Professional Documents

Culture Documents

Irc-43-1972 Tools-Equipment-And-Appliances-For-Concrete-Pavement-Construction

Irc-43-1972 Tools-Equipment-And-Appliances-For-Concrete-Pavement-Construction

Uploaded by

Ashok Kumar Saha0 ratings0% found this document useful (0 votes)

20 views40 pagesOriginal Title

irc-43-1972 tools-equipment-and-appliances-for-concrete-pavement-construction

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views40 pagesIrc-43-1972 Tools-Equipment-And-Appliances-For-Concrete-Pavement-Construction

Irc-43-1972 Tools-Equipment-And-Appliances-For-Concrete-Pavement-Construction

Uploaded by

Ashok Kumar SahaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 40

IRC: 43-1972

RECOMMENDED PRACTICE

FOR

TOOLS, EQUIPMENT

AND

| APPLIANCES

FOR

CONCRETE PAVEMENT

CONSTRUCTION

Published by

THE INDIAN ROADS CONGRESS

Jamnagar House, Shahjahan Road,

New Delbi:110011

1996

Price Rs.40/-

(Plus Packing & Postage Charges)

IRC: 43-1972

RECOMMENDED PRACTICE FOR TOOLS, EQUIPMENT

AND APPLIANCES FOR CONCRETE PAVEMENT

CONSTRUCTION

1. INFRODUCTION

11, Even though greater mechanisation of concrete pavement

construction has a lot to commend itself both from. the point of

quality and output of construction, in view of peculiar socio-econothic

infra-structure of our country most of our constructions are bound to

be carried out with a minimum of mechanisation for quite some time,

In addition to small mechanised units, semi-mechanised concrete

pavement construction requires a number of emall, though none-the-

less special, tools and appliances. for various manual phases. While

comparatively larger units. such as those for baiching of concrete

materials, mixing and compaction of concrete, etc., are manufactured

commercially in the country. and standard specifications for these exist

oensure their performance, no_such standards are available for the

smaller tools and appliances. They are also not commercially avail-

able and have normally (o:be got fabricated by the field engineer for

the particular project.

1.2, In the absence of any guidelines in respect of these smatler

tools and appliances, the field engincers have been experiencing. diff

culties when executing concrete paving jobs. It has, therefore, been

felt necessary to. provide some bass for the fabrication of such’ tools

and appliances in keeping with the performance requirements, by

way of three dimensional skeiches and brief description of the essen-

tial features. For plants fabricated commercially, reference has been

drawn to the relevant standards,

13. This recommended practice was prepared by the Cement

Concrete Rozd Surfacing Committee (personne! given below). TL was

then processed and approved by ihe Specifications and Standards

Committee in their meeting held on the 18h and 19th November 1971.

Later, it was finally approved by the Executive Commitice in their

meeting held on the 26t1 and 27th April 1972 and by the Council in

their 78th meeting held at Nainital on the 10th July, 1972.

This recommended practice is closely allied to IRC: 15-1970*

and should be used in conjunction with that standard.

* ‘Stanéard Specifications and Code of Practice for Construction of Concrete

Roads"

IRC: 43-1972

PEtsonnet. oF Tit Cones ConcesT# ROAD SURFACING COMMITTEE

1. Shri KK. Nembiar — Convenor

2. Dr. R.K. Ghosh = Member-Seeretary

Members

Shei MM, Bose 1, Shri A.R. Satyanarayana Rao

Shri B.R. Chopra 12, Shei N.V. Shastry

5. Dr. MAP. Dhir 13. Shri $.B.P, sinha

6. Shri C.LIN, Tyengar 14. Shei S.N. Sinha

1, Shri M.D. Kale 15. Shri N.S, Surya

8 Dr SK. Khanna 16. Shei HG. Verma

9. Col. O.P, Narula 17, Dr. ILC, Visvesvaraya

10, Shri N.L. Patel

2, TOOLS, EQUIPMENT AD APPLIANCES

A list of tools, plants and appliances required for semi

gonerete pavement construction as practised in. this

country; is given below. The list is arranged according 10 different

Phases of work, starting from subgrade compaction io the sealing oF

Phase I. Subgrade & Seb-Base Compaction

(D Commrction equipment \three wheeled or tandem roller, pneumatic

roller, vibratory roller‘ sheep eo olen

GY SaagTine deviees (water-ories, Bhistes. (water eariers) or watering

ans)

Phase 2. Fixing Formwork & Preparing the Sub-Base for Conereting

i) Formwork and iron stakes

) Bulk-bead

Aili) Scratch templates or strike bourds

(iv) Pick axes, shovels & spades

Phase 3. Couerete Manufacture

(Shovels and spades

Gi) Sieving serceas

‘Weigh butcher! Aggregate measuring boxes

iv)" Water pump

() Water measures

(i) Concrete mixer

Phase 4. Transportation, Laying’and Compaction of Concrete

Whee! barrous)tron pans

Wooden bridges

Spades

IRC: 41-1972

(ix. Concrete vibrators: Tuternal and Screed type

(©) Wooden heed tamper

Phase 5, Finishing Operations : Surface & Joints

@) Wooden bridges

Float

"Three metre long straight edge

Mild steel sections for making joint grooves

Eidglng Tools; edging tool & double-edging too!

Canvas belt

Long handled broom

Graduated wedge gauge & straight edge

Diamond extir (for making sat-cut joins)

‘Grinder (for gringing Toes! high spo)

Phase’6. Curing

{Hessian cloth oF polyethylene shesting

Phase 7. Cleaning & Sealing of Joints

() Tron caker

Gi) Coir brush

Gi), Cyele pump

{Wy) Kerosene stove

{v)_ Thermometer

(vi) ‘Ceamserring pot

Gi) Painier brush

(iit) Rousing kewle

(is) Seruper

2.2. Plate [illustrates the various tools, plants and appliances

arranged on a flow chart of concfete pavement construction in accor

dance with the phase of construction in which required.

23, Apart from the tools, equipment and appliances required

for construction, as mentioned in para 2.1,, it will be necessary to set-

up a well-equipped field laboratory for regularly, carryiig out quality

control and acceptance checks. Equipments required for such a

Inboratory are listed in Annexure 2,

3. MATERIALS FOR TOOLS, EQUIPMENT AND APPLIANCES.

Materials used in the manufacture of tools, equipment and

appliances should conform to the relevant Indian Standards, whenever

such standards exist. Standards for the” mnost frequently’ empleyed

materials, viz., mild stecl, wood and wood screws are given below :

(1S: 3629-1966 Specifications for Structural Timber in

Building,

te: 43.1972

(ii) 18: 226-1969 Specitications for Structural Steel (Standard

Quality).

(iil) 18 ; 808-1964 Specifications for Rolled Stecl Beam, Channel

and Angle Section.

(is) 18: 3954-1966 Specifications for Hot Rolled Steel Channel

Section for General Engineering Purposes.

(s) 18: 451-1961 Specitications for Wood Screws.

(i) 18+ 1173-1967 Specifications for Hot Rolled and Slit Stee!

Tee Bars.

Standards for other materials, needed only for particular tools,

ate indicated under description of the concerned tool, Where no

Standards. are available, the materials used should be of approved

quality to ensure satisfactory performance.

4A. OUTLINE SPECIFICATIONS FOR TOOLS,

EQUIPMENT AND APPLIANCES

4.1, Phase 1: Subgrade and Sub-base Compaction

4.1. Compaction equipsent

Road rollers for compaction of subgrades and sub-bases shoul

be 6-8 or 810 tonne three wheel or tandem smooth-wheel rollers

(conforming to 1S : 5502-1969), vibratory rollers (conforming to 1S

'$500-1969**), sheep's-foot rollers (conforming to 1S + 4616-1968), of

pneumatic-tyred rollers (conforming to IS; 5501-1969@) suitable for

the materials to be handled.

4.1.2, Watering equipment

Water-lorries of suitable capacity, with appropriate water-

sprinkling attuchment at the rear ensuring uniform distribution of

water over the entire width and adjustment of the rate of flow to the

desired level, should be used for watering. Where such :water-lorries

fre not available, ordinary watcring-cans such as these conforming to

TS; 4065-1967 about 25 ky capacity may be used for the: purpose.

7 Standard Specifications (or Smooth-Wheeled Diesel Road Rollers “e

++ Standard Specifications for Vibratory Rotlers |

1 Standacd Specitiestions for Sheep's-foot Rollers

G@ Standard Specificstions for Poeuimatis-tyred Rollers

“| Standard. Specieations for Watering Cans, or Bhisties (Water-enrviers)

IRC: 43-1972

4.2, Phase 2: Fixing Formwork and Preparing Sub-base for

‘Concreting

4.2.1. Formwork and iron stakes

‘The formwork should consist of mild steel channels for straight

engths and wooden sections reinforced with mild steel angles for

curved portions, Manufactured sections are also available in the

market and may be used if they meet Ine construction requirements.

The general requirements for formwork as given in IRC : 15-1910

shouldbe complied with, The details of mild steal stakes for fixing mild

steel chanuel and wooden formwork are given in Fig. 1

4.2.2. Bulk head

The bulk-head, sed for closing the const ion at an expansion

joint, or for making an emergency construction joint in case of

machinery breakdowns, should consist of a hardwood beam with hole

Arilled glong its centre Tine to accommodate the dowel bars if provide

ed, and with its top and bottom faces conforming to the cross-

profile of the finished pavement and sub-base course respectively.

Sometimes a two-piece bulk-head is preferred from the point of

construction convenience. Fig. 2 shows a typical bulk-head,

In case of dowelled coustrustions, the bulkheads should be used

in pairs, one being positioned at the joint proper, and the second a

ie further, to keep the projecting part of the dowels in proper

alignment,

4.2.3. Secateh template or strike board

‘Tho scratch template used for checking the trueness of the

subgrade or sub-base surface should consist of a hard wood board

fitted with handies, with its lower face conforming to the desired

cross profile or camber and having steel nails fixed thereto at regular

intervals. A (ypical scratch template for slabs not excceding 4m in

width is shown in Fig. 3

4.2:4, Pick-axe, powrabi, spade and shovel

Pick-axes, powrahs, spades and shovels used. for correcting lew

and high spots in the subgrade, granular sub-base or concrete should

conform to the relevant Indian Standards, viz.,, IS: 273-1961", 18:274

(Part 1—1966+# and IS: 1759-1964, The wooden handles for picks

Spi tor Picks and Beaters

Specifications for General Purpose Shovels

‘+ Shocilicntions for Powrahs

fonamys oats pur ayes cost oT Sea

sonrounytur uy axe suofsaaWp [IV : TION

SW os WRB

Y-¥ Noluoas

he

waa WAS

ae THs) C [anal

vant 40

2301S YBLAiO

J

Aiaien, 30,

2S Bas

NoLLWAa73

IRC 43-1972

Peo Ang wepooM “eH

senza BUY “T—ia10N

auoseag—: TwiVBANWy

nv

‘wa smusneay

$ = =e Abe aa

ae

at ar =e

VY NOILOaS

‘Save TanOG Wos BON 3UNGD eat

+—_+

! ff

ar

i : of

i faa

nomsa0 ws 13H0o ¥ I fz | @aAnd aide 0H-25 nd

usd Sy S310H wos oNIDYaS

1 UL a2e sLoIsueWID {IY SION

9 PIOUS IE 3ePOaP 10g

ST Uinoys WM EOF jo IPI a4.

9 Raa Seine 3 a ‘OOM Juposp 40 (Es poucseas —: aVIVaIYA

NVId doL SIV NV1d WOLLOG STV

SM3Y9S GOOM SM3YOS QO00M

QV3H_XNNS Y3.LNNO9 “SON 9

| spake

yt

7 aeenccek ty ~o+ +

s@-9v1S 40 HLOIM

Sav Tawa

40 WOLLOG 3H MOTEE

NOlLVAata /CNWSIONLOarOWd STN

BOVu9-GNS 40 FNdONd

SESS3NNOIHL @vIS ~001|—— 00z—__—- 002 aauine3u OL 3avW

ae

Biv SW aro yt

MOL WW,

Lo

8 I |

IRC: 43-1972

: 2892-19644, for powrahs to IS: $942: 19704,

1 2897-1965@. The spades may be of any

should conform to I

and for shovels to I

standard make,

4.3, Phas: 3: Concrete Manufacture

4.3.1. Steving sereens

The sieving screens for aggregates should consist of hard-wood

or steel frame, to which the square-mesh wire cloth of appropriate

mesh size, conforming to the 1S:2405-19634¢ is fixed, ‘The screens

should be provided with a stand to support them in position during

use, The drawing of a typical sieviig sereen is shown in Fig, 4.

4.3.2. Welgh bateher (for weigh batching)

‘The weigh-batchess for proportioning concrete aggregates should

conform to 18:2722-1964*,

4.3.3. Apgregate messtiring hoxes (for volume batching)

In case volume batching is permitted for aggregates, the aggre-

gate measuring boxes should consist of deep, narrow, wooden boxes

fixed with handles on either side for carriage. Some typical boxes of

different capacities are given in Fig. 5. }t should be ensured that the

sides and bottoms of the measuring boxes retain their shape during

use and do not bulge when loaded. If needed, wooden. stiffening

battens should be used at the sides or bottonis to’ ensure this.

43.4, Water pumps

Water pumps, if required for pumping water for concrete mixing

and euring operations, may be of centrifugal type conforming to 1S :

1520-1960%*, or any other suitable pump of approved quality and

make,

43.5, Water measures

For the purpose of correct gauging of the mixing water, fluid

measures of capacity 6 to [5 litte may be used. Where concrete

mixers are fitted with water measures, itis preferable to use them.

Altematively, empty five-titre, two-litre amd one-titre tins may

bbe used us water tmeasures, Inv the list case it should be ensured

that the tias are not bent or deformed ‘and they deliver correct

“Specifications for Wooden Handles for Picks and Beaters

ations for Wooden Handles for Powrahs

Specifications for Wooden Handles for Shovels,

Specifications for Wire Clothiand Perforated Plates for Industrial Sioves

Specifications for Partable Swing Weigh Batchers for Concrete (Single

fang Double Bucket Type)

Specifications for Horizontal Centrifugal Pumps for Clear Cold Fresh

Water

2) OS

9

IRC : 43.1972

sri xosxse

vopoon SunaeS

sans “pty

oom {ns 20 son pewoseag—! Wiest.

10

IRC : 43.1972

SIDE VIEW

1. All dimensions are in millimetres

2, Thickness of planks=25 mm.

Length | Breadth

| Height

ininetees | inmetres

ae,

capacity 'F.P.S. waite

aoism’ | 1/2eubie ot 2s | SB) 83

0030 mP | 1 cubic fot oo

0.0375 ut | th cabic feet 0.50

tga \ jae |_|

24 cubic feet

0.075 m*

u

Inc s44-1972

volume of water to the nearest 0.05 litre, The tins should be provided

with suitable handles,

4.3.6, Concrete mixer

The conciete mixers should be of the required capacity and

conform to IS: 1791-1968", when teste accordance with IS: 4634~

1968**, Mixers having rated capacity fess than 200 litres of mixed

concrete per batch should not be used

4.4. Phaw 4: ‘Transportation, Laying and Compaction of

Concrete

4.4.1, Wheel barrow

‘Wheel barrows (with single or two wheels) when used to trans-

port conerste over short distances from the mixer to the position of

placement should conform to IS: 2431-1963} and IS: 4184-1967}

respectively.

4.4.2. Wooden bridges

Wooden bridges, used for spanning the slabs to enable the

masons to carry out sarface finishing operations on the compacted

concrete, or to enable placrment of conerete in case of reinforced

concrete’ pavements without disturbing the reinforcement mesh, should

conform to the dimensions shown in Fig. 6, for a limiting. slab width

of 4m, For finishing operations alone, a ige_ (limiting slab

width 4 m) as showin in Fig. 7,may be adopted, For larger lab

width, suitable design should be prepared for each case

4.4.3, Conerete vibrators

‘The concrete vibrators of immersion and screed board types

for compaction of concrete al site should conform to the 18:250S-1968%

and IS:2506—1964@ respectively. In the former case petrol-driven

engine could also be permitted,

4.4.4.

‘The hand tamper, used in lieu of screed board vibrator for

compacting conérete for minor jobs, or as an emergency stop-gap

Specifications for Batch Type Concrete Mixes

Method of Test and Performance for Batch Type Conerete Mixers

Specifications for Steel Whee! Barrows (single wheel type)

Specifications for Steel Wheel Barrows (vith two wheels)

Specifications for Concrete Vibeators-Immversion Type (racaot for elect

cally driven ones omy)

Specifications for Screed Board Concrete Vibcators

12

s8pLg spoon 9 “at

oom 85 10 s3po2p paunseag—: TWHAaLYTK

“| oals

O9X SL 37S 927

Ob X09

AZIS SU3N34aLS

|

Gen reR HR et =

Se

IRC : 43-1972

IRC : 43-1972

arrangement in case of breakdown of the screed ‘board, vibrators,

‘ould consist of a hard wood beam of rectangular section of suffi

‘weight to ensure adequate compaction and should be fixed

securely with sturdy handles to withstand the tamping action. A typi-

cal dimensioned sketch is included in Fig.8. The lower face of the

Tamper board should conform to the desired profile of the pavement

cross-section, and be fitted with a mild steel shoe of appropriate

width, as in the case of screed board (IS: 2506—1964) to prevent

wear.

45. Phase 5, Finishing Operations; Surface and Joints

45.1. Float

The float used for smoothing thie compacted concrete, should be

made of hard wood board of dimensions shown in Fig. 9, planed to

fruc surface‘and fixed with a suitable handle as illustrated.

4.5.2, Straight edge

‘The straight edge used for checking the trueness of the finished

pavement surface in the longitudinal direction should consist of a

hard-wood section 3 m long fixed with handles as per dimensions

shown in Fig. 10, The lower face of the straight edge should be planed

toa true surface,

45,3. Mild steel seetions for joint grooves

‘Tac mild steel section for forming the groove of dummy con-

traction joint should consist of a flat section with flat supporting

pieces fixed thereto (Fig.11). Alternatively, T-Seotion of appropriate

size with webs cut at the ends to provide support over. the formwork

should be adopted. In either case, fo facilitate lifting, the flat supports

should be provided with suitable mild steel handies welded bctow

their exireme ends or with holes as illustrated in Fig.11 A&B res-

peetively.

‘Tae mild steel section for protection of groove over the ex-

pansion joint filler during construction should consist. of rectangular

‘or square bar section, depending onthe expansion joint width, with

mild steel handles fxed (Fig. 12). Its length should be 5 mm less than

the pavement width to ficilitste removal

‘The top and bottom edges of these mild steel sections should be

shaped to correspond to the camber of the pavement at the

joint. !

ASA, Edging tools

The single-edging tool used for rounding the transverse edges

at expansion joints and the longitudinal edges should conform to the

Is

edwer puey wpoons “9 “Si

m8 482) JO

Syeot pauostog—: WEA

ASIA WOLLOR-NVTS SIVH 1

tr FFL

gE+ + +

aL i

=f

W-V NOILOSS

See

NOILVA3 13

anand

BiV1d SW

IRC : 43-1972

=O

STONVH VIG OF

IRC: 43.1972.

1200

Lea

FRONT ELEVATION

‘WOOD SCREWS:

i —a

t

GL iis 8

PLAN

Marentat. :~Seasoned teak or sal wood

Nore :—Alll dimensions are in millimetres

Fig9. Float

IRC : 43.1972

M3IA WOLLOG-NV1d 47VH

Sepe NiBIENS “or FE

40 3801 pouowess “fs Tvr¥aLYW

MBIA dOL=NV1d 31VH

YA NOIWLOIS:

of

NOILVA313 LNOWs

"SON 09‘(vz 912)

LuvdY “WW $2 SM3¥9S OV3H

NNNS"D HLIM O3M3YOS KWWYLd 3a

cong —_OL HOIKL WWE BVT ‘SW:

J

:

aujof uorsuedys 20; worioeg “SW “ZI -STE

simot aM

por gy

gumnbs 40 12 SN: SVTNRLYAL

on podeys 3q. ino

eee)

ANIOT NOISNVaX3

NOILVA313

= as g ts 40 HAI,

eaiK SI= 8V7S 40 HOI: A»

— 1 ——— io

G0Y 'W'W Zh k-osi-—t—os.— -

pos sw 'z

o's “1 awe

dulof worestuoa 03 suonas SW “TT “Bs

WOSIS=LIOWVIIO a i Iwao visa v f

to NVId ie WV Id ¥

ae = qe gi: SSS ile

F051 —+-——— s1- avis 30 Him et st= ay 20 Hum ——j Jef

I

bs i Fo E

He ¢ #4

ssiwvon unavanve fou + saver. uaane fot

(SBRLIUTUH NI 3BY SNOISNIWIO TY ' v

om

qwlof vorseedxs 20) noNOIg "SK “Zt BL

justo aun 1 paodsois09

‘saps tionog pee do. “z pos ‘SW

‘Uraze suo|suawIp [Ty “1 —2 ALON anmnbs 10 1ey ‘SN | SNRLYA

NV1d

SS

NOILVAI313 LNIOF NOISNWEX3

WK ————— i= avs 40 HOM: 20 HOM

RS = a] ry

_——_ emt

[ogi- 08

90 “WW ZI

por "SW 'Z

WS “I TE

yayof wonresiuon 40} stones 's'AE “TT “BE

Tin do Wiad v

od be qi NvId 1a

fe- 3 O13 8 SS ir

wouvasns | souara

fosi}-_—— «1 ave 40 vtugim fa ay 40 tom ——}

I ==

pe ah as

7 i v

ssanvoriL anawanve Sou # ssmopeu, Lavan a

SRL TIN ay sHOISIEWIG TY aa

727

IRC: 43.1972

requirements indicated in Fig. 13. The double edging tool, used for

ELEVATION SIDE VIEW

Mareniats :—1. Hendle—Seasoned teak or sal wood

| 2, Piate—Mild steel shest 3 mm thick

Nore {All dimensions are in millimetres

Fig. 13. Edging tool

sounding transverse edges at dummy contraction joints, to ensure same

level on. either side of the joint should correspond to Fig. 14,

4.5.5. Canvas belt

Just before the conerete becomes non-plastic, the pavement sur-

face is belted with a canvas belt. ‘The belt should have width not

fess than 20) mm and be at least 1m longer than ‘the slab width as

20

—_—_—_—_—_—_—_——X—X

IRC 243-1972

¢ maar

ADIU S26" f

és ELEVATION SIDE VIEW

PLAN

MATERIAL 1, Hanille—Searonedl teak or sal wood

2) Plate—Mild steel sheet 3 mm thick

Nowy “All dimensions are in millimetres

Fig. 14. Double edging too!

a

IRC ; 43-1972

per IRC: 15-1970. It should be made from canvas cloth conforming

to IS:1424-1970*, and should be provided with stitched folds at either

end to pass the oodei handles (Fig.15) through.

40 DIA. WOODEN HANOLE

‘SIDE JOINT STITCHED. ‘

A

200-1

i

4s0—___|

a bee

[ a "

o ‘CENTRAL JOINT STITCHED SECTION cA

——— PAVEMENT WioTH+ 1000 ‘tl

PLAN

oo—

ELEVATION

Marana

1. Belt canvas having two folds

2, Round handles, seasoned teak or sal wood

Nove :—All dimensiéns are in millimetres

Fig. 15. Belt

‘Specifications for Cotton Canvas, Scoured, Dyed or Water-proofed

22

SS

Inc :43-1972

4.5.6. Long-handled coir broom

The long handled coir-broom for giving broom marks across

the pavement surface to make it skid-resistant should conform to the

requirements given in Fig. 16, The coir fibres should mect the

°

"END VIEW

Handfe=Bamboo!

2: Brush —Woodon, with bristles of hard opie fibre (geade 9 or

higher grade corresponding to 18:898-1964)

‘Ati dimensions are in millimeties

Fig. 16. Coir fibre brush

2B

Mareniat,

Nore

——————————————————————

IRC 243-1972

requirements of 1S:898—1964*, and be of grade 3 or higher thaw. his

Specification, ‘The broom should be replaced when the coir bristles

Wear down fo a length of about 40 mm.

45.7. Graduated master straight edge with wedge seale

‘The master straight-edge, used in conjunction with the gradu:

ated wedge (conforming to 1:226—-1969)** to check high and low

Spots along any line on the pavement should consist of 3m OH

sont tee! Ghannel section (conforming to 1S:3954—1966*# #) with ral

swe stands welded at either end. ‘The dimensions should be as

“hownin Plate IL, Itshould be ensured that the lower face of the

Straight edge is truly straight, and that the height of its stand is exact-

iy the same as of the wedg> gauge at the zero mark in the centre,

4,58. Diamond cutter

Rotating dise diamond cutter of travelling type. should be

capable of giving the cut to required depth and width and, should

fave appropriate arrangement for lowering. and raising the blags. te

par deoyed fevel, Tt should alo have suitable guides, for enabling

any crekt cut to be made. along the desired line, The diamond

ator having Water-feeding arrangement may be of any approved

standard make,

4.5.9. Grinder

Portable electrical grinder with flexible shaft drive of approved

design should be used for grinding any high spots on the hardened

‘concrete surface.

4.6, Phase 6. Curing

4.6.1, Hessian cloth

Hessian cloth used in initial euring of concrete should, be ob-

tained in rolls of 1to 1} m width. The quality should conform to

the sequirements of 18:2818-—971}. Alternately, other hessian cloths

‘of approved quality may be used.

46.2. Polyethylene sheeting

“the sheeting, if used for membrane curing should have) mink

mum thickness of 100 gauge and should be of approved quality.

* Specifications for Coir Fibre |

Specifications for Structura) Steet (Standard Quality)

sex Specftestions for Hot Rolled, Stee! Channel Secions for Genova!

“Engineering

{Specifications for Indian Hessian

”

TT

IRC : 43-1971

| 4.7. Cleaning and Sealing of Joints

Details of tools needed for cleaning and sealing the joint grooves

are as under :

(Ion faker, for removing any foreign materiel from the joint

grooves (Fig. 11)

4h

nly) |

oT

ELEVATION SIDE VIEW

fe aaa

PLAN

Mareqial. MS. rod 12 me dia

‘Note :—All dimensions ace in millimetres

Fig. 17. Raker

Gi Coir brush, forcleaning the joint grooves. It should conform to

the requirements of para 4.56, except that there should he to

handle and length should be only 300 mm,

Cycle pumps, for blowing of loosened foreign material from the

joint grooves, May be of any make of approved quality.

(iv) Kerosene stove, for heating the joint ‘sealing compound drums.

| May be of ny standard make of approved quality, — Ifa

bressure type Kerosene stove is used, it should conform to IS:

1342-1968."

(‘Thermometer 0-300°C, for controlfing the temperature of the joint

sealing comapeund. should conform to the: requirements of 19:

2480 Roast

~_ F Specification for Oil Pressure Stove

) ** Specifications for General Purpose Glass ‘Thermometers

25

on

IRC : 43-1972

(0 goa oe Oe eet ee ettien ee

5¢M THICK

ASBESTOS ROPE

COVERING

eo

ci E at

imc

PCAN dimensions are in millimetion

rns. Sree ve

IRC: 441972

(vii) Painting brush, 23 ma size, tat type, for applying the primer coat

{o the cletned joint groove before pouring the sealing compound.

May be of any make of approved quality.

(Will) Pouring kettle, for pouring the heated sealing compound in the

cleaned and primed Joint groove (Fig. 19).

(ix) seraper fr scraping off any excess sealing compound. overtowin

the lat groove (g.2). .

MINIMUM BALANCED SET OF TOOLS, EQUIPMENT

‘AND APPLIANCES,

5.1. For smooth progress of work, without sny_ boitlenecks,

itis essential to acquire a minimum balanced set of tools, equipment

aud appliances needed for different phases of construction. Detai

cof such a balanced Set for small sized constructions envisaged herei

with a daily concreting output of 20-30 cu.m., are given in

Annexure 2.

& ANCILLARY ITEMS OF TOOLS AND EQUIPMENT

6.l, In addition to the tools, equipment and appliances covered

in preceding Clauses, certain ancillary items will be needed at concrete

paving works for taking measurements, marking distances, storage of

water, routine repairs to machinery, etc. A list of these items is given

at Annexure 3. Though by no means exhaustive, the list includes all

such items which will generally be needed

7) MAINTENANCE AND UPKEEP OF ‘TOOLS, EQUIPMENT

AND APPLIANCES

7.1. The need for proper maintenance and upkeep of various

tools, plants and equipments cannot be over-emphasised to ensure

quality construction. Some of tho tools and equipments especially

tend to develop inaccuracies and defects with use. ‘Their constant

checking and rectification should form a part of daily routine. Points

‘eserving utiention in this respect are brought out in Annexure 4,

qeikputrick Todi Pwe Led.

ooo aeves Ladunteia Bata

100K

Aadaid, Mains Cos

‘Marhce Bead, Hew Oelbl

2

IRC: 43.1972

Gap at the top between

two containers to be

covered with M.S. circular

Hing plate 2 mm thick

Lid bana

2 men thi

MS. plat

‘Top tid tg

behingal

Welded

5 sam thi

astestos

covering

Handle

1 mom th

Rivets

165:

Rivets

Lid

welded

Seg

tela

as

cE

Detail of joint at A-A

Marenaae 1

Nora :—All dimensions are in miltimeties

Fig. 19. Pouring kettle

CO

IRC: 43.1972

{

SIDE VIEW

Nove :—All dimensions are in millmstees

Fig. 20. Seraper

IRC: 43-1972

Annexure 1

DETAILS OF FIELD EQUIPMENT

‘The minimum equipment essentigl for carrying out control and accep

tatce tests is given Below :

{) 1S. Test Sieves 450m dia, 1S, si, 45.0 mm, 22:4 mm,

12 tu and 4,60 min with id and pan (ae per 1S 460-1978)

one set

(2) {@) IS Test Sieves, 20 cm dia., 1S sizes 2.36 mm,

BS Pee aed Soo. 300,150 ‘and 75 microns,

| AiR Tiland pao per 18. 460-1962) one act

«o) Fine camel haie brush forcing the sieves — Ore No.

| 3) Graduated glass cylinder 200 ml. capacity — Two Nos.

| (4) Semiautomatic balance, 7 kg capacity — One No.

(5) Seméautomati balance, 1 ky sapaciy ~ O16 No:

(6 *15 cm ccibermoutiy. (for, wo. c's casting)

| fas paris 316-198) clase 2.91) 12 Nos.

(n eSem 18 em x15.0m beam moutds (for $90

SET esalag ds por Is 25161939 cause 14.1) 12 Nos

(8) Tamping rods, for compacting cube/beam moulds

Camping cots (05 SoM Gosek 7a

‘SSosatvel) 2 Nos

(Leach)

(9) Slump cone, complete with tamping rod and 30 ern

Stee! rule (as per JS 7 1190-1959 clause 3.1.2) — 2 sets

(10) Dial type spring balance, 100 kg capacity 1 No.

(Ul) Enamel teays; 30 em x 15 en x 5.6m 6 Nos.

(12) Pyenometers — 4 No.

(13) Field oves with kerosene stove - No.

(14) Hand operated hydraulic. compression. testing

Machine 100 ton capacity with attachment for flexi

al éesting of beam sainptes — 1No,

(13) Rifle box — 2.Nos

(16) Sample tins, beskers, graduated cylinders, wash

battle, thermometer (0-100°C), steel spatula, pair of

tongs, ete r

oan _—________4

fn case the max, size of the aggregate employed ata project dd

not exceed 10mm, 10-cm cube moulds and $0 em x 10 cm x 10¢

Seam moulds may be used as permissible in 1S: 456-1964.

30

és

Note ~The

IRC: 43-1972

for ‘handling

1 -$e0p, towel and shove! lig SR cach

(18) Core cutting machine for 10 em or 15 em cores — 1No

tis meant for x daily output. of about 20:30 cum, of

concrete. But except in the case of beim/cube moulds, the

‘equipment listed can nately cope witha dally concrete’ out~

Ditt of upto 90 eum., provide that workheads are in close wick

‘nity so as fo enable’ the same equipment to be used centrally.

‘Additional 6 beaim/eubbe moulis wilt have to bo provided hn Ins

ase for every adlitiona! 30 cu.m. of concreting Per da}.

Jn case the workhoads are far apart and. it i not convenient to

use the same equipment for several workheads, the’ minimum

egulred equipment will ave fo be provided at each workbead

ately.

Annexure 2

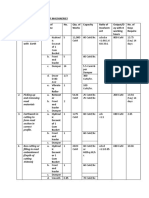

MINIMUM BALANCED SET OF FOOLS, EQUIPMENT:

"AND APPLIANCES

{ay Suitable Compaction esinment

{bp Bist watersasti=ns)

2. Pickeaxe

vel

3, Scratch Template oF sirtke Board

4. ta) Formwork For (wo day's work

{) Stakes for former

5, Sieviny Soren

6. Weigh Batches (Double- Hopper

Swing Tse)

4. Aggreaate Measuring Boxes {FOF

Sitime batching nls)

‘alternative fo No. 6, 4m 6286 permitted

3. Water Measures

9, Concrete Mixer

10, Conerete Vibrators

(a) Internal Vibrators:

{iy foe bienway pavements

(ii) Yor aieBiekd pavements

py Sereed Bowed Vibrators

Ae Wheel pasrows

(lovin capac)

1, Hand Tamper Board

13. Float

14, Straight Edge

45, Bulk-head

(A few Henaths

100 3

one set oneset

(as. 228, 12 and $60 9m

1 =

fone set One se,

(0015, 0.03, 60375 mT

Oneset One st

Mey 2, 1 and 0.5 1M

IRC 243-1972

No. required No, standby

Mild Steel Sections for Making

Joint Grooves

(@) for expansion joints

{(b) for contraction joints

Euging Tools

(a) Edging toot

(b) Double edging toot

Canvas Belt

Long-baniled Coir Broom

Graduated Master Straight Edge

with Wedge Gai Leet =

Dinmond Cuter foptional) 1 sna Suiits

Portable Grinder ere?

. Wooden Bridges 4 2

Hessians Cloth Suleient to cover one day's work

“200 a.)

Tools for Joint Sealing

(@) Tron Raker

(0) Coit Brush

© Grete Pump

(3) Kerosene Stove

(c) Thermometer (0-300°C)

(0) Painter Brush (25 mm)

Replucemerts for any items tecoming unserviceable should be made

pvopiy so that the rete mune along ulthceded andbog faee

working is always available,

31972

Annexure 3

EQUIPMENT, ETC, FOR CONCRE

ANCILLIARY (TEMS OF TOOLS

PAVING WORKS:

Rot

Woseéguied

tor Checking Level & Marking Distance

Donmpy Level and Levelling Stil sath

aioe Gb m), Metall Tape (0 m) {each Re

| Stel Te Ge Rope (12 im dl) 2 ie

Rangiog Rods $ i aoe

For Preparaton of Sub-bae for Const oy

Cole Brushes 0

ole Brae ysee at por 381 A1631967) 1

ove Cans $

vac matecre ot Covert ning Handing of Matis

anja 6

eairen x

cae ara for water storage (200 ice

as 2s

simply Tine ute enact) io

reo Pane By

re eee (8m x1) 0136 mm 99108) 3

reife {

Hei ins (5.0443 m a9BFOX) 4

or Hing & Reaevng Forsork

Mason's Tend 2 balls

Mammets @ kb 28) 2 each

Mar Go.s0 um i, 1500 mm Kost) 1

bese

Mason's Trowel and Straight Edge

Spirit Level (20 mm)

‘Spares for Repairs to Kquigment

‘Assorted nuts, belts, nails"and sorews:

spaies for eonerete misery seed. vibrator (specially handlersPrisgs &

eubbort betes) internal vibrator and weigh batchers

Toot kit for general purpose including sets of lists wench whe

00s ea ATUEe lems such a5 stontge, sted Ton cement, ates SEER sank,

see nce for atic diversion and regulation, ee Mich do nol

appurienioc® rc of tools, equipment and apianess, But Which fe neve

Siltasy essential for any concrete paving job-

34

Se

IRE: 43-1972

‘Amexure 4

ROUTINE MAINTENANCE AND UPKEEr OF TOOLS,

i RQUIPMENT AND APPLIANCES,

‘The following point should fort a part of routine daily. check-up of

lant s0 as to ensure quality construction

1, Serateh Template or Strike Board: The tnieness of setting of nails

to cross-profile should be checked daily before commencement of

work,

2. Formwork: (1) The straightness of formwork in both the horizontal

and vertical planes should be ensured before each use, When fixed,

should be ‘checked with wav suraigh cdge and any ceparture

Brester than 1.5mm duly rectified. @)'The formwork. should be

thoroughly cleaned and should not have any Foreign material sticking

thereto,

3. Sleving Sereens: It should be ensured that the sieves are thoroughly

lean and that there is no displacement or breakage of the. mesh

wires, ete,

4. alg Batata: (9 Thecalibotin of he wg Satchels shoud

checked regularly by meapsof'a set of standard weights ever the

full working range in tse. (2) The koife-rdge mppous shouldbe

regeany cleaned, (3) Free movement ofthe dist needle shoud te

aure

Measuring Boxes: Wherever volume batching is. permitted, the true-

fess of shape and correctness of dimensions of the measuring boxes

should be ensured,

6. Watee Measures : The calibration of the water measures. should. be

‘checked regularly against standard graduated cylinders,

7. Concrete Mixer : (1) Any wom out mixer blades (worn more than

20 mm) should be repluced, (2) After any “break "in. construction

longer than 20 minutesand at the end of the day's work, the mixer

deur should be thorougiiy Washed and etenned,

8. Concrete Vibrators: Regular servicing of the ‘un

done to keep them in good working order,

9. Surface Finishing Tools: Floals and straight edge, shoula be daily

checked before use for trucness, and any departure from a tee

6 plane surfice should be rectified before use-

should be got

4

a 10. Mild Steel Sections for Making Joint Grooves: Tho truensts and

* straightness should be checked before use, especially. in case of the

‘mild steel flats for making contraction joint grooves, as they are

sometimes likely to get bent during insertion in the concrete.

35

TRE: ABT

At, Canvas Belts Shoul be

are.

‘Long Handed Coie Broom Treo el

sear, an wen ‘out brooms should be rep =

ss

tet Maen eugene Mage owl

‘not be ng peck acceetary ron

ale

ital checking. be

sue

a

Be

SisyHa LNauaama or

GaGaIN STONVEiad¥ GNY S101

DNIMONS NOLLOAUISNOD LNW

AVA TIMWONOD JO LAVHO MOTE

SHONWeIdaY ONY ANDwaiNDY “St0OL livin at

te rane

re: asa

38 PLATE H MASTER STRAIGHT—EDGE AND GRADUATED WEDGE SCALE

‘TOOLS & APPLIANCES FOR

(CHECKING PAVEMENT

SURFAGEUNEVENNESS

‘Nose :-Al dimers ate fe miietes

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Indian Highways: Emerging Opportunities For Profitable PartnershipDocument12 pagesIndian Highways: Emerging Opportunities For Profitable PartnershipAshok Kumar SahaNo ratings yet

- Irc-Sp-25 Gideline On Maintenance of Road Roller PDFDocument41 pagesIrc-Sp-25 Gideline On Maintenance of Road Roller PDFAshok Kumar SahaNo ratings yet

- Irc 90 1985 Guidelines For Selection Operation and Maintenance of Bitumious Hot Mix Plant PDFDocument67 pagesIrc 90 1985 Guidelines For Selection Operation and Maintenance of Bitumious Hot Mix Plant PDFAshok Kumar SahaNo ratings yet

- Indla Highvv: Par IamentDocument5 pagesIndla Highvv: Par IamentAshok Kumar SahaNo ratings yet

- Rectification of Accident Black Spot Preparation of Proposal and Sanction Approval Regarding On 26th August 2019.-MinDocument11 pagesRectification of Accident Black Spot Preparation of Proposal and Sanction Approval Regarding On 26th August 2019.-MinAshok Kumar SahaNo ratings yet

- General Power of Attorney-FinalDocument6 pagesGeneral Power of Attorney-FinalAshok Kumar SahaNo ratings yet

- Format For Analysis of Rate of Reinforcing Steel Supplied by ContractorDocument1 pageFormat For Analysis of Rate of Reinforcing Steel Supplied by ContractorAshok Kumar SahaNo ratings yet

- Rate Analysis of Tor SteelDocument1 pageRate Analysis of Tor SteelAshok Kumar SahaNo ratings yet

- Roadwork Equipment CapacityDocument3 pagesRoadwork Equipment CapacityAshok Kumar SahaNo ratings yet

- Surface & Subsurface Geotechnical InvestigationDocument5 pagesSurface & Subsurface Geotechnical InvestigationAshok Kumar SahaNo ratings yet

- Rate Analysis of Carried EarthDocument4 pagesRate Analysis of Carried EarthAshok Kumar SahaNo ratings yet