Professional Documents

Culture Documents

Chapter 1 PDF

Chapter 1 PDF

Uploaded by

Harvey Pagaran0 ratings0% found this document useful (0 votes)

7 views1 pageOriginal Title

Chapter 1.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 pageChapter 1 PDF

Chapter 1 PDF

Uploaded by

Harvey PagaranCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

CHAPTER 1

41.1 Several of the admixtures which may be used in concrete mixes are listed below

together with some of the reasons for using them,

(a) Aitentrainment admixtures are added to increase concrete’s resistance to freezing

and thawing and to promote better resistance to the deteriorating action of de-icing salts

(0) Acclerating admitures such as calcium chloride speed up concrete's early strength

development.

(©) Retarding admotures such as various acids ot sugars or sugar derivatives are used to

slow down the setting of concrete and to retard temperature increases.

(@ Superplasticizers are admixtures made from organic sulfonates. They are added to

‘concretes to reduce water contents while at the same time increasing slumps and workability

(€) Waterproofing additives are generally some type of soap or some type of petroleum as

perhaps esphait emulsions. They are sometimes applied to hardened concrete and at other

times added to concrete mixtures

{The addition of silica furne, which is more than 90% silicon dioxide, will cause

increases in the strength and density of concretes.

4.2.When a concrete member is loaded in compression it not only shortens in length but

‘also expands laterally. The ratio of the lateral expansion to the longitudinal shortening is referred

to as Poisson's ratio. For the design of most concrete structures no consideration is given to this

ratio. is value, however, may be significant in some cases such as in the analysis and design

of arch dams, tunnels and some other statically indeterminate structures,

1.3 Some of the factors which affect the creep of concrete are the level of stress in the

concrete, the temperature, the humidity, the percentage of water-cement paste in the mix, the

‘presence or lack of reinforcing steel, and the size of members as it affects the volume to

surface area ratio.

41.4 Creep in concrete can be lessened by curing the concrete longer, using steam curing,

using higher strength concretes, keeping temperatures lower, keeping humidities high, and by

Using lower percentages of cement-water paste.

1.5 If the concrete in columns is creeping or that is becoming shorter in length it will tend to

get out of the way of the loads and thus more and more of the ioads will be carried by the

reinforcing bars which themselves have little creep,

1.8 Silica fume particles hold more water than cement particles. The resulting water/cement

ratios are smaller and strengths are higher. The use of silica fume particles in concrete causes

increases in the strength and density of the concrete because the ultra fine silica fume particles

are dispersed between the cement particles.

4.7 The rolled on deformations on reinforcing bars result in better bonding between the

concrete and those bars.

1.8 “Soft metric” reinforcing bars are exactly the same as standard reinforcing bars except

‘they are marked with metric units, Their aumbers, as #22 or #25, represent their diameters

rounded to the nearest millimeter.

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Lecture HydraulicsDocument27 pagesLecture HydraulicsHarvey Pagaran0% (2)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Contract Agreement For Construction: With Office Address at Roxas Ave, Poblacion District, Davao City, 8000 Davao Del SurDocument2 pagesContract Agreement For Construction: With Office Address at Roxas Ave, Poblacion District, Davao City, 8000 Davao Del SurHarvey PagaranNo ratings yet

- Introduction To Site PreparationDocument29 pagesIntroduction To Site PreparationHarvey PagaranNo ratings yet

- Painting&Tile WorksDocument14 pagesPainting&Tile WorksHarvey PagaranNo ratings yet

- Sieve AnalysisDocument2 pagesSieve AnalysisHarvey PagaranNo ratings yet

- Wastewater Treatment Using Biofilters For Roxas Avenue CanalDocument27 pagesWastewater Treatment Using Biofilters For Roxas Avenue CanalHarvey PagaranNo ratings yet

- Philippine Iron Construction & Marine Works, Inc.: Employment Application FormDocument4 pagesPhilippine Iron Construction & Marine Works, Inc.: Employment Application FormHarvey PagaranNo ratings yet

- Theoretical Background-Akoa Lang 2Document11 pagesTheoretical Background-Akoa Lang 2Harvey PagaranNo ratings yet

- Architectural Plan SampleDocument1 pageArchitectural Plan SampleHarvey PagaranNo ratings yet

- Which of The Traits Described in The Videos Are Most Useful/important To You As A Leader?Document2 pagesWhich of The Traits Described in The Videos Are Most Useful/important To You As A Leader?Harvey PagaranNo ratings yet

- 10 Chapter 10 SummaryDocument3 pages10 Chapter 10 SummaryHarvey PagaranNo ratings yet

- RC ProjDocument2 pagesRC ProjHarvey PagaranNo ratings yet

- Construction Contract: Chua, Condes, Maravilla, Pader, TilendoDocument70 pagesConstruction Contract: Chua, Condes, Maravilla, Pader, TilendoHarvey PagaranNo ratings yet

- RC Design (Catoc-Flores)Document22 pagesRC Design (Catoc-Flores)Harvey PagaranNo ratings yet

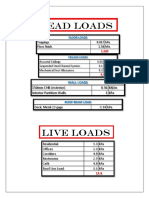

- Dead Loads: 150Mm CHB (Exterior) 0.36 KN/M Interior Partition Walls 1 KpaDocument1 pageDead Loads: 150Mm CHB (Exterior) 0.36 KN/M Interior Partition Walls 1 KpaHarvey PagaranNo ratings yet

- Cement HistoryDocument1 pageCement HistoryHarvey PagaranNo ratings yet

- NDRRMP: Disaster Preparedness Disaster Preparedness Managing Hazards and Risks Managing Hazards and RisksDocument7 pagesNDRRMP: Disaster Preparedness Disaster Preparedness Managing Hazards and Risks Managing Hazards and RisksHarvey PagaranNo ratings yet

- Statement of The ProblemDocument3 pagesStatement of The ProblemHarvey PagaranNo ratings yet

- Statement of The Problem: Flood Causes Damages Not Just To Life, But To The Economy and Society As A WholeDocument3 pagesStatement of The Problem: Flood Causes Damages Not Just To Life, But To The Economy and Society As A WholeHarvey PagaranNo ratings yet