Professional Documents

Culture Documents

Selectomat SL - Service Instructions

Selectomat SL - Service Instructions

Uploaded by

hem midlands100%(3)100% found this document useful (3 votes)

797 views41 pagesOriginal Title

selectomat sl _ Service Instructions

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(3)100% found this document useful (3 votes)

797 views41 pagesSelectomat SL - Service Instructions

Selectomat SL - Service Instructions

Uploaded by

hem midlandsCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 41

Service instructions

Steam sterilizer

SELECTOMAT SL

CE Cem

SELECTOMAT SL_ns_en 0911_V2.02

CONTENTS:

4

2

6.11. 2009

INTRODUCTION.

DESCRIPTION OF THE UNIT.

2.1 Steruzer cHansen...

2.2 Steau ceneraron.

2.3 PireworK.

2.3.1 ScHEME OF PIPEWORK CONNECTION - APPLIED ELEMENTS...

2.3.2 Sremy Taxes

3

3

3

3

3

3

24° Coverase. 4

2.5 ELECTRIC CONNECTION. 4

2.68.1. Block cicrau 4

2.5.2 _ DESCRIPTION OF THE ELECTRIC CONNECTION DIAGRAM, 4

2.5.2.1 NETWORK PART assssnnnststnnnnnnie svnnnnnnnnnenee even

2.5.22 — SwircHacaro, 4

5

5

5

6

6

6

7

7

8

9

9

2.5.2.3 FRONT PANEL (ON THE LOADING SIDE).

2.5.2.4 Rear PANEL (ON THE UNLOADING SIDE).

2525 — Inours,

25.26 Ovreuts.

2.8.2.7 HagowaRe PROTECTION...

2.6 DESCRIPTION OF THE AUTOMATICS FROM THE VIEWEOINT OF SOFTWARE.

2.7 LOADING OF BIOS, AFLICATIONS AND LANGUACES...

2.7.1 LoAoINe oF alos.

2.7.2. LOADING OF THE APPLICATION...

2.7.3 RULES FOR WORK WITH THE PROGRAM LOADER EXE.

FUNCTION OF THE UNI

31 PIPING OIRGRAM ao snmnnnnnnnninnnnnnnnnnnnnsnn®

ADJUSTENT OF THE UNIT, SETTING THE PARAMETERS.

4.1 MENU ~ SETTING AND SERVICES ACCESSIBLE FOR THE UTILITY TECHNICIANS .nsntunnneeennnnnnnsnnnnnnnnne

A440 Test oF sarery eLeueNts. 40

41.2 DISPLAY OF BLOCKS nn ssennnnnnnnernnnnnneel

4.1.3. Sunway oF INPUTS - OUTPUTS. nannies

444 Device conAGuRATION. 42

4..5._ SeTnNa oF THE DEWCE.. 12

41.5.1 SERIAL NUMBER AND CHARGES COUNTER.. - snnnnnnesnnnnnnnne

4.1.5.2 Orrser oF pressure. 12

4.1.5.3 OFFSET OF TEMPERATURES coum snnnnnininnnnnnnnsnnnnmnnennnnne

4.1.5.4 Serrins THE o00Rs conn ott

4155 Unis 13

4.1.5.6 INTERNAL GENERATOR smnmnntnnnnnnnn snnmnninnnnnnnnneinnnnnnnsnnninnel

4.1.5.7 WATER SAVING TEMPERATURES orn onntnnennnnnnnee lS

4.15.8 —Anwnistaaron - PRESET (ACCESS SareTY AND DOOR ALOCKING PASSWORD). 13

4.1.5.9 SERVICE PLANNING (NEXT MAINTENNANCE)... sonnei nee

41.6 — DOWNLOAD OF PROGRAMS. nsonnnnnnnnnnnnnnn sone nnn

4.1.7 Proceames sons, 44

4.1.8 Syste vERSION.. 15

41.9 Leo PANEL OFFSET. . fo 15

4.2. __ REPLACEMENT OF THE PARTS OF ELECTRONICS. 15

4.2.1. REeLACEMENT OF THE ELECTRONICS BOARDS... 15

4.2.2. BATTERY REPLACEMENT. 16

4.2.3. REPLACENENT OF THE CONTACT PANEL ~ FRONT PANEL. 16

4.2.4 REPLACEMENT OF THE TOUCH PANEL AND DISPLAY = REAR PANEL, conned

4.3. DEFINITION OF THE PROGRAM PARAMETERS. 16

4.3.1 THe WAY OF DEFITIO OF THE PROGRAMME PARAMETERS, conned

4.4 DESCRIPTION OF THE STERILIZATION PROGRAUNE PARAMETER’ 17

4.4.1 SENSE OF INDIVOUAL PARAMETERS.. AT

4.4.2 Use oF pr sensors ACOORDING TO THE UNCONFIG OATA. oun 18

45° Vacuum tesr.. 19

46 Air veTecToR oA

‘SUPPLEMENTS:

[SETTING THE PRINTER PARAMETERS. 4 sneer

STERILIZATION CYCLE — DRAWING NO: KV_202... nnn 1 sHeeT

‘Cownecmion SELECTOMAT SL 4.6X 3:300-420V PE 2450465... 14 susers

Enon REPORTING : : vo 2swcers

Service instructions

1 INTRODUCTION

This Service manual Is valid for SELECTOMAT SL models

‘and it contains the summary of data concerning the product,

necessary to make the repair works, maintenance and

device check

Itassumes knowledge of both the Instructions for use,

written as a separate document, and annexed connection

slagrams.

2 DESCRIPTION OF THE

UNIT

‘The SELECTOMAT SL unit belongs on the category of large

steam sterlizers. Its designed to be used in the health service

‘acilties, in central steriization stations in the hospitals and

generally in all branches where sterile goods are used

2.1 STERILIZER CHAMBER

In the sense the sterlizer chamber is a pressure vessel

Another standard, holds for operation, maintenance,

revisions and tests of pressure vessels.

‘The chamber is made from chrome-nickel-molyodenum

Stainless steel of grade AISI 316L and ASI 316Ti. The inner

surfaces of the chamber are surfaced,

‘The steriizer chamber is closed by a vertically slidable,

electrically or manually operated door. The door ang

‘chamber are thermally insulated with mineral fibre

(thickness 60-130 mm).

‘The door and the chamber are thermally insulated by

‘mineral wool. An electrically operated door Is fied with a

protective bar with four switches situated under the door

cover. The door drive coupling Is adjusted to develop a force

(of 160 N when closing the door. A manually operated door is

fitted with a locking magnet with respective position switches

‘voiding opening the door in case that the pressure in the

‘chamber has not yet reached the atmospheric level. The

basic sealing element of the door system is a hose-lke seal

BU Into a groove in the vessel. After starting the program

the seal is pushed against the door by steam pressure, what

‘secures tightness between the vessel and the door. After

finishing the the program, the seal is pulled back into the

{groove by vacuum, In models 666 - 6612 the left pair of the

oor travelling rollers i ited with an excenter for adjusting

the clearance betiveen the guide bars.

‘The sterlizer chamber is provided with two test connections

vith pipe threads ISO 228-G1/2.A and G1-Aallowing to

introduce checking sensors into the chamber. The chamber

contains shelves for placing the goods being sterilized, or a

‘multi-story frame for the model BW loacing trucks.

2.2 STEAM GENERATOR

‘The sterlzers are delivered in three variants FD, ED,

FED. The builtin electric heated steam generator (variants

FD, FED, or possibly FDT) is designed to generate clean

steam from completely demineralized water. The generated

‘steam shall not contain hydrazine (N.H,) or other volatle,

corrective chemicals and corrasion inhibitors.

‘The steam generator may be supplied only with respectively

treated, totally demineralized water. A treatment on the

principle of reverse osmosis is duly recommended.

‘The power input as per sterilizer models amouns to:

4461636, 22,5kW

666 36 kW

6916512 45 kW

9612 63 kW

e618 72 KW

‘The steam genarator is made from chrome-nickel-

molybdenum stainless sieel of grade ASI 3167

‘The boller is fed by means of the feeding pump from a

storage tank with controlled water level. The water level

In the boiler itself is controlled by level suitches. There Is

a double protection of the heater elements. The lowest

Permissible water level NW is secured by the safety level

switch B91 (locking the svitching-on of heating power). The

‘operational height ofthe water level's maintained by the

level switch 890, having also a protective function.

In case that water has not been refilled within a certain

time limit (approx. 40 s), the heating power is reversely

switched off, The control ofthe steam generation is

Performed by a pressure gauge in dependence on the

steam pressure. Excessive values of the steam presure

are avoided by built-in safety pressure limiter. The heater

elements are switched on and off successively in blocks with

approximately 18 delay.

2.3 PIPEWORK

2.3.1 SCHEME OF PIPEWORK CONNECTION

= APPLIED ELEMENTS

Yo1 ~ ¥600, ~ active valves

vivi20 «safety valves, hand-operated,

reduction,

Back check valves, thermo regulating

520-831 pressure switches:

585.691 -level switches

1 ~ feeding pump

Fi-F30 = filters

PE1-PE200 pressure sensors

PI flow limiter

01-0200 = steam traps (condensate discharge)

wi -water-ring vacuum pump

PTt-PT20 temperature sensors

1 heater elements

CHL ~ cooler

2.3.2 STEAM TRAPS

‘Two steam traps Spirax-sarco types are used standaraly in

the devices.

1. ‘direct’ type BTP 13S - 0350210, which Is for MMMM

fitted by a liner with °G* marking

2. ‘angular’ type BPT 1340350211, which Is for MMM

fitted by a liner with "E* marking

‘The liners are delivered in the form of a set or as a spare

part too and they are, by recommendation, bound with the

corresponding trap (see the spare pars list),

‘The marking is also in the liner body.

liner 0350208, “G" type (for the 0350210 trap)

liner 0350207, *E” type (for the 0350211 trap)

SELECTOMAT SL_ns_en 0811_V2.02 3

‘Service instructions

‘The “G" type liner is set “more sharply” (near the temperature’

steam pressure balance) and It's therefore dedicated for

traps connected to the outlet from the sterilisation chamber

(now newly also for the direct trap of the stearvstaam

exchanger - FDD)

This liner is not so much suitable for condensate draining from

Jackets as the draining Is too rapid, noisy. in some cases.

The “E" type liners set to “standard” (Le. a ite bt under the

balanced state, than the previous type) and it is dedicated

for other traps, where the softer drain is required. E.g, the

condensate drain from the jackets, supply pipe ete.

This iner isnot suitable forthe chamber, as It drains the

condensate for this not enough purpose and it can cause a

distortion of the measured temperature on the main PT sensor

problems withthe residual air non-condensed gases etc.

The liners are mechanically changeable and itis necessary,

during the replacement, to replace them by a suitable type

and vith certain knowledge,

2.4 COVERAGE

‘The units covered with stainless pane's of 1.4301 material

quality. there is also a lockable service-door in the covering,

2.5 ELECTRIC CONNECTION

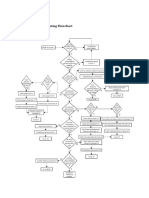

2.5.1 BLOCK DIAGRAM

The apparatus is controlled with micro processor automatics,

From the following chart itis obvious the basic arrangement

of the electrical equipment of the apparatus:

xe

as

ae

cone,

s coumaster |p REM8S.

ess

The basic interface attendance ~ apparatus" is the contact

panel on the loading side of the sterilizer, which is controlled

‘with the processor MASTER, This processor also ensures

‘the contact with peripheries (PC. printer, chip-card, MIC),

Inthe unloading side there Is a smaller contact panel, which

is controlled with the processor BACK.

Further the apparatus contains the processor SLAVE, which

processes the information from the dighal (switches) and

analog (temperatures and pressures) of inputs and controls

the outputs,

In order to secure the safety as well as in the case of

failure of the procassor SLAVE, the apparatus contains a

block of haraware protection, whieh Is controlled withthe

processor MASTER and some inputs (see the chapter of|

hardware protection)

4 SELECTOMAT SL_ns_en 0911_V2.02

2.5.2 DESCRIPTION OF THE ELECTRIC

CONNECTION DIAGRAM

‘The electric connection diagram is inthe supplement of

these Instructions. The connection dlagram is attached to

these Instructions. The following page numbers correspond

to the clagram 2468466 v.14 and alagram 2471105 v4 (UL

variant), n higher versions, the numbers can ditfer

2.5.2.1 NETWORK PART

‘The connection of the sterilizer wiring Is shown on pages 1

and 2. Page 3 shows the secondary voltage distioution of

the T1 transformer to the individual electronic boards.

Meaning of the respective components is folowing

Eres [Heaters

F501, GOS, | Crcult breakers of heaters

F505, F507

KK? | Contactos

QT AT AT_| Creut breaker ralay af motors

wr TWacuum pump motor

cr Pump motor - generalor

2 Pump motor methylene

FLT Fluorescent amp

tuth electron Datast

Ti Transformer

Fr Guout tse for sup of THA

lectronies

7 Cutout tse for daplay Tam

Deckightn the oaaing side

= ‘Cutout fuse for supply of To aA

slemate outputs and contract

ar fe pana ne unoaang

Fa Cut-cutfuse fer supply of TE aA

the mputs and deel Curent

outouts

= Fuse for Tard FL? Trae Saaov

2A tar 220

“TaAfor 208 (UL)

a ‘Swietboard Tan

2.5.2.2 SWITCHBOARD

In the shest No. 4 itis drawn the arrangement of the

respactive components in the switchboard

‘The detailed connection of the X1 and X3 terminal boxes

is on the sheet No. 5. This is applied in a device with

maximum configuration. In simpier devices, the unused

terminal connectors are not fitted. The flexible supply cable

is connected to the L1, L2, L3, and PE terminal connectors

Page 5 shows the left version ofthe distribution board for

the UL variant,

‘The interconnection of the VP_CPUS (SLAVE) processor

board with the VP_PDC (OC outputs) and VP_PAC (AC

outputs) power boards is drawn on the sheet No. 8. The

number of power boards depends on the equipment

configuration

‘To the connectors XS1 and XS2 ofthe board VP_CPUS it

is led out the internal busbar RS485, if there are connected

both two connectors (two-door version), the switch S1-1

(between the connectors XS1and XS4) must be in position

OFF", ifitis connected only one connector (one-door

Yersion), S11 must be in position ON”

‘The connector XP8 serves for connecting of PC (recording

of bios)

‘Service instructions

‘The connectors XP3 and XP4 serve for interconnecting of

the sterlizers between them (control of consumption). Ifthe

cables are connected to both connectors, the switch S1-2

‘must be in position .OFF*, if there is connected only one

connector, 1-2 must be in position ON"

2.5.2.3 FRONT PANEL (ON THE LOADING SIDE)

Pages 6, 7 and 14 show the interconnection ofthe individual

front panel elements.

‘The titable panel for the SELECTOMAT SL models consists

Cf the touch panel glued by a double-sided adhesive tape

tothe display, of the VP_M_LB121 board, inserted into the

isplay, ofthe converter for CFL (display illumination) and

of VP_CPUM (MASTER) processor board, forthe SP HP

E and SP HP S models it consists of the touch panel with

ispiay (one part), of the VP_LVDS board, of the converter

for CFL (display llumination) and of VP_CPUM processor

board. On the rear side of the front panel, the VP_KON

connector board is placed and the chip card reader, printer

and servo (for SELECTOMAT SL models) are connected to

ft

‘When making connection of the servo itis important to take

care of the postion of the black wire ~ see the diagram

Furthermore on it there are connectors for connection to

PC (RS232, USB and ETHERNET). To the connectors XS1

‘and XS2 IIs led out the internal busbar RS486, Ifthe cable

|s connected only to one of them, itis necessary that the

both two switches S1 (oaside the connectors X81 and XS2)

‘would be in position .ON", otherwise both the switches S1

‘must be in position OFF.

‘To the connectors XS1 and XS2 of this board i sled out

the Internal busbar RS486. Ifitis connected only the cable

conly to one of them, itis necessary that the both switches

81 (beside the connectors XS1 and XS2) would be in

Position .ON", otherwise both the switches St must be in

position OFF.

Ifthe VP_CPUME...processor panel s used in SP HP E or

SP HP S models, it replaces the VP_CPUM, VP_KON and

\VP_LVDS panels ~ see page 14.

2.5.2.4 REAR PANEL (ON THE UNLOADING SIDE)

In the shest No. 9 and 10 itis dravn the mutual

interconnection of the respective elements of the rear panel

‘The rear panel consists, for SELECTOMAT SL models,

cf the touch panel, display, convertar for the display

lilumination and VP_CPUB processor board, for the

‘SELECTOMAT SL models only of VP_CPUBE processor

board. The internal RS485 bus Is brought on the XSt and

XS2 connectors of the processor boards. ifthe cable is

Connected only to one of them, itis necessary that both St

‘switches (close by XS1 and XS2 connectors) are in the “ON

position, otherwise, both $1 switches must be in the “OFF”

position,

2.5.2.5 INPUTS

Page 11 shows the connection ofall inputs.

Digital inputs are connected to XP1 - XP4 connectors on

\VP_OPUS panel (there is @ LED at each input lighted up

whan the switch is on) and analogue inputs are connected to

XPS - XP7 connectors,

“Meaning of the respective components connected to the

Inputs and their function is following

DIGITAL INPUTS

Taantication [Meaning Function within

Sontened

contact

a Thermal relay — vacuum pamp | motor

veroaded

a2 Thermal relay — generator pump | motor

veroaded

a Thermal relay — pump ‘motor

matiien overloaded

52 Pressure swich 15 Bar sot (6S) | under pressure

207 Pressure swrch 1 5 Bar-sbt (ES) [under pressure

B31 Pressure switch 3 Bar without

— generator pressure

[7 Bottom lever gauge ~ Gemiwater [flooded

Bao Upper level gauge -demivaterr [flooded

590 (HW) | Upper evel gauge - generator | flooded

'B81 (NW) | Botiom level gauge generator | Todd

B10 Upper oval naicator -methylené [Hooded

E101 Botton level ndcstor-mettylene [flooded

BI02 Exleral level ixicator- loosed

methylene.

Si Envy door (65) closed cased

Sia Enty door (83) opened ‘opened

S12 Input service doer (65) (&xmodel [opened

ETE] Input door (B5) closed (9x model) [ opened

S12 Safety sip — entry door (BS) [not pressed

Ss Output door (ES) closed closed

sist Output door (ES) opened ‘opened

S132 Out serve doo (ES) (acrnade) [opened

Sas Ouipat dor ES)ctesed(@%x [orsned

a Safety stip — output door (ES) | not pressed

i Blocking — ack of electncty [blocked

‘ANALOG INPUTS

Taantication [Meaning Evaluated by

processor

E11 (SL) | Pressure wanscucor chamber | SLAVE

PET 2 (MST) | Pressure transducer chamber_[ MASTER

PED. Pressure vansducer casing || SLAVE

PED Pressure tansducer—casing 1 [ SLAVE.

PES Pressure vansducer- generaior [ SLAVE

EIT Pressure vansducer ait SLAVE

EVO? Pressuro ranscucot —eoiyatoam | SLAVE

PEIOS Pressure tansducer — water for | SLAVE

vacuum pump

PETG [Pressure vansducer—enty | SUE

PETS Converter pressure sotened | SLAVE

ator (EW)

PE 106 | Pressure converier-hesing steam | MASTER

PTt1 (SW) [PT sensor— chamber ‘SLAVE

PIT (MST) | er sonsor— chamber MASTER

PT PT sensor —waler saving ‘SLAVE

PTS 1(S1v)_| PT sensor— solutions, resene [SLAVE

PTS2 (MST) | PT sensor — solutons MASTER

PTA PT sensor — generator SLAVE

PTS. PT sensor demwator SLAVE

PTB. PT sensor — detection afar [SLAVE

‘SELECTOMAT SL_ns_en 0911_V2.02 5

‘Service instructions

2.5.2.6 outputs

‘The connection of the AC outputs is shown on the sheet No,

‘12 and of the DC outouts on the sheet No. 13,

The switching Is indicated on the povier board of the

electronics VP _P... with appropriate LED diodes.

Meaning of the respactive components connected to the

‘outputs is following

2.5.2.7 HARDWARE PROTECTION

Due to safety purposes the outputs, which in case of

tundesirable switching can endanger the user, or possibly to

‘damage the apparatus, are blocked by means of the relays,

which are switched with the switches being independent

to the automatics of the apparatus. The connection of the

relay colls Is obvious trom the sheet No. 9. The appropriate

6 ‘SELECTOMAT SL_ns_en 0911_V2.02

eta Weng aE antci of ese relays ae rearesrid inte sees Ne

os, valve or iing feet 1

oa ee So ‘The moment, vhen its possible to switch the outputs, is

— SSS ‘2bvious from the falling table:

chamber Nome] isentfea- [Rely —[Swich

WS Vaive of he ng sa oy aeer 85) ite [ten

ee [e ote ing st output or Mave —]YaT [RTS OSs

“ean katt [B201*-stt ssealea

Yo Vaie or discharging ofthe chamber wins ide [EO ets seats

ves Vai fr discharging of to st (only chamber 313 Goer BS closes

door BS) ‘Valve ‘Yoo KIB '$11+S13 - doors BS +ES are

Yas1 [ave for dasharaing ot st wean elosed

{cuiput door ES) josiot.

Yaa ‘Cooing water vave or fhe a jeses | Of of

stactor Vave —[¥o0 | KIS | S¥1 door BS e cones

YaT ‘Air datactor vaive - condensate ea

7 A delector ave at gee

a0) ‘cooing water ve or veouum DUN vave [Yat | KIa1 | St1-door BS cones

Yan ‘Valve fo locking of he condensate “Sean

suet cond teste

ve ave or vent ssf _ ;

cor iD sence dor closed

E07 | Stenizebie avalon terval Waloes S25

Yar Val for vacuum breaking of te S00

acum pump. ‘Motor ot [M3 ‘$13.2 — service door closed

Ye Vawe or desudoiig ihees ford

Y150, Valve for degasification door

ia Rave fordetaraton one ack vave [Yat | Yoo1 | St3-door ES dosed

YIO ‘Valve for jacket pressuring wit ir jeacr

Icounorgressue) Es:

ca awe io ake soraving Connee. [RT| GT] G7 casa af oveionang af

Yet Vawe or disenarging ta Shambor tor for {ng meter dscomects the

Yee aie for dscherang te jacket ser oi

Yoo Valve of waste steaming ‘Gonnec- [K2 a2 ['Q2 in case of overloading of

Yaoi Valve of walr showering tor for the motor aconneets the

Yé02___|Vave Methylene Re pure coke

503) yous. ocamber ‘aerating Connec- [KS Cy |Q3 in case of overloading of

{methylene} tor for the motor disconnects the

Yeo ‘Vaive Methylene — pomp bidging the pump ok

Vi6 Valve Heating steam ce

Ki Conecior for Mi —vasuum pump V¥1 tostoe [Rek? |"? [Ntcenerstor = oosed

12 Enty door (85) openng reatng BSt-in th gonorator here is

Enty doo" (85) reversal sg) Dette Oa

1 ‘ut coor (E5) opening (ERE soci KA, Ka

Quit door (ES) reversal (cosng) AIAG, 70 [Electron bona vP_OPURT

@ ‘contacior for BS = UMD CT puis (iough VP. KON)

gererair LAG. RT| Elecvont boars vF_CPUM

co Cantactor or HO pump C2 apis tivcugh VB KON)

metnyione. "Tor independent door seal

a Contactors forheatng

ca Canacios fo healing

i ‘Contactors for heating 2.6 DESCRIPTION OF THE AUTOMATICS

ca Contactors forheating FROM THE VIEWPOINT OF SOFTWARE

All control activites are performed by two independent

microprocessors. The microprocassors cooperate in relation

‘of master and slave. Communication between the Master

‘Service instructions

and the Siave takes place via R&486 bus, fully controlled

by the Master. In moments, when the situation asks for,

the Master sends required data to the Slave, in reverse

direction pieces of periodically sampled information ara

transferred in form of data packets with fixed structure

It the apparatus is the two door type, to the busbar RS485 it

is connected another microprocessor (back). wich ensures

‘the control of the apparatus form the side of the material

unloading.

“The following table shows the access of both

microprocessors to the peripherals,

‘Access i evfemal nitiabon or

ossibity to perform activity

Communication win he PC operation [YES [NO [RO

Barametors

Measurement of te Tem

chamber

Taster] Slave | Back

Twente [YES [ves [No

transition to the intial state from the master, Le. in the

chamber itis atmospheric pressure and the slot will be de-

sealed, The processor back receives from the attendance

Of the apparatus the instructions for the requested activity

and hands over them to the processor master, which further

processes them,

2.7 LOADING OF BIOS, APLICATIONS

AND LANGUAGES

For recording — download of the sottvare equipment into

the steriizer the program Loader EXE" serves. Software is

transmitted on the serial line RS 232 2 PC by means of the

cross cable:

Cannon 8 female

Measurement of he pressuroin the [NO _[ VES [NO

heating jacket

Measurement ofthe pressure nthe [YES [VES [NO

chamber

Contiol of switches for eectiomagneie [NO | YES [NO

valves, feeding pump, vacuum pump,

heating. docrdnving motor

Tnformation on the status of no [ves [No

the folowing sensors the door

electromagnet, tne door-end switch

Wate’ fave sviienes nthe heating

Jackel and the water storage tank

Information on the staus of pressure [NO [VES [NO

swiches

[Access io ho LOD splay LED aspay [YES [NO [VES

[Access t the keyboard Yes_[No_| Yes.

Sound signaling Yes_[No_ [Ves

Printing i the panier Yes [No [NO

Information on the power supply fal-out | YES NO__[NO

RAM backup Yes [No [NO

Check of curantflowinihe heating [NO [YES [NO

jacket water pump

Check of current flowin the vacuum [NO [VES [NO

pump,

Software of the apparatus has two main layers, BIOS ang

APLIKACE. BIOS ensures the communication between

the appropriate processors. And further the upgrade of the

application. The application ensures the correct function of

the sterilizer. The processor master receives the instructions

‘rom the attendance for tne requested activity and at tne

‘same time for the control it assesses from the processor

slave the states of sensors, values of measured variables

and also the information regarding tothe fact, within which

phase of terization cycle the process is found, Many of

ecessary data are obtained independently, or it compares

‘them to the parallel obtained data from the slave. Ife

attendance gives instruction to the commencement of

the activity, the master sends in direction to the slave the

packet of necessary parameters.

‘The processor slave is entrusted the course of the

steriization cycle on the basis of the information from

the processor master. Slave has a direct access to the

outputs (valves, contactor...) and to the inputs (thermal

and pressure sensors, switches, ..). Ifthe slave detects.

the error. it notifies of the fact the processor master and

‘freezes its activity, Le. all the action variables take up the

safe state and itis waiting. Only after deleting the error

by the attendance the slave receives the instruction to

@ @)

8 ®

@ “)

6) ©)

7 ”

@) @)

6) +> 6)

It we want to download the software, then we start the

program ,Loader EXE", on the upper bar we select with

‘a mouse the fle .Flle--Open the file" anc choose the fle,

‘which we want to download. On the surface of the program

there will appear @ window with the listing of the program

(The fies are marked in a mnemonics manner such as

BiosMtlist...). Then on the upper bar we select .Oovmnload-

Load the flefprocess the batch”

When starting the download itis necessary that the window

‘with the isting should have a blue bar. Afr starting the

download it's possible to swteh over the window. But it

‘must not be closed.

2.7.1 LOADING OF BIOS

Bios is loaded into every processor board separately

(VP_CPUM, VP_CPUS, VP_CPUB). Fortis pursose

ach of these boards has a connector for connecting of

a serial ine RS232 for VP_CPUM tis located on the

board VP_KON). With respect tothe fact thatthe switches

‘which endble to load the Bios, are located on the boards of

electronics, before ts loading itis necessary to uncover the

boards.

In loading the bios there is erased the processor memory, In

which thera are stored all the information on the apparatus

(apart trom the system version), therefore itis necessary,

before you record — load the bios on the beards of

electronics VP_CPUM, to backup the folowing information

(see. print...

= Configuration ofthe device

‘SELECTOMAT SL_ns_en 0911_V2.02 7

‘Service instructions

+ Setting of the device

+ Offsets

Blos Is loaded in the folloving method:

1. Start the Loader exe

2. Open the file ,BiosMibox.fis' (so as It would have a blue

ber)

vooclMst for VP_CPUM

‘Siv for VP-GPUS

ck for VP_CPUB,

3. Select ,Dowmload->Load the fle/process the batch*

4, To observe the instruction on the screen:

‘Switch over the processor inte the boot mode":

‘Switch over the Doth switches DIP on the electronics

board into position ON

= For VP_CPUM (inside the front hinged panel) DIP

RESET

+ For VP_CPUSB (the rear panel)

= For VP_CPUS (in the switchboard)

8 ‘SELECTOMAT SL, ns_en 0911_V2.02

Reset the processor by the button RESET

= Confirm the dialog

‘Walt unt on the PC in the window .Listing ofthe process"

itis sted .End .

Switch over tha processor from the boot mode"

‘Switch over the both switches DIP on the electronics

board into posttion OFF

Reset the processor by the button RESET

‘After loading the bios itis necessary again

= Toload the application

+ To perform the complete setting ofthe device including

the offsets

~ Toload the sterilization programs

Note:

Ifon the electronics board VP_CPUM or VP_CPUB there is

recorded ~ loaded only the bids, the appropriate screen is

black:

2.7.2 LOADING OF THE APPLICATION

‘The device must be in the slesping state (the process is not

running) and there must not be selected the utility service:

Download of programs". When downloading the application

there Is erased the RAM backup memory, therefore itis

necessary to racord the user's settings under the menu

items ,Seiting of the dispiay", .Print” and as well as the

number of the performed batches,

When downloading the application, the PC is connected

to the sterlizer via the connector RS232 on the electronics

board VP_KON, and also for the electronics boards

\VP_OPUS and VP_OPUB. As to be first it must be

dovinloaded the application (including the languages) into

the electronics board VP_CPUM.

The apeleation loaded nthe folowing method

‘Start the Loader exe

2 \VpeMltoc fs" (80 as it would have a blue

000 Mist

‘Sl pro VP-CPUS

Bck for VP_CPUB

pro\VP_CPUM

‘Service instructions

3. Selact .Download-> Load the flleiprocess the batch ,

4. Wait unt on the PC in the window ,Listing of the

process" there is listed ,End

5. When loading into the electronics boards VP_CPUM

open the language file .VpsMtMstLag’, for te

‘electronics board VP_CPUB ,VpsMItSckLng”

6. Select .Download-> Load the fle/process the batch,

7. Observe the instructions on the screen

= Select maximally 4 languages — they must be the

‘same as for Mst

and Bck!

Wait unt on the PC in the window ,Listing of the

process" itis listed ,End ,

2.7.3 RULES FOR WORK WITH THE PROGRAM

LOADER.EXE

Rule no. 1

It you want to download some file into the sterlizer, then

before the selecting ,Download’ the window of this fle must

have a blue bar!

Rule No. 2:

I you want to close the Hitachi Loader and it does not work,

please, select ,Download->Stop" |

Rule No. 3

ao not close the window forthe file, which Is being

downloaded !

Rule No. 4

It some action is not successful, please, repeat it (also for

several times) |

3 FUNCTION OF THE

UNIT

3.1 PIPING DIAGRAM

It within the automatics it is activated the generator, the

‘pump C1 reflls with demineralised water into the generator,

from the storage tank via the fiter F7, backflow valve V14

and valve V7. Reaching the necessary level Is secured by

the level switch B90. Aftar starting the generator the heater

elements TT begin to heat. The boller is brought onto the

‘operating pressure, which is belng scanned by the pressure

‘gauge PE3. The valve Y99 opens for approximately 2s after

every water refling to decrease concentration of salt in the

boiler. The level switch 891 secures protection of the neater

‘elements. The pressure switch B31 serves as protection

against overpressure. Valve V6 Is used for manual mud

Open’, to open the directory. in which there are stored

the appropriate data fies, in the line ,fles of the type" to

select the correct type of the flle, to choose the required

fe It must appear inthe line .name ofthe fle") and to

push the button “Open’. On the PC screen there appears

the definition field with parameters. By means of tha

cursor arrows, or by means of the mouse, the appropriate

parameters are selected and then they are modified. The

key Enter in general opens the dialog window for editing the

value of the selected parameter. A double click on the left

pushoution of the mouse substitutes the key Enter

‘The tabulator changas the active column of parameters,

Atinished packet of parameters can be stored on the

computer di

By this there are defined the files of concrete parameters,

how thay are referred to in the paragraphs about software

ais,

Itwe should define a program, we select within the program

UNICONFIG.EXE menu .Communication->Data export

By confirming the program Is transferred to the device and

there is set the following program. After downloading the

programs itis necessary to store the changes. For the:

transfer its possible to utllze also the Icons on the auxiliary

bar.

Warning:

‘The parameter changes may unfavourably influence the

sterlization cycle and therefore they may be changed only

by the authorized person. For this purpose its better to

utlize only the programs created in the manufacturing plant.

‘The manufacturing plant does not hold any responsiblity for

the damages caused by improper setting of the parameters,

‘Service instructions

4.4 DESCRIPTION OF THE STERILIZATION Tene of ‘S| Duraton time of sterization

stonteaton Fo xposurelvalve ofthe parameter Fo

PROGRAMME PARAMETERS Tampere of] "S| Required tomperature 0 stenzaion

stenizaton

‘The annexe KV_202 shows the general image of 2 ‘omporsure ‘Aso to eauedserizavon

standard sterlzaion cycle. The cycle comprises the eeatan fea {Stipe ad fom ina esting

foloning phases. preseure) Sonicaton emperatre t's

ee intl sate ‘ests oreparavon ctermoned tre epalatg pressure

. Bren Temperate] 7G] When string a esut

10 Pressurization ofthe generator one Minteaton erperatie be

" Pressurization of the jackete sn ompstrs i oxcose

3 Coe eas bein etn

{314 ——_tevacvelon- exhauston a Stain stp vl

8 ‘st evacuation - keeping vacuum tne scoames KV.200

6 ‘st evacuation - steam filing econ

7 ‘tst evacuation - pressure kept up vacuum

18 2nd evacuation - exhaustion Fressure al ‘the | kPa | see annexe KV_202

18 2nd evacuation - keeping vacuum Po ~

20 2nd evacuation - steam filing Fesugare |e [scenes W202

63,64 ‘Steaming - steam filing Pressure atthe |" kPa [see annexe KV_202)

6. Steaming - steam discharging pont

33 Heating rine 120 3 [ao amnana RDO

98 Sterilzation Number of Paramtor

39,100 Pressure release normal programs Prevacistons Scorn W202

104 Drying - exhaustion Tressue ative | —WPa ee annexe KVL200

402 Drying - pressure kept down pomt 811

4103 Drying - aeration Pressue tne | Wa | se annexe RVLZOD

104. Drying - pressure kept up. Pom TEL

140,141 Annexeary aeration Tae T21 s__[see annexe KV_202

2 Our iaedais Pressure atime | KPa] 80 amoxs Kv_202

pom

Pressure ate | Pa a0 amare KVL202

Note: . point B17 _

Athe customer's request some devices can dispose porte en RE

‘ith special erograme witn a paral diferent course, For foes fe

‘example: Solutions pregram witnseltzocling, sotions irease seen = a e

Program with forced cooling etc. levee ‘speed s ‘Time increase, speed controlling

ose

4.41 SENSE OF INDIVIDUAL PARAMETERS ages Geet] We [Romance as ComaG

indiviual parameters of striisation programmes are increase speed]| 3 | Tne wcrease speed controling

descrted n the folowing table, as they are disolayed inthe, of -tme

UNICONFIG programme forthe classical nonsoluton cycle Incense peed | Wa _ | otro roam, spot conaira

off oesear

Beamer] Unis [esenpton increase speed | 3 [Tm mcrease speed conroling

prom or tne

‘Description ‘The name of the program as it wall Paralel stairs: s Not used

Aisplayed on the dspley and will be upwerds-tme

smite ne ptr steam

age Gas. sung, Basie gars |S |Notused

sterilization BD vee pause

Stange ‘ime saber | = | Teneou betoe he serizaton

‘Switch Type of ‘Adjustment of the temperature | exposure

echialnper Cotolng sonar S00 Bo Pena = [Exhaust of condensate by pana

‘Swich Fo. ‘Switching of cycle controling exngust of ‘he valve Y20 during the heating

Sane BRS ase (eat se

Sig oe or Noted Pena at Te iran tear by pane

exhaustot frovave Wang he toning

Swicr Tum onthe a ceecor eangunsote

detector Seats et

Swich Turns ote Dacelogcal er Petod of 3 [Emraust of condensate by onenna

Broga Sete {nova Ya0 nrg he open

‘Switch Door ‘0- through chamber, 1- non through ‘steniization

iegt chanbe pause

sooo crobe olpessue Hew ihe Boros oF Tie | Banat of condoneate by anon

‘ante ot ‘an of pessre Wisin eames, eee]

Sess cndansate

‘eatnet

‘SELECTOMAT SL_ns_en 0911_V2.02

17

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- ACM619 Service Manual I ACM619 Anesthetic Workstation: O2 Ppeak FDocument14 pagesACM619 Service Manual I ACM619 Anesthetic Workstation: O2 Ppeak Fhem midlands100% (2)

- Technical Bulletin: i-STATDocument4 pagesTechnical Bulletin: i-STAThem midlandsNo ratings yet

- Autoclave Repair and TroubleshootingDocument5 pagesAutoclave Repair and Troubleshootinghem midlands100% (2)

- Import Setting From USBDocument2 pagesImport Setting From USBhem midlandsNo ratings yet

- Autoclaving at 121 DegreesDocument13 pagesAutoclaving at 121 Degreeshem midlandsNo ratings yet