Professional Documents

Culture Documents

Us20150240322a1 PDF

Us20150240322a1 PDF

Uploaded by

mazaherramazani0 ratings0% found this document useful (0 votes)

24 views12 pagesOriginal Title

US20150240322A1.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views12 pagesUs20150240322a1 PDF

Us20150240322a1 PDF

Uploaded by

mazaherramazaniCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

US 20151

cu») United States

20150240322.

cz) Patent Application Publication co) Pub. No.: US 2015/0240322 Al

Sakaguchi et al.

(54) SLAG REMOVAL DEVICE AND SLAG

REMOVAL METHOD

(71) Applicant: MITSUBISHI HEAVY INDUSTRIES,

LID.,"Tekyo UP)

Inventors: Masakazu Sakaguch

‘Tsutomu Hamada, Tokyo (JP); Takeshi

Okada, Tokyo (UP); Setsuo Ometo,

Tokyo (IP); Kellehi Nakagawa, Tokyo

ae}

Tokyo UP:

MITSUBISHI HEAVY INDUSTRIES,

LTD.,"Tokyo UP)

(73) Assignee

(21) Appl.Nos — 14428,907

(22) PCTFiled: Sep. 10,2013

(86) PCT No

$371 (M1,

(2)Date

PevisP201v07s414

Mar. 17, 2015

G0) Foreign Application Priority Data

Sep.20.2012 (UP) 2012-207275

2

(43) Pub, Date Aug. 27, 2015

ication Classification

ca)

200601)

(2005.01)

(2005.01),

(2006.01)

(2)

C218 7/00 (2013.01), C21B 5/003 (2013.01):

C218 S/001 (2013.01); F27D 3345:

(2013.01), £27 28/00 (201301),

6 ABSTRACT

Provided isa slag removal device fora blast fumace, capable

‘of readily and olably achieving slg removal using a simple

‘device configuration, even when pulverized coal is use that

has not had the softening temperature thereo adjusted, and

capable of reducing as much as possible the risk of pipe

‘damage, ete. The slag removal device for a blow pipe is

provided ia blow pipe that injects auxiliary fuel pulverized

coal together with hot air from a tuyere fora blast furnace

‘ain boy tht produces pig ion from iron ore. jet nozzle

tha injects solids having a higher fasion point than th tem-

perature in the vicinity of the myere and having a particle

‘amicter greater than that ofthe pulverized coal, nto puver

‘ned coal that Hows inside the blow pipe and into the hot ag,

is provided in the slag removal device

soups

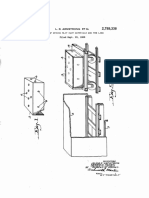

Patent Application Publication Aug. 27,2015 Sheet 1 of 4 US 2015/0240322 AI

soLas

FIG. 1

US 2015/0240322 AI

Aug. 27,2015 Sheet 2 of 4

Patent Application Publication

enlisting

é'Old

we

Patent Application Publication Aug. 27,2015 Sheet 3 of 4 US 2015/0240322 AI

30

FIG. 3

83

de

Patent Application Publication Aug. 27,2015 Sheet 4 of 4 US 2015/0240322 AI

US 2015/0240322 Al

SLAG REMOVAL DEVICE AND SLAG.

REMOVAL METHOD.

‘TECHNICAL FIFLD

10001] ‘The present invention relates to a slag removal

‘device anda slag removal method fora blow pipe foruse with

blast lumace, and in paniculata slag removal deviceand

‘slay removal method that ean be advantageously wsed on 3

blow pine for injecting pulverized coal obtained by ensshing

Jow-grade eoa into-a furnace as an ilar’ fuel along with

hot aie

BACKGROUND ART

10002] A blast furnace’ used to produce pig iva fom iro

‘ore by introducing feedstocks such as iron ore, limestone,

‘oul, ad the like into the interior ofa bast Furaace main body

from the apex thereof, and injecting hot air and pulverized

‘coal (PCT coal) as an auxiliary fuel through a tuyere located

tovant the bottom on a sie ofthe furnace.

10003] In a blast fumace of this sort, if low-grade coal

enerlly having alow ash melting point of 1,100 10 1.300?

C, such 98 sub-bituminous coal oF lignite, is used as the

pulverized coal during the operation of injecting pulverized

‘coal, the oxygen contained inthe roughly 1,200" C. bot aie

used to inject the pulverized coal into the fumace engages ia

8 combustion reaction with part ofthe pulverized eae. The

‘combustion heat generated thereby causes low-melting point

‘oul (“slag”) t0 melt within the injection lance or tuyere.

10004] The melted slag is rapidly cooled through contact

with the tuyere, whichis constantly cooled in onde o protest

tom the temperature ofthe blast fumace, As esl solid

slag adheres tothe tuyere, leading to the problem of blockage

inthe blow pipe flow path

{0005} In order to solve such a problem, for example, in &

‘cate where the slag solening temperature in the pulverized

‘oa is fos, as inthe technique ofthe related art disclosed in

Patent Document I described below a solening temperature

adjusting process is performed so as to reach a melting point

Which isthe temperature inside the furnace o higher, and the

slag is prevented from adhering wo the tuyere

[0006] In addition, Patent Document 2 described below

discloses removing slag by injecting hac halls into a tuyere

froma furnaoe-exterior side end of the tuyere

[0007] Furthemore, in order to remove deposits whic

‘accumulate in gaps formed at end sections of tWo lances,

Patent Document 3 described below discloses vibrating the

Jances by injecting solid chips with a partiele diameter of 1.0

2am,

CITATION LISTS,

Patent Literatures

10008} Patent Document 1: Japanese Unexamined Patent

Application No, 105-156330A,

10009] Patent Document 2: Japanese Unexamined Patent

Application No, H06-192714A

[0010] Patent Document 3: Japanese Unexamined Patent

Application Publication No, 2006633768,

Aug. 27, 2015

SUMMARY OF THE INVENTION

Problems to be Solved by the Invention

[0011] However, the following problems havebeen pointed

‘ut in the related art techniques described above,

0012} A problem withthe related art technique disclosed

in Patent Document 1 s that completely (unifomly) mixing

pulverized coal and solid additives (a slag making agent) is

ficult and, as a result, itis not possible to prevent slag

‘oxming in portion where the mixing ratio ofthe additives is

lessthan a predetermined valve. Inaditon, ina ease oF using

additives, there is also a problem in that extra costs are

Jncurred since a new source ofealeium oxide (CaO) such as

Jimestone or sepentine is necessary.

[0013] Next a problem with the related art technique di

closed in Patent Document 2sthat all ofthe hard balls donot

always collide with the slog. Ths, if there are any hard balls

that do.not colic with the sag, there isa concern that these

balls will directly collide with the inner surface ofthe blow

pipe, creating te risk of problematic damage to the pipe or

{he like from the collision ofthe balls. In Patent Document 2,

the slag broken using the hard balls is formed on air injection

‘uyeres and insulation rings,

[0014] The related art technique disclosed in Patent Doeu-

‘meat 3 is for vibrating lances and application thereof to @

blow pipe ora tuyere is dificull

[0015] In view ofthese circumstances, there is @ demand

Tora slag removal deviee fora blow pipe for use with blast

furnace facilites that allows for easy and reliable slag

removal using as simple a deviee arrangement as possible

‘without adjusting a softening tempersture, In addition, there

isa demand for slag removal device fora blow pipe for use

‘with blast furnace facilities that reduces the risk of pipe dame

‘age and te like as much as possible and allows for easy and

‘liable slag removal using a simple a device arrangement as

possible

[0016] The present invention has been made to solve the

problems deseribed shove and an object ofthe present iaven-

tion i to provide a slag removal device and a slag removal

‘method fora blast fumace which are able to achieve easy and

reliable slag removal using a simple device configuration

{even when using pulverized coal that has not had the soften-

ing temperature thereof adjusted and which are capable of

‘een as much as possible the risk of pipe damage, and the

Tike.

“Means for Resolving the Problems

[0017] In order to solve the problem described above, the

present invention employs the following means.

[0018] _ slag removal device according toa frst aspect of

the present invention isa slag removal device fora blow pipe

‘whieh is provided in a blow pipe that injects pulverized coal

asan auxiliary fuel along with hot air from a tuyere of bast

umace main body that produces pg ion from iron or, with

slag ofthe pulverized eoal ineluding 2 component that mets

fs 8 result of the hot air and/or combustion heat of the pal

verized coal, The slag removal deviee is provided witha jet

roze that injets solids having a higher melting point than

the temperature in the vicinity of the tuyere and having a

particle diameter greater than that of the pulvesized coal, into

‘he pulverized coal that ows inside the bla piped nto the

US 2015/0240322 Al

hot ai, the jet nozzle being provided wih a solids supply

system that supplics the solids and hor provided therein a

‘open close conto valve.

10019} According to the slag removal devie aeonding to

the ist aspect ofthe resent invention, theres provided jet

nozzle that injects solids having higher ming poet than

the temperature inthe vicinity of the tuyere and having &

parle ameter arater Un tht ofthe pulverized oa, sto

thopulverized coal tat flows inside the blow pipe and into the

hot air Alb, the jt nozzle is provide with a slid supply

system that supplies the solids and has provided therein a

‘openelose control valve. Thereby, the solids that are blown

ftom the jet nozzle into the inter ofthe blow pipe proceed

without meting withthe Now of hot air asa propulsive Tore,

and itis posible to remove slg by aplying & mechanies

Rc 10 slag adhered inthe vicinity ofthe aver. In tc

it spossible to seth ow of the hot ar asthe propa

sive fore ofthe slid inside the bls pipe

{0020} Examples of suitable solids include pranular eo

slog, ime grains pelt rains, interedoe, on poder, and

the like, and one ype ora mixtereof «pray of types may

he used rom among these

10021] tispreerble thatthe invention desribedabovebe

provided witha siting ow forming section tht generates

‘swiring flow ia flow of the hot ai at position om a

upsieam sie rom an injection ance tat nes the polver

$2ed oa in a iterio ofthe blo pipe

{0022} Duct ths, the blown solids are concentrated near

‘and collide with pipe inner surface ora tere incr surface

‘where slag adhered a aresl ofcontfigal force dacto te

Swing fow formed inside the blow pipe

10023] Itspreferale that the invention described above be

provided with a jet nozae that eects liquid towad slag

Sdhesion are inside the blow pipe, the jet nozle being poe

ded witha iguid supply system tat supplies the higukdand

has provided therein an open/close ontrl valve

10024} Due t this, tis possible to carry out the stog

removal by quenching the adhered solid ska by lghid eje=

tion and destroying the solid slag by them compression

before perfonming the slag removal sing the soli,

10025) The etanzleforthesolids and the jet nozzle far the

Tigid deseibed above may each be provided separately, or

say bean integrate no.zle where sponsible To selec the

«ection material by changing the lw channel with an open-

ing and closing operation of the openislse control vale

10026) Ics desirable thatthe invention deseribed above be

provided witha slag detecting means that detects sag adbe

Fon stats according toa pressure difeental between ho

pressure on an upstream side of the jet noze ad hots

pressure in vicinity of an out ofthe bow pipe

10027] “The ahesion ofthe slag reduces the eross-seetonal

seo of helo pth and asa resis possible forthe slog

‘detecting means to detect an inrease inthe pressure differ

‘ental det a iereane in the peetreLss

10028} Inthe vention described above ts preferable tat

the liquid andor the solids be ejecta by opening the open!

else conto valve upon the slg adhesion status detected by

the slog detecting moans being deveined to be a slag

removal tiresold valve or more and thatthe ejecting ofthe

Figo andor the solids be topped by closing the open/close

‘emtol valve upon the slag adhesion evel detected the slog

‘etcting means being determined to be less than a sag

removal stop threshold value

Aug. 27, 2015

[0029] Due to this, it i possible to eect liquid from the

liquid jet nozzle of solids from the jet nozzle only when

necessitated by high slag adhesion level.

[0030] Its preferable that the invention described above be

provided with an alam output threshold value settoa value at

‘whieh the slag adhesion status is preaterdhan the slag removal

‘threshold value

[0031] Duc to this, it is possible to detect that the slag

‘removal isnot being performed by the liquid jet nozzle or et

sozale as planed

[0032] Aslag removal method according oa seeonel aspect

fof the present invention i slag removal method for blow

pipe which i applied in a blow pipe that injects pulverized

foal as an auniliary fuel along with bo ir fom a tuyere of a

blast famace main body that produces pig iron from iron ore,

‘ith slag of the pulverized coal including a component that

‘melts asa result of the hot air andor combustion heat ofthe

pulverized coal The blow pipe is provided with a jet nozzle

that injets solids having a higher melting point than the

‘emperaturein the vicinity of the uyere and having a particle

ameter greater than that ofthe pulverized coal, into the

pulverized coal that flows side the blow piped nto the hot

fir anda jet nozzle that ejects a liquid toward slag adhesion

area inside the blow pipe. The method includes steps of

removing slag i a first stage where slag removal is initially

carried out by ejecting cay the liquid from the jet nozzle, and

removing slagina second stage where slag removal is erred

‘out by ejecting only the solids from the jet nozzle upon it not

being possibleto achieve a predetermined slag removal inthe

removing slag in a fist stage

[0033] According to the slag removal method according to

the second aspect ofthe present invention, there is provided a

jet nozzle that injects solids having a higher melting point

‘han the temperate in the vicinity ofthe tuyere and having a

particle diameter greater than that of the pulverized coal, into

{he pulverized coal that ows inside the bl pipe and nto the

hot si, and a jet nozzle that ejects a Higuid toward a slag

adhesion area inside the blow pipe. Aso, the method includes

‘sleps of removing sag ina first stage where slag removal is

initially eartied out by ejecting only the Tiquid rom the jet

ore, and removing slag in a sooond stage where slag

removal iscatried out by ejecting only’ the solids fom the et

ozele upon it not being possible to achieve a predetermined

‘lag removal inthe removing sag ina ist stage Thereby. the

removing sag in a fit stage using liquid ejection with litle

risk of wear or damage to the pipe in comparison with the

collision of the solids is carried out with priority, and more

reliable slag removal s possible by carrying out the removing

slagin asecond stageby eecting onl the solidsonly ina case

‘where it was not possible to carry out the slag removal with

the Liquid ejection,

[0034] Its desirable thatthe invention described above be

provided witha step of removing slag ina third stage where

lag removals carried ut by gesting the solids and the liquid

‘ogether pont not being possibleto achieve predetermined

slag removal in the removing slag in a second stage.

[035] Due to this, the reliability ofthe slag removal is

{urter improved. Examples of suitable liquids in sucha case

include combustible liquids such as heavy ol

EFFECT OF THE INVENTION

[0036] According to the slag removal device and slag

removal method of the preset invention described above,

since the slag is destroyed and removed by the ejection of

US 2015/0240322 Al

Tiguid andthe ejection of solids, its possible to achieve easy

1d reliable slag removal using a simple device configuration

‘even ina case of using pulverized eval that has not had the

ollening lemperature tereol adjusted and itis possible to

reduce the risk of wear, damage, or the like tothe pipe by

prioritizing the liguid ejection,

10037] As a result, even low-grade coals having low ash

melting points of1,100° C. to 1,300° C, such as sub-bitu

‘ous coal or lgnite, can be used as the pulverized coal co

‘tituting the auxiliary fuel through modifications in which

these are used as feedstock coal. That i, oxygen included ia

the approximately 1,200” C. hot air used t injet the amsil-

jry fuel engages in combustion reaction with the pulverized

‘oa, and low-melting point slag melted by the combustion

heat prociced by this combustion reaction coms into contact

‘with and is rapidly eooleby the cold tuyere; thus, evenifthe

slag solidified and adheres othe tuyere the adbering lagean

‘easily eheoken and removed by spraying thesame with uid

‘or solids, preventing blow pipe Dow path blockages.

BRIEF DESCRIPTION OF THE DRAWINGS.

10038] FIG. 1is a schematic illustration ofan embodiment

‘faslag removal device anda slag removal method according

to the present invention.

10039] FIG. 2 is a schematic stration of « modified

‘example of a switling flow forming section for the slag

removal device and he slag removal method depicted in FIG.

1

[0040] FIG. 3 is main part enlarged view of a configura-

tion example ofa slag detecting means for the slag removal

‘device and the slag removal metho! depicted in FIG. 1.

[0041] FIG. 4 is anillustration of an example arrangement

‘ofa blast furnace to Which the slag removal device and the

sag removal method ilusteated in FIG. 1 are applied

DETAILED DESCRIPTION OF THE INVENTION

[0042] Description wil be given below of an embeat

‘of the slag removal device and slag removal method

Jing tothe present invention with reference to the drawings.

[0043] | Theslag emmoval deviceand slag removal methodol

the present embodiment are nsed with bast furnace in which

pulverized Tons-prade coal constituting the Teestock coal is

Injected throughout a tuyere into a bast furnace along with

hot air

[0048] For example, ina blast furnace such as tat illus

trated in FIG. 4, feedstock 1 constituted by iron ore, lime-

stone, and coal or the like is fod from a metered feedstock

feeder 10 via a transport conveyor Hina a furnace apex

hopper 21 provided a the apex ofa blast furnace main body

20.A plurality of tuyeres 22 is provided ina lower side wall

‘of the bast furnace main body 20 at a roughly uniform piteh

in the circumferential drcction. Each of the tuyeres 22 is

Tinked toa dawastream end of a blow pipe 30 for feeding hot

into the interior ofthe blast furnace main body 20, The

upstream end of each ofthe blow pipes 30 is connected to 3

hot air fesder 40 constituting the source of the hot air 2

supplied to the inteioe of the blast furnace main body 20

[0045] A pulverized coal producing device $0 that per

rms a pretreatment (modification) such as evaporating

‘moisture in the coal out of the feedstock val (sub- bituminous

‘oa, lignite, or other low-grade coal) followed by pulveriz-

ing the low-grade coal to pracce pulverized coal, s provided

near the blast farnace main body 20,

Aug. 27, 2015

[0046] Modified pulverized coal (modified coal) 3 pro-

‘dace by the pulverized coal producing device SVis conveyed

by acarier ys 4, such as nitrogen yas, to acyelone separator

60, The pulverized coal 3 conveyed hy the yas is separated

rom the carrier gas 4hy theeyelone separator 6, after which

the coal fill info and is sored in a storage tank 70, This

modified pulverized coal 3 is used as blast face injection

caal (PCI coal) forthe blast furnace main body 20.

[0047] ‘The pulverized coal 3 within the storage tank 70 is

‘ed into an injection ance (hereafter, “lance” 3 ofthe blow

pipe 30 described above. The pulverized coal 3 combusts

‘bpon being. fed into the hot a Rowing through the blow pipe

30, producing a Name at the end of the blow pipe 30 and

Torming a raceway, This causes the coal or the ike contained

inthe feedstock I being introduced int theblast frnace main

body 20 1 combust. As result, the iron ore contained i the

‘feedstock 1s reduced, Becomes pig iron (molten iron) 8, and

js removed through a pig iron outlet 23

[0048] Prefered properties of the pulverized coal 3 fet

from the lance 31 into the blow pipe 30 as blast furnace

injection coal, that is, ofthe modified pulverized coal (anxil

ity fuel) formed by modifying and pulverizing low-grade

coal, are an oxygen atom content (dry basis) of 10 to 18

‘weight %, and an average pore size of 10 to 50 sanometers

(om). A more preferable average por size forthe modified

pulverized eos is 20 10 $0 nanometers (an).

[0049] In pulverized coal Shaving such properties, there is

a large release of and reduction in tarsforming groups of

‘oxygen-containing functional uroups (carboxyl groups, alde-

hhyde groups, ester groups, iydroxyl groups, et.) but break-

dow (ection) ofthe main skeleton (the combustible com-

ponent primarily formed from carbon, hydrogen, and

‘oxygen s greatly suppressed. Ths, when the col is injected

through the tuyeres 22 into the blast fernace main body 20

‘long with the hot ar 2, the high oxygen atom content ofthe

‘main skeleton and the lage diameter of the pores aot oly

‘eiltates dispersion of te oxygen inthe hot air 2 into the

coal, but also greatly impedes the generation of ta, allowing

{or complete combustion with almost no uncombusted car

bon (soot) being produced,

[0050] In ordero proluce (modify) this pulverized coal 3,

adrying stp of heating (at 110 1 200° C. for 0.5 to 1 hours)

and drying the sub-bituminous eval, Ignite, or other low

rade coal (dry-basis oxygen atom content: greater than 18

‘Weight %; average pore size: 3 t0 4 nm) constituting the

eedstock coal ina low-oxygen atmosphere having an oxygen

concentration of S vol % or less is performed in the pulverized

nal prodvcing device $0,

[081] After moisture is removed in the drying step

‘dseribed above, a dry cisillation step in which the feedstock

coals reheated (at 460 10 $90° C., preferably 500 to 550°C.

for 0.5 to 1 hours) in a low-oxygen ambient atmosphere

(oxygen concestration: 2 vol % oF less) is performed. Dry

stilling the feedstock coal in this dry distillation step

removes generated Wate, carbon dioxide, and tar in he form

‘of ry sillation gas or dry distillation ol,

[052] ‘Te feedstock coal then proceeds ts eoaling step in

‘whieh the coal js cooled (to 50” C. or fess) in a low-oxygen

atmosphere having an oxygen concentration of 2 vol % oF

less, then pulverized (particle diameter: 77 um of loss (80%

pass) in a pulverization step,

[0083] Theembodiment, for example, as illastated in FIG.

1 and FIG. 2, is provided with a jet nozele 80 for injecting

Tiquid 6 or solids 7 with respect tothe interior ofthe blow pipe

US 2015/0240322 Al

30 in onder to remove slag $ adhering tothe surface of the

Jnner wall of the blow pipe 30, the tuyere 22, and the inner

‘wall in the vicinity thereof constituting slag adhesion reas

‘One ora plurality of the jet nozzles 80 is appropriately pro-

vided in the circumferential direction, for example, along the

Jnner circumferential surface ofthe blow pipe 30.

[0054] In such a case, examples of preferred liquids 6 that

‘are ejected from te et nozzle 80 include combustible liquids

suchas water or beavy ol In addition, examples of prelerred

solids 7 that are ejected from the et nozzle 80 include gran-

Jar coal slag, lime grains, pellet grains, sintered or, iron

powder, and the like, and one type ora mixture ofa phuraity

‘ftypes may be wed from among these

W085] The liguid 6 ejected from the jet nozzle $0 rapidly

‘cools the sig adhering to the blow pipe 30 or inthe vicinity

fof the tuyere 22 by effectively ulizing the latent heat of

‘vaporization the Higuid, Since the slag S rapidly cooled as 9

result of the ejection of the guid 6 is broken by thermal

‘contraction, its possible 1 easily remove the sag S.

10036] In contast, since the solids 7 which are ejected rom

the jet nozzle 80 proceed without melting the inside of the

blow pipe 30 with the How of the hot air 2 as a propulsive

fre, the solids 7 collide with the slag $ adhering in the

Vicinity of the uyere 22, Accordingly, itis possible for the

solids 7o apply a mechanical impact othe slag S by colid-

ing therewith, Asa result, itis possible to easily remove the

slag S which undergoes the collision withthe solids 7 since

the slog S is destroyed by the impact at the time of the

collision,

10057] Inordertokeep the opening ofthe outlet ona nozale

‘end 8 from which the Muid 6 or the solids Tare ejected from,

being clogged with pulverized coal 3, slag S, or the like, the

Jet nozzle 80 is preferably disposed at a position substantially

janed, with respect tothe axa direction ofthe blow pine 30

‘with an end section Ma of the lance 31 from which the

pulverized coal 3 is fed, or slightly to the upstream side

there. In such a case, the nozzle end 81 of the jet nozzle 80

preferably has 2 nozzle shape, in particular, for ejecting the

‘uid ina near shape in the direction of the tuyere 22,andan

‘arrangement in which the ejection direction can be altered

may be adopted, 2s necessary, ITan arangement in whieh the

‘jection dieetion of the nozzle end 81 can be altered is,

adopted the supply pressure of the liquid oa solids carrier

fas can be used to swing or rate the nozzle.

[0088] The position with respect to the sudial direction at

hich th jet nozzle 80 is disposed is preferably close to the

de wall of the Blow pipe 30 so as not to resist the low pa

‘of the hot air 2 and so thatthe noze is eapable of diretly

spraying at slag S adhering tothe side wall of the Blow pipe

30

{0089} For example, a strted in FIG, 3, he jt nozzle

80 is connected Wa liquid supply source 83 via liquid

supply pipe #4.

10060] “The laud supply pipe 84 comprises, a6 primary

‘ements, a delivery pump 85 for pusspn the liquid i te

liguid supply souree 8 tothe jet noi 80, and an openclose

‘contol valve 6 for controlling the liquid supply (on and off)

to tho jot nozzle 80 hy switching between open and closed

sates

{0961) Furthermore, the jet nozzle 80 is connected 10 8

sols supply source 87 vi slic supply pipe 88

[0062] Thesoidssuppy source 7 is provided witha solids

‘arir gas ply sna which snot ils the d=

ing, for example, sueh a nitrogen was or the Tike, for the

Aug. 27, 2015

solids, The slid supply pipe 88 comprises as primary el

‘ents, an opeaiclose control valve 89 for controling the

Solids supply (on and of) wo the jet nozzle 80 by switching

between open und close states

[0063] The open/close consol valves 86 and 89 are opened

tuylclosed aeconding othe value of a presre dlfeceatil AP

‘measured By a diferent pressure gauge 90. Tivo pressure

Jntake pipes 900, 9b ae connected wo the diferent pres

sre gatige 90 so as to measure the pressredifercntal AP

between, for example, main hot ai pipe 32 and a down-

stream positon ofthe Blow pipe near tayere22 of thle

Pipe 30

[0064] In ths manner, te jet nozze 80 is provided with

Tigudsuppy system that supplics guid 6 to Beejected and is

provided with the apenflose conto valve86, a solids supply

Stem that supplies te solid 7 0 be ejected ands provided

with the openelose control valve 89. and the differenti

pressure pgs (he slag detecting means) 90 which detects

{he state ofthe slag in the slag.ahesion are, Accordingly it

Js posible forthe et nozzle 8 lusuuted in the drawings

select eitherone othe liquid 6or the solids from one nozzle

end 81 ort eect bo ofthe lguid 6 and the solids 7 atthe

Same time according (© the open and closed sates ofthe

‘peniclose cont valves 86 and 89.

{0065} In the following description, as ihsrted in dhe

awings, description wil be given of configuration in

‘which he igid supply system andthe olds soppy system

de connected to one jt nozle BD; however, the present

invention sot limited to his configuration Specialy the

Iigoid supply system and the solids supply system may be

configure tobe povided with gid jet nozzle or sods

|etoweale which te independent ofeach other

(006) ‘Teslag adhesion eve isdetemined fom the pres-

sue dierent batween the ht ae pressure on the upstream

Sideof be jet nozale80 and thebot pressure ite iin

ofthe outer ofthe blow pine 30.

{0067} Specialy, when there is slag 8 adhering wo the

finer wall of the Blow pipe 30 or eae the tuyeres 22, the

roduction inthe eross-soctional area of th Hw path ofthe

bow pie 30 restesa presure loss, lading to. ection ia

the pressureof the ew of hota rom the mainhotairpipe 32

tothe blast frase main body 20, Thus, the resure intake

Pipe Ma connected to the main ht aie pipe 32 an the pres

Sure intake pipe 96 connect toa dowasiem position of

the blow pipe 30 are used to measure the peesure differenti

Pin thchot ir Pheforeund aller the slogadbesionarea sing

‘hediffrental pressure gauge 99, andthe sizeof he pressure

teen AP used estimate the sag S adhesion sate.

(0068) The pressure differential AP 50 measured is com

pated toa preset threshold value, and used in opening and

Closing the apeaiclose conta valves 6 and 89 deseribed

shove

{0069} In the jet nozzle 80 described above, the slog

removal aay’ be eure! out by ejecting te guid 6 oF the

solids 7 separately. othe slog removal may be cared ou by

ejecting br ofthe Higid 6 andthe solids 7 tthe sae ine

[0070] ovsever, asa preferable slag emoval method, che

slag removal is inily cared xt by only esting te lati

Fromthajetnozzle 80 asthe comoving slg ita first stages,

in case hor it snot posible to achieve a predetermined

Slag removal nthe remoting slag fist stage, the solids 7

fr eto scparly rom the jet nozae 80 as the removing

slag ina second stage.

US 2015/0240322 Al

10071] In addition, as necessary, removing slag in a third

sage in which slag removal i carried out by ejecting the

Tiguid 6and the solids 7 from he jetuozzle80 atthe same time

maybe providedso aso hecuriedout ina case where its not

possible to achieve a predetermined slag removal in the

Femoving shig in a second stage

10072] "Specifically inthe slag removal in which the liquid

6 is ejected, there isan advantage in tat there is lite risk of

‘wear, damage, or the like to the pipe in comparison with the

slag removal by collision withthe solids 7

10073] Accordingly, the romoving stag ina second stage is

‘arti out only when the removing slag ina frst stage using

the liquid ejection is caried out with priority and it was not

possible to remove the slag S with the liquid ejection, for

‘example, only when it was not possible to confirm that the

slag removal was completed even when the liquid ejection

was performed eontinubusly for a predetermined time, AS 2

result, itis possible to reliably remove even the slag S which

‘was lt removed with the Tiquid 6 using the force of the

Jmpact from the solids 7.

10074) Asamore prefeableslag removal method, in acase

Where the solids 7 are ejected separately from the jet nozzle

‘0s theremoving sag ina second stage and itis not possible

to achieve the predetermined slag removal even with the

removing slag ina second stage in which only the solids 7 are

‘ejected, the slag removal i fre eaeied ont by ejecting the

liquid 6nd the solids 7 fromthe jet nozzle Oat the same time

a8 the removing slag. in a third stage. It is desirable that @

‘combustible liquid be used as the liquid 6 the removing slag,

ina thied stage.

10075] Its possible to eect the liguid 6nd the solids 7 at

the same time in the removing slag in a second stage.

10076) Detailed description will be given below of the

threshold value forthe pressure differential AP and the pro-

‘ess of controlling dhe opening and closing of the open/close

‘contol valves 86 and 89 based on the pressure diferental AP

reasured by the differential pressure gage 90. Inthe follow

description, both ofthe Liguid 6 andthe solids Tare ejected

the same time and the operation ofthe delivery pany 85is

started soa to eject the liquid srom the jetnozle 80 ina sate

‘where the apen close contol valve 86 is open

10077) In the embodiment, two threshold values are set:

namely frst threshold value (slag removal resol valve)

HI foropening theopen/elose contol valves 86 and 89 when

the valves are ina closed state, anda second threshold value

(slag removal stop threshold value) LL for elosing the open!

‘lose contol valves 86 and 89 when the valves ae inn ope

10078] For the wo threshold values, the same values may

be used inthe removing slag in the first stage, the second

stage, nd the lke described above, or for example in a case

such as where the removing slag ina first stage using liquid

‘jection is caried out with priority, values which are lager

than the removing slag in first stage may be used in the

removing slag of subsequent stages

10079] “In other words, the first threshold value (slag

emoval threshold vale) HL. is used to open the openiclse

‘contol valves 86 and 89 and eject the liquid 6 and the solids

7T when the slag adhesion level detected by the differential

pressure gauge 90 constituting the slag detecting means is

determined to beat or above the slag removal threshold val.

[0080] The second threshold value (slag removal stop

threshold value) LL is used to close the open/lose control

valves 86 and 89a and stop cjetion ofthe liquid 6 and the

Aug. 27, 2015

solids 7 when the sla adhesion level detected by the fee

ail pressure gnuge constituting thes detecting means

Js determined obs Less dan the slag removal stop thresakd

val

[0081] The openelose contol valves 86 an 89 ae set

the closed state when operation stars Gi tthe inal se-

{ing}, when tere is ao slog S adhesion, and dhe pressure

Aiffrenta AP detected by thedfferetial pressure gnuge 90

{slower than the second threshold valve LL with there being

Almost no pressure differential (A=)

[0082] _Asthe operation the bas mace contnies fom

‘hein sting described above slag Spraally ares to

an acumlates onthe side wall ofthe blow pipe 3nd the

tuyere 20, with the result thatthe How pa resistance also

sradully increases due to theredtin nthe cross-sectional

fen ofthe flow path. Accordingly when the vale of the

pressure iffoental AP detec bythe diffrent presure

iuge 90 increases an eos the fist threshold valve HL

{his is detected by te differential pressure gauge 90, which

cutputsanopen signal tothe openilose control valves 86 and

¥.

[0083] "The openiclse contol valves 86 and 89 are opened

4s the result of the open signal, and, simultaneous. the

delivery pump 88 is started As result te liquid 6 stored in

tne Tid supply source 89s ejected from the jet nozzle 80

toward the interior f the blow pipe 30, and, at thesame time,

{ho solids T which restored the solids supply source 87 are

ko ejected fom the et moze 80 toward the interior ofthe

bow pipe 30

{0084} Asa result, when the eject liquid 6 contacts the

adhered slg 8 the latent het of vaporization therot i lst,

rapidly cooling te slag. For this eason his rapid cooling

catses the sig, which sa vteous, bite solid to undergo

‘api thennal shrinkage, breaking and removing the slog 8,

‘which undergoes them shrinkage asa esto the ction

fof the liquid 6, fom the side wall. Specialy, the slag

having een broken into comparatively small chunks, is

removed othe atti o the blast farsa main Body 20 by

the low of bot air 2 and ud

{0085} On the oer hand, te ejected solids 7 Now inthe

rection ofthe uyere 22 withthe Dow ofthe hot si andthe

brite slog S which is a vtoous, rte sf is Broken and

ens bythe fore of the impact oeeurring whea the solids

Feontct the acered slag S. 8s 8 result, the slag $ which

seetives the foes of be impact upon eoliing with tbe bids

“is broken and removed rom the wall surface. Specialy.

the slag 8, having been broken into comparatively sm

chunks is removed to te interior of he bas farce main

body 20 bythe low ot hot air 2 and Mu

{0086} Removing the slg Sin this way’ odes the How

pa esistaneastecross-seetiona area ofthe flow channel

Inoteases, reducing the presse diferent AP detected by

thedfeenial pressure gauge 90. When the pressure difer

catial AP detocted by the dilfecatial pressure age 90

lecreases so a to reach the second threshold vale LL, the

lose signal is outptted to the open/close contol valves 86

fund 89. Since the openiclose contol valves 86 and 89 aze

Closed according tothe close signal und the operation ofa

aver pump 92isalsostppedat the same time, the jection

ofthe guid 6 an the solids 7 is stopped

[0087] The first hesbold value HL described above is set

to slighty larger vale tht the second tresbold val LL

‘sed 10 open the openicose conta valves 86 and 89 (ie,

US 2015/0240322 Al

HL>LL) in onder to create hysteresis between the eo valves

tnd prevent Frequent opening and closing of the open/close

‘contol valves 86 and 89,

10088) In this manner, the provision of the jet nozzle 80,

‘which removes the slag $ by using the latent heat of the

‘vaporization the liquid 6 rapidly coo! the slag S,orusing

the foree ofthe impact ofthe solids 7 to pulverize the sag,

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Joining of Mo To Cosb by Spark Plasma Sintering by Inserting A Ti InterlayerDocument3 pagesJoining of Mo To Cosb by Spark Plasma Sintering by Inserting A Ti InterlayermazaherramazaniNo ratings yet

- April 23, 1957: Filed Sept. 25, 1953Document4 pagesApril 23, 1957: Filed Sept. 25, 1953mazaherramazaniNo ratings yet

- Cracking and WarpingDocument7 pagesCracking and WarpingmazaherramazaniNo ratings yet

- Slip Casting MethodDocument17 pagesSlip Casting MethodmazaherramazaniNo ratings yet

- The Effect of Rotating Atomizer Geometry On The SaDocument7 pagesThe Effect of Rotating Atomizer Geometry On The SamazaherramazaniNo ratings yet

- TEPZZ - 7Z 99 B - T: European Patent SpecificationDocument8 pagesTEPZZ - 7Z 99 B - T: European Patent SpecificationmazaherramazaniNo ratings yet

- Airworthiness Bulletin: 1. EffectivityDocument3 pagesAirworthiness Bulletin: 1. EffectivitymazaherramazaniNo ratings yet

- Easa Airworthiness Directive: AD No.: 2015-0042Document2 pagesEasa Airworthiness Directive: AD No.: 2015-0042mazaherramazaniNo ratings yet

- Easa Airworthiness Directive: AD No.: 2013-0015Document2 pagesEasa Airworthiness Directive: AD No.: 2013-0015mazaherramazaniNo ratings yet

- mm2017 02 ENERGY ENVIRONMENTAL CAREDocument4 pagesmm2017 02 ENERGY ENVIRONMENTAL CAREmazaherramazaniNo ratings yet

- Airworthiness Bulletin: AWB Issue: Date: 1. EffectivityDocument3 pagesAirworthiness Bulletin: AWB Issue: Date: 1. EffectivitymazaherramazaniNo ratings yet

- User Guidelines For Waste and Byproduct Materials in Pavement ConstructionDocument5 pagesUser Guidelines For Waste and Byproduct Materials in Pavement ConstructionmazaherramazaniNo ratings yet

- Airworthiness Bulletins: General AdviceDocument24 pagesAirworthiness Bulletins: General AdvicemazaherramazaniNo ratings yet