Professional Documents

Culture Documents

Hybrid Systems PDF

Hybrid Systems PDF

Uploaded by

paramarthasom1974Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hybrid Systems PDF

Hybrid Systems PDF

Uploaded by

paramarthasom1974Copyright:

Available Formats

HyBrID sysTems

Precast concrete components can be combined with other construction

materials, particularly steel or cast-in-place concrete, to create a “hybrid” system.

Examples include architectural precast concrete cladding supported on a struc-

tural steel or cast-in-place concrete frame as well as precast, prestressed double

tees or hollow-core used as the floor system on a parking garage where the main

structure is steel.

Whenever two materials are combined to create one structural system, the at-

tributes of each material must be evaluated and addressed to ensure the proper

outcome. The appropriate steel and cast-in-place concrete standards should be

applied in all cases, and it must be remembered that the standards for each ma-

terial do not apply to buildings of composite construction, such as with concrete

floor slabs supported by steel columns or with concrete-encased, structural-steel

members or fireproofed frames.

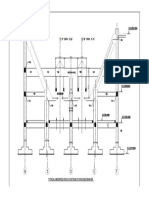

Structural-Steel Framing Supporting Architectural

Precast CONCRETE Cladding

Structural-steel-framing tolerances should conform to standards issued by the

American Institute of Steel Construction. Precast concrete panels should follow

the steel frame as erected, because the allowable tolerances for steel-frame

structures make it impractical to maintain precast concrete panels in a true verti-

cal plane in tall structures. The adjustments that would be required to make the

Mariott Pewaukee West, Pewaukee, Wis.; connections practical are not economically feasible.

Architect: FRCH Design Worldwide;

Photo: The Spancrete Group Inc.

A practical and economical solution is to specify the more stringent AISC

elevator-column erection tolerances for steel columns used in the building façade

that will receive the precast concrete panels.

A structural-steel-frame building presents different erection and connection con-

siderations from a concrete-frame building. For example, structural-steel beams,

being relatively weak in torsion when compared to concrete, generally require the

load to be applied directly over the web or that the connection be capable of sup-

porting the induced torsion. This in turn places a greater structural requirement

on the connection and creates difficulties during erection if any rolling behavior

occurs in the steel beam.

Observations in the field have shown that where precast concrete panels are

erected to a greater height on one side of a multistory, steel-framed building than

on the other, the steel framing will be pulled out of alignment. Precast concrete

panels should be erected at a relatively uniform rate around the perimeter of the

structure. If this does not happen, the designer of the structural frame should

determine the degree of imbalanced loading permitted.

DESIGNING WITH PRECAST & PRESTRESSED CONCRETE 4B-9

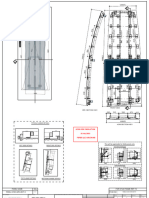

sTruCTurAl-sTeel FrAMing suPPorTing A PreCAsT,

Prestressed CONCRETE Floor System

At times, it may be beneficial to create a structural-steel frame that supports

either double tees or hollow-core plank as the floor and roof system. This has

been used in parking structures, office buildings, and other applications. The

objective in all cases should be to utilize the positive attributes of each material

to its best advantage such as the resistance to corrosion of double tees used in

a parking garage.

As noted above, consideration must be given to the different standards govern-

ing the materials to be used.

Cast-In-Place Concrete Frames

Cast-in-place concrete frame tolerances are given in ACI 117, Standard

Tolerances for Concrete Construction and Materials, unless otherwise stated in

the specifications.

These tolerances are not realistic for tall buildings. In addition, greater variation

in heights between floors is more prevalent in cast-in-place concrete structures

than in other structural frames. This can affect the location or matching of the in-

serts in the precast concrete units with the cast-in connection devices. Tolerances

for cast-in-place concrete structures may have to be increased to reflect local

trade practices, the complexity of the structure, and climatic conditions.

It is recommended that precast concrete walls should follow concrete frames in

the same manner as for steel frames, if the details allow it and appearance is not

affected.

Unless the cast-in-place structure is executed to above normal tolerances, the

width of joints must be designed to allow for a large tolerance. The actual joint

Meridian, Columbia, S.C.;

Architect: SWSC; Photo: ©2003 Brian C. Robbins, width may differ in each bay and will certainly require sealants with corresponding

Robbins Photography Inc. flexibility. Joint widths may be adjusted to allow them to be equal at either end of

a panel, but equalizing the joints on either side of a column should not be done

unless panels can be adjusted horizontally after erection. The problems this can

cause are avoided where the cladding passes in front of the columns and the

jointing is between the panel edges.

4B-10 DESIGNING WITH PRECAST & PRESTRESSED CONCRETE

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Launching Girder PDFDocument26 pagesLaunching Girder PDFparamarthasom19740% (1)

- 2013 04 Technotes Secant Pile Construction WaterproofingDocument2 pages2013 04 Technotes Secant Pile Construction Waterproofingparamarthasom1974No ratings yet

- C ConstructionIssues NGDocument3 pagesC ConstructionIssues NGparamarthasom1974No ratings yet

- Th04 140Document4 pagesTh04 140paramarthasom1974No ratings yet

- Prashant CV 04-11-2022Document4 pagesPrashant CV 04-11-2022paramarthasom1974No ratings yet

- PG Tech Update Piled WallsDocument6 pagesPG Tech Update Piled Wallsparamarthasom1974No ratings yet

- Adobe Scan 27 Dec 2022Document3 pagesAdobe Scan 27 Dec 2022paramarthasom1974No ratings yet

- Student Stresses in BeamsDocument3 pagesStudent Stresses in Beamsparamarthasom1974No ratings yet

- Performance of WallDocument7 pagesPerformance of Wallparamarthasom1974No ratings yet

- Permiability Test ResultsDocument1 pagePermiability Test Resultsparamarthasom1974No ratings yet

- Chem EnggDocument5 pagesChem Enggparamarthasom1974No ratings yet

- Eva Measurement FormulaDocument14 pagesEva Measurement Formulaparamarthasom1974No ratings yet

- Investment Return Calculations and Senior School MathematicsDocument11 pagesInvestment Return Calculations and Senior School Mathematicsparamarthasom1974No ratings yet

- ConcreteConnections PDFDocument1 pageConcreteConnections PDFparamarthasom1974No ratings yet

- Torsional Buckling of I Beam PDFDocument5 pagesTorsional Buckling of I Beam PDFparamarthasom1974No ratings yet

- DFII Steel Webinar 6 Brochure PDFDocument1 pageDFII Steel Webinar 6 Brochure PDFparamarthasom1974No ratings yet

- Cross Section PDFDocument1 pageCross Section PDFparamarthasom1974No ratings yet

- Shear and Load BearingDocument6 pagesShear and Load Bearingparamarthasom1974No ratings yet

- Concrete Sensors PDFDocument19 pagesConcrete Sensors PDFparamarthasom1974No ratings yet

- Precast SystemsDocument13 pagesPrecast Systemsparamarthasom1974No ratings yet

- Ayrshire Steel FramingDocument41 pagesAyrshire Steel FramingingdanbeloiuNo ratings yet

- Cold Formed SteelDocument99 pagesCold Formed SteelPaul John AguilarNo ratings yet

- US Army USAR FOGDocument314 pagesUS Army USAR FOGShane Briggs100% (3)

- Site Report: Light House Project (PM Awas Vikas Yojana)Document10 pagesSite Report: Light House Project (PM Awas Vikas Yojana)sudeepNo ratings yet

- Windposts: and Parapet PostsDocument8 pagesWindposts: and Parapet PostsMartinNo ratings yet

- DoorDocument120 pagesDoorsahatNo ratings yet

- Project Cost SampleDocument24 pagesProject Cost SampleSebastian Garcia100% (1)

- 2021 LATBSDC ProceedingsDocument210 pages2021 LATBSDC ProceedingsCarsonBaker100% (1)

- Water Tank To Column Detail: Advanced Diploma of Building Design Footing Layout Student Accommodation S01Document7 pagesWater Tank To Column Detail: Advanced Diploma of Building Design Footing Layout Student Accommodation S01hmaisano1100% (1)

- HILTI Technical Guide Volume 1Document175 pagesHILTI Technical Guide Volume 1xpertsteelNo ratings yet

- Sci P328Document26 pagesSci P328Tiago CastelaniNo ratings yet

- Prashant Tharmarajan MFKA2007 TTTDocument143 pagesPrashant Tharmarajan MFKA2007 TTTashtj2000No ratings yet

- ConstructionCatalog2015Document44 pagesConstructionCatalog2015racing.phreakNo ratings yet

- Fire Rated User GuideDocument76 pagesFire Rated User Guidesreesweet90100% (2)

- Internship Report 17l-4621 2020Document33 pagesInternship Report 17l-4621 2020Mirza TalhaNo ratings yet

- Cost Comparison Steel vs. ConcreteDocument20 pagesCost Comparison Steel vs. ConcreteHibozo82% (17)

- 03 Steel Roof DesignDocument31 pages03 Steel Roof DesignvarunNo ratings yet

- Tolleranze PCIDocument20 pagesTolleranze PCIkurtainNo ratings yet

- Arena AssessmentDocument81 pagesArena AssessmentAnonymous BAzcBzWuNo ratings yet

- AIT Consulting ProjectsDocument12 pagesAIT Consulting ProjectsfahdlyNo ratings yet

- SCI ED020 Sustainability of Light Steel ConstructionDocument4 pagesSCI ED020 Sustainability of Light Steel ConstructionTiago CastelaniNo ratings yet

- Building Construction IV Steel ConstructionDocument47 pagesBuilding Construction IV Steel ConstructionmitualvesNo ratings yet

- BXUV.P204 Fire Resistance Ratings - ANSI/UL 263Document5 pagesBXUV.P204 Fire Resistance Ratings - ANSI/UL 263AlexNo ratings yet

- Acoustic Installation ProcedureDocument3 pagesAcoustic Installation Proceduremazumdar_satyajitNo ratings yet

- Steel Brickwork: Frames InfillingDocument6 pagesSteel Brickwork: Frames InfillingKausalya PurushothamanNo ratings yet

- SectionDocument18 pagesSectionSham ParitNo ratings yet

- Unit 9 Process 2Document13 pagesUnit 9 Process 2Aryatirta PredanaNo ratings yet

- Rsmli CH03 GRC Bot 9Document1 pageRsmli CH03 GRC Bot 9Muhammad BilalNo ratings yet

- Corium BrochureDocument24 pagesCorium Brochureyashiro732No ratings yet

- Backdraft Dampers CatalogDocument12 pagesBackdraft Dampers CatalogTed K NagaraNo ratings yet