) | (22012.2)) | (22012.2)) | (220122) ) 7 ( 220(2.2} )

2 ~ 2

STEEL ia oa (220(2.2}) | ( 220(2.2)) A ( 220(2.2} )

175160R 14H x z x

ALUMINUM ~ - (220122}) | (220122)) FF (220221)

= .

vveissisv | ALUMINUM - - 7 - (24072.4)) =

‘SPARE TIRE

x T

‘STD TRE 145/6013 (200231) - _ aietasfeieiecy -

2 *

STO TIRE 165/65R14 ( 220(2.21) - (2012.2) 7 es if

a

STD TIRE 175/60R14 - i (220/22) ) in = ia :

° ° ° ° °

‘T105/70 Dia (420162}) | (a20ta2iy | (420142)) | (420142)) | (420142) =

7 7

7125/70 Di4 - - - - - (42014.2) )

‘@ = Standard equipment, a = Optional equipment,

Figures in parentheses (_) are the frontrear air pressure (kPalkglicm'}

‘rsxoso03 ot

FS-66

————

3 DISC WHEEL

3-1 OUTLINE

1, 15-inch disc wheels have been additionally set.

5-¥et.o0008

3-2 SPECIFICATIONS

WHEEL] 13 x4508] 14x86) | 14x5) | 15x58)

tem STEEL ‘ALUMINUM:

‘A: Rim width fmmJ] 114 127 = [| =

B:Rim diameter [mm] 3204 | 3548 = 280.2

C:PCD [mmy} 100 = = =

‘D: Hub hole diameter = ce Se =

{me]]

E: Offset {oonj| 35 40 = =

F: Boltdiameter —_{mmj] 14 = 3 —

RS-67

SS UU apapanaeypapepeaye cea

1 NEAR SUSPENSION

te1 OUTLINE

1. Asa result of the setting of the 15-inch tires, some components have been additionally provided.

1-2 COMPONENTS

1-2-1 SHOCK ABSORBER

1. Exclusive parts whose damping force has been optimized for the 15-inch tires have been additionally

set.

2. The construction remains unchanged

5.85-c0022

5.95-co0ne

1-2-2 COIL SPRING

1. Exclusive parts whose spring constant has been optimized for the 15-inch tires have been additionally

set

2. The construction remains unchanged.

3. On 16-inch tire-equipped vehicles, a spacer has been added at the rear spring bumper section.

fs-Rs-conts

7’ SOIL SPRING (TORSION BEAM TYPE)

1-1 REMOVAL AND INSTALLATION

1-1-1 REMOVAL AND INSTALLATION PROCEDURES

(1) COMPONENTS

1

2

a

4

5

(2) RI

©

5

4

3

IEMOVAL AND INSTALLATION PROCEDURES

‘Absober, shock ear

Bumper, rear spring

‘Spacer, bumper black

‘Sheo!, ear spring upper

‘Sheet, rear spring

#1:Vehicles equipped

with 18-inch tres

[res.2ti2.3

Unvesiia7

Tightening torque

Unit: Nm

® © F Spring, coil rear

ascoro-rontot

DPS-69

ac

1 TRIVE SHAFT

1+. OUTLINE

1. Asa result of mounting of Type K3-VET engine, additional setting has been made.

2. The construction remains unchanged

esos.)

‘4-1-1 SPECIFICATIONS

Drive methoo WO. aNd

Engine type Ed K3-VE_ KS-VET, K3-VE_

“Transmission type MT MTAT | AT MT

Distance up tojoint [RH (mm) 625.8 (with] [622.2 (with) 620.2 (wiih [474.0 [without

[Damper] LH (mm) 408.7 [Without] | 404.8 [Without] 402.8 [Without] 404.8 [Without]

Joint type Front axle side Belltype | = 7 -

Ditferential side | Double oftset type | Tripod type = =

TORT

vesoszcnure

BR-70

—_————

1 WTLINE

1. On vehicles mounted with Type K3-VET engine, 14-inch ventilated disc brakes have been employed at

the front wheels.

BR curcowne

2 BRAKE MASTER CYLINDER

2-1 OUTLINE

1. The construction remains unchanged, except the external appearance.

8 c-o12

3 BRAKE BOOSTER

3-1 OUTLINE

1, On LHD vehicles mounted with Type K3-VET engine, an 8-inch single brake booster with brake assist-

ing mechanism has been provided.

2. The construction remains unchanged.

en-esroo010

4 RONT BRAKE

4-1 OUTLINE

1. For assured sufficient braking force, 14-inch ventilated

disc brakes have been employed on vehicles mounted

with Type K3-VET engine.

4-< SPECIFICATIONS

Engine type EW-DE EJ-VE KaVE K3-VET

Disc

pe (Wentilated) ai 7 -

Piston diameter (mm) 50.8 = = Sit

Disc rotor diameter (mm) Ea = = 206

Disc rotor thickness (mm) 16 = = 17

Pad area (em') 36 = = 35

TERETE

en encecor

1 FRONT DISC BRAKE PAD (14 INCH)

« INSPECTION

1

Check the pad thickness through the inspection hole of

the cylinder for the inner side or from the rear of the

caliper for the outer side,

SPECIFIED VALUE: 9.5 mm

ALLOWABLE LIMIT: 1.5 mm

1-2 REMOVAL AND INSTALLATION

1-2-1 REMOVAL AND INSTALLATION PROCEDURES

(1) COMPONENTS

fe

Unit :

(2) REMOVAL AND INSTALLATION PROCEDURES,

D7

2

6

3 ©

64

5 3

Bol, brake alse cylinder

Pin, cylinder side

Pad, disc brake No.1

Pad, aise brake No.2

‘Shim, ant-equeat

Pate, disc brake pad guide

Plate disc brake pad guide

Tightening torque

Nm

mssosooare ead

enroro-romce

BR-72

* SRONT DISC CALIPER (14 INCH)

3-1 DISASSEMBLY AND ASSEMBLY

3-1-1 INSPECTION

(1) BRAKE PAD THICKNESS

1. Check the thickness of the disc brake pad, and replace it if the thickness is less than the limit,

‘SPECIFIED VALUE: 9.5 mm

ALLOWABLE LIMIT: 1.5 mm

wrccacence

3-1-2 DISASSEMBLY AND ASSEMBLY PROCEDURES

(1) COMPONENTS

&

TeSES

* : Non-reusable parts

T Tightening torque

Unit : Nem

=: Rubber grease

senses

(| ISASSEMBLY AND ASSEMBLY PROCEDURES

112 a Bot, ess brake cylinder 7 6 9 Shim, ant-squeal

@ 11 bv Pin. syinder slide 6 Sh Boot. pin

3 10 © Mounting, esc brake cylinder © 4 1 Boot eyinder

4 8 d- Pad,dise brakaNo.t @ 3 | Piston, dise brake

@ 8 © Piate, dscbrake pad guide @ 2 & Seakpiston

© 7 {Pad dso brake Noz 12 1 1 Oybnder, disc brake

enroce recone

BBE-73

1 “XTERIOR

1-1 HOOD

i

On turbocharger-equipped vehicles, a hood air scoop has newly been provided to feed outside air to

the intercooler,

2 SEAT

2-1 REAR SEAT

1, A saddle type headrest has been provided as option on

the rear seat.

3 LAMPS

te 1 FRONT FOG LIGHT

(On turbocharger-equipped vehicles, SSW fog lamps have

been set as standard equipment

2. On natural aspiration vehicles destined for the EU specifi-

cations, SSW fog lamps have been set as optional equip-

ment, except some grades.

7 2 REAR COMBINATION LIGHT

On turbocharger-equipped vehicles, clear type rear com-

bination lamps have been provided as standard equip-

ment,

2. On 1.32 natural aspiration vehicles, clear type rear combi-

nation lamps have been set as optional equipment, ex-

cept those destined for the AUS specifications,

4 WIPER AND WINDSHIELD WASHER

4-1 WINDSHIELD WASHER TANK

1. On T/C LHD vehicles the location of the washer tank has been changed to the underside of the left

headlight

esenanac

5 AUDIO SYSTEM

5-1 ANTENNA

1. The toof rear antenna has employed a tiltable type. The

new antenna is detachable, as is the case with the hither-

to-employed type.

NOTE

* To listen to the radio, adjust the antenna approximately

60" rearward. There are cases where the radio cannot

be tuned in when the antenna is at an angle other than

approximately 60° rearward.

f 9OWER WINDOW

6-1) POWER WINDOW SWITCH

1, Anillurtination has been added to the AUTO switch of the )

power window switch at the driver's seat side. SS

NOTE Or

* The lamp goes on when the IG is turned ON.

ft SC

Se

6-2 CIRCUIT DIAGRAM

Power window

ub switch

Power window

‘sub switch

Power window

‘sub switch

(Passengers ear ett) (Rear right)

seat side)

Driver seat Passenger seat Rear passenger ear passenger

seat (Right) seat (Left)

Bc

BBE-76

1 HOOD

._. REMOVAL AND INSTALLATION

1-1-1 REMOVAL AND INSTALLATION PROCEDURES

sanesomcn2 ccd

14a Guide Ay, cool air init

2 3 b Spacer

3 2 ¢ Gamishassy, hood air duct

41d Hood sia

seeHoD0-7. 0001

2 HEAD LIGHT LEVELING

2-1 UNIT CHECK

2 _HEAD LIGHT LEVELING SWITCH

1. Ensure that resistance between the respective terminals as conforms to following specifications.

SPECIFIED VALUE: Resistance between respective terminals.

Position 0 TApprox. 2.1K

Postion 1 TAppIOX. 199

Terminal 1-2 Postion? ADPIOK. 14KO Connsetor

on fear (Head light leveling switeh side)

Position 4 [Approx 09 ka Fi 5

Terminal 1-8 Each position ABpIOK 2.4K

TEREST s[/4{3]2}4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Manual Taller Wide 55Document156 pagesManual Taller Wide 55Felipe Ignacio Cortes Fuentes83% (6)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Maps PDFDocument4 pagesMaps PDFFelipe Ignacio Cortes FuentesNo ratings yet

- Injector Specs JDM PDFDocument54 pagesInjector Specs JDM PDFFelipe Ignacio Cortes Fuentes0% (1)

- D Circuit Diagram by Function: To IndexDocument281 pagesD Circuit Diagram by Function: To IndexFelipe Ignacio Cortes FuentesNo ratings yet

- Bosch 0 227 100 211 Ignition Control With MegaSquirt-II PDFDocument5 pagesBosch 0 227 100 211 Ignition Control With MegaSquirt-II PDFFelipe Ignacio Cortes FuentesNo ratings yet

- HalE6X PDFDocument1 pageHalE6X PDFFelipe Ignacio Cortes FuentesNo ratings yet

- Daihatsu Charade G10Document185 pagesDaihatsu Charade G10pikinos88% (8)