Professional Documents

Culture Documents

Commond Rail System Toyota Kijang Innova

Commond Rail System Toyota Kijang Innova

Uploaded by

Dian Idawati0 ratings0% found this document useful (0 votes)

16 views68 pagesSistem common rail innova

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSistem common rail innova

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views68 pagesCommond Rail System Toyota Kijang Innova

Commond Rail System Toyota Kijang Innova

Uploaded by

Dian IdawatiSistem common rail innova

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 68

Diesel Injection Pump

SERVICE MANUAL

Common Rail System for

TOYOTA HILUX / KIJYANG INNOVA /

INNOVA 1KD/2KD

OPERATION

July, 2004

DENSO CORPORATION 00400077

©2004 DENSO CORPORATION

All Rights Reserved. This book may not be reproduced

oF copied, in whole or in part, without the writen

permission of the publisher.

1. PRODUCT APPLICATION LIST .

14.

2. OUTLINE .

24.

22.

3. CONSTRUCTION AND OPERATION

34.

32.

33.

34,

35.

DIAGNOSIS SYSTEM

4a.

42.

43.

44,

45.

46.

TABLE OF CONTENTS

PRODUCT APPLICATION LIST

(OUTLINE OF SYSTEM

‘SYSTEM CONFIGURATION .

DESCRIPTION OF MAIN COMPONENTS .

DESCRIPTION OF CONTROL SYSTEM COMPONENTS .

EGR CONTROL SYSTEM.

DIESEL THROTTLE (ELECTRONICALLY CONTROLLED INTAKE AIR THROTTLE MECHANISM) .

FUEL FILTER WARNING

DESCRIPTION

DTC CHECKICLEAR

CHECK MODE PROCEDURE

DTC (DIAGNOSTIC TROUBLE CODE) CHART .

FAIL-SAFE CHART .

EXTERNAL WIRING DIAGRAM

23

Bes Y

1. PRODUCT APPLICATION LIST

4-1, PRODUCT APPLICATION LIST

Vehicle Name Part Type DENSO Part Car Manufacturer Reference

rea SGT | SOTO

Tew S| SOTO

ator TaD

[EngineECU——=—S=* «MAT 75800-6590 | 896670K200 |

MAt75800-6600 | _696610K210

MAt75800-6610 | _696610K220

MA175800-6650 | 696610K250

MAT75800-6640 | 696610K260

MAt75800-6630 | _ 696610K290

THAT75800-6620 | 696610K300

THAT75800-6660 | 696610K370

MAt75800-6670 | 696610K320

MA175800-6680 | 696610K330

MAT7S800-6710 | 896610K340

MAt75800-6720 | _896610K350

MA175800-660 | 696610K360

MA175800-6670 | _ 696610K370

EDU Torso S447 eaa7OTIOT1

01310-5481 ‘3987071021

EGR valve VN101397-1000 | 258000L010

‘Aecelerator pedal module 98800-3140 [7812009070

DENSO Part

(Car Manufacturer

Vebicle Name Part Type Number hart eben. | Reference

FILUXIKUYANG INNOVAINNOVA | Supply pump Suizao00-0350 | Z2T000L020 HPS

2KD-FTV Injector 31095000-5520 | 236700L010

Rail 31095440-0551 | 238 T00L010

NE sensor 29600-1151 | 90979-05050

"TDC sensor (29600-0630 | 90918-05025

Coolant temperature sensor | 179700-0881 | 69422-83030

Ful temperature sensor 779730-0020 | _60454-60070-8

“Turbo pressure sensor 79800-7470 | 89421-71020

‘ir ow mater ‘VN197400-4000

Engine ECU ‘MAT75800-6800 | 896610K390

MAT75800-6740 | _896670K400

MAT75800-6760 | 896610K470

MAT75800-6780 | 896610K440

MATTSBO0-5790_ | B966T0KA50

MIAT7S800-6730_ | G966T0K460

MAT75800-6750 | 896610K470

MAT7S800-6770 | 896610K480

MIAT75800-6830_ | B966T0K400

MAT75800-6850 | 696670K500

MAT75800-6870 | 896610K530

EDU vorsto-saai | 6987077011

Torao-S4e1 | 6987077021

EGR valve ‘vw101397-0880 | 258000020

‘Accelerator pedal module 79800-3140 | 7812008070

2. OUTLINE

24, OUTLINE OF SYSTEM

The common rail system was developed primarily to cope with exhaust gas regulations for diesel engines, and aimed for

1. further improved fuel economy; 2. noise reduction; and 3. high power output.

© This Common Rail System meets the Step Ill Stage of the

European Emission Regulations as shown in the figure on Example: Exhaust gas regulation (Europe)

the right. ‘Step ll (2000)

0 v one (]

. nonin) axa

‘A. System Characteristics:

The common rail system uses a type of accumulation chamber called a ral to store pressurized fuel, and injectors that

contain electronically controlled solenoid valves to spray the pressurized fuel nto the cylinders. Because the engine ECU

controls the injection system (including the injection pressure, injection rate, and injection timing), the system is unaffect-

ed by the engine speed orload. This ensures a stable injection pressure at al times, particularly in the low engine speed

range, and dramatically decreases the amount of black smoke ordinarily emitted by a diesel engine during start-up and

acceleration. As a result, exhaust gas emissions are cleaner and reduced, and higher power output is achieved

‘a. Injection Pressure Control

+ Enables high-pressure injection, even in the low engine speed range.

+ Optimizes control to minimize particulate matter and NOx emissions.

. Injection Timing Control

Optimally controls the timing to suit driving conditions.

Injection Rate Control

Pilot injection control sprays a small amount of fuel before the main injection.

Common Rail System

7

Injection Pressure Control Injection Timing Control] injection Rate Control

COptiization, High preseurizaton Optimization | [8 Piotiniecton

Coneron ra syste Common aisysem] [5] _¢ fo.

aes \ y |= Crankshaft ‘angle —>

2 . ijeaion Guaity Conta

g

3 Cynder jection

‘Conventional} <= = ‘Convéntional| volume correction

é pump le

‘Speed —> Injection Speed —> a

pes TEI

B. Comparison to the Conventional System

Incline, VE Pump Common Rail System

High-pressure Pipe

Momeni High Pressure

r

Tw

Timer

Nozzle

Govemor

He

system iniooRanp

YY uJ

Eine

jain ay Ca

Pump (Governor)

lect Tirig Coa

Engine ECU, Injector (WW)

Pump (Timer) Engine ECU, Injector (TW)

Rising Pressure] Pump. Engine ECU, Supply Pump

Distributor Pump. Engine ECU, Ral

rictenPeswe Cart] Dependent upon Speed and Injection Quantity

Engine ECU, Supply Pump (SCV)

“1 TWV; Two Way Valve “2 SGV: Suction Control Valve azv16

2:2, SYSTEM CONFIGURATION

‘A. Main System Components

Location (1)

Instrument Panel J/B Assy

‘AMT H-fuse

ECU-IGSGAUGE Fuse

STOP Fuse

IGN Fuse

MET Fuse

ST Fuse

‘Combination Meter.

pics

Accelerator Pedal

Rod Assy

(Accelerator Pedal

Position Sensor)

Engine Room R/B, J/B

@ Integration Relay

(EDU Relay, MAIN Relay)

GLOW Relay

ST Relay

ALT H-fuse

GLOW H-fuse

BATT P/t Huse

AM2 Hfuse

EFI Fuse

b.

Location (2)

eee Injector Manifold Absolute Pressure Sensor

MAF Meter Diesel Turbo IAT Sensor Diesel Throttle Body Assy

E-VRV for EGR:

EGR Valve Assy

Actuator

{OC Motor,

Nozzle Vane

Giow Plug Assy’ ‘Camshaft Position Sensor

(Crankshaft Position Sensor Supply Pump

Manifold Absolute Pressure Sensor

Diesel Turbo IAT Sensor

E-VAV tor EGR

EGR Valo Assy

(GOR Vato Poston Senger

Common Fal Assy

(Pressure Limter)

‘Commen Ral Ass

(Fuel Pressura Sensor Assy)

ECT Sensor

Injector

Glow Plug Assy

‘Crankshaft Position Sensor

‘Camshaft Position Sensor

“supply Pump

B. Outline of Composition and Operation

Composition

‘The common rail system consists primarily of a supply pump, ral, injectors, and engine ECU.

Fuel Temperature Sensor a

Engine Speed =

Accelerator Opening —» |

Intake Air Pressure,

___J

MRorcae Bessure—=| engine ecu

Imake Ar Temperature =|

oolant Temperature >

Cronshen glee

Cinder Recognition Sensor AA A

Intake Aiftow Rate —f

wai Pressure

Cir ject

gai Probie

Sena I

io

aia

_ Fut

Ester

orf] Cod T ret

J}

Fuel Temperature Sensor SCV

Supply Pump (Suction

ey PumP Control Valve) Fuel Tank’

b. Operation

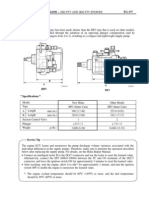

(1) Supply pump (HP3)

The supply pump draws fuel from the fue! tank, and pumps the high pressure fuel tothe rail. The quantity of fuel dis-

charged from the supply pump controls the pressure in the ral. The SCV (Suction Control Valve) in the supply pump

effects this control in accordance with the command received from the ECU.

(2) Rail

The railis mounted between the supply pump and the injector, and stores the high-pressure fuel.

(8) _ Injector (X2 revised type)

This injector replaces the conventional injection nozzle, and achieves optimal injection by effecting control in accordance

with signals from the ECU. Signals from the ECU determine the length of time and the timing in which current is applied

{o the injector. This in tum, determines the quantity, rate and timing of the fuel that s injected from the injector.

(4) Engine ECU

The engine ECU calculates data received from the sensors to comprehensively control the injection quantity, timing and

pressure, as well as the EGR (exhaust gas recirculation).

You might also like

- Service Manual Common Rail System Isuzu 4HK1 6HK1Document48 pagesService Manual Common Rail System Isuzu 4HK1 6HK1vagpoul95% (148)

- Isuzu D-Max 2011 Axle Service ManualDocument162 pagesIsuzu D-Max 2011 Axle Service ManualWilmer Huanga0% (1)

- Mitsubishi 4N13, 4N14 Engines PDFDocument35 pagesMitsubishi 4N13, 4N14 Engines PDFRa Aranzaso75% (4)

- Denso Toyota Hilux Common RailDocument68 pagesDenso Toyota Hilux Common RailRonald Yanes93% (73)

- Mitsubishi Pajero 4m41 EngineDocument42 pagesMitsubishi Pajero 4m41 Engineesyjam100% (14)

- Control Engine - 1kd-Ftv and 2kd-FtdDocument25 pagesControl Engine - 1kd-Ftv and 2kd-FtdEulicer Armengol93% (74)

- Mazda 3 6 MZR-CD2.2 EngineDocument46 pagesMazda 3 6 MZR-CD2.2 EnginejorgeNo ratings yet

- Ford Ranger T6 2011.50my Workshop Repair ManualDocument11 pagesFord Ranger T6 2011.50my Workshop Repair ManualTetsunari Koda100% (2)

- U341E GearDocument18 pagesU341E Gearpalaboy88875% (12)

- U341E GearDocument18 pagesU341E Gearpalaboy88875% (12)

- 1kd FTVDocument2 pages1kd FTVGregory Ashley87% (15)

- Engine 1KD, 2KDDocument72 pagesEngine 1KD, 2KDjimmy_huamancayo97% (61)

- Common Rail System (CRS) : Toyota 1Kd/2Kd EngineDocument31 pagesCommon Rail System (CRS) : Toyota 1Kd/2Kd EngineJuan Alberto Bucaro100% (33)

- DENSO Common Rail Isuzu 4HK1 6HK1 Service Manual PagesDocument6 pagesDENSO Common Rail Isuzu 4HK1 6HK1 Service Manual Pagesspalomos50% (4)

- Practical Process Control for Engineers and TechniciansFrom EverandPractical Process Control for Engineers and TechniciansRating: 5 out of 5 stars5/5 (3)

- Toyota 1kd 2kdDocument31 pagesToyota 1kd 2kdMispa Serv100% (5)

- 1kd-Ftv and 2kd-Ftv FipsDocument8 pages1kd-Ftv and 2kd-Ftv FipsSultan Ahmed Khan100% (23)

- DENSO Common Rail Mitsubishi L200 Triton 4D56 4M41 Service Manual PagesDocument11 pagesDENSO Common Rail Mitsubishi L200 Triton 4D56 4M41 Service Manual PagesJB0109198275% (16)

- 1KD-FTV and 2KD-FTV EnginesDocument25 pages1KD-FTV and 2KD-FTV EnginesSergio Olivares Cortes100% (7)

- Common Rail Hino - ToyotaDocument41 pagesCommon Rail Hino - Toyota0808833892% (24)

- Denso Mitsubishi L200 Common Rail PDFDocument53 pagesDenso Mitsubishi L200 Common Rail PDFAlex Renne Chambi100% (10)

- Isuzu N-Series Elf Workshop Manual - Section 6 - Engine 4J Series - LG4H-WE-9691Document691 pagesIsuzu N-Series Elf Workshop Manual - Section 6 - Engine 4J Series - LG4H-WE-9691Alejandro Peña Pineda100% (10)

- Denso Toyota Hilux Common RailDocument68 pagesDenso Toyota Hilux Common Railbugyman_02100% (4)

- Motorul D4DDocument185 pagesMotorul D4Ddoruk1964100% (5)

- Hilux GD SeriesDocument17 pagesHilux GD SeriesNging Yu100% (7)

- Difference Between Toyota Hilux Vigo G and Toyota Hilux Vigo eDocument37 pagesDifference Between Toyota Hilux Vigo G and Toyota Hilux Vigo eDavide Boreaneze100% (1)

- Engine: 1Kd-Ftv and 2Kd-Ftv EnginesDocument46 pagesEngine: 1Kd-Ftv and 2Kd-Ftv EnginesJorge Luis Garcia ArevaloNo ratings yet

- Toyota 14Document76 pagesToyota 14Dadang Lukmanul HakimNo ratings yet

- Kijang Inova DieselDocument109 pagesKijang Inova Dieselbernadus ari wibowo100% (1)

- 1GD-FTV Engine Control Ecm ComponentsDocument3 pages1GD-FTV Engine Control Ecm ComponentsDaniel rodriguez alayo100% (5)

- Cruise Control (1GD-FTV, 2GD-FTV), ECT and A/T Indicator (1GD-FTV, 2GD-FTV), Engine Control (1GD-FTV, 2GD-FTV)Document7 pagesCruise Control (1GD-FTV, 2GD-FTV), ECT and A/T Indicator (1GD-FTV, 2GD-FTV), Engine Control (1GD-FTV, 2GD-FTV)Kyawzin MinNo ratings yet

- HiluxDocument11 pagesHiluxCarlos Eduardo Zelidon100% (2)

- L300 Mitsubishi Delica 4D56 EngineDocument76 pagesL300 Mitsubishi Delica 4D56 EngineYOJuanca100% (4)

- Engine: Workshop ManualDocument249 pagesEngine: Workshop ManualRiyan Pate Kamang100% (19)

- 04 Engine ProperDocument5 pages04 Engine Properwilliam_senati20057051No ratings yet

- DENSO Common Rail Fuso Fighter 6M60 Service Manual PagesDocument12 pagesDENSO Common Rail Fuso Fighter 6M60 Service Manual PagesAlex Renne Chambi100% (4)

- w58 RebuildDocument49 pagesw58 RebuildtfphoenixNo ratings yet

- 4D56Document106 pages4D56Nery Bardales Leon0% (2)

- Service Manual: Common Rail System For NISSAN YD1-K2 Type EngineDocument40 pagesService Manual: Common Rail System For NISSAN YD1-K2 Type EngineBryan Edu Curay ZavalaNo ratings yet

- Engine 1KD 2KDDocument72 pagesEngine 1KD 2KDJavier Espinosa100% (8)

- WWW - Nasicoelec.ir: Electrical Wiring DiagramDocument60 pagesWWW - Nasicoelec.ir: Electrical Wiring DiagramMuhammad Fauzi100% (2)

- Cylinder Head Bolt Tightening SequenceDocument2 pagesCylinder Head Bolt Tightening Sequenceອູ່ ໄຊ ອິນເຕີNo ratings yet

- 1KD EngineDocument53 pages1KD EngineAHMADELHAYS100% (8)

- 009 - 000 - 000-2GD-FTV Engine Mechanical PDFDocument273 pages009 - 000 - 000-2GD-FTV Engine Mechanical PDFJosé Ignacio Quijada RojasNo ratings yet

- Common Rail System (CRS) SERVICE MANUAL: Operation: YD2K3 EngineDocument44 pagesCommon Rail System (CRS) SERVICE MANUAL: Operation: YD2K3 EngineAntony ColonnaNo ratings yet

- D96 Toyota Injector Driver Circuit Diagram PDFDocument3 pagesD96 Toyota Injector Driver Circuit Diagram PDFSelvin GalindoNo ratings yet

- HP4Document88 pagesHP4Alexander Neyra100% (4)

- Hino Dutro Service ManualDocument41 pagesHino Dutro Service ManualJegerpodden100% (1)

- Service Manual NissanDocument39 pagesService Manual NissanSky TripNo ratings yet

- Common Rail System For NISSANDocument40 pagesCommon Rail System For NISSANAntonio Ramos Vazquez90% (10)

- Carte Toyota PDFDocument185 pagesCarte Toyota PDFpana1968mc5186100% (1)

- DENSO Common Rail Hino E13C Service Manual PagesDocument11 pagesDENSO Common Rail Hino E13C Service Manual PagesYohanor Saputera88% (26)

- Phun Xang Dien Tu p1 8097Document351 pagesPhun Xang Dien Tu p1 8097Đức Hòang100% (1)

- Variable Speed Pumping: A Guide to Successful ApplicationsFrom EverandVariable Speed Pumping: A Guide to Successful ApplicationsRating: 3 out of 5 stars3/5 (2)

- Microprocessor Programming and Applications for Scientists and EngineersFrom EverandMicroprocessor Programming and Applications for Scientists and EngineersNo ratings yet

- Incompressible Flow Turbomachines: Design, Selection, Applications, and TheoryFrom EverandIncompressible Flow Turbomachines: Design, Selection, Applications, and TheoryNo ratings yet

- Ec ZD30 TD27 Nissan PatrolDocument1 pageEc ZD30 TD27 Nissan Patrolpalaboy88850% (2)

- 2 PDFDocument1 page2 PDFpalaboy888No ratings yet