Professional Documents

Culture Documents

Denso CRD Injectors: Toyota 1KD-FTV: 2005 - 2018 Hiace 2005 - 2015 Hilux 2006 - 2015 Prado Injector Operation

Denso CRD Injectors: Toyota 1KD-FTV: 2005 - 2018 Hiace 2005 - 2015 Hilux 2006 - 2015 Prado Injector Operation

Uploaded by

Kumar HemrajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Denso CRD Injectors: Toyota 1KD-FTV: 2005 - 2018 Hiace 2005 - 2015 Hilux 2006 - 2015 Prado Injector Operation

Denso CRD Injectors: Toyota 1KD-FTV: 2005 - 2018 Hiace 2005 - 2015 Hilux 2006 - 2015 Prado Injector Operation

Uploaded by

Kumar HemrajCopyright:

Available Formats

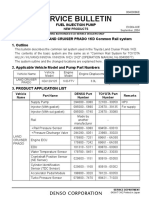

Denso CRD Injectors: Toyota 1KD-FTV

Denso CRD

Injectors:

Toyota 1KD-FTV

2005 - 2018 Hiace

2005 - 2015 Hilux

2006 - 2015 Prado

The 3.0L 1KD-FTV turbo common Injector Operation

rail diesel engine has gone

The 1KD-FTV uses the Toyota D-4D

through a few revisions since its

System which stands for “Direct

introduction to Australia in 2005.

Injection 4 Cylinder Common Rail

This article will cover the injectors,

Diesel Engine” of which the main When the engine is running high-

which is one of the areas that is

components (pump and injectors) pressure diesel is constantly supplied

catching many technicians out,

are supplied by Denso. Below is a to all the injectors via the common

as they assume that all 1KD-FTV

basic overview of the injector, and its fuel rail. Unlike diesel engines of the

engines are the same, which is not

operation which is similar to other past, a solenoid or piezo-actuator

the case.

common rail systems. along with the high-pressure diesel is

Diagram #1

Basic Operation of the Denso CRD Injector

High Pressure Return Wiring

Pressurised fuel from

Two-Way Valve

the pump pushes down

(TWV) Solenoid

on the command piston

which forces the nozzle Bleed Orifice

needle valve closed.

Control Chamber

Command

Nozzle

Pressure Piston

Needle

Shoulder

When the TWV Solenoid is energised, it opens the bleed orifice which reduces the pressure in the

control chamber. The high-pressure fuel can now press on the pressure shoulder of the nozzle

needle which raises the needle from the seat which allows fuel to be injected. When the TWV is

turned off the fuel pressure in the control chamber raises and closes the nozzle needle again.

Tech Talk – November 2018 4601

Denso CRD Injectors: Toyota 1KD-FTV

used to open and close the injectors to opening and closing of the injector for events to occur, common rail system

allow a more accurate delivery of fuel fuel delivery. See Diagram #1 injectors require high voltage and a

into the combustion chamber. current control mechanism to operate

As these injectors are computer

effectively.

The high-pressure fuel that enters the controlled, it is now possible to

injector is split in two directions. Some have multiple injection events for As a result, the ECU uses an Electronic

is directed down to the nozzle and the one combustion cycle which greatly Driving Unit (EDU), which generates

majority is sent to the control chamber. increases output and efficiency of the approximately 110 volts and high

The actuator circuit is used to alter the engine. To overcome the high fuel current to open the injectors. Once

pressure between the control chamber pressures present, and to operate open the voltage drops back to 12

and the nozzle, therefore, allowing the fast enough for the multiple injection volts in a current controlled mode

to keep the injector open. As the

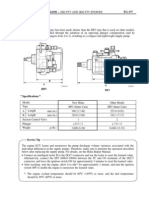

Diagram #2 EDU is a significant contributor to

Injector Driver Unit the operation of the injectors its

The injector driver is operation should not be overlooked

used to raise the voltage when diagnosing systems. A more

detail explanation of its operation is a

and current to allow the

story for another day.

injectors to complete

See Diagram #2

multiple injection events for

each compression stroke. To cope with the extremely high

pressures, multiple injections per

WARNING: The injector combustion cycle and high voltage

driver can produce and current, modern injectors are

dangerous levels of voltage built to very fine tolerances, which

and current. means small changes can affect

Diagram #3

2009-2011 Hilux 1KD-FTV Injector Wiring Diagram

Wire Colour Legend Connector

Black B Blue L Red R White W Tan T

Example of Wire Coding B/W Brown BR Dark Blue DL Sky Blue SB Yellow Y

ECU Green G Light Green LG Silver SI Pink P

Splice

Grey GR Dark Green DG Orange O Violet V Shield Wire

Black White

A25

A24

A23

A22

A21

A32

A7

Common Earth for W/B P B/W R V Y/R GR Y BR 1 2 W/B A6

W

Throttle Body

and Turbo Driver

Pressure

Discharge

Valve

G1

H5

H4

H8

H7

H3

H2

F3

F4

Injector Driver (EDU)

G6

G4

G2

G3

G5

F2

F1

F6

F5

B W B P L Y L W B

2 2 2 2

W/B

1 1 1 1

No.1 No.2 No.3 No.4 BR

Injector Injector Injector Injector

A5 A4 A3 A2 A1 B5 B2

From EDU

Relay

4602 Tech Talk – November 2018

Denso CRD Injectors: Toyota 1KD-FTV

the operation of the common rail

Injector Seals / Washers poor fuel quality they can start to

systems. jam the nozzle and command piston

When first released the 1KD-FTV when the engine is cold. This will

I will now run through the different

engine used copper washers to seal allow an incorrect amount of fuel to

areas that cause problems.

the injectors to the head. Failures in be injected. Some of the symptoms of

Fuel Quality this area would allow combustion this problem are:

gases into the valve cover which

As stated earlier common rail would turn the oil into sludge. If left • Loud engine knock when the

injectors are working very hard under unchecked it has been known to block engine is cold

extreme pressures. Depending on the the oil pickup in the sump and starve

quality of the fuel that has been used • Rough idle

the engine of oil, which destroys the

the average life-span of the injectors

may decrease. Good fuel quality can

bearings. However, the turbo bearings Injectors Worn:

seem to be the first to go.

see your common rail diesel system Hot Engine Knock

continue to operate up to and beyond There has been an updated part

If the clearances inside the injectors

the expected life of the vehicle. for the injector seals. So, if you are

become too large, this will also allow

replacing the injectors, never reuse

excess fuel to be injected

Injector Compensation the old seals and make sure you are

Values using the updated seals. Symptoms include:

A scan tool’s live data can be very Some technicians are inspecting the • Lack of fuel economy

helpful in finding the cause of engine oil pickups for carbon build up at each

service with an endoscope through • Rough idle

trouble. The ECU will tune itself over

time to achieve the smoothest idle by the sump plug hole, and if it is looking • Rough running with low load and

increasing or decreasing the amount blocked they remove the sump and engine speed

of fuel injected. Injector compensation clean it out and replace the injector

seals. If you are replacing the injectors • Black smoke from the exhaust

values are a guide to potential

issues and need to be looked at in you should check the oil pick up. NOTE: Further diagnosis is required

conjunction with other data to assess See Diagram #4 at this point as these are similar

the performance of the injectors. Some of the symptoms of this symptoms to a cracked piston.

problem are: Conduct a compression test to

NOTE: Compensation values should

confirm.

only be used as a guide as there are • White smoke from the exhaust

other mechanical variables that can and engine rattles from a cold Once you have completed the above

cause them to be out of specification. start diagnostic checks you should be

Some of the main culprits are intake • Sludgy oil confident that the injectors are the

manifolds blocked with carbon and • Blocked oil pick up problem.

low compression. You should check

for these problems first, then move Injectors Worn: Injector Coding Problems

on to the fuel system starting with Cold Engine Knock VACC’s Technical Advisory Service has

the suction control valve, then the been receiving calls from members

injectors and high-pressure pump. As the injectors wear through normal

that have fitted a set of injectors and

operation over the life of the product

they will not code to the ECU. After

Electrical Problems or have had premature wear through

some interrogation from our Technical

As these injectors are electrically

triggered, there can be electrical Diagram #4

If an injector seal fails, it will cause the oil to become sludgy,

faults which can cause problems. Oil Pick Up and it will block the oil pickup. You can check this through

Loose connections and damaged

wiring will usually trigger a fault code the sump plug hole after draining the oil.

in the system. The injector solenoid

can be checked with the following

procedure.

• Turn Ignition OFF.

• Disconnect the harness from the

injector.

• Measure the resistance across the

injector terminals

• It should be 0.42 -0.52 Ω at 20˚C

Tech Talk – November 2018 4603

Denso CRD Injectors: Toyota 1KD-FTV

Advisors, the full story comes out. What injectors which are compatible with Pilot Quantity Learning

has happened is that a second-hand set the Euro specification of your engine

of injectors or an entire second-hand and its ECU. Use the table as a guide After the injectors have been fitted

engine has been fitted to a vehicle and for what you have. If your vehicle is and coded to the ECU, the Euro IV and

the ECU will not accept the codes or close to the changeover date for Euro above specification engines will need

if it does the engine is over fuelling or III and Euro IV it could be either. If the to go through a separate relearning

lacking power. This is a common trap as EGR valve does not have coolant pipes procedure. Failure to complete this will

many people assume that all 1KD-FTV it is Euro III, if it does have coolant result in the ECU recording the DTC

engines are the same as parts can be pipes running to it, then it is Euro IV. P1601: Injector compensation code.

fitted from early to later models. This is See Diagram #6 1. With a compatible scan tool, under

an incorrect assumption. To be sure, remove one injector and

special or guided functions, select

quote the part number which is on the

Since this engines introduction it has “Pilot Quantity Learning”

body of the injector to make sure you

had to be updated to meet the tighter NOTE: This is the same for other

get the same Euro specification.

emissions regulations and one of the vehicles with Denso system,

See Diagram #7

ways this has been done is by changing Mitsubishi call it “Small Injection

the specifications of the injectors. As WORKSHOP TIP: Quantity Learning” other

you can see in the table, this engine has

It is recommended that you attempt manufacturers will have a different

had to comply with Euro III, IV and V

to code the injectors to the ECU variation.

specifications. Each change has brought

with it new components and updated before you fit them to the engine. 2. With the vehicle in neutral, start

systems. See Diagram #5 This will save you time and a set of

the engine and allow it to idle.

high-pressure pipes if they are not

Even though the injectors will look compatible. 3. When operating temperature

identical they are not interchangeable NOTE: Many suppliers will not accept is reached, select the option to

from one Euro specification to another. returned injectors if they have been commence the relearn procedure.

The first piece of advice is, do not fit fitted to an engine. The “Glow Plug” light on the dash

second-hand injectors as you might It is good practice to write the injector should now be flashing, indicating

be fitting more trouble. New and codes on a piece of paper in the that the relearn procedure has

reconditioned injectors will be sealed, order you will be fitting them before started.

second-hand injectors might have been entering the codes into the scan

open in a dusty shed and it only takes a 4. Quickly increase the engine speed

tool. Human error is also common

very small amount of contamination to in failures to code injectors, as the to 3000 rpm for 1 second, then

cause problems. codes are small it is easy to misread allow it to return to idle.

Second, only fit new or reconditioned the digits and letters (B’s and 8’s are a 5. Continue to cycle the engine in

common mix up).

the above step until the scan tool

indicates that learning is complete.

Diagram #5 NOTE: This might take a long time.

Types of 1KD-FTV engines. Euro Emission Specification 30 cycles on average, we have

heard that some take over 100

Model Euro Specification Year Range Output cycles.

Hiace Euro III 2006 to 2010 80 kW 6. P1601 can now be cleared.

Hiace Euro IV 2010 to 07/2015 100 kW Injector Removal

Hiace Euro V* 07/2016 to 2018 100 kW

1. Remove the engine cover.

Hilux Euro III 2005 to 07/2006 120 kW

Hilux Euro IV 08/2006 to 05/2008 127 kW 2. Remove the vacuum hoses and

wiring from the MAP sensor.

Hilux Euro V* 2009 to 2015 127 kW

Prado 120 series Euro IV 08/2006 to 11/2007 127 kW 3. Remove the intercooler.

Prado 150 series Euro IV 2009 to 2009 127 kW 4. Disconnect the wiring harness from

Prado 150 series Euro V* 2009 to 2015 127 kW the injectors.

*NOTE: There is some debate about what is classed as a Euro V spec 1KD-FTV 5. Remove components as necessary

engine. There was a change in injector design in 2009 which some injector

re-manufacturers are calling a Euro V spec injector. However, Denso does not to gain access to the high-pressure

agree. They say the only Euro V Hilux and Prado are those fitted with the new injector pipe at the fuel rail.

1GD engine. There is a Euro V 1KD-FTV in the Hiace from 2016. Always check the

injector part numbers to get the correct injector for your engine and vehicle. 6. With a 17mm injector pipe socket

4604 Tech Talk – November 2018

Denso CRD Injectors: Toyota 1KD-FTV

Diagram #6

1KD-FTV Engine Layout Injectors

One way to check what sort of 1KD-FTV you have is

by checking the EGR cooler. If it has coolant pipes, it is

Euro IV spec. No coolant pipes it is Euro III.

NOTE: There are different designs of EGR coolers.

Injector pipe seals

Fuel Rail

EGR Cooler

EGR Cooler

loosen the high-pressure injector and fuel rail and discard. injector leak off pipes. Discard the

pipes at the injectors. NOTE: These are single-use items. washers.

NOTE: Cover the injectors with a

9. Using a screwdriver, pry out the 13. Remove the banjo bolt from the

rag to prevent fuel from running

four injector pipe seals from the leak off pipe to the head.

into the valve cover.

valve cover. See Diagram #6

14. Remove the bolts from the

7. Remove the injector pipe

10. Remove all hoses from the valve injector clamps and discard the

brackets that attach to the intake

cover. washers.

manifold.

11. Remove the valve cover. 15. Remove the injectors. If they

8. Remove the high-pressure

injector pipes from the injectors 12. Remove the banjo bolts from the are to be refitted record their

Diagram #7

Injector Part Number Location

The only way to know for sure which

injectors your engine has is to remove

one and quote the part number on

the side of the injector body. When ordering parts, you need the

following information to get the correct

injectors:

1. Make, Model and Year

2. VIN

3. Part Number from the injectors

It is essential to give the correct

vehicle deals to make sure that you get

injectors which are compatible with

the ECU in the vehicle. Otherwise, the

injectors will not code to the ECU.

Tech Talk – November 2018 4605

Denso CRD Injectors: Toyota 1KD-FTV

original position. NOTE: If the the valve cover. Then fit SST (17 mm crows foot spanner), or

injector seal has failed the injector 09280-00010 to the head and 35 Nm if using an injector pipe

might be stuck in the head due to apply 250 kPa of air into the leak socket.

carbon build up. A puller might be off pipes. Then drip engine oil

13. Tighten injector pipe clamps to

required to remove the injector. over each of the banjo bolts and

5 Nm.

check for bubbles. Repair leaks as

16. Remove all injector seals from the 14. Refit all other components in

necessary.

head and discard. reverse order.

9. Fit a new valve cover gasket and

Installation refit the valve cover. Tighten the 15. Bleed the system by pumping

NOTE: If fitting new injectors, you bolts to 9 Nm. the lift pump on the fuel filter

should code them to the ECU before until it goes hard.

10. Install four new injector pipe seals

installation to make sure they are

into the valve cover. 16. Carry out the Pilot Quantity

correct for the vehicle.

See Diagram #6 Learning procedure with a scan

NOTE: If refitting the injectors, be sure tool. See page 4604.

to refit them in their original positions 11. Fit the NEW injector pipes to the

otherwise you will have to re-code injectors and fuel rail, along with 17. Start the engine and check for

them to the ECU. the clamps. Do not tighten them fuel and oil leaks.

at this stage.

1. Fit new injector washers/seals into For more information on the 1KD-

the injector hole in the head. 12. Tighten each injector pipe at the FTV engine, log in to Tech Online

See Diagram #8 fuel rail first then at the injector to or call VACC’s Technical Advisory

32 Nm if using SST 09023-12701 Service.

2. Fit new “O” rings to the injectors

with clean engine oil.

3. Install the injectors into the head Diagram #8

in the correct order Injector Clamp and Washers.

4. Fit the leak off pipe to the injectors

with new washers on the banjo

When replacing Injector Clamp

bolts. Do not tighten fully at this

injectors they must

stage.

be all of the same

5. Install the injector clamps and type, you can not

bolts with NEW washers. mix and match Euro

See Diagram #8 specifications.

6. Tighten the injector clamp bolts to You must also replace

22 Nm. the washer on the

7. Tighten the injector leak off banjo injector clamp and

bolts to 16 Nm. the washer at the

nozzle end.

8. Tighten the injector leak off banjo

bolt to the head to 13 Nm. “O” Ring

NOTE: The workshop manual now

recommends that you pressure

test the leak off pipes as follows.

Remove the leak off fitting from

the rear of the head outside of

We would like to thank the team at Cornell Diesel

Systems for their assistance with this article

cornells.com.au

4606 Tech Talk – November 2018

You might also like

- E ECD0106Document3 pagesE ECD0106Miguel Chacon100% (5)

- Denso Toyota Hilux Common RailDocument68 pagesDenso Toyota Hilux Common RailRonald Yanes93% (72)

- Piezo Injector CurrentDocument6 pagesPiezo Injector CurrentSutikno100% (2)

- 1KD FTVDocument10 pages1KD FTVnicamarcos100% (7)

- HINO J08C J05C Type Engine PDFDocument29 pagesHINO J08C J05C Type Engine PDFDiego Cadena100% (3)

- GDI DENSO InjectorsDocument19 pagesGDI DENSO InjectorsPāvels SmilgaNo ratings yet

- Governors For Inline Injection Pumps PDFDocument58 pagesGovernors For Inline Injection Pumps PDFOlivier ORMAN92% (26)

- TH Catalog For Oerlikon Fairfield MFG - 08 PDFDocument212 pagesTH Catalog For Oerlikon Fairfield MFG - 08 PDFFernando Sabino100% (5)

- Ecd V4Document28 pagesEcd V4Mark100% (5)

- EECD0001Document36 pagesEECD0001Sergey Gusev100% (3)

- CR InjectorDocument15 pagesCR Injectortransl637986% (7)

- Denso g4Document6 pagesDenso g4DenisEcheverri50% (4)

- 4m41 Pump160061130 Bomba VE VRZ EE14E 11162 VRZ Service ManualDocument117 pages4m41 Pump160061130 Bomba VE VRZ EE14E 11162 VRZ Service Manualesyjam67% (3)

- DENSO X2 InstructionDocument13 pagesDENSO X2 InstructionAnonymous 5tkF5bFwO100% (3)

- Common Rail Injector Repair Tool Sets Instruction ManualDocument17 pagesCommon Rail Injector Repair Tool Sets Instruction ManualAnonymous 5tkF5bFwO100% (1)

- Denso InjectorDocument20 pagesDenso Injectoraddelyn_robescu8794100% (7)

- Denso Common Rail Injector Test Data PDFDocument28 pagesDenso Common Rail Injector Test Data PDFFernando SanchezNo ratings yet

- Denso Cri Repair Guide v4Document22 pagesDenso Cri Repair Guide v4Misuka Misi97% (38)

- Denso Procedure For Servicing 2 Nozzles InjectorsDocument41 pagesDenso Procedure For Servicing 2 Nozzles InjectorsCostas Ponehundred75% (4)

- YwDocument36 pagesYwBogdan Batakovic100% (2)

- 1kd-Ftv and 2kd-Ftv FipsDocument8 pages1kd-Ftv and 2kd-Ftv FipsSultan Ahmed Khan100% (23)

- Nawa e Saliheen Book PDF Free Mirrors A 86456703Document1 pageNawa e Saliheen Book PDF Free Mirrors A 86456703Zahid Hussain100% (4)

- Commonrail Diesel AK TrainingDocument8 pagesCommonrail Diesel AK TrainingCOMENONo ratings yet

- Common Rail DensoDocument9 pagesCommon Rail Densocapra7093% (15)

- Piezo ElectricmeteringDocument7 pagesPiezo Electricmeteringeko sulistyo utomo100% (1)

- Repair Guide For Denso Common Rail Injector RepairDocument22 pagesRepair Guide For Denso Common Rail Injector Repairrafael100% (1)

- Unit InjectorsDocument26 pagesUnit InjectorsKumar ByesNo ratings yet

- Denso Bosch Common RailDocument29 pagesDenso Bosch Common RailCiprian Albert100% (27)

- NGD 0605 S enDocument154 pagesNGD 0605 S enJuan José Rodriguez100% (15)

- Calibracion Doble ResorteDocument60 pagesCalibracion Doble ResorteHector Jamaica100% (6)

- EPS 205 Frequently Asked Questions 2 8.28 PDFDocument32 pagesEPS 205 Frequently Asked Questions 2 8.28 PDFDarshan Diesel100% (2)

- Common Rail Injector Repair ProcedureDocument4 pagesCommon Rail Injector Repair ProcedureSoeAye100% (6)

- Iniettori Delphi e DensoDocument1 pageIniettori Delphi e DensoAmadeus De La CruzNo ratings yet

- CRDI ManualDocument14 pagesCRDI ManualVinAy SoNi80% (5)

- 8th Session Injector Construction and OperationDocument4 pages8th Session Injector Construction and OperationВячеслав ГлушакNo ratings yet

- Control FuellDocument51 pagesControl FuellGuadalupe GuerreroNo ratings yet

- Module 05 - Valve TrainDocument4 pagesModule 05 - Valve TrainJefford Vinson Valdehueza100% (1)

- 3000EM Common Rail Test StandDocument1 page3000EM Common Rail Test StandkampeeNo ratings yet

- CRS (ECD-U2P) For Land CruiserDocument45 pagesCRS (ECD-U2P) For Land CruiserВячеслав ГлушакNo ratings yet

- Power Steering PumpDocument8 pagesPower Steering PumpFordiNo ratings yet

- Flow Control Valves DVE: Up To 350 Bar Up To 160 L/minDocument5 pagesFlow Control Valves DVE: Up To 350 Bar Up To 160 L/minVijay BhureNo ratings yet

- Delphi Codigos de Calibracion Del InyectorDocument8 pagesDelphi Codigos de Calibracion Del Inyectorghostrpg100% (3)

- Intake System: Parts LocationDocument7 pagesIntake System: Parts LocationMenzie Peter RefolNo ratings yet

- Diesel Edc 3 PDFDocument22 pagesDiesel Edc 3 PDFRadu CristinaNo ratings yet

- Priorety and Orbitrol CircuitDocument8 pagesPriorety and Orbitrol CircuitIslam ShoukryNo ratings yet

- EUCASS2017-490Document8 pagesEUCASS2017-490Alex LNo ratings yet

- Evopicv Tech Manual en 5a62d7d99eDocument80 pagesEvopicv Tech Manual en 5a62d7d99eAmando GonzalesNo ratings yet

- Pompe Clu3 E1001 Carte TehnicaDocument2 pagesPompe Clu3 E1001 Carte TehnicaAnonymous RCPxaonfvNo ratings yet

- Of Your Slips, Bumps, & Shudders With These Unique TCC Control FixesDocument3 pagesOf Your Slips, Bumps, & Shudders With These Unique TCC Control FixesAqidi MohammadNo ratings yet

- Maintenance Plan FINAL3.docx33333333Document12 pagesMaintenance Plan FINAL3.docx33333333Lungelo HlongwaneNo ratings yet

- Oil Hydraulic Rotary Flow Dividers and Pressure IntensifierDocument8 pagesOil Hydraulic Rotary Flow Dividers and Pressure IntensifierHans BartelsNo ratings yet

- 02_S_667-INT250-71000399-1-147092381757ac84290eef68.46127207Document1 page02_S_667-INT250-71000399-1-147092381757ac84290eef68.46127207IDEA RefrisolICENo ratings yet

- Priorety and Orbitrol CircuitDocument8 pagesPriorety and Orbitrol CircuitIslam AttiaNo ratings yet

- Trans Chapter5Document80 pagesTrans Chapter5Sivapriya SamyNo ratings yet

- Unit 2: Load Sensing, Pressure Compensated Hydraulic SystemsDocument19 pagesUnit 2: Load Sensing, Pressure Compensated Hydraulic SystemsMohammed KhalidNo ratings yet

- 103 Series - DS - EN - 04.2011 - V1.4Document4 pages103 Series - DS - EN - 04.2011 - V1.4rafael lalaNo ratings yet

- The Gentle Giant of NiederaussemDocument6 pagesThe Gentle Giant of Niederaussemjayesh gohilNo ratings yet

- Reducing Fuel ConsumptionDocument26 pagesReducing Fuel Consumptioncharliek500No ratings yet

- Application Center Backhoe Loaders: Head: Philippe FillonDocument12 pagesApplication Center Backhoe Loaders: Head: Philippe FillonStar SealNo ratings yet

- FlowCon Topic Letter PICV Vs Conventional SolutionDocument3 pagesFlowCon Topic Letter PICV Vs Conventional Solutionmohamed ghareebNo ratings yet

- 04_Intro_Non_Standard_ApplicationsDocument19 pages04_Intro_Non_Standard_ApplicationsShakerMahmoodNo ratings yet

- 03 Ts 51Document4 pages03 Ts 51giovanni ampueroNo ratings yet

- HazratAbuTalibNabiThayYaWasi PDFDocument338 pagesHazratAbuTalibNabiThayYaWasi PDFZahid HussainNo ratings yet

- Gaya Waqt Phir Hath Ata Nahi PDFDocument52 pagesGaya Waqt Phir Hath Ata Nahi PDFZahid HussainNo ratings yet

- AasmaniNaseehatain1of2 PDFDocument124 pagesAasmaniNaseehatain1of2 PDFZahid HussainNo ratings yet

- YouthAndStress PDFDocument19 pagesYouthAndStress PDFZahid HussainNo ratings yet

- Grade 1 History: Madrasat Ahlul'Bait Islamic SchoolDocument69 pagesGrade 1 History: Madrasat Ahlul'Bait Islamic SchoolZahid HussainNo ratings yet

- ShakiyateNamaz PDFDocument4 pagesShakiyateNamaz PDFZahid HussainNo ratings yet

- مقتل لھوف PDFDocument163 pagesمقتل لھوف PDFZahid HussainNo ratings yet

- WBDK CompanyprofileDocument24 pagesWBDK CompanyprofilePiet VeermanNo ratings yet

- FlacDocument454 pagesFlacMaria Paula Pineda MartínezNo ratings yet

- Oliver Injection Double Block ProductsDocument3 pagesOliver Injection Double Block Productsandy131078No ratings yet

- Pile Load TestDocument6 pagesPile Load TestChristian JhansiNo ratings yet

- Lockout / Tag Out Program: Presented by DOSHTIDocument21 pagesLockout / Tag Out Program: Presented by DOSHTIKanupriya100% (1)

- HI Design DatasheetDocument4 pagesHI Design DatasheetTran KieuNo ratings yet

- HCU2040PXB1: Hubbard Products LTD Hermetic R744 Condensing UnitsDocument169 pagesHCU2040PXB1: Hubbard Products LTD Hermetic R744 Condensing UnitsLinh Tran NgocNo ratings yet

- CE323 Quantity Surveying Lecture 5.1Document54 pagesCE323 Quantity Surveying Lecture 5.1Alec PantaleonNo ratings yet

- Sealing Deck PenetrationDocument2 pagesSealing Deck PenetrationEddie ChanNo ratings yet

- Chapter-6b Welded Connection CENG417Document28 pagesChapter-6b Welded Connection CENG417zakai zakiNo ratings yet

- b8b8m LinecardDocument4 pagesb8b8m LinecardJEVNo ratings yet

- Experiment 132: Determination of The Viscosity Coefficient of A Liquid and The Temperature-Viscosity DependenceDocument3 pagesExperiment 132: Determination of The Viscosity Coefficient of A Liquid and The Temperature-Viscosity DependenceMphoentle MaleboNo ratings yet

- Inventory Cfm56 5Document4 pagesInventory Cfm56 5Fitrah Firdaus100% (1)

- Dryer DesignDocument39 pagesDryer DesignPrashanth Chidambaram75% (4)

- d12 Series PDFDocument112 pagesd12 Series PDFSilviaCuevaNo ratings yet

- Gravity Sewer Acceptance Testing Results Sheet: Sewer Pipeline Pressure TestDocument1 pageGravity Sewer Acceptance Testing Results Sheet: Sewer Pipeline Pressure TestLulouch Raiz100% (1)

- Review of The Shear-Stress Transport Turbulence Model Experience From An Industrial PerspectiveDocument13 pagesReview of The Shear-Stress Transport Turbulence Model Experience From An Industrial PerspectiveVyssionNo ratings yet

- Atkins Wind Loads On Steel Box GirdersDocument10 pagesAtkins Wind Loads On Steel Box GirdersMarcoFranchinottiNo ratings yet

- Ycm Company BrochureDocument28 pagesYcm Company BrochureCNC SYSTEMSNo ratings yet

- Amarillo Endurance-OM-09.2022Document8 pagesAmarillo Endurance-OM-09.2022Anonymous CMS3dL1TNo ratings yet

- Fuel Injection Aua, Aub, Bby, BBZ, BkyDocument148 pagesFuel Injection Aua, Aub, Bby, BBZ, Bkylordmb2002No ratings yet

- Please Take Two 2 Digits After Decimal For Calculations.: Rename "Quiz4"Document2 pagesPlease Take Two 2 Digits After Decimal For Calculations.: Rename "Quiz4"Pravesh KumarNo ratings yet

- Iron PilesDocument6 pagesIron Pileschino1286No ratings yet

- Building Services III-hvac NotesDocument28 pagesBuilding Services III-hvac NotesSri SandhiyaNo ratings yet

- Bobcat Technical Information Bulletin - CompressDocument2 pagesBobcat Technical Information Bulletin - Compressgerman orejarenaNo ratings yet

- Hanil Catalogue (2012)Document100 pagesHanil Catalogue (2012)Soma GhoshNo ratings yet

- Clogging IndicatorDocument30 pagesClogging IndicatorIrman RostamanNo ratings yet

- Styrolution TDS401600170785Document3 pagesStyrolution TDS401600170785shahin_723No ratings yet

- 2020 - Open Channel Flow - Lecture NotesDocument16 pages2020 - Open Channel Flow - Lecture NotesAhmed MaherNo ratings yet