Professional Documents

Culture Documents

Iocl Duplex 415C

Uploaded by

Raviraj Shashikant Patil0 ratings0% found this document useful (0 votes)

8 views12 pagesOriginal Title

IOCL-DUPLEX-415C

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views12 pagesIocl Duplex 415C

Uploaded by

Raviraj Shashikant PatilCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

JACOBS

Gient | Piant Location Code | Contract No.

TOcL__| PK PTAEXPANSION Perinat Tag No

Page

[ WAcuOA VAPOR CONDENSER Dec Re aac TaRO NT panomT

MECHANICAL DATA SHEET

This specification andior its contents, information and specific principles of design are the exclusive property of Jacobs

Engineering India Private Limited and is furnished to you with the agreement that it fs not to be reproduced in any

‘manner, copied oF medifiad nor is to be relayed in part or in whole to any other fm ar individual for any other project

without the writen agreement with Jacobs Engineering India Private Limited. Acceptance of this document wil be

construed as an agreement to this statement Further, lis hereby sisted that the sole purpose of this document is Io

provide the information required fer producing dravings and for carrying oul required design calculations by vencor

‘eating the requirements as stated and codes as referred al respecive pages.

Revo. | Bale] Desaiion Reveed [nace Checked

pages: \y

‘A _| 25.02.2020 | Issued for Enquin BK gas | SVE NOAA

¥

Page _| Description

1 __| Gover page:

Referance codes and documents

Process and mechanical details

Nozzie schedule

General arrangement

‘Top View & Flange details

Tube layout

(0 | General Requirements

E|sofenfa fears

PROJECT

OWNER

EPCM SERVICE FOR PX & PTA EXPANSION

INDIAN O!L CORPORATI

PANIPAT

JACOBS

Gent | Plant Location | ‘Area Code | Contract No. | 44AC7500.

TOL _| PX & PTA EXPANSION Panipat 2 Tag No, 2EE1-415C

Page. Zot 10

VACUUM VAPOR CONDENSER Doe No. “#4AG7500-21/V 0470008184

20 REFERENCE DOCUMENTS

| Codes: i — _ ee

[ASME | ASME Sec Vili Div. 1, Edtion 2017 For Pressure paris |

‘ASME Sec Il, Edition 2017 For Materials

‘ASME Sec IX Edition 2017, For Welding

— ‘ASME B 16.5 Edition 2017 For Flanges.

"ASME B 16.47 Series B Edition 2017 For Large Diameter Flang

ASME 8 15.20 Ecition 2017

For Gaskels

TEMA_[ TEMAS" Edition

For Shell & Tube exe

A_[ EJMA 10" Edition

For Expansion Joint aa

1S B75, Pan-3, Ed 2016 (Amd. 12016) For Wind load consideration

IS 1895, Part, Ed 2015

For Seismic design consid

‘API __| API660, Edilon, 2015

For Shell & Tube exchangers

| Project specications [standard

[ 34ACTSOO-ZIP. 047003018

4AC7500-00IV.02/0108/Aa

“44AC7500-00/V.02/01 18/A4

[44AC7500-00NV.02/0704A4_—

44AC7500-O01V.02/0109/A4

| 44ac7500-001v. 02/071 0/84

General Speci

Ge Painting

“General Specification

for Insulation

~T44AC7500-00/V.02/0124/A4

“@4ACTSO0-O0NV.02/011 3/84

'44AC7500-001V.02/0122/A4 Standard Specification for welde:

“44AC7500-00IV.02/0139/A4 _Goneral notes for Heat Exchanger sal

“Supplementary Specification for CS vessels

44AC7500-00NV.02/0132/A4 General Specicaion for PMI al Vendor s work 4

44ACTSO0-OOIV.02I0133/A4 General Specticaon for Expanded Tube to Tubs Shea

SHACTS00-0OIV.02/0135/A4 General Specifeation for welding zi

44AC7500-00IV.02/0136/A4 ——Slandard or anchor balls

‘Siandard for bot ightering

Standard

ITP for Shell an

Jacobs Standar

‘Allachments

JACOBS

Ghent | Plant Location ‘rea Code | Contract Wo. | +4AC7500

Tock __| PX & PTA EXPANSION Panipat 2 TagNo__| 281-4150

Paae 3 ort

‘VACUUM VAPOR CONDENSER Doe Na “44NCTS00-21NV O4/0008IR4

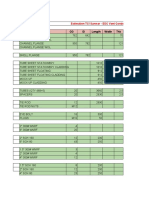

3.0 PROCESS & MECHANICAL DETAILS.

Design ote % | ASME Sec Vil, DW. 1, £42077 [ASE See Vi bie EO BOT

x [TEMA DeTr] [eT 181 NACE Maor7s, wmo103 [LER

Tnade Ba [sid [mm | Wo-ofunie [1 | Tube GO wiht fam] 1905 85 ay

Tue Leng 356d —[ mm | (Sraight engi) 17) | No.of hes 78

Eachanger ype BEM | Passed [Shel 1_[Tube._1| Tube pich or ~

Psion [De wana [Horgan Tube nyu

Fuia |) “Tubs to tube shee joint ‘Sarge Weld UipiEiprnad

Fa anit 7 Tg The | Bafa iyi ut) 16 Hears 174 1)

"Vapor 4 ig let Bate Spacing [a] 1)

Liquid a I kg/hr. | Baffle Spacing [mm] 298,

Noncondaabla ay ie fhe | Balto type Single saga)

Design tmp. Shot i TE) W7aTT74 iT} eSupport ite ‘ |

“Design tomp. Tube (2) | 174474 4) [26 Ne. oftio rods 2 i

‘Shell Operating em, info Ow ped [0 | Seal eds a

Tue Operating temp. tn |r20"[ Ow 00” | ) Data sheet and dimensional layout

c} More severe one of specifications f standards / special notes or local regulation & standards

In case of conflict among the requirements of the documents, vendor shall get clarified by Jacobs.

con case to case basis

8.1.23 Specific requirements

1) Alltubes shall be made from single continuous length,

2) Incase of U tubes, same shall be ecdy current tested before bending

2) Ali nozzle attachment welds shail be OP / MT examined alter root run and final pass

4) Following tests shall be carried out after PWHT!

+ All butt welds of shell, chant and nozzle shall be RT examined. For weld overlayed

components, RT shail be carried oul prior to clad restoration and PWHT. UT shall be

‘cartied out for all above butt welds

+ UT examination far all nazzie attachments

+ DP/ MP examination for all attachment welds on pressure parts

+ Hardness check for weld, HAZ & base materia

Finish of all machined components shall be minimum 12 microns (500 RMS}, unless

otherwise stated, Paris subjected to LUT shall have a finish of minimum 6 microns,

surfaces of

be DP /MT

with thickness more then

20mm shel

ested

For stacked exchangers hydro testing shall bo as follows:

a) Individually exch

JACOBS

Equipment shall be dried and thoroughly cleaned both inside and outside and all water, dirt

weld metal spatter, welding electrode stubs and foreign matter shail be removed

tems shall be marked conspicuously with tag number adequately sized (use white oil paint)

All sealing flange surfaces and other machined surfaces shall be coated with 2 suitable rust

preventive Hike Teciyl and shall be closed with woeden covers with at least four boils & nuts and

soft gasket sheet in position to prevent mechanical damage during transport

Bolt threads shall be lubricated with Molykote (Molybdenum disulphide grease)

‘Tapped holes shall be filed with acid-free grease

All. compari

nuts in posi

19 | blind Ranges shall be bolted onto the nozzle flanges with gasket and all bolts &

Horizontal equipment with saddles shall be transported using saddles fer support during anspor’

Allother equipment shall be supplied with suitable temporary saddles. If slffeners ave required for

safe transport, same shall be pravided by vendor

Loading of the equipment at vendor's works inlo the truck / waller | wagon shall be

responsibilty of vendor

Equipe

hall be 5

‘under Ne pressure

USED ABBRIVATIONS

Corrosion Allowance

Full Vacuum,

= Not Applicable

Nominal Bore

Killed Garbon Stee!

Lov Alloy Steel,

Flat Face

Raised Face

Slip On

Weld Neck

= Long Weld Neck

SelfReinforced

Lap Joint

Post Weld Heat Trea

Ponetrant Testing

Magnetic Testing

Uttasonic Testing

Radiography Test

ent

ing

Heat Conservation

Weld Overlay

Standard

Nominal Pipe Size (Dimensionless number]

Non-Destruciive Te

Seem!

SMLS

Giek [Pa Tan Convacna. [Hai]

TOCL | PX PTA EXPANSION Panipat 21 TagNo. | 2-E145¢

ope [at 0

ACUI VAPOR CONDENSER Sachs ACTRRO ANT ow

6.4.24 Packing Instructions

caren

|

Hl

EEE inectemnmare

pee INDIAN OIL CORPORATION LIMITED:

ar = INTEGRATED PXOPTA COMPLE, PAMPAT

FE (PURIFIED TEREPHTHALIC ActD PLANT)

a :

HaPEHEPEESH EI

He ciovcs B ENGINEERS

pcre © elo

Ores 4 TOUBRO LMITED , xeon |

BOYCE WFC CO LTD, MUMBA, INDIA

PRODUCT ENGINEERING DEPT. PED

Sheet-8

; A |g Ty ae ~| Peele.

i it f lhe, BE 2 bole § leuk s|Ele

le ea

A PMU deh fo et) eS lad

MOTT ECEET Al] cee le) & ieee

A be Bess feel lee § lanl SA yl) 38

y bcs Fos el Hed Hi ill eg

i Es tet, 222 : 5 he ST 8e

Me) ge i 3 ;

oO) amis

Zz

Seti lan se anats

ARREST

LEK OKRNN AARNE

TIRE RRR

RRR ANAK NNSA RRR

CIO KLAN

NN RRR

ES “

ERR

annuus

RReeererR Rr

RR KKK RR KK

ROAR KANG

RRR RRR RRR

SK AKA 8

RHR SoH:

SEE

XXX NNNN

EXXXXXXXXAN

RE

Ronan

XX

XOX

RR

XX

Re

BERR Sais

OK

RN NR

RS

© eumornouresoosososynuc meet yer ueemeey

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Mind Power Unlimited - A Transformational WorkshopDocument3 pagesMind Power Unlimited - A Transformational WorkshopRaviraj Shashikant PatilNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Estimation TCI Sanmar - EDC Vent Condenser Tag No E-102Document5 pagesEstimation TCI Sanmar - EDC Vent Condenser Tag No E-102Raviraj Shashikant PatilNo ratings yet

- E-23 - Company ProfileDocument11 pagesE-23 - Company ProfileRaviraj Shashikant PatilNo ratings yet

- Road and Bridge Construction EquipmentDocument112 pagesRoad and Bridge Construction EquipmentRaviraj Shashikant Patil100% (2)

- Raigad SsatdDocument1,908 pagesRaigad SsatdRaviraj Shashikant PatilNo ratings yet

- Case StudiesDocument13 pagesCase StudiesRaviraj Shashikant PatilNo ratings yet

- Registration Form For Wind Power Project Developers / Manufacturers 1Document6 pagesRegistration Form For Wind Power Project Developers / Manufacturers 1Raviraj Shashikant PatilNo ratings yet

- QMS Documentation: Click The Mouse To Advance Slides and Animations in This Slide ShowDocument11 pagesQMS Documentation: Click The Mouse To Advance Slides and Animations in This Slide ShowRaviraj Shashikant PatilNo ratings yet

- VC Handbook 2014Document39 pagesVC Handbook 2014Raviraj Shashikant PatilNo ratings yet

- Export Oriented Units, Projects (100% EOU)Document14 pagesExport Oriented Units, Projects (100% EOU)Raviraj Shashikant PatilNo ratings yet

- Wine Flavor ProfilesDocument10 pagesWine Flavor ProfilesRaviraj Shashikant PatilNo ratings yet