Professional Documents

Culture Documents

D010 E84 PDF

D010 E84 PDF

Uploaded by

Angie Cerinza Acosta0 ratings0% found this document useful (0 votes)

11 views7 pagesOriginal Title

D010-e84.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views7 pagesD010 E84 PDF

D010 E84 PDF

Uploaded by

Angie Cerinza AcostaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

ORGANISATION INTERNATIONALE

DE METROLOGIE LEGALE

BUREAU INTERNATIONAL DE METROLOGIE LEGALE

114, RUE TURGOT — 75000 PARIS — FRANCE

“Téléphone : 33 (1) 87.12.82 ot 285.27.41

“Toles : SVPSV 660670 F ATTN OIML.

@

INTERNATIONAL Document wn: 10

GUIDELINES for the DETERMINATION

of RECALIBRATION INTERVALS

of MEASURING EQUIPMENT

USED in TESTING LABORATORIES

Based on a report of

ILAC TASK FORCE E

adopted by the International Committee of Legal Metrology in 1984

First edition 1984

INTERNATIONAL DOCUMENTS

of the INTERNATIONAL ORGANIZATION of LEGAL METROLOGY

Tie dogument « Work Poticy of OIML >, adopted in principle by the 4th International Conference

pf Legal Metrology in 1972, mentions the possibility for the Organization to publish International

Documents meant to facilitate the harmonization of national regulations concerning ‘metrolouy

and likely to contribute to the development of metrology services

These documents do not have the rigid character of International Recommendations, that

is to say, in particular, that the provisions of article VITI of the Convention, by which Member

States «shall be morally obliged to implement these decisions as far as” possible», do not

apply.

GUIDELINES for the DETERMINATION

of RECALIBRATION INTERVALS

of MEASURING EQUIPMENT

USED in TESTING LABORATORIES

Introduction

‘An important aspect of the efficient operation of a calibration system within a

testing laboratory is the determination of the maximum period between successive

calibrations of reference standards and measuring equipment. A large number of

factors influence the frequency of recalibration and should be taken into account

by the testing laboratory and by the accrediting authority. The most important factors

are:

— type of equipment,

— manufacturer's recommendation,

— trend data obtained from previous calibration records,

— recorded history of maintenance and servicing,

— extent and severity of use,

— tendency to wear and drift,

— frequency of cross-checking against other reference standards,

— frequency and quality of in-house check calibrations,

— environmental conditions (temperature, humidity, vibration, etc.),

— accuracy of measurement sought.

The cost of calibration cannot normally be ignored in determining the recalibration

intervals and this may therefore be a limiting factor. It is obvious from all these

stated factors that a list of recalibration intervals which can be universally applied

cannot easily be constructed. It is more useful to present guidelines on how

recalibration intervals may be established, and then reviewed once calibration on a

routine basis is under way.

There are two basic and opposing criteria which are required to be balanced

when deciding on the recalibration intervals of each measuring instrument. These are :

— the risk of a measuring instrument going out of tolerance when in use should

be as small as possible,

— the annual calibration costs should be kept to a minimum,

Therefore, methods are presented in this International Document for the initial

selection of ‘recalibration intervals and the readjustment of these intervals on the

basis of experience. Initial recalibration intervals for a wide ‘range of equipment

have been gathered from industry in reply to a questionnaire circulated to accrediting

authorities in certain countries. These are presented in a separate document. The

BIML note

Task force E of the International Laboratory Accreditation Conference (ILAC) prepared a

report on initial recalibration intervals of measuring equipment used in. testing’ laboratories,

ILAC 83 transmitted this report to OIML for consideration and publication.

The report was subdivided into two parts, published separately :

— this International Document,

— the document « Examples of initial recalibration intervals »,

values given can serve as a guideline for determining initial recalibration intervals,

but this should be done with care, taking into account the influence factors stated

above, which may cause the values to vary widely,

Initial choice of recalibration intervals

The basis of the initial decision in determining the recalibration interval is

invariably the so-called engineering intuition. Someone with experience of measurements,

in general, or of the instruments to be calibrated, in particular, and preferably with

knowledge of the intervals used by other laboratories, makes an estimate for each

instrument or group of instruments as to the length of time it is likely to remain

within tolerance after calibration.

Factors to be taken into account are :

— the instrument manufacturer's recommendation,

— expected extent and severity of use,

— the influence of the environment,

— the accuracy of measurement sought.

Methods of reviewing recalibration intervals

Once calibration on a routine basis has been established, adjustment of the re-

calibration intervals should be possible in order to optimise the balance of risks

and costs as stated in the introduction. It will probably be found that the intervals

ey selected are not giving the desired optimum results ; instruments may be

less reliable than expected ; the usage may not be as anticipated ; it may be sufficient

to carry out a limited calibration of certain instruments instead of a full calibration ;

the drift determined by the recalibration of the instruments may show that longer

recalibration intervals may be possible without increasing risks, and so on.

If the shortage of money or shortage of staff means that extended recalibration

intervals are necessary, it should not be forgotten that the costs of using inaccurate

instruments are not insignificant. If an estimate of these costs be made, it may well

be found more economic to spend more money on calibration and thereby reduce the

recalibration intervals.

‘A range of methods is available for reviewing the recalibration intervals. They

differ according to whether :

— instruments are treated individually or as groups (eg. by manufacturer or by

type),

— instruments go out of calibration by drift over time or by usage,

— data are available and importance is attached to the history of calibration of

the instruments.

No one method is ideally suited for the full range of instruments encoutered.

Furthermore, it should be noted that the method chosen will be affected by whether

the laboratory intends to introduce planned maintenance. There may be other factors

which will affect the laboratory's choice of method. The method chosen will, in turn,

affect the form of records to be kept.

The so-called engineering intuition which fixed the initial recalibration intervals,

and a system which maintains fixed intervals without review, are not considered as being

sufficiently reliable and are therefore not recommended.

Method 1 : automatic adjustment or « staircase » (calendar-time)

Each time an instrument is calibrated on a routine basis, the subsequent interval

is extended if it is found to be within tolerance, or reduced if it is found to be

outside tolerance. This « staircase » response may produce a rapid adjustment of

intervals and is easily carried out without clerical effort. When records are maintained

and used, possible trouble with a group of instruments indicating the desirability of a

technical modification, or preventive maintenance, will be known.

A disadvantage of systems treating instruments individually may be that it is

difficult to keep the calibration work-load smooth and balanced, and that it requires

detailed advanced planning.

Method 2 : control chart (calendar-time)

Significant calibration points are chosen and the results are plotted against time.

From these plots, both scatter and drift are calculated, the drift being either the

mean drift over one recalibration interval, or in case of very stable instruments, the

drift over several intervals. From these figures the optimum interval may be calculated.

This method is difficult to apply, in fact, very difficult in the case of complicated

instruments and can virtually only'be used with automatic data processing. Before

calculations can commence, considerable knowledge of the law of variability of

the instrument, or similar instruments, is required. Again, it is difficult to achieve

a balanced workload. However, considerable variation of the recalibration inter-

vals from the prescribed is permissible without invalidating the calculations ;

reliability can be calculated and in theory at least it gives the efficient recalibration

interval. Furthermore, the calculation of the scatter will indicate if the manufacturer's

specification limits are reasonable and the analysis of drift found may help in

indicating the cause of drift.

Method 3 : « in-use » time

This is a variation on the foregoing methods. The basic method remains unchang-

ed but the recalibration interval is expressed in hours of use, rather than calendar

months. The instrument is fitted with an elapsed time indicator, and is returned for

calibration when the indicator reaches a specified value, Examples of instruments are

thermocouples, used at extreme temperatures, dead weight testers for gas pressure ;

Jength gauges’ (i.e. instruments that may be subject to mechanical wear). The

important theoretical advantage of this method is that the number of calibrations

performed and therefore the costs of calibration varies directly with the length of

time that the instrument is used.

Furthermore, there is an automatic check on instrument utilisation. However,

the practical disadvantages are many and include :

— it cannot be used with passive instruments (e.g. attenuators) or standards

(resistance, capacitance, etc.),

— it should not be used when an instrument is known to drift, or deteriorate

when on the shelf, or when handled, or when subjected to a number of short

onoff cycles ; it should in any case have a calendar-time back-up,

— the initial cost of the provision and installation of suitable timers is high, and

since users may interfere with them, supervision may be required which again

will increase costs,

— it is even more difficult to achieve a smooth flow of work than with the

methods mentioned above, since the (calibration) laboratory has no knowledge

of the date when the recalibration interval will terminate.

Method 4 : in service checking, or « black-box » testing

This is a variation on methods 1 and 2, and is particularly suitable for complex

instruments or test consoles. Critical parameters are checked frequently (once a day

or even more often) by portable calibration gear, or preferably, by a « black box »

made up specifically to check the selected parameters. If the instrument is found

out of tolerance by the « black box » it is returned for a full calibration.

The great advantage of this method is that it provides maximum availability for

the instrument user. It is very suitable for instruments geographically separated from

the calibration laboratory, since a complete calibration is only done when it is

to be required. The difficulty is in deciding on the critical parameters and

designing the « black box ».

Although theoretically the method gives a very high reliability, this is slightly

ambiguous, since the instrument may be failing on some parameter not measured by

the « black box ». In addition, the characteristics of the « black box » itself may

not remain constant.

Examples of instruments suitable for this method are density meters (resonance

type) ; Pt-resistance thermometers (in combination with calendar-time methods) ;

dosimeters (source included) ; sound level meters (source included)

Method 5 : statistical approach

When large numbers of identical instruments ic. groups of instruments are to be

calibrated, the recalibration intervals can be reviewed with the help of statistical

methods. Detailed examples can be found in the work of L.F, Pau and references.

4. Examples of recalibration intervals

Although there is a wide scatter in recalibration intervals of measuring instruments

used in calibration and testing laboratories depending on accuracy level and working

conditions, it is useful to create an international forum for the exchange of information

on initial recalibration intervals.

Therefore, it has been decided to elaborate a separate document, entitled « Examples

of initial recalibration intervals » as a basis for know-how exchange. All interested

countries are invited to make contributions. Care will be taken to ensure that the

document remains up-dated.

5. Bibliography

Methods of reviewing calibration intervals

Electrical Quality Assurance Directorate

Procurement Executive, Ministry of Defence

United-Kingdom (1973)

Establishment and adjustment of calibration intervals

National Conference of Standards Laboratories

United-States of America (1970)

Périodicité des Calibrations

LF. Pau, Ecole Nationale Supérieure des Télécommunications

Paris - France (1978)

ORGANISATION INTERNATIONALE

Ww DE METROLOGIE LEGALE

BUREAU INTERNATIONAL DE METROLOGIE LEGALE

11, RUE TURGOT — 75009 PARIS — FRANCE

“Telphone: 33 (1) 878.12.82 ot 28527.11

“Telex : SVPSV 680870 F ATTN O1ML ILAC 84

London, 22-26 October 1964

NOTE

on the INTERNATIONAL DOCUMENT No 10

‘GUIDELINES for the DETERMINATION of RECALIBRATION INTERVALS

Of MEASURING EQUIPMENT USED in TESTING LABORATORIES'

‘The report presented to ILAC by its working group E was transmitted to

the International Organization of Legal Metrology for consideration and

possible publication, in conformity with the Resolution ILAC 5/83 adopted by

TLAC 83.

This report is subdivided into two parts :

=a document "Examples of initial recalibration intervals" widely distributed

in June 1984; additional information was requested, from the recipient States,

with the intention of updating this document by the end of 1985,

=a draft International Document (*) submitted to the OIML Member States for

study, comment and vote, and to certain International Institutions concerned,

for study and comment.

At the closing date of voting (31 August 1984), the results (20 yes, 1 no,

0 abstention) allowed the draft to be considered as adopted; some comments

were received : some, of mostly editorial nature or not concerning the technical

content of the text, were taken into consideration; others, more general,

will be taken into consideration at a later date, during a revision of DI No 10.

In this way, it was possible to avoid certain difficulties rightly mentioned by

Dr. Lawrence D, Eicher, Assistant Secretary General of 180, in his letter

ISO-ILAC 84, dated 1984-07-23.

Whilst distributing this DI No 10, OIML requests the readers to make

any comments which would help to improve or complete the text. The creation of

an OIML working group or of a joint ILAC-OIML working group, to be responsible

for the continuation of the work, is at present being examined.

(#) see explanations on OIML International Documents on page 2 of DI No 10.

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Sjhs2a (En)Document84 pagesSjhs2a (En)Márcio EstevamNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Installation Instruction ElevatorDocument42 pagesInstallation Instruction ElevatorMárcio Estevam100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- LED Lamp Material SheetDocument2 pagesLED Lamp Material SheetMárcio EstevamNo ratings yet

- Documentação para Integração de TerceirosDocument1 pageDocumentação para Integração de TerceirosMárcio EstevamNo ratings yet

- Manual VexpensesDocument20 pagesManual VexpensesMárcio EstevamNo ratings yet

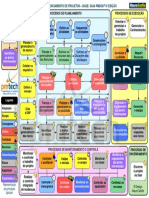

- Fluxo PMBOK 6aDocument1 pageFluxo PMBOK 6aMárcio Estevam100% (1)

- FISPQ Óleo DegomadoDocument6 pagesFISPQ Óleo DegomadoMárcio EstevamNo ratings yet

- Proposta Flessak - ApucaranaDocument3 pagesProposta Flessak - ApucaranaMárcio EstevamNo ratings yet

- Graxa AliplexDocument1 pageGraxa AliplexMárcio EstevamNo ratings yet

- Checklist Horímetro CompressorDocument1 pageChecklist Horímetro CompressorMárcio EstevamNo ratings yet

- Fispq DenvertecDocument10 pagesFispq DenvertecMárcio EstevamNo ratings yet

- Smartlink Atlas CopcoDocument1 pageSmartlink Atlas CopcoMárcio EstevamNo ratings yet

- Manual de Bolso HP 50GDocument197 pagesManual de Bolso HP 50Gharoldquot100% (3)

- Spare Parts Máquina Lavagem de Piso A5Document113 pagesSpare Parts Máquina Lavagem de Piso A5Márcio EstevamNo ratings yet