Professional Documents

Culture Documents

A Pilotscale Flotation Column To Produce Beneficiated Coal Fractions

Uploaded by

mancel cardenasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Pilotscale Flotation Column To Produce Beneficiated Coal Fractions

Uploaded by

mancel cardenasCopyright:

Available Formats

Fuel 84 (2005) 1879–1883

www.fuelfirst.com

A pilot-scale flotation column to produce beneficiated coal fractions

having high concentration of vitrinite maceral

Juan Barraza*, Jorge Piñeres

Escuela de Ingenierı́a Quı́mica, Universidad del Valle, Ciudadela Universitaria Meléndez, Cali, Colombia

Received 25 October 2004; received in revised form 21 March 2005; accepted 22 March 2005

Available online 19 April 2005

Abstract

A pilot-scale flotation column was used to produce beneficiated vitrinite-rich fractions from two coal samples from south western

Colombia, Guachinte and Yolanda. The coal samples of less than 38 mm in size were processed in the flotation column at pH ranging from 7

to 11 using various concentrations of a particular frother. Results showed that, using a single stage separation, maximum mass yield of float

fractions was 84.6% w/w for Guachinte coal and 55.5% w/w for Yolanda. The maximum ash removals were 71.7 and 76.5% for Guachinte

and Yolanda coals, respectively. This corresponds to sulphur removals of 63.2% for Guachinte coal and 75.4% for Yolanda coal. The highest

concentration of vitrinite was obtained using Yolanda coal. It was in the order of 99.8% at neutral pH and when using the highest frother

concentration. This result is the highest concentration of vitrinite maceral reported in the literature using a pilot-scale flotation column.

q 2005 Elsevier Ltd. All rights reserved.

Keywords: Vitrinite maceral; Column flotation; Colombian coals

1. Introduction macerals have differences in both hydrophobicity and

electrokinetics surface properties, flotation process could

Beneficiated coal is usually produced in treatment plants be implemented to produce concentrated coal macerals [2].

where mineral matter is decreased and organic matter is A study [6] was carried out to measure contact angle on

increased [1]. However, nowadays the trend is to beneficiate several coal samples in order to quantify the hydrophobicity

coal in order to concentrate maceral groups. of individual coal maceral. It was found a hydrophobicity

Several researchers [2–4] have shown that macerals have decreasing order liptiniteOvitriniteOinertinite having a

some chemical properties which can increase the aggregated typical range of contact angle of 90–130, 60–70 and 25–408,

value of the coal. Liptinite, for instance, can be used as raw respectively. This decreasing order of hydrophobicity

material for chemical products. Vitrinite can be a raw agrees well with the lithotype and maceral flotability results

material for liquefaction and gasification processes; whereas obtained from previous investigations utilizing

inertinite is a basic material to produce activated carbon and conventional flotation cells [2,6,7].

graphite. Process to float coal involves conventional cell and

Macerals separation is usually carried out at laboratory column flotation. The former uses big air bubbles, which

scale based on the difference in the gravitational or surface produces high turbulence; whereas the latter can separate

properties of the macerals. Although macerals separation by fine coal particles owing to the use of small air bubbles,

centrifugation has some advantages, this technique is which create a quieter environment. A deep layer of frother

limited to laboratory scale [5]. Due to the fact that coal and the addition of wash water at the top of the column, give

also an additional improvement in selectivity between

hydrophobic and hydrophilic particles, as well as in the

* Corresponding author. Tel: C57 2 3312935; fax: C57 2 3392335. amount of hydrophobic particles.

E-mail address: jubarraz@univalle.edu.co (J. Barraza). The aim of this work was to obtain float coal fractions

0016-2361/$ - see front matter q 2005 Elsevier Ltd. All rights reserved. having high concentration of vitrinite maceral using a pilot

doi:10.1016/j.fuel.2005.03.021 scale flotation column.

1880 J. Barraza, J. Piñeres / Fuel 84 (2005) 1879–1883

2. Experimental pH of pulp and frother concentration were selected as

control variables since they were the most significant in

Two bituminous coal samples from South western preliminary tests. Response variables included mass

Colombia, Guachinte and Yolanda, were used in this yield of float fractions, ash, sulphur and maceral content

study. The coal samples were ground and sieved down to of floats. All runs were made in duplicate. The

!38 mm. Those analyses were carried out in accordance experimental error based on repeated experiments was

with ASTM methods. Maceral content in a v/v mineral- G2% for mass yield data, G0.5% for ash, G0.1%

matter free basis was obtained by using a Leitz microscope sulphur, G2.0% for maceral content and mineral matter

equipped with a 32! magnification oil-immersion lens and and G0.02% for vitrinite reflectance.

a 10! magnification eyepiece. A point counting device was

attached to the microscope semi-automatic stage which

allowed 500 separate maceral points to be counted for each 3. Results and discussion

analysis.

A 5 cm diameter conventional flotation column of 3.1. Proximate and petrographic analysis of parent coals

5 m high and made from acrylic material was used in

this study. Pulp feeder point was placed at 120 cm Table 1 shows proximate and petrographic analysis of

below the top. In order to increase the pulp residence the parent coals. Results show that Guachinte coal is higher

time, a flow of recirculated tails was located at 65 cm in volatile matter than Yolanda coal. However, Yolanda

of distance below the feeder. Both, frother and air were coal exhibits higher ash and sulphur content than Guachinte

supplied at 38 cm of distance above the bottom of the coal. Heat values are related to ash content. Guachinte coal

column. The bubbler, made from ground glass, was has higher heat value. It may be due to its lower ash

17 cm long. percentage.

All runs were carried out using a single separation In terms of maceral concentration, results in Table 1

stage and a pulp concentration of 2.5% w/w. Three- show that both parent coals have approximately similar

millilitre of collector (creosote oil) were added to the inertinite content. However, Yolanda coal has higher

pulp. In order to have a good distribution of bubbles vitrinite content than Guachinte coal. Guachinte coal

through out the column, a 1.7 bar airflow of 2.15 l/min exhibits low concentration of liptinite and Yolanda coal

was used. The frother (Lauril ether sulphate of sodium) virtually none, which could be due to it was counted some

mixed with air, was added by means of a peristaltic liptinite as mineral matter. Results in Table 1 show also that

pump at a flow of 42.2 ml/min. Three different Yolanda coal presents higher vitrinite reflectance than

concentrations of frother were used: 0.0075, 0.0100 Guachinte coal. It means that Yolanda coal has higher rank

and 0.0125% v/v. The pulp was fed into the column at than that of the Guachinte, and as expected the volatile

a flow rate of 2.92 l/min and the tails at 2.4 l/min. This matter content of samples correlates well with its vitrinite

guaranteed a constant interface level at 23 cm above the reflectance.

feeder position which aided to produce a stable foam.

pH used were 8.0, 9.5 and 11.0. To obtain those figures, 3.2. Effect of pH and frother concentration on mass yield,

NaOH 1.1 N standard was used. Blank run (without ash and sulphur content of floats

addition of NaOH) was carried out to evaluate the effect

of NaOH presence. It produced a pH of 7.1 for The effect of both pH and frother concentration, on mass

Guachinte coal and 7.5 for Yolanda coal, respectively. yield, ash and sulphur content of floats on a dry basis is

pH under 7 was not used due to column flotation shown in Table 2. Using a single stage, mass yields of float

material (acrylic) and pump material (iron cast) are not fractions from Guachinte coal were in the range

suitable for acidic conditions. 54.1–84.6%. The highest yield (84.6%) was found using a

Although the flotation process is a function of several frother concentration of 0.0100% v/v and a pH of 9.5. A

factors such as particle size, oxidation, rank of coal, relatively high mass yield (70.1%) was also obtained using a

pulp concentration, pulp residence time, and air flow; normal pH of 7.1 (without NaOH presence) and the highest

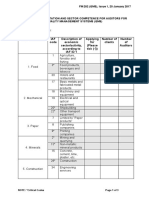

Table 1

Proximate and petrographic analyses of parent coals

Parent coal Proximate analysis, wt%, db Maceral content, vol%, mmf Rank, vol% Calorific Sulphur,

value, kJ/kg wt%, db

Ash VM FC Vitrinite Liptinite Inertinite VRo HHV ST

Guachinte 9.8 47.4 42.8 76.9 18.8 4.3 0.47 5727.4 1.6

Yolanda 15.6 23.2 61.2 96.8 0.0 3.2 0.80 5607.9 2.4

mmf, Mineral matter free; db, dry basis.

J. Barraza, J. Piñeres / Fuel 84 (2005) 1879–1883 1881

Table 2 Regarding sulphur content, in general, sulphur content of

Mass yield, ash, and sulphur content of floats as a function of pH and frother floats is lower than that of the parent coals. No appreciable

concentration

differences among sulphur content figures are observed. The

Coal Mass Ash, Ash Sulphur, Sulphur lowest sulphur content for Guachinte and Yolanda were 1.1

samples yield, wt%, db removala, wt%, db removalb, and 1.4%, respectively, which was achieved without

wt%, db wt%, db wt%, db

addition of NaOH and by using a frother concentration of

Guachinte 0.0075% v/v. Those results produced the highest sulphur

Parent 9.8 1.6

8.0/0.0075c 80.8 6.6 45.2 1.2 38.4

removal for Guachinte (63.2%) and for Yolanda coal

8.0/0.0125 69.9 6.8 51.7 1.3 41.9 (75.4%).

11.0/0.0075 70.3 5.8 58.6 1.2 47.7

11.0/0.0125 72.3 6.9 48.8 1.3 43.1

9.5/0.0100 84.6 6.7 42.5 1.3 34.1 3.3. Effect of pH and frother concentration

7.1/0.0075d 54.1 5.1 71.7 1.1 63.2 on floats maceral content

7.1/0.0125d 70.1 6.5 53.6 1.2 48.7

Yolanda Floats maceral content results as a function of pH and

Parent 15.6 2.5

8.0/0.0075c 53.1 11.2 61.8 1.8 60.2

frother concentration are given in Table 3 In general,

8.0/0.0125 46.5 12.9 61.4 1.9 64.3 vitrinite maceral content of floats is higher than that of the

11.0/0.0075 34.4 12.2 73.2 1.7 75.9 parent coal, whereas liptinite, inertinite and mineral matter

11.0/0.0125 34.4 12.0 73.5 1.7 76.3 are lower. However, liptinite maceral content of floats of

9.5/0.0100 55.5 10.5 62.7 1.7 62.1

Yolanda is higher than that of the parent coal.

7.5/0.0075d 43.3 8.5 76.5 1.4 75.4

7.5/0.0125d 46.6 11.1 66.9 1.4 73.5 Vitrinite concentration of float fractions for Guachinte and

a

Yolanda was in the range 89.9.1–95.2% and 96.9–99.8% v/v,

Ash removal, %Z[1K(yield)(float ash)/(feed ash)]!100.

b respectively. The highest vitrinite concentration (99.8%) was

Sulphur removal, %Z[1K(yield)(float sulphur)/(feed sulphur)]!100.

c

Coal samples obtained at pH/frother concentration. found using a frother concentration of 0.0125% v/v and a pH

d

pH obtained without addition of NaOH. of 7.5 (without addition of NaOH). This result is the highest

concentration of vitrinite maceral reported in the literature

frother concentration of 0.0125% v/v. This result is using a pilot-scale flotation column.

important from point of view of maceral production and It was generally observed that for all the conditions of pH

reactive cost, especially the cost of NaOH. The range of and frother concentration used, vitrinite concentration of

float mass yields found from Yolanda coal was between float fractions from Yolanda coal were higher compared to

34.4 and 55.5% using a pH of 9.5 and a frother those obtained from Guachinte coal. Despite of that, the

concentration of 0.0100% v/v. column flotation process was more effective to concentrate

It was generally observed that for the various conditions vitrinite in Guachinte coal than that of the Yolanda coal.

of pH and frother concentration used, mass yields of float

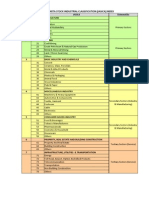

Table 3

fractions from Guachinte coal were higher compared to Petrographic analysis of floats as a function of pH and frother concentration

those obtained from Yolanda coal. This behaviour may be

due to the fact that the air bubbles have a higher probability Coal Vitrinite, Liptinite, Inertinite, Mineral

samples vol%, mmf vol%, mmf vol%, mmf matter,

to catch the organic particles from Guachinte coal since it vol%

has higher organic matter content than Yolanda coal.

Guachinte

In terms of ash, results in Table 2 indicate that, in

Parent 76.9 18.8 4.3 12.2

general, ash content of floats is lower than that of the parent 8/0.0075a 88.9 7.9 3.2 7.1

coals. No appreciable differences among ash content figures 8/0.0125 95.2 3.1 1.6 7.9

of floats are observed. The lowest ash content for Guachinte 11/0.0075 89.9 7.1 3.0 9.6

and Yolanda coal floats were 5.1 and 8.5%, respectively. 11/0.0125 90.3 6.7 3.0 4.3

9.5/0.0100 90.4 7.3 2.4 7.2

This was achieved without addition of NaOH and by using a 7.1/0.0075b 90.3 8.2 1.4 1.6

frother concentration of 0.0075% v/v. 7.1/0.0125 89.1 8.9 2.1 4.0

Despite the little differences in floats ash content, there Yolanda

are some variations in the percentages of ash removal, Parent 96.8 0.0 3.2 33.5

which can be observed in Table 2. The highest ash removal 8/0.0075a 96.9 1.9 1.2 5.0

8/0.0125 98.7 1.1 0.2 9.6

for Guachinte (71.7%) and for Yolanda coal (76.5%) was

11/0.0075 98.6 0.2 1.2 8.6

obtained without addition of NaOH and using the lowest 11/0.0125 99.1 0.9 0.0 3.5

frother concentration. 9.5/0.0100 98.7 0.5 0.4 7.1

From the above results, it appears that the best conditions 7.5/0.0075b 99.2 0.8 0.0 2.8

used in this work to obtain float coals having low ash 7.5/0.0125 99.8 0.2 0.0 4.8

content are normal pH (without addition of NaOH) and the a

Coal samples obtained at pH/frother concentration.

b

lowest frother concentration, 0.0075% v/v. pH obtained without addition of NaOH.

1882 J. Barraza, J. Piñeres / Fuel 84 (2005) 1879–1883

Fig. 3. Photography of maceral in Guachinte parent coal.

Fig. 1. Photography of maceral in Guachinte coal. Sample obtained without

NaOH addition (pH 7.1) and frother concentration of 0.0075% v/v.

It means that the increasing percentage for Yolanda coal (on

the basis of vitrinite concentration in parent coal) was 3.1%

whereas Guachinte coal was 23.8%.

Photographs of parents and floats having high concen-

tration of vitrinite are shown in Figs. 1–4. Comparisons

between photographs confirm that exist high concentration

of vitrinite maceral in floats.

Liptinite concentration of floats from Guachinte coal is

lower than that of the parent coal, whereas liptinite in floats

from Yolanda is higher. It may be due to Guachinte coal

could present low resinite (which conforms liptinite and has

hydrophobicity [2]), whereas Yolanda has high resinite

content.

Mineral matter concentration of floats is also lower than

that of the parent coal. Mineral matter decreased in

Guachinte coal from 12.2 to 1.6% v/v, whereas for Yolanda Fig. 4. Photography of maceral in Yolanda parent coal.

coal was from 33.5 to 2.8% v/v. Those results are in

agreement with ash concentration of floats, which are lower

than those of the parent coal. It is shown by comparing

Figs. 1 and 2, which have low presence of mineral matter,

with Figs. 3 and 4, having high presence of mineral matter.

4. Conclusions

The column flotation separations showed different mass

yields, ash and sulphur concentration of floats for the

Yolanda and Guachinte coals and hence optimization of the

operation condition (pH and frother concentration) is

required for each coal.

Pilot-scale test using column flotation separations

indicated that it is effective in producing concentrates with

a vitrinite-rich fraction. The highest vitrinite concentration

Fig. 2. Photography of maceral in Yolanda coal. Sample obtained without (99.8%) was found using a frother concentration of

NaOH addition (pH 7.5) and frother concentration of 0.0075% v/v. 0.0125% v/v and a pH of 7.5 (without addition of NaOH).

J. Barraza, J. Piñeres / Fuel 84 (2005) 1879–1883 1883

This result is the highest concentration of vitrinite maceral References

reported in the literature.

[1] Leonard J, Hardinge B. Coal preparation. Littleton Colorado: Society

for Mining, Metallurgy and Exploration, INC; 1991 p. 3.

Acknowledgements [2] Honaker R, Monhanty M, Crelling J. Miner Eng 1996;9:449.

[3] Kizgut S, Miles N, Cloke M. Production of coal maceral concentrates

The authors would like to acknowledge the support of by flotation. Coal science and technology series 24. vol. II. Amsterdam:

Colombian Institute of Science and Technology (Colcien- Elsevier; 1995 p. 1553.

[4] Hower J, Kuehn K, Parekh B, Peter W. Fuel Process Technol 2000;

cias) through the research program ‘Young Researchers’. 67:23.

The assistant of Miss Astrid Blandon for performing the [5] Dyrkacz G, Bloomquist C, Hortwitz E. Fuel 1981;16:1571.

petrographic analysis at Universidad Nacional de Colombia [6] Arnold B, Aplan F. Fuel 1988;68:651.

(Medellin) is also acknowledged. [7] Esen B, Selma, Sabriye S. Fuel Process Technol 1998;55:101.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- NTPC DiaryDocument97 pagesNTPC Diaryacorna0% (1)

- Column Flotation A Selected Review. Part I. Finch1991Document12 pagesColumn Flotation A Selected Review. Part I. Finch1991mancel cardenasNo ratings yet

- 8ADocument17 pages8Aselene50% (2)

- Effect of Particle Size On The Reverse Flotation of Subbituminous CoalDocument8 pagesEffect of Particle Size On The Reverse Flotation of Subbituminous Coalmancel cardenasNo ratings yet

- An Improved Model For Simulation of Flotation Circuits PDFDocument13 pagesAn Improved Model For Simulation of Flotation Circuits PDFmancel cardenasNo ratings yet

- Seed Moisture Dependent On Physical and MechanicalDocument15 pagesSeed Moisture Dependent On Physical and Mechanicalmancel cardenasNo ratings yet

- (English) History of Insurance in India - Keerthi History (DownSub - Com)Document5 pages(English) History of Insurance in India - Keerthi History (DownSub - Com)Monnu montoNo ratings yet

- Case AnalysisDocument25 pagesCase AnalysisNem Morera100% (1)

- Mining Valuation Lesson: Cut-Off Grade Theory and Practice: 04 Dec 2011 Comment: 0Document8 pagesMining Valuation Lesson: Cut-Off Grade Theory and Practice: 04 Dec 2011 Comment: 0davidchaileNo ratings yet

- SWOT Analysis On Readymade Garment Industry in BangladeshDocument3 pagesSWOT Analysis On Readymade Garment Industry in BangladeshMd.Latifull Alam100% (1)

- Republic of The Philippines Nueva Vizcaya State University Bayombong, Nueva Vizcaya STRATEGIC PLAN 2019-2023 Extension and Training ProgramDocument4 pagesRepublic of The Philippines Nueva Vizcaya State University Bayombong, Nueva Vizcaya STRATEGIC PLAN 2019-2023 Extension and Training ProgramJoemar SubongNo ratings yet

- GW 05 5 en 2204 MaDocument100 pagesGW 05 5 en 2204 MaazharzebNo ratings yet

- FAR - Biological AssetsDocument1 pageFAR - Biological AssetsJun JunNo ratings yet

- FM 202 QMS Issue 1-20 JanDocument4 pagesFM 202 QMS Issue 1-20 Jandaniel manafNo ratings yet

- Custom Seat Rail FormDocument1 pageCustom Seat Rail FormIvan Ezequiel CastilloNo ratings yet

- Daftar Emiten BEIDocument23 pagesDaftar Emiten BEIisnaini latifah0% (1)

- Critical Thinking and Discussion Question (Chpter8)Document3 pagesCritical Thinking and Discussion Question (Chpter8)Qasih Izyan100% (3)

- Underwater Cutting and Welding KitDocument5 pagesUnderwater Cutting and Welding Kitromeo baveraNo ratings yet

- The Pretoria News July 11 2017 PDFDocument25 pagesThe Pretoria News July 11 2017 PDFBoki VaskeNo ratings yet

- Thailand at The Turn of CenturyDocument2 pagesThailand at The Turn of CenturyAlexis MechaelaNo ratings yet

- V1 BHI - Parkkent PresentationDocument71 pagesV1 BHI - Parkkent PresentationA. U. QureshiNo ratings yet

- A Guide To Insurance ClaimsDocument6 pagesA Guide To Insurance ClaimsNKOYOYO HANNINGTONNo ratings yet

- A Study On Perception of Investors Investing in Life InsuranceDocument109 pagesA Study On Perception of Investors Investing in Life InsuranceSujal BedekarNo ratings yet

- Swot Beekeeping BGDocument8 pagesSwot Beekeeping BGlorenzo1970No ratings yet

- Indian Economy On The Eve of IndependenceDocument38 pagesIndian Economy On The Eve of Independencesocial sites100% (3)

- Ayub KhanDocument8 pagesAyub KhanAbdul AleemNo ratings yet

- Unece Standard Ffv-45 Mangoes: 2017 EDITIONDocument8 pagesUnece Standard Ffv-45 Mangoes: 2017 EDITIONNur A AlamNo ratings yet

- English Diagnostic Report Togo - Rev - Eng PDFDocument95 pagesEnglish Diagnostic Report Togo - Rev - Eng PDFfidelioas2000No ratings yet

- My Class NotesDocument24 pagesMy Class NotesKhushi ThakurNo ratings yet

- WATS - 2019 - IATA From Mail PDFDocument7 pagesWATS - 2019 - IATA From Mail PDFRombout100% (1)

- WM N Deltech 2012Document4 pagesWM N Deltech 2012Claudio TurlherNo ratings yet

- BFI 306 Finance ExamDocument4 pagesBFI 306 Finance ExamBOL AKETCHNo ratings yet

- Leonido Pulido PPT - Sept 3 2020Document16 pagesLeonido Pulido PPT - Sept 3 2020Karen Jella EscobinNo ratings yet

- Isbp PDFDocument2 pagesIsbp PDFmackjblNo ratings yet