Professional Documents

Culture Documents

BTSPAT of GMUDA2

Uploaded by

dumindu1Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BTSPAT of GMUDA2

Uploaded by

dumindu1Copyright:

Available Formats

Our Ref :200701164340

Date :06-Jul-2020

PAT DETAILS

SiteID/Name GMUDA2 / Udatuttiripitiya_2

Tower Type/Height GF_4_Leg/60 m

PAT Category BTSPAT

Performed By Mobitel

Genaral Info

No Task Status

1.1 BTS Type DBS3900

1.2 BTS Configuration 222

1.3 Frequency Band 1800

LTE

1.4 RFU/RRU Type 3953w

1.5 Battery Capacity 92Ah

1.6 PAT Type Expansion

1.7 PAT Status Pass

Earthing

No Task Status

2.1 Feeder cable earth connected to ECB at 90 bend, within 1m N/A

(Vertical rise) - Major

2.2 Feeder cable earth within 1m from bottom feeder connector N/A

- Major

2.3 If vertical feeder length Greater than30m additional feeder N/A

cable earth connected to ECB at every 30m level - Major

2.4 Feeder cable earth within 1m from top feeder connector - N/A

Major

2.5 If horizontal feeder length Greater than20m additional N/A

feeder cable earth connected to ECB at every 20m distance

- Major

2.6 TMA Earthing through proper clamping on tower - Major N/A

2.7 Feeder earth kit sealing with self-bonding tape - Major N/A

Generated through InfraMS Page 1/17

2.8 All GI pipes are earthed from one side (With nut & bolt). N/A

Usually it should be from SPD end to the bus bar (35mm2

cable and lug for power cable GI pipe grounding, 25mm2

cable and lug for E1/FE cable GI pipe grounding) - Major

2.9 BTS cabinet is earthed using 35mm2 cable, lug and N/A

washers. It must be to the bus bar at the side of the cabinet

plinth - Major

2.10 AC power cable shield should be earthed using 35mm2 N/A

cable lug to ECB at the meter cubical - Major

2.11 Patch panel and power distribution box (ACPDB) at the BTS N/A

end are earthed to the main ECB using 35mm2 cable and

lug - Major

2.12 SPD should be installed at the meter cubical end wherever N/A

possible and earthing to the nearest bus bar using 35mm2

cable and lug - Major

2.13 SPD pole (If mounted to the plinth) should be earthed by N/A

35mm2 Cu cable - Major

2.14 SPD pole (If separate) should be earthed by Cu tape - Major N/A

2.15 Steel plinths are earthed by Cu tape with nut & bolt - Major N/A

2.16 Horizontal outdoor cable ladder should be earthed using N/A

35mm2 cable and lug - Major

2.17 Outdoor cable ladder support should be earthed using Cu N/A

tape. Support pole needs to be connected by nut & bolt -

Major

2.18 Tower ECBs are earthed using 35mm2 earth cable - Major N/A

2.19 RRU DC power cable shield should be earthed at the BTS OK

end - Major

2.20 RRU should be earthed using 16mm2 earth cable to ECB - OK

Major

Hardware Installation

No Task Status

3.1 Cabinet(s) bolted to plinth correctly with washers.Use 04 N/A

bolts & it must be GI - Major

3.2 No obstruction at BTS fan & door filters cleaning - Major N/A

3.3 Cabinet door can be opened and closed easily - Major N/A

3.4 Cabinet door can be locked and unlocked easily - Minor N/A

3.5 Power supply system is secured properly to the floor or N/A

plinth - Major

3.6 Battery terminal tightening is done during the PAT using a N/A

torque wrench (Shoto: 9~11Nm, Leoch: 3.9~5.4Nm) - Major

Generated through InfraMS Page 2/17

3.7 Battery breather lines are installed properly - Major N/A

3.8 Battery system is installed properly. 35mm2 DC cables from N/A

battery cabinet are secured with GI coated flexible PVC if

less than 5m and GI pipe if more than or equal 5m - Major

3.9 No. of batteries installed N/A

3.10 Battery type & capacity N/A

3.11 Battery parameter settings are done correctly - Major N/A

3.12 No external damages in cabinets - Major N/A

3.13 Proper fastening of units inside the cabinet (BBU,sensors N/A

etc.) - Major

3.14 Cable inlets and outlets are sealed properly in order to be OK

protected from water, humidity, dust, rodents and insects -

Major

Cabling

No Task Status

4.1 Power and signalling cables are separated - Minor OK

4.2 Connections of RF cable to RFU are secured properly - N/A

Major

4.3 DC power cable from the BTS cabinet to the rectifier (+) bus N/A

bar and (-) bus bar are installed correctly - Major

4.4 Feeder cable routing (Jumper cable is less than 3m with drip OK

loop. In case of more than 3m prior approval shall be

obtained in TSSR/Readymade jumper cable must be used) -

Major

4.5 AC power cable from the meter cubical to the SPD and from N/A

the SPD to the ACPDB are installed properly. It should be

4x16mm2 armored cable secured with GI pipe and at the

SPD fixing end secured with GI coated flexible PVC - Major

4.6 AC power cable from rectifier to the ACPDB is installed N/A

properly. It should be 4x10mm2 non-armored secured with

GI coated flexible PVC - Major

4.7 Proper installation of fibre cable from BTS to RRU (Each OK

fibre cable is secured separately using PVC, fibre clamps

are fixed at 2m intervals, top & bottom of PVC ends are

sealed properly, bending and tower top fibre cables are

secured with GI coated flexible PVC) - Major

4.8 Suitable fibre length shall be selected and the extra length N/A

shall be secured completely using a rubber harness or PVC

casing and shall be tightened to the cable ladder - Major

4.9 E1 cable is connected properly at the BBU to the TX N/A

devices (For NodeB, 8E1 cable must be laid and connected

to the BBU) - Major

Generated through InfraMS Page 3/17

4.10 Alarm cables for sensors and alarm panel are installed N/A

properly - Major

4.11 All cables are routed and labelled properly - Major OK

4.12 Electrical wiring neatness (Proper securing with buried GI & OK

GI coated flexible PVC) - Minor

4.13 Using proper colour code & approved cables for power N/A

connection (Including load cable, indoor & outdoor)

Ö Recommendation; L1,L2 & L3 colour - Brown, Black, Grey

N colour - Blue - Major

4.14 AC power cables laying over the plinth should be in 1.5 inch N/A

GI coated flexible PVC - Major

4.15 DC power cables laying over the plinth should be in 1 inch OK

GI coated flexible PVC - Minor

4.16 Use two colour code for DC cable - Minor OK

4.17 FE cable is connected from the BBU to the TX devices N/A

properly and secured with PVC or GI pipe (PVC is used

when outdoor cable length is less than 5m, GI pipe is used

when outdoor cable length is more than 5m) - Major

4.18 Fibre cable is connected from the BBU to the TX devices OK

properly and secured with PVC or GI pipe (PVC is used

when outdoor cable length is less than 5m, GI pipe is used

when outdoor cable length is more than 5m) - Major

4.19 E1 cable is connected from the BBU to the TX devices N/A

properly and secured with PVC or GI pipe (PVC is used

when outdoor cable length is less than 5m, GI pipe is used

when outdoor cable length is more than 5m) - Major

4.20 All FE/E1 cables should be connected to relevant surge N/A

protecting boards in the BBU - Major

4.21 Physically check the E1 from TX devices to the BTS - Major N/A

4.22 Use proper DC cable for connecting RF cabinet to TP N/A

cabinet (35mm2 or 2x16mm2 Black & Blue) - Major

Antenna and Feeders

No Task Status

5.1 Feeder type - Minor fibre

5.2 Feeder length - Minor 0

5.3 Fibre length - Minor 60*3

5.4 Top jumper fixed - Minor Sector A

Sector B

Sector C

Sector P

Sector Q

Sector R

Generated through InfraMS Page 4/17

5.5 Top jumper type - Minor DIN-4.3

5.6 Top Jumper Remarks - Minor N/A

5.7 Bottom jumper fixed - Minor N/A

5.8 Bottom jumper type - Minor N/A

5.9 Bottom Jumper Remarks - Minor N/A

5.10 Top jumper length - Minor 3

5.11 Bottom jumper length - Minor N/A

5.12 Feeder clamping - Major N/A

5.13 Fibre clamping - Major Less Than=2m

5.14 Feeder/Fibre labelling - Major OK

5.15 Feeder/fibre inlet & other cable openings are sealed OK

properly using durable UV-resistant products - Major

5.16 GPS antenna installation and cable routing are done N/A

properly (Using clamps when fixing to tower member and

cable ladder) - Major

5.17 Antenna type & model (Manufacture Code No.) - Major Huawei 8 port

5.18 Sector A Antenna down Electrical tilt (Measure through 4

digital tilt meter) - Major

5.19 Sector B Antenna down Electrical tilt (Measure through 4

digital tilt meter) - Major

5.20 Sector C Antenna down Electrical tilt (Measure through 4

digital tilt meter) - Major

5.21 Sector D Antenna down Electrical tilt (Measure through N/A

digital tilt meter) - Major

5.22 Sector P Antenna down Electrical tilt (Measure through N/A

digital tilt meter) - Major

5.23 Sector Q Antenna down Electrical tilt (Measure through N/A

digital tilt meter) - Major

5.24 Sector R Antenna down Electrical tilt (Measure through N/A

digital tilt meter) - Major

5.25 Sector S Antenna down Electrical tilt (Measure through N/A

digital tilt meter) - Major

5.26 Sector W Antenna down Electrical tilt (Measure through N/A

digital tilt meter) - Major

Generated through InfraMS Page 5/17

5.27 Sector X Antenna down Electrical tilt (Measure through N/A

digital tilt meter) - Major

5.28 Sector Y Antenna down Electrical tilt (Measure through N/A

digital tilt meter) - Major

5.29 Sector Z Antenna down Electrical tilt (Measure through N/A

digital tilt meter) - Major

5.30 Sector A Antenna down Mechanical tilt (Measure through 0

digital tilt meter) - Major

5.31 Sector B Antenna down Mechanical tilt (Measure through 0

digital tilt meter) - Major

5.32 Sector C Antenna down Mechanical tilt (Measure through 0

digital tilt meter) - Major

5.33 Sector D Antenna down Mechanical tilt (Measure through 0

digital tilt meter) - Major

5.34 Sector P Antenna down Mechanical tilt (Measure through 0

digital tilt meter) - Major

5.35 Sector Q Antenna down Mechanical tilt (Measure through 0

digital tilt meter) - Major

5.36 Sector R Antenna down Mechanical tilt (Measure through 0

digital tilt meter) - Major

5.37 Sector S Antenna down Mechanical tilt (Measure through 0

digital tilt meter) - Major

5.38 Sector W Antenna down Mechanical tilt (Measure through 0

digital tilt meter) - Major

5.39 Sector X Antenna down Mechanical tilt (Measure through 0

digital tilt meter) - Major

5.40 Sector Y Antenna down Mechanical tilt (Measure through 0

digital tilt meter) - Major

5.41 Sector Z Antenna down Mechanical tilt (Measure through 0

digital tilt meter) - Major

5.42 Sector A Antenna at correct tower leg - Major A

5.43 Sector B Antenna at correct tower leg - Major B

5.44 Sector C Antenna at correct tower leg - Major C

5.45 Sector D Antenna at correct tower leg - Major N/A

5.46 Sector P Antenna at correct tower leg - Major A

5.47 Sector Q Antenna at correct tower leg - Major B

5.48 Sector R Antenna at correct tower leg - Major C

5.49 Sector S Antenna at correct tower leg - Major N/A

5.50 Sector W Antenna at correct tower leg - Major N/A

Generated through InfraMS Page 6/17

5.51 Sector X Antenna at correct tower leg - Major N/A

5.52 Sector Y Antenna at correct tower leg - Major N/A

5.53 Sector Z Antenna at correct tower leg - Major N/A

5.54 Sector A Antenna at correct tower height - Major Existing

5.55 Sector B Antenna at correct tower height - Major Existing

5.56 Sector C Antenna at correct tower height - Major Existing

5.57 Sector D Antenna at correct tower height - Major N/A

5.58 Sector P Antenna at correct tower height - Major Existing

5.59 Sector Q Antenna at correct tower height - Major Existing

5.60 Sector R Antenna at correct tower height - Major Existing

5.61 Sector S Antenna at correct tower height - Major Existing

5.62 Sector W Antenna at correct tower height - Major Existing

5.63 Sector X Antenna at correct tower height - Major Existing

5.64 Sector Y Antenna at correct tower height - Major Existing

5.65 Sector Z Antenna at correct tower height - Major Existing

5.66 Sector A Antenna directions (According to Mobitel Existing

information, measure through cell alignment tool) - Major

5.67 Sector B Antenna directions (According to Mobitel Existing

information, measure through cell alignment tool) - Major

5.68 Sector C Antenna directions (According to Mobitel Existing

information, measure through cell alignment tool) - Major

5.69 Sector D Antenna directions (According to Mobitel Existing

information, measure through cell alignment tool) - Major

5.70 Sector P Antenna directions (According to Mobitel Existing

information, measure through cell alignment tool) - Major

5.71 Sector Q Antenna directions (According to Mobitel Existing

information, measure through cell alignment tool) - Major

5.72 Sector R Antenna directions (According to Mobitel Existing

information, measure through cell alignment tool) - Major

5.73 Sector S Antenna directions (According to Mobitel Existing

information, measure through cell alignment tool) - Major

5.74 Sector W Antenna directions (According to Mobitel Existing

information, measure through cell alignment tool) - Major

5.75 Sector X Antenna directions (According to Mobitel Existing

information, measure through cell alignment tool) - Major

Generated through InfraMS Page 7/17

5.76 Sector Y Antenna directions (According to Mobitel Existing

information, measure through cell alignment tool) - Major

5.77 Sector Z Antenna directions (According to Mobitel Existing

information, measure through cell alignment tool) - Major

5.78 Feeder/fibre & jumper connectors are sealed properly using OK

durable UV-resistant products - Major

5.79 TX VSWR Test (Less than or equal 1.4) - Major Sector P

Sector Q

Sector R

5.80 RX VSWR Test (Less than or equal 1.4) - Major Sector P

Sector Q

Sector R

5.81 TX VSWR Test (Greater than 1.4) - Major N/A

5.82 RX VSWR Test (Greater than 1.4) - Major N/A

5.83 TX DTF Test (Less than or equal 1.05) - Major N/A

5.84 RX DTF Test (Less than or equal 1.05) - Major N/A

5.85 TX DTF Test (Greater than 1.05) - Major N/A

5.86 RX DTF Test (Greater than 1.05) - Major N/A

5.87 Antenna pole is vertical - Major N/A

5.88 Antenna pole is not vertical - Major N/A

5.89 Ability to reach the antennas for O&M works - Major OK

5.90 GPS verification Latitude (Check by LMT) - Major Existing

5.91 GPS verification Longitude (Check by LMT) - Major Existing

External Alarm Test

No Task Status

6.1 Intruder Alarm (Including battery cabinets) - Major N/A

6.2 Smoke Detector Alarm - Major N/A

6.3 Temperature Alarm (Including battery cabinets) - Major N/A

Generated through InfraMS Page 8/17

6.4 Water Leakage Alarm - Major N/A

6.5 Main AC Fault Alarm - Major N/A

6.6 DC Under/Over Voltage Alarm - Major N/A

6.7 Battery Low Voltage Alarm - Major N/A

6.8 Fan Fault Alarm (Including battery cabinets) - Major N/A

6.9 Surge Arrester Alarm - Major N/A

6.10 DC Under Voltage Threshold (Value) - Minor Existing

6.11 AC Under Voltage Threshold (Value) - Minor Existing

6.12 Battery Circuit/Loop Broken Alarm - Major N/A

Call Test

No Task Status

7.1 Mobile to Mobile - Major OK

7.2 Mobile to Other - Major OK

7.3 GPRS Testing - Major OK

RF Cable Diagram for RFU

No Task Status

Miscellaneous

No Task Status

9.1 Black UV-resistant ties are used for outdoor cable fastening OK

- Minor

9.2 Site is clean - Minor OK

9.3 Retain the additional engineering materials for future use N/A

(Bonding tapes, insulation tapes etc.) - Minor

Site BOQ

No Task Status

Integration Test

No Task Status

Generated through InfraMS Page 9/17

11.1 AC power test - Phase to Neutral (V) Existing

11.2 AC power test - Neutral to Earth (V)

11.3 DC power test - BBU (V)

11.4 DC power test - RRU1 (V)

11.5 DC power test - RRU2 (V)

11.6 DC power test - RRU3 (V)

11.7 VSWR test by LMT (If using fibre optical, VSWR is less than

or equal 1.3) S0

11.8 VSWR test by LMT (If using fibre optical, VSWR is less than

or equal 1.3) S1

11.9 VSWR test by LMT (If using fibre optical, VSWR is less than

or equal 1.3) S2

11.10 Transmit output power test by LMT (dBm) S0

11.11 Transmit output power test by LMT (dBm) S1

11.12 Transmit output power test by LMT (dBm) S2

11.13 Remote parameter: At UE connection mode and near the

site (NodeB): CPICH_RSCP is greater than -85 dBm

11.14 Remote parameter: At UE connection mode and near the

site (NodeB): CPICH_Ec/Io is greater than -8 dB

11.15 Remote parameter: At UE connection mode and near the

site (eNodeB): RSRP is greater than -90 dBm

11.16 Remote parameter: At UE connection mode and near the

site (eNodeB): SINR is greater than 19 dB

11.17 UE location update is successful OK

11.18 Video call is successful OK

11.19 Data download test result (Mbps)

11.20 Data upload test result (Mbps)

11.21 Primary scrambling code - S0

11.22 Primary scrambling code - S1

11.23 Primary scrambling code - S2

Inventry S/N

No Task Status

12.1 BTS Cabinet Serial number

Generated through InfraMS Page 10/17

12.2 TX Cabinet Serial number

12.3 Battery Cabinet Serial number

12.4 RFU 1 Serial number

12.5 RFU 2 Serial number

12.6 RFU 3 Serial number

12.7 RFU 4 Serial number

12.8 RFU 5 Serial number

12.9 RFU 6 Serial number

12.10 BBU Serial number

12.11 UPEU 1 Serial number

12.12 UPEU 2 Serial number

12.13 UPEU 3 Serial number

12.14 FAN 1 Serial number

12.15 FAN 2 Serial number

12.16 GTMU Serial number

12.17 WMPT Serial number

12.18 LMPT Serial number

12.19 UMPT Serial number 210305488610KC000133

12.20 WBBP 1 Serial number

12.21 WBBP 2 Serial number

12.22 WBBP 3 Serial number

12.23 UBBP 1 Serial number 022HEJ10G7005919

12.24 UBBP 2 Serial number

12.25 UBBP 3 Serial number

12.26 LBBP Serial number

12.27 UTRP Serial number

12.28 UEIU Serial number

12.29 UELP Serial number

12.30 UFLP Serial number

12.31 ULIG Serial number

Generated through InfraMS Page 11/17

12.32 SLPU Serial number

12.33 DCPDU Serial number

12.34 RRU 1 Serial number 2102311BBK10J4001017

12.35 RRU 2 Serial number 2102311BBK10J4001016

12.36 RRU 3 Serial number 2102311BBK10J4000896

12.37 RRU 4 Serial number

12.38 RRU 5 Serial number

12.39 RRU 6 Serial number

12.40 RRU 7 Serial number

12.41 RRU 8 Serial number

12.42 RRU 9 Serial number

12.43 RRU 10 Serial number

12.44 RRU 11 Serial number

12.45 RRU 12 Serial number

12.46 PSU 1 Serial number

12.47 PSU 2 Serial number

12.48 PSU 3 Serial number

12.49 PSU 4 Serial number

12.50 Monitoring Module (SMU) Serial number

12.51 User Interface Module (UIM) Serial number

12.52 GPS Serial number

12.53 Combiner 1 Serial number

12.54 Combiner 2 Serial number

12.55 Combiner 3 Serial number

12.56 Combiner 4 Serial number

12.57 Antenna 1 Serial number N01990006505

12.58 Antenna 2 Serial number N01990008011

12.59 Antenna 3 Serial number N01980023744

12.60 Antenna 4 Serial number

12.61 Antenna 5 Serial number

Generated through InfraMS Page 12/17

12.62 Antenna 6 Serial number

12.63 Antenna 7 Serial number

12.64 Antenna 8 Serial number

12.65 Antenna 9 Serial number

12.66 Battery 1 Serial number

12.67 Battery 2 Serial number

12.68 Battery 3 Serial number

12.69 Battery 4 Serial number

12.70 Battery 5 Serial number

12.71 Battery 6 Serial number

12.72 Battery 7 Serial number

12.73 Battery 8 Serial number

12.74 Battery 9 Serial number

12.75 Battery 10 Serial number

12.76 Battery 11 Serial number

12.77 Battery 12 Serial number

12.78 Battery 13 Serial number

12.79 Battery 14 Serial number

12.80 Battery 15 Serial number

12.81 Battery 16 Serial number

Inventry Qty

No Task Status

13.1 SPD Qty 0

13.2 ACPDB Qty 0

13.3 Meter cubical Qty 0

13.4 32A 4P breaker Qty 0

13.5 40A 4P breaker Qty 0

13.6 DC breaker Qty 0

13.7 4x16mm2 AC cable Qty (m) 0

Generated through InfraMS Page 13/17

13.8 4x10mm2 AC cable Qty (m) 0

13.9 GI pipe length Qty (m) 0

13.10 Additional cabinet Qty 0

13.11 SPD pole Qty 0

13.12 Feeder earth kit Qty 0

13.13 Feeder length Qty (m) 0

13.14 Fibre length - per fibre (m) 60

13.15 Feeder clamp Qty 0

13.16 Fibre clamp Qty 60

13.17 RRU DC power cable Qty (m) 171

13.18 TMA Qty 0

13.19 GSM antenna bracket Qty 0

13.20 GI plinth Qty 0

13.21 Conversion plate Qty 0

13.22 Cable ladder Qty (m) 0

13.23 Cable extension bar Qty 0

13.24 35mm2 earth cable Qty (m) 0

13.25 25mm2 earth cable Qty (m) 0

13.26 16mm2 earth cable Qty (m) 6

13.27 35mm2 DC cable Qty (m) 0

13.28 25mm2 DC cable Qty (m) 0

13.29 16mm2 DC cable Qty (m) 0

13.30 Bus bar (Inside cabinet) Qty 0

13.31 Cu tape Qty (m) 0

13.32 ECB Qty 0

13.33 GI coated flexible PVC Qty (m) 35

13.34 PVC pipe length Qty (m) 162

13.35 IF cable Qty (m) 0

13.36 Jumper cable (3m) Qty 12

13.37 Jumper cable (5m) Qty 0

Generated through InfraMS Page 14/17

13.38 Ethernet cable Qty (m) 0

13.39 Cad weld Qty 0

13.40 Optical fibre cable (Multi-mode) Qty 3

13.41 SFP module (Multi-mode) Qty 6

13.42 Optical fibre cable (Single-mode) Qty 0

13.43 SFP module (Single-mode) Qty 0

13.44 RRU power earth kit Qty 0

13.45 For TX: Ethernet cable Qty (m) 0

13.46 For TX: Fibre cable Qty (m) 2

13.47 For TX: Single-mode SFP Qty 0

13.48 For TX: GI pipe Qty (m) 0

13.49 For TX: GI flexible Qty (m) 0

13.50 Ladder support pole 1m Qty 0

13.51 Ladder support pole 2m Qty 0

13.52 Ladder support pole 3m Qty 0

13.53 GPS arrester Qty 0

13.54 GPS cable (m) 0

13.55 4X4 PVC casing Qty (m) 0

13.56 Combiner bracket Qty (with steel tie) 0

13.57 Extended RRU bracket Qty 0

13.58 (Combiner + RRU) bracket Qty 0

13.59 Installation materials package Qty (including bonding tape, 1

insulation tape, cable tie etc.)

13.60 Battery installation materials package Qty (including lug, 0

terminal, breather line and loop-broken alarm cable for 4-8

batteries)

13.61 Battery installation materials package Qty (including lug, 0

terminal, breather line and loop-broken alarm cable for

12-16 batteries)

PAC Eligibility

No Task Status

14.1 PAC Eligibility - Earthing OK

Generated through InfraMS Page 15/17

14.2 PAC Eligibility - Hardware Installation OK

14.3 PAC Eligibility - Cabling OK

14.4 PAC Eligibility - Antenna and Feeders OK

14.5 PAC Eligibility - Alarm OK

Punch List

No Task Status

15.1 Punch List item1

15.2 Punch List item2

15.3 Punch List item3

15.4 Punch List item4

15.5 Punch List item5

15.6 Punch List item6

15.7 Punch List item7

15.8 Punch List item8

15.9 Punch List item9

15.10 Punch List item10

Genaral Remarks

No Task Status

16.1 PAT Remarks Mobitel direct implementation site

Site Images

No Task Status

Image Proof

Generated through InfraMS Page 16/17

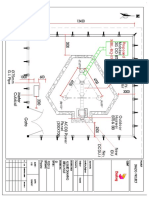

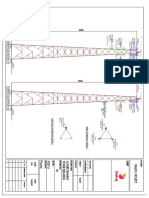

RFU cable diagram BOQ Plinth Image

Meter Cubical Image ACDB Images SPD Images

Special Notes

Huawei shall inform any inventory mismatches within 2 weeks from the PAT approved date in the system.

If there are no changes within this period, approved inventory will be considered for issuing PAC.

Approver's Remarks

Name Comments Date Org

Varuna Hemachandra Approved. Mobitel direct 2020-07-06 14:28:36 Mobitel

implementation site

Process Infomation

PAT Performed By PAT Pass By

Chamindu Chathuranga Varuna Hemachandra

Mobitel Mobitel

2020-07-06 14:28:36

Generated through InfraMS Page 17/17

Powered by TCPDF (www.tcpdf.org)

You might also like

- Netsure Control Unit (Ncu) : User Manual, Umm830B Document Code: 11 Ko 7503 JL (Revision B, October 24, 2014)Document172 pagesNetsure Control Unit (Ncu) : User Manual, Umm830B Document Code: 11 Ko 7503 JL (Revision B, October 24, 2014)Sahand ArasNo ratings yet

- Cognition and Hierarchy Rethinking The Microfoundations of Capabilities' DevelopmentDocument20 pagesCognition and Hierarchy Rethinking The Microfoundations of Capabilities' Developmentdumindu1No ratings yet

- Business Intelligence and Analytics - Research DirectionsDocument12 pagesBusiness Intelligence and Analytics - Research Directionsdumindu1No ratings yet

- The Link-Prediction Problem For Social Networks: David Liben-NowellDocument13 pagesThe Link-Prediction Problem For Social Networks: David Liben-Nowelldumindu1No ratings yet

- Teece Et Al-1997-Strategic Management JournalDocument25 pagesTeece Et Al-1997-Strategic Management JournalAsna UswatunNo ratings yet

- NetSure 701 A30 - User ManualDocument58 pagesNetSure 701 A30 - User ManualJames Erwin GupongNo ratings yet

- MBL-RQ-050998 - Pinpara Site Layout - DWG PDFDocument1 pageMBL-RQ-050998 - Pinpara Site Layout - DWG PDFdumindu1No ratings yet

- MBA508 HRM - S2 - Rec and Sel - HODocument13 pagesMBA508 HRM - S2 - Rec and Sel - HOdumindu1No ratings yet

- NetSure 701 A50 - User ManualDocument96 pagesNetSure 701 A50 - User ManualJune JangNo ratings yet

- Preliminary Acceptance Test (Mobitel) - TXDocument9 pagesPreliminary Acceptance Test (Mobitel) - TXdumindu1No ratings yet

- MBA508 HRM - S3 - Employee Discipline - HO PDFDocument25 pagesMBA508 HRM - S3 - Employee Discipline - HO PDFdumindu1No ratings yet

- Training: Session ExtractsDocument11 pagesTraining: Session Extractsdumindu1No ratings yet

- PAT Status:: MobitelDocument20 pagesPAT Status:: Mobiteldumindu1No ratings yet

- Mba508 HRM - S1 - SHRM - HoDocument11 pagesMba508 HRM - S1 - SHRM - Hodumindu1No ratings yet

- MBL-RQ-050998 - Pinpara Tower Layout - DWGDocument1 pageMBL-RQ-050998 - Pinpara Tower Layout - DWGdumindu1No ratings yet

- Kaudulla ModelDocument1 pageKaudulla Modeldumindu1No ratings yet

- Pinpara Dialog AP MBL-RQ-050998Document1 pagePinpara Dialog AP MBL-RQ-050998dumindu1No ratings yet

- 611 Eirc1: - Pass - Reject - Pass With MinorDocument23 pages611 Eirc1: - Pass - Reject - Pass With Minordumindu1No ratings yet

- PAT Status:: - Pass - Pass With Minor El - Reject ElDocument16 pagesPAT Status:: - Pass - Pass With Minor El - Reject Eldumindu1No ratings yet

- Rcl6Nka. Mobitel: Pat StatusDocument20 pagesRcl6Nka. Mobitel: Pat Statusdumindu1No ratings yet

- LTERRU - ANTENNASWAP of COL523 - 201007100817Document18 pagesLTERRU - ANTENNASWAP of COL523 - 201007100817dumindu1No ratings yet

- Moratuwa UniversityDocument23 pagesMoratuwa Universitydumindu1No ratings yet

- BTSPAT of ZHOM53Document18 pagesBTSPAT of ZHOM53dumindu1No ratings yet

- Hapugasthalawa TSSRDocument19 pagesHapugasthalawa TSSRdumindu1No ratings yet

- TBC Battery Cabinet AlarmDocument16 pagesTBC Battery Cabinet Alarmdumindu1No ratings yet

- GMALU1Document21 pagesGMALU1dumindu1No ratings yet

- Galle SLT PDFDocument23 pagesGalle SLT PDFdumindu1No ratings yet

- Moratuwa UniversityDocument23 pagesMoratuwa Universitydumindu1No ratings yet

- Muddaragama-Existing Site Layout-Model PDFDocument1 pageMuddaragama-Existing Site Layout-Model PDFdumindu1No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Control Remoto VORDME ThalesDocument170 pagesControl Remoto VORDME Thalesexeluc75No ratings yet

- Reyrolle 5 Platform: Protecting Grids With ConfidenceDocument52 pagesReyrolle 5 Platform: Protecting Grids With ConfidenceSidnei PelegrinNo ratings yet

- Licence Microsoft OS / Biznisoft: Mega VivaDocument7 pagesLicence Microsoft OS / Biznisoft: Mega Vivavlada1589No ratings yet

- 1734 Ib8s Ob8sDocument148 pages1734 Ib8s Ob8sJair PinhoNo ratings yet

- 18ECE205J - FPGA-based Embedded System Design - Unit - 1Document151 pages18ECE205J - FPGA-based Embedded System Design - Unit - 1Vikram Adithya AnandNo ratings yet

- Program: B.Tech, CSE, Semester-III, Year-II CS-304: Digital Systems K-Map-02Document21 pagesProgram: B.Tech, CSE, Semester-III, Year-II CS-304: Digital Systems K-Map-02Prakhar DixitNo ratings yet

- Testing A Transistor With A Digital Multimeter - Inst ToolsDocument5 pagesTesting A Transistor With A Digital Multimeter - Inst ToolsshafieeNo ratings yet

- Antenna PatternDocument1 pageAntenna PatternHirak Jyoti MazumdarNo ratings yet

- T 1000 PLUS en PDFDocument8 pagesT 1000 PLUS en PDFMario ŠincekNo ratings yet

- Xilinx XC9500 CPLD Series: The Low-Cost Solution For 2.5V, 3.3V, and 5V ApplicationsDocument2 pagesXilinx XC9500 CPLD Series: The Low-Cost Solution For 2.5V, 3.3V, and 5V ApplicationsAntonio VelkovNo ratings yet

- Exora - MCBs & DBs - CatalogueDocument48 pagesExora - MCBs & DBs - CataloguePrahaladNo ratings yet

- EH Manual EnglishDocument6 pagesEH Manual EnglishHasan CosalevNo ratings yet

- Virtual Laboratory: Circuit Construction Kit - DC: InstructionsDocument6 pagesVirtual Laboratory: Circuit Construction Kit - DC: InstructionsSharon Gracia LigutanNo ratings yet

- Engine OverheatDocument30 pagesEngine OverheatGopuNo ratings yet

- Honeywell 914CE2 3 DatasheetDocument149 pagesHoneywell 914CE2 3 DatasheetjokoNo ratings yet

- SE - EEP Syllabus New 17-18 CGPADocument38 pagesSE - EEP Syllabus New 17-18 CGPAlvb123No ratings yet

- 2 SC 2240Document6 pages2 SC 2240silvertronicNo ratings yet

- SJ 1045EXeDocument232 pagesSJ 1045EXeRenato CarneiroNo ratings yet

- Detcon Model TP-524D: Instruction ManualDocument41 pagesDetcon Model TP-524D: Instruction ManualMarthin PurbaNo ratings yet

- Ariston Dishwasher Service ManualDocument23 pagesAriston Dishwasher Service Manualmohamed TohamyNo ratings yet

- Final Year Project ReportDocument57 pagesFinal Year Project ReportVAnshaj Crickfreak JhaNo ratings yet

- Modbus IO Module v1.2Document12 pagesModbus IO Module v1.2Andrey KuzhilnyNo ratings yet

- Models - Heat.microchannel Heat SinkDocument16 pagesModels - Heat.microchannel Heat SinkvishnuNo ratings yet

- AK4386ET - Asahi Kasei Microsystems Co., Ltd. (AKM) - Datasheet - SupportDocument18 pagesAK4386ET - Asahi Kasei Microsystems Co., Ltd. (AKM) - Datasheet - Supporttushar contractorNo ratings yet

- Lic-Model ExamDocument1 pageLic-Model ExamarivasanthNo ratings yet

- Assignment 1 UM AnswersDocument10 pagesAssignment 1 UM AnswersMaheswaran UmaiyorupaganNo ratings yet

- Test 1 SKEE3223 201520161 Rev3 - SOLUTION PDFDocument3 pagesTest 1 SKEE3223 201520161 Rev3 - SOLUTION PDFBAHARUDIN BURAHNo ratings yet

- SDMyers Test Packages BrochureDocument4 pagesSDMyers Test Packages BrochureYesid FigueroaNo ratings yet

- MicrocontrollersDocument1 pageMicrocontrollersprettyswagNo ratings yet

- Basic Cell Specification (BS Series)Document4 pagesBasic Cell Specification (BS Series)parahu ariefNo ratings yet